1. Mahogany is wood of various red shades.

The most famous breed of mahogany is called mahogany. Mahogany is easy to cut, process, it is ideal for finishing works. But at the same time it does not have high strength. It can be fiery, patterned, striped, smooth, marked, knotty, etc.

This type of wood is brittle, but hard. it decorative material, very valuable, from which furniture has been made for a long time. The cost of such products is very high. Truth, lemon Tree very difficult to process due to the peculiarities of the structure.

It has a pattern with dark veins, sometimes cast in purple. The hardness is more than that of oak about twice. Very well polished durable tree. Can be used to make musical instruments, furniture, parquet, etc. The type of wood is classified as elite.

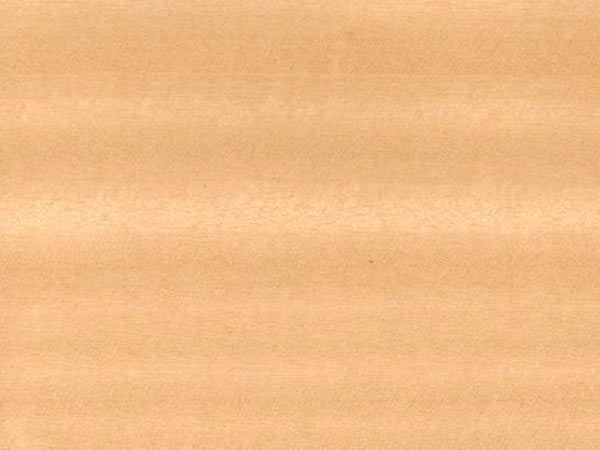

This type of wood was equated to semi-precious. An unusual pattern of a characteristic reddish-yellow hue. Durable, lasts a very long time, but processing is complicated by structural features. Products made of Karelian birch have practically no equal in beauty.

A tree with such an exotic name grows in Madagascar, in South-East Asia and Oceania. Material of stunning beauty and strength. Ideal wood for carpentry and finishing work. But for our country, products made from it are a real exotic.

These are tropical trees, the wood of which is characterized by increased rigidity. Teak products are distinguished by durability, strength, and moisture resistance. The teak looks very nice. It can be parquet, furniture, etc.

This is an African tree species that can grow up to 30 m in height. Both premium and ordinary furniture are made from wood. But mostly decorative veneer for cladding is made from it.

Another name that is sometimes found is iron tree. Its color, as a rule, depends on the place where it grows. From light brown with a yellow tint to almost black. It can be found in the regions of Central and South America. Wood is mold and rot resistant chemical treatment, lasts a very long time.

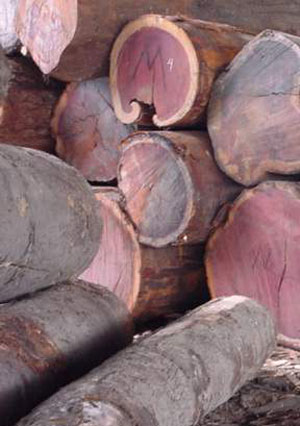

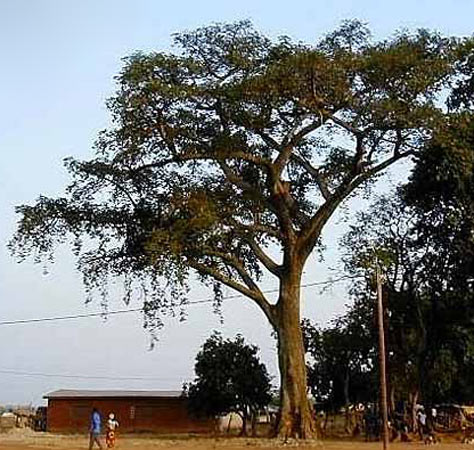

A rather common name, because even scientists have not yet agreed on how to call it after all. This giant tree from Africa has a huge number of names. Grows up to 50 m tall. In a number of properties it is comparable to oak and teak, while it costs a little less.

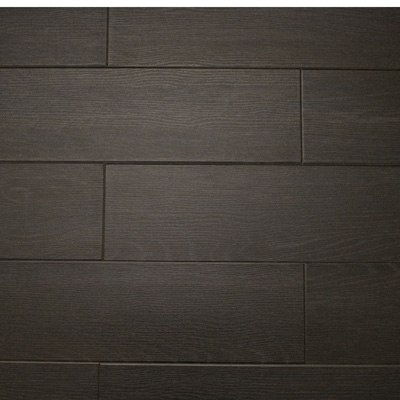

Grows in the tropical forests of Africa. Dark wood with high density. Wenge is widely used for decorative coatings, production of fingerboards for guitars, knife handles, parquet. It can also be grown as an ornamental plant.

Brazilian tree that can grow for hundreds of years. The wood is heavy and dense, ideal for exclusive parquet. Can be treated with oil and wax. Widely used in construction, not afraid of moisture.

Very hard wood with high density. Another name is gonkalo. Outwardly very beautiful. Mainly goes for block parquet, finishing of yachts, exterior and interior carpentry, furniture manufacturing.

The sequoia is also called the mammoth tree. gigantic coniferous trees with a trunk diameter of about 12 m and a height of up to 110 m. They can live up to 5 thousand years. Wood of attractive appearance, suitable for a variety of purposes. It has considerable lightness, is not subject to decay.

A hard and durable wood, although it is not easy to process. But on the other hand, paint fits well on it, you can imitate ebony. Goes to the manufacture of all kinds of parts.

- - a separate genus or species of trees with some General characteristics that distinguish them from others (pine, spruce, etc.). [Construction of wooden and composite bridges. Part 1. SRO NP "MOD SOYUZDORSTROY] Heading term: Varieties ... ...

Carbonate rocks- - rocks consisting of calcite minerals (see Limestone), dolomite, magnesite, siderite and various impurities. By composition, carbonate rocks are divided into three groups: limestone, dolomitic and carbonate-argillaceous. By… … Encyclopedia of terms, definitions and explanations of building materials

Igneous mountain rocks- (igneous) - rocks formed from molten magma as a result of its cooling and solidification with the transformation into high-strength massifs. Magma can solidify both at a depth inside the earth's crust (deep rocks), and at ... ... Encyclopedia of terms, definitions and explanations of building materials

Deep rocks- (intrusive) - formed during the slow cooling of magma in the depths of the earth's crust at high pressures from the overlying layers of the earth. This contributed to the formation of rocks with a dense granular crystalline structure, a large average ... ... Encyclopedia of terms, definitions and explanations of building materials

Mountain carbonate rocks- - sedimentary hard rocks(carbonic salts, limes, magnesias, ferrous oxides), which together or separately form large masses of sedimentary (limestone, dolomites, marls, etc.) or metamorphic (marble, etc.) rocks and consisting of more than ... Encyclopedia of terms, definitions and explanations of building materials

Mountain siliceous rocks- - dense, often shale rocks, consisting of pure silicic acid, largely amorphous, soluble in caustic potash (siliceous shale, flasks, tripoli, etc.). [Handbook of road terms, M. 2005] Term heading: Mountain ... ... Encyclopedia of terms, definitions and explanations of building materials

Rocks mountain metamorphic- - modified rocks formed as a result of the transformation of igneous or sedimentary rocks under the influence of high temperatures, and signs of primary sedimentary or magmatic origin they have partially or completely ... ... Encyclopedia of terms, definitions and explanations of building materials

Igneous mountain rocks- - igneous rocks formed during the solidification and crystallization of magma. [Terminological dictionary for concrete and reinforced concrete. Federal State Unitary Enterprise "Research Center" Construction "NIIZHB them. A. A. Gvozdeva, Moscow, 2007, 110 pages] Topic of the term: Mining ... ... Encyclopedia of terms, definitions and explanations of building materials

Asphalt rocks- - porous rocks (limestones, dolomites, sandstones, clays, sands) impregnated with bitumen. Bitumen is extracted from these rocks or ground and used in the form of asphalt powder. [Dictionary of building materials and products for students ... ... Encyclopedia of terms, definitions and explanations of building materials

Erupted mountain rocks (effusive)- - varieties of igneous rocks formed from molten magma that came to the surface of the earth and solidified in the form of covers, flows, domes. [Handbook of road terms, M. 2005] Term heading: Rocks Headings ... ... Encyclopedia of terms, definitions and explanations of building materials

Books

- Species of Wood, Jesse Russell. This book will be produced in accordance with your order using Print-on-Demand technology. High Quality Content by WIKIPEDIA articles! Species of wood are called its varieties, ...

- Tree Species of the World, G.I. Vorobyov. This book will be produced in accordance with your order using Print-on-Demand technology. The Directory "Tree Species of the World" consists of three volumes. The first and second volumes are...

CATALOG OF WOOD SPECIES

BUT

abachi

Abacha (Triplochiton scleroxylon). Other names for abacha: obeche (Nigeria), wawa (Ghana), ayous (Cameroon). The abacha tree is large, forest-forming, 45 m or more high, with broad plank-like roots, pointed along the edges, sometimes rising along the trunk to a height of 6 m or more. The diameter of the trunk above the zone of plank roots can reach 1.5 m. It is found in most countries of West Africa. The color of abacha wood is creamy white to pale yellow color. Abacha wood is soft, but strong and dimensionally stable. The texture is fine and even. Application of abacha: interior decoration saunas, in particular shelves (the material has a low thermal conductivity, so it does not heat up), as well as frames, boxes, furniture, veneer, sports equipment, toys.

Apricot

Apricot (Apricot tree, lat. Prunus armeniaca: "Armenian plum"; German Aprikose) small tree or shrub and belongs to the Rosaceae family. The homeland of the apricot is China, where its wild roots are still found. However, in Europe it became known from Armenia (hence the botanical name in Latin). Subsequently, the apricot came to Rome, as mentioned in his writings by the ancient Roman scientist and writer Pliny the Elder. Apricot sapwood is small. On a longitudinal section, the wood has a pale pink tint with numerous dark stripes and lines, giving a characteristic ornamental pattern. The texture is quite rich and beautiful. Apricot should be classified as a medium-drying species. Like many high-density woods, it requires mild drying conditions, but lumber has little tendency to warp and crack. Apricot wood has high hardness and wear resistance.

White acacia

White acacia - originally from North America, brought to Europe in 1601. It is bred and grows well in Ukraine, the Caucasus, the Crimea, as well as in Central Asia, one of the main breeds of Hungary. White locust is a heartwood ring-vascular rock with a very narrow yellowish sapwood, sharply demarcated from a greenish-gray or yellowish-gray heartwood. High strength and resistance to rotting make it possible to use this wood as mine props, piles, etc. It is suitable for dry and damp rooms, for their interior and exterior finish. White acacia wood is an excellent material for parquet. In addition, excellent doors are made from it, which are stronger than oak. Wood of a white acacia behaves ideally in joints on glue and on screws. For finishing products from it are equally well suited as paints and varnishes based on organic solvents, as well as water-soluble varnishes, paints and stains.

Amaranth

Amaranth (Peltogyne spp, Peltogyne paniculata, Peltogyne purpurea), family: Fabaceae or Leguminosae (Caesalpiniaceae group). Other names: amaranth (USA), koroboreli, saka (Guyana), purperhart (Suriname), pau roho, amarante (Brazil). Amaranth grows in Central and South America to the south of Brazil. Amaranth reaches a height of 25 m with a trunk thickness of up to 0.8 m. Heartwood - in a freshly sawn tree it has a grayish brown color, but under the influence of light it oxidizes and becomes purple-purple in color. Most often, amaranth boards are used in two areas: where high strength is required, especially under dynamic loads and high stresses - floor coverings, the manufacture of gymnastic equipment, springboards, skis, cues, etc., and where wood of an unusual color is needed with unique shades - furniture and cabinetry production, panel cladding, production of bar counters, carvings, inlays.

afromosia

Afrormosia (Afrormosia, Afrormosia elata, lat. Pericopsis elata), legume family (Fabaceae). In height, Afromosia reaches 55 m with a trunk diameter of 1.5 m -2 m. The trunk is usually straight and does not have a butt, and big trees can have a clean trunk without branches at a height of up to 30m. Growth area: mixed forests Ivory, Ghana, Cameroon and Congo (formerly Zaire). Afromosia is used as an alternative to teak in many industries, especially where strength and stability are required from wood. It is mainly used in yacht building, interior decoration, furniture production, for the production of piece and artistic parquet, massive floor boards, in carpentry and building structures. In particular, Afromosia is used to make street doors, garden furniture, windows, steps, etc.

Azobe

Scientists know the tree under the names Lophira alata - Lofira winged, Lophira procera - Lofira high.

An adult tree grows to a height of 10-15 m, individual specimens reach 40-50 m. The trunk diameter is on average 1.5 m. The leaves are variable-standing, simple, smooth, lanceolate. Young red foliage. The flowers are white. The fruits are smooth and ovoid.

Other names for this tree species

Several tree names are common on the African continent, some of which can also be found in European countries. Azobe, bongossi, ekki, eba, asso, edoum, ous, handui, kaku, akele, bang, okoa, akoga, akoura, aya, boncole, mahogany ironwood

Wood characteristics

The color of the heartwood is from brown-red to dark brown or dark purple, whitish or slightly purple blotches are possible. Sapwood color is pink. The wood fibers are very tangled. hard to give in manual processing. For example, to hammer a nail or screw in a screw, you must first drill a hole under them. When processed, wood emits bad smell. The wood is resistant to insects and fungi. Has a slight matte sheen.

Quince

Quince (Quince)- a fruit tree growing in the Caucasus and Central Asia. Cultivated throughout the Mediterranean and Central Europe. The wood is quite strong and hard, but prone to decay. Wood color - brown, red-brown.

Used to make knife handles.

Anegre (Anegre, Аningre) - a tree that grows in equatorial Africa, from West Africa to East.

Density is about 600 kg/m3. Wood does not stand out with a pronounced texture, although sometimes there are specimens with beautiful patterns. The color of the wood is from pale yellow to light brown. Anegre wood has a beautiful sheen and is often used in the manufacture of musical instruments and veneer for furniture and interior doors.

Anchar (Antiaris)- an evergreen tree that grows in the Pacific region, as well as in Africa. The density of wood is 430 kg/m3.

The anchar tree is reputed to be poisonous, although only its sap is poisonous, which stands out from the damage to the bark. Contact with the skin, this juice can cause damage. A real, deadly poison can be prepared from anchar juice only by distillation or dehydration. The core of the anchar is quite soft, yellow or yellow- Brown color no clear texture.

Mainly used as decorative veneer.

B

Buckout (Hawaiac tree)

Bakout (Havayak tree) Guajacum officinale (medical guaiacum) - Lignum vitae and Guajacum sanctum (sacred guaiacum) - Iron wood, a genus of evergreen trees of the parnolistnikovye family. Backout - low (up to 10-13 meters), slow-growing evergreen trees with leathery pinnate leaves, articulated branches and beautiful light blue flowers. Backout wood is one of the heaviest: its density at 15% humidity is 1300 kg/m3. The wood is wear-resistant, but difficult to process, contains a lot (about 1/4 mass) of guaiac resin used for medicinal purposes, and has self-lubricating properties (especially in water). Backout is used as a material for bearings, blocks, templates in mechanical engineering, shipbuilding, for turning products, and backout is also used to make balls and bowling pins.

Balsa (hare chrome)

Balsa, Balsa (Balsa, Ochroma pyramidale)- A deciduous tree native to tropical America. It is also grown in India and South East Asia. The color of the wood is almost white with a yellow or pink tinge. This is one of the lightest tree species: a density of about 160 kg/m3. A freshly cut tree contains more than 90% water, but dries quickly and, unlike the baobab, does not crumble into dust, but acquires good strength.

Due to these properties of wood, balsa materials, in addition to their low weight, also have excellent sound and vibration absorbing properties. In the industry, balsa is used in mechanical engineering in the production of vibration-absorbing pillows; in aircraft construction as a soundproofing material.

In ancient times, balsa was used to build rafts and canoes. No wonder Balsa is translated from Spanish as Raft.

Balsa is very fond of aircraft modellers. Compared with the same carbon fiber, balsa has a number of advantages: ease of processing, relatively low price, maintainability. Well-glued, properly sawn balsa structures are very strong. This effect is also achieved due to the fact that during impacts, the resulting loads are absorbed by the material itself.

Balsa is also used to make water rescue equipment and fishing gear. Elite surfboards are also made from balsa.

Velvet tree (Amur velvet)

Amur velvet (Amur cork tree) - Phellodendron amurense. Amur velvet is a tree up to 25 meters high, in appearance resembling an ash or a huge mountain ash with an ash-gray trunk. The bark is velvety to the touch, which is reflected in the name - velvet tree, velvet. Velvet attracts not only decorative. From its bark, removed as the cork matures, cork plates are obtained, which are then used for various needs: in the manufacture of shoes, for capping the best wines, for fishing tackle floats, for tropical helmets, life buoys and belts, for polishing optical glasses.

The cork bark is removed in such a way as not to damage the vital tissues of the tree. Already on next year a new layer of cork is formed on it. And a few more years will pass - and the bark is again suitable for removal, for the preparation of much-needed raw materials.

The widespread use of cork is explained by its properties such as elasticity, flexibility, impermeability to water, gases, heat, electricity, sounds, and resistance to chemical reagents. And in our age of the heyday of the chemistry of synthesis, which supplies us with a lot of all kinds of substitutes, it has not yet been possible to find a substitute for the most ordinary cork. Nature turned out to be a truly unsurpassed master, who produced a material with a complex of excellent qualities. long time believed that only a cork oak can give a full-fledged cork. However, in the thirties, Soviet researchers found that Amur velvet cork is not inferior to oak cork.

Amur velvet blooms from mid to late June. Inconspicuous dioecious flowers (on some trees numerous male, on others female) are collected in brushes. The plant is pollinated mainly by bees, attracted here by an abundance of nectar. Under favorable conditions, in warm and humid weather during the flowering period, velvet gives 8-12, and in Ukraine up to 18 kilograms of honey per strong bee colony. One hectare of plantations provides 250-280 kilograms of honey, very High Quality. It is dark yellow, thick, does not crystallize for a long time due to the low glucose content, very pleasant in taste and surprisingly aromatic.

Velvet wood of the Amur beautiful pattern, dark brown, like bog oak. It is light, durable, low hygroscopic, does not dry out, polishes well, resists decay and damage by insects. It is not surprising that it is widely used for the manufacture of furniture, baguettes, skis, gun stocks, plywood, wooden parts aircraft and cars. The wood is very similar to ash wood, but it is somewhat darker.

Velvet is also valued medicinally. Chinese medicine recommends a strong decoction of bast as a diuretic and antipyretic, while Tibetan medicine recognizes the plant as capable of treating tuberculosis. Russian ethnoscience suggests using a decoction and infusion of its bast, leaves and fruits against liver diseases of the gastrointestinal tract and some others. Velvet harvest - up to 10 kilograms of fruit from one tree. By the beginning of October, the fruits mostly fall to the ground, and those remaining on the branches serve as good food for woodpeckers, thrushes, pigeons, and magpies, which contribute to the settling of the plant.

Amur velvet is the oldest representative of the Far Eastern flora, a living monument of tertiary vegetation. It is found in the forests of Northern China and North Korea, but it is especially abundant on our Far East. Here the plant is confined to the valleys of the Ussuri and its tributaries and the middle reaches of the Amur. In the Amur region, velvet is found in the lower reaches of the Bureya, Zeya and Selemdzha. Usually velvet grows singly or in groups and only occasionally forms small pure forests. It settles, as a rule, on clearings. Quite picky about soil and moisture. In dry weather, its buds are often showered unopened. One of the reasons for low drought tolerance is superficial root system. Frost damages when young. Life expectancy up to 300 years.

Currently, the plant is found in park plantings in Moscow, St. Petersburg, Kursk, Voronezh, Penza and many other cities.

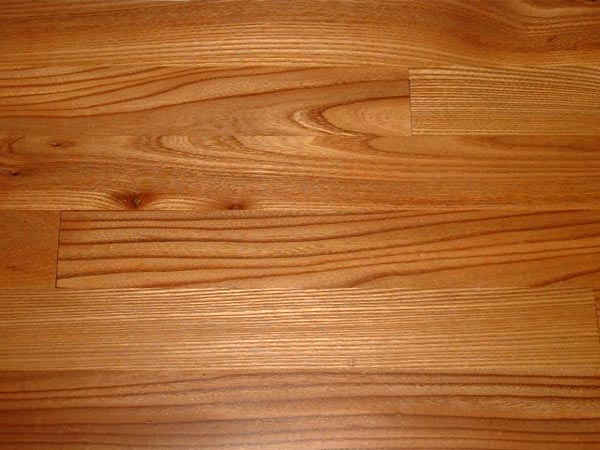

Birch- deciduous tree, one of the most common in the northern hemisphere. The density of the most common species is about 600 kg/m3. There are more than 100 species of birch in the world, differing in size, life expectancy, and wood properties. So it exists as a dwarf birch, growing near the Arctic Circle, whose branches spread along the ground. In temperate latitudes, a birch tree can reach a height of 50 meters, and a trunk diameter of one and a half meters. Some live seeing birches up to 300-500 years. A birch used in industry is cut down at the age of about 70 years.

Birch wood color, milky white, with hints of yellow and pink. Very soft and pleasant to look at. Annual rings are weakly expressed.

Perhaps no single type of tree is used comprehensively. There was a particularly reverent attitude towards birch in Russia, because they made shoes, dishes, tar from it, lit the huts with torches.

At present, birch is used to make medications, birch sap - apiary. Birch firewood is considered one of the best for cooking and space heating, as it does not contain tar and does not emit soot when burned. In addition, they have excellent heat capacity, burn for a long time and evenly.

Birch wood is quite strong and hard, it is used in the production of decorative veneer, plywood, furniture elements, parquet board and laminate. When in contact with water, birch products must be treated with antiseptics, because. birch wood is susceptible to decay.

![]()

The value of birch is determined by its unpretentiousness, the ability to grow quickly and renew itself in any conditions. Its wood is well processed and well polished. Plywood, parquet, skis, turning products are made from it. Karelian and burl birch wood is especially valued in furniture production. Due to the fact that it does not rot, the so-called birch bark letters- Old Russian letters and documents scratched without bark. (11th-15th centuries). Light and durable boats, birch bark tuesas, boxes and other utensils were made from birch bark. Birch gives firewood.

Birch is one of the most revered trees among the Slavs. In many places, it was planted next to the house in the hope that the birch would bring prosperity to the family, contribute to the multiplication of the family, and protect it from troubles. From ancient times, rituals with trees and birch branches, performed on the feast of the Holy Trinity, have been preserved.

Beech- deciduous tree widespread in the temperate climate of the northern hemisphere: North America, Russia and especially in Europe. In Russia, it prevails in the Caucasus, in the region of Greater Sochi, where beech forests form in the mountains up to a height of 2500 meters. The tree is not tall, up to 30 meters high and with a trunk diameter of up to one and a half to two meters.Beech has a dense dense crown. Almost the same twilight reigns in beech forests as in spruce forests. Beech absorbs a lot of moisture from the soil and releases a lot of moisture into the air - sometimes fog forms under the cover of beeches. A tree lives up to 500 years, but after 100 years the tree begins to hurt and the wood loses its quality.

The density of beech wood is about 700kg/m3. The wood is quite hard and dense, but is prone to decay, so it is not recommended to use it outdoors. Sapwood and heartwood are almost indistinguishable in color. The color of beech wood is yellow with a grayish tint. In the sun it darkens and acquires a reddish tint. The texture of wood is especially clearly visible in the radial and tangential sections.

The use of beech is very diverse. Beech wood is widely used in the chemical industry for the production of paper, acetic acid, alcohol. Beech is perfect for the production of bent furniture - when steamed, beech wood bends beautifully. Decorative veneer, parquet boards, musical instruments, packaging containers, toys and souvenirs are also made from beech.

Beech (lat. Fágus) - genus deciduous trees beech family. Density (670 kgm3) lives 250 - 300 years and reaches a height of 40 m and a diameter of 2 m. Beech has a heavy, hard, very durable, but not resistant to decay, light brown wood with a reddish or yellowish tinge. Hardness (according to Brinell) 3.7 - 3.9. The annual layers are clearly visible. core rays wide, on a radial section they look like shiny stripes, and on a tangential section - inclusions. It cuts poorly, may crack when dry. Steamed beech wood bends well. On a radial cut, it has a beautiful texture. Beech wood has always been valued by furniture makers for its rich texture and good workability. However, the Austrian furniture maker Michael Thonet provided the greatest popularity to beech products. His bent Viennese chair (chair no. 14), made mainly of beech, set a record that is unlikely to ever be broken. Over the period from the end of the 19th century to the beginning of the First World War, over 50 million pieces of such chairs were produced around the world.

Formally, it is not a tree, botanists attribute it to the family of cereals. But in their own useful properties bamboo is not inferior to real trees.

The density of bamboo is about 700 kg/m3, which is comparable to the density of oak. This plant is native to Southeast Asia, but is currently different kinds Bamboo is grown all over the world, including in Russia and the Caucasus. Bamboo is very unusual plant, it blooms extremely rarely. Depending on the species, every 20 or even 100 years. After flowering, the plant dies. This phenomenon is not yet fully understood - it is not clear what triggers the flowering process.

The use of bamboo is very multifaceted: it is food, building materials, and household items. Bamboo is also used to make musical instruments and fishing gear. Bamboo is traditionally used in the production of parquet boards and solid floor boards.

The natural color of bamboo is straw or golden yellow. The texture is also very unique. Bamboo almost does not shrink and does not warp. In addition, it has antiseptic properties and is very durable.

Bakout - wood of evergreen trees from the genus Guaiacum, growing in Central America and in the Caribbean islands. The wood is extremely durable, hard and heavy: density 1300kg/m3. Drowning in water. The color of the heartwood is olive to black-green. Since these trees grow very slowly and are of great value, the species is in danger of extinction.

Thanks to their unique properties, backout wood is used where hardness and strength are needed. In addition, wood contains a large number of resin, which is a natural lubricant. These properties made it possible to use backout in the production of bearings for ship propellers subjected to heavy loads and located adverse conditions sea water.

Backout is also used for the production of decorative veneer, but more often backout wood is used in turning, as well as by wood lovers for the manufacture of mallets, mortars and pestles, knife handles, etc.

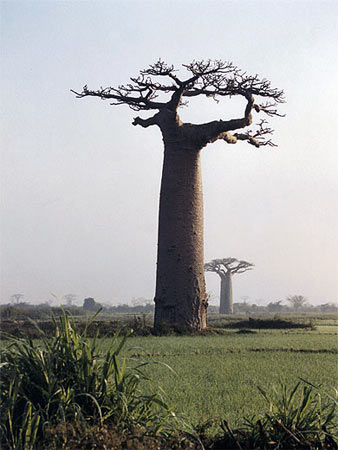

Baobab

Baobab, Adansonia digital (Baobab, Adansonia digitata)- a tree inhabitant of the African savannas and the Australian semi-deserts. The baobab is unique not only because of its size (it is the thickest tree in the world, its circumference reaches 10 meters), but because of its bizarre appearance: tree branches are more like roots. This tree is highly respected. local residents, because it not only benefits its fruits, bark and leaves, but also can become a refuge for a whole tribe: up to 40 people fit in some baobab trunks.

Baobab wood is very porous and loose, which is actually a sponge that absorbs thousands of liters of water during the rainy season. Therefore, elephants love to feast on baobab wood during a drought period. Due to these features, baobab wood has no industrial value.

The baobab is a symbol of Madagascar, only here grows a species of baobabs with a long thick trunk and a small flat crown on top.

Balau

Balau, Bankirai, Bangkirai (Balau, Shorea)- a tree growing in the tropical forests of Southeast Asia: Indonesia, Malaysia, the Philippines. Many species of this genus are listed in the Red Book. Trees reach a height of 80 meters and 2 meters in diameter.

The density of wood is about 1100 kg/m3. Balau wood is light brown to dark brown, with a reddish tint. The pattern on the cut is inexpressive, annual rings are barely distinguishable.

Balau wood is valuable primarily because it is practically not subject to decay, moisture, and damage by insects. It has a high resistance to stress.

Balau is used in the production of terrace and deck boards, bathroom floors, garden furniture.

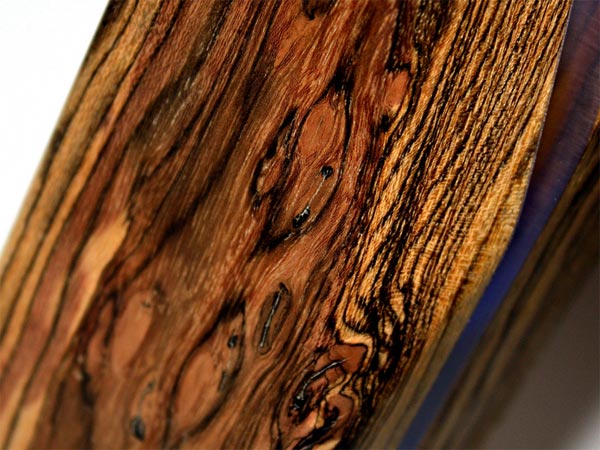

Bokote

Bokote, Zirikot, Zirikote (Bocote, Cordia)- enough rare tree native to the Caribbean, Mexico, and Central and South America. Some species of trees of this family are also found in Africa.

The tree is small: up to 30 meters in height and up to 1 place in diameter. The density of Bokote wood reaches 940 kg/m3. The strength of the wood is above average, but susceptible to damage by insects.

Bokote is valued primarily for the beauty of its wood. You can't confuse it with any other. The heartwood is yellow-brown with almost black veins and large quantity dormant buds called "bird's eye". Unlike knots and knots, these formations are processed quite well. The color of the stripes tends to darken with the age of the tree, so fairly mature trees are harvested industrially. It is interesting that when processed, Bokote wood emits the smell of pickled cucumber that is so familiar to us.

Bokote is used for the manufacture of billiard cues, butts of weapons, knife handles, musical instruments, in elements of expensive furniture, for the manufacture of various souvenir products. Bokote wood is valued wherever beauty and strength are required.

Bubinga (Bubinga, Guibourtia) - a tree native to equatorial Africa.

It reaches a height of 50 meters and up to 2 meters in diameter. The density of wood is about 900 kg/m3. The heartwood is red-brown in color with dark veins, fairly dense and hard. Possesses beautiful texture. Freshly cut wood has an unpleasant smell, which disappears when dried.

Bubinga wood is used in the production of decorative veneer, parquet, furniture elements. Due to its impressive size and the fact that bubinga sapwood is quite thin, the trunk can be used for the production of unfinished countertops. This tree is also loved by manufacturers of musical instruments: bass guitars, drums and especially harps. It is also used for the production of bows and in the interior of expensive cars.

AT

Cherry- a small tree, up to 10 meters in height, growing in a temperate climate. This fruit tree belongs to the plum genus. The closest relatives of cherries are sakura, cherry, plum, apricot, bird cherry. The homeland of cherry is usually considered the Crimea and the coast of the Caucasus. Currently, cherry is grown throughout Russia for ornamental and agricultural purposes.

In woodworking, in addition to common cherries, American cherries (black cherries), Brazilian cherries and Patagonian cherries are used. All of them are slightly different in color and wood texture. Otherwise, they are similar. The density of cherry wood is about 600kg/m3. The wood is much softer than oak, it is perfectly processed and bends - they are made from cherries bent furniture.

The colors of cherry wood are very soft and warm, ranging from yellow-pink to red-brown. The texture is not too expressive, annual rings are not bright, but very beautiful. "Cherry color" has long been one of the main colors in furniture production. Surely you will be offered this color when choosing a facade, for example, a kitchen. Cherry is used for the manufacture of furniture and door veneer, furniture elements, parquet and parquet boards. Very popular with cabinetmakers.

![]()

Elm (elm, birch bark) Deciduous tree growing in the temperate climate of the northern hemisphere: in America, Europe, Asia.

Elm lives up to 200 years and grows up to 40 meters in height and up to 2 meters in diameter. Elm leaves are very beautiful: ribbed with sawtooth edges, different in size and shape. For the similarity of foliage with ligature, elm got its name. The foliage and wood of the elm is susceptible to various insects and fungi: the wounded tree quickly rots at the site of the lesion. In Europe, as a result of the defeat of the so-called Dutch disease (the fungus ceratocystis ulmi), huge populations of elms dry up.

The density of elm wood is about 650 kg/m3. The wood is quite strong and viscous. Color from gray-brown to dark brown with a red tint. Annual rings are clearly visible, the pattern on the cut is very beautiful. Many cabinet makers recognize elm as the most beautiful of European species.

Elm wood is used to make paper, boxes, hockey sticks, furniture, household items.

wenge

Wenge (wenge)- a tree that grows in West and South-West Africa. The tree is small: up to 20 meters in height and up to one meter in diameter. The density of wenge wood is about 920 kg/m3.

The wenge tree is famous primarily for the beauty of its wood. It is brown in color with dark chocolate streaks. The color of the wood depends on the meta growth and can range from light brown to almost black. The wood pattern is very decorative and is truly African. Wenge cannot be confused with any other wood. In addition, wenge has great strength, resistance to stress, insect damage.

Due to its qualities, wenge has gained immense popularity among connoisseurs of natural wood. Wenge parquet is one of the most expensive on the market. Wenge floors look very stylish and beautiful, serve for a long time and at the same time retain their original appearance. In addition, wenge wood is used for the manufacture of decorative veneer, furniture elements, musical instruments, various souvenirs. The beauty of wenge wood has another side - it is mercilessly destroyed by poor African countries in pursuit of excess profits. In the future, if the wenge tree does not completely disappear, the price for it may become sky-high.

G

Goncalo (tiger tree)

Goncalo Alves, Tigerwood- wood of trees of the species Astronium graveolens and Astronium fraxinifolium. The gonkalo tree is native to Central and South America, from Mexico to Brazil. The main supplier of gonkalo wood is Brazil. A tree with a height of 30-40 meters and a trunk diameter of 1 1.5 meters.

The wood is very dense and heavy (995 kg/m3). Gonkalo wood gained popularity due to its unusual, "tiger" pattern. The heartwood is yellow or orange-gold in color with dark brown or almost black stripes and spots. Has natural gloss, darkens on the sun.

Goncalo wood has excellent physical and chemical properties: after drying, it does not crack or warp. It is not subject to attacks of insects and almost does not get wet. Thanks to these properties, gonkalo is used in the construction of yachts and ships, terraces and arbors.

In addition, gonkalo is used to make floor coverings: parquet and massive board. Tiger wood floors look very nice and decorative. Decorative veneer, cues, bows, knife and pistol handles are made from goncalos.

Hornbeam

Hornbeam- a genus of relatively small deciduous trees from the birch family, up to 20 m high and up to 80 cm thick trunk. Density is about 750 kg/m3. Widely distributed in Central, Southern and Western Europe, Iran and Asia Minor.

The hornbeam has light, heavy, viscous wood. The pattern of annual rings is weakly expressed.

Often this species has a cross-layered structure of wood, as a result of which the hornbeam is relatively difficult to machine. The sapwood has little difference in the transition to the core.

After prolonged careful drying, the hornbeam is practically not subject to warping, and its hardness becomes higher than that of oak.

I use the hornbeam for the production of musical instruments, turning products, veneer. Hornbeam is widely used for the manufacture of parquet boards, floor boards. Sanded and lacquered wood gives a unique effect due to its twisting (twisting). To prevent the formation of cracks, it is necessary to drill holes for screws and nails.

![]()

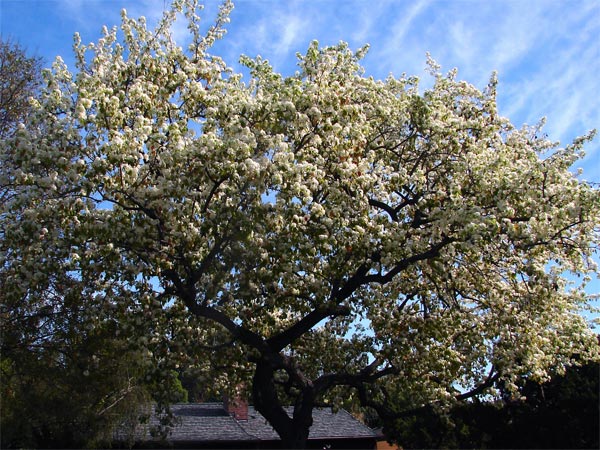

Pear

Pear- a fruit tree of the rose family, up to 15m high, trunk up to 50cm thick. Density: 700 - 750 kg/m3. It grows in Europe, Asia, North America and North Africa. The wood is dense, hard, well processed. To increase the hardness, the wood is soaked in water for a long time, after which it is slowly dried. With proper drying, the pear almost does not warp or crack, but is prone to wormholes.

The color of the wood is pinkish-yellowish-white or brownish-red. In furniture production, pear is often tinted black. The texture is fine with slightly pronounced pores and a pattern of annual rings.

It is used in furniture production, decoration of expensive cars, products of arts and crafts. Great for fine carving.

Under favorable conditions, it can live up to 300 years, reach a height of 20 - 25 m, a thickness of 50 - 80 cm. Pear wood is well-deserved fame among carpenters - dense, uniform, slightly knotted, hard. When dried, it cracks and warps a little, but dries out a lot. Dry it with great care. The wood is pinkish with a slight lilac tinge, the older it gets, the darker it is and is highly valued in the production of high-end furniture. The wood is straight grained, well polished and pickled.

The place where the lightning struck was considered sacred, and believers reached out to it. For a long time, a hermit monk lived inside the oak. It turned out that there was enough space in the sacred tree for a Catholic chapel. It is located on the top floor, which leads to wooden staircase. The tree, 18 meters high and 16 meters in girth, welcomes thousands of tourists every year.

The solid wood niche is represented by: oak, beech, maple, ash, sycamore, boxwood.

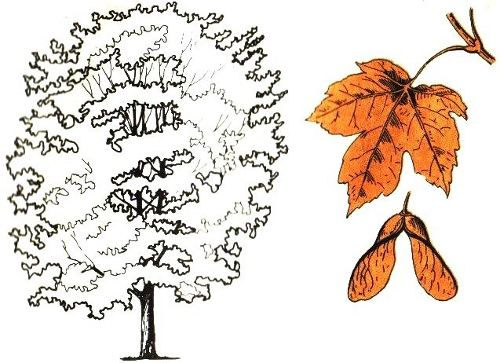

Oak (Fig. 1). Several varieties grow in Russia, but the most common summer oak is the pedunculate oak. He meets separate arrays in the European part, as well as in the Crimea and the Caucasus.

Rice. 1 Oak

Oak wood is hard, heavy, characterized by high strength and decay resistance, beautiful texture and color. Greenish-brown, with a powerful rough pattern of fibers, and the light parts of the wood are distinguished by a special strength and some kind of bone sheen. Oak is easily machined, well finished and bends, used for carving and in interior design. It is used in carpentry and furniture, cooperage and plywood industries.

Due to the scarcity of oak wood in carpentry it is used mainly in the form of planed plywood, in construction it is used for the manufacture of parquet. AT furniture industry bog oak is valued, having a dark gray color. Naturally stained oak is obtained from oak trunks that have been in river water for a long time (hundreds of years). Bog oak characterized by increased hardness. Oak is used in shipbuilding and for underwater structures. From wood and oak bark, an excellent raw material is obtained for the manufacture of an extract of tannins, the very name of which comes from the word "oak".

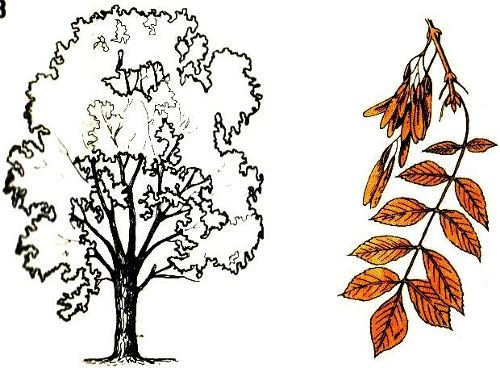

Beech (Fig. 2) grows in the Caucasus, Crimea and Western Ukraine. Beech wood with a beautiful texture in the radial section, very strong, bends well, but is prone to decay. Depending on age has different colors. The species is sapwood, the wood is light with a yellow-red tint. The annual layers are clearly visible on all sections, the vessels are small, the core rays, resembling wide stripes, darker than wood, in color, are visible on all sections and form a speckled or spotted texture characteristic of beech. Beech is a dense, hard material, easy to process, cut and turn, plastic, paints and finishes well. Bent furniture, riveting for barrels for butter and oil products, parquet frieze, sliced veneer, drawing accessories (rulers, triangles), cases for carpentry tools, details of musical instruments. Beech wood is a valuable raw material for dry distillation in the production of acetic acid, tar and creosote.

Rice. 2 Beech

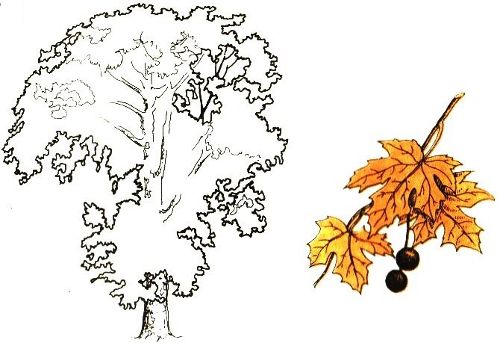

Maple (Fig. 3). Several species grow on the territory of Russia, mainly in middle lane and in the south of the European part, in Ukraine, in the Crimea and in the Caucasus. The most common are Norway maple, field maple and white maple (sycamore) small-leaved.

Rice. 3 Maple

Maple is a sapwood species with white wood with a reddish-brown tint. Annual rings are clearly visible, on all sections, core rays are visible, which are darker than wood. On the radial section, dashed ripples in the texture are noticeable, which is characteristic of the entire rock. Maple wood is dense, hard, strong and heavy, easy to cut and finish. It is used for the production of musical, including bowed instruments, in mechanical engineering. Maple is used to make handles, planer blocks, shoe lasts, sports equipment and much more. On the trunks of a maple, sagging or caps are sometimes formed - an excellent material for various crafts.

Ash (Fig. 4) - widely distributed in the middle and southern strip of the European part, in the Caucasus, in the Crimea. Differs in the high durability and viscosity, very beautiful texture. In color and structure, ash resembles oak wood, grayish with bright, clear, coarse fibers, but it is slightly lighter than oak, most often dull gray, sometimes white color, the zone of large vessels in the annual layers is wider.

Rice. 4 Ash

Ash wood is used in the same way as oak wood. Ash is especially valued in furniture production. It is easily processed, almost does not crack during drying, and gets off well. High impact strength, ability to bend determine the use of ash for the production of sports equipment (skis, oars, tennis rackets), in the manufacture of tool handles, in the ship, carriage, aircraft and automotive industries. Used to make stair railings, as well as equipment for horse-drawn transport.

The plane tree (Fig. 5), or plane tree, grows in the south of Russia, the Caucasus, Transcaucasia and Central Asia. The rock is spring, the color of the sapwood is grayish-brown, the heartwood is red-brown. The core rays are clearly visible and much darker than the wood. The texture of the wood on the cuts is very decorative. The wood is dense, hard, with good mechanical properties, well processed, cut and finished. Used in the furniture industry finishing material and for the production of various artistic products.

Rice. 5 Plane

Boxwood (Fig. 6) grows on the Black Sea coast of the Caucasus, in the Crimea, in the Far East.

Rice. 6 Boxwood

The species is sapwood, the wood is of a homogeneous structure, yellow in color. Differs in durability, very high hardness. Boxwood is used to make durable shuttles for looms, wind musical instruments, buttons, engraving boards. It is used for carving and turning.

Wood species

Depending on what you want to do, use one or another type of wood.

First of all, you need to determine whether the bar you have chosen belongs to conifers or hardwoods. Conifers have a sharper, resinous smell. In addition, the macrostructure of such wood species is better distinguished than that of deciduous ones. Coniferous wood species include pine, larch, fir, spruce, cedar.

- Coniferous wood

- Hardwood

- Wood fruit trees

- Rare wood

- Pine

- Cedar

- Fir

Spruce- the second most important and used coniferous breed. Compared to pine, spruce is inferior to it in many ways. First of all, this is caused by a large number of knots in the wood. Yes, and processing it lends itself to a little worse. There is a little less resin in spruce wood, which affects its poor resistance to atmospheric phenomena.

Cedar, or Siberian pine, on building qualities not inferior to spruce, and sometimes even surpasses it. Cedar wood is very easy to work with, but at the same time, like spruce, it is not resistant to decay.

Fir, in terms of its working qualities, is not much different from spruce: it is easy to process and practically does not perceive chemicals. Just like spruce wood, it contains little resin, which is why the wood quickly rots in the open air without special treatment.

Hardwood Hardwoods are divided into hardwoods and softwoods. The wood of such species practically does not smell, and the smell intensifies only with a fresh cut of the wood and its processing. The most commonly used hardwoods are oak, birch and ash. The most common among softwoods are aspen and alder.

Hardwood:

- Ash

- Birch

- Elm, birch bark, elm

- Nut

- Aspen

- Poplar

- Alder

- Linden

Beech also applies to hardwoods. In terms of its qualities, it practically does not concede to oak. Just as good as oak, it can be processed, bent and impregnated with various chemical solutions. This quality contributes to the durability of the varnish and paint coating. But due to the fact that beech strongly warps when dried, is prone to decay with the formation of wormholes, it is little used in the manufacture of furniture.

Ash most often used in the manufacture of furniture, veneer and parquet. Such wide application ash wood is primarily due to the qualities of its wood: strong, viscous, durable, resistant to decay, with a beautiful textured pattern, which warps a little during shrinkage and bends well when steamed.

Birch used slightly less frequently than ash. First of all, this is due to low resistance to decay, high shrinkage and susceptibility to warping. But birch wood itself lends itself well to processing, making it possible to make small relief carvings. In addition, birch wood is well impregnated chemicals, perfectly holds a varnish covering.

Elm, birch bark, elm represent the same breed. Among the main qualities that this breed possesses are: density, strength, viscosity and low porosity. During shrinkage, the wood practically does not warp and does not crack. In addition, after steaming, the wood can be bent as you wish. But because of its dense and finely porous structure, wood is difficult to polish, poorly planed and painted.

Nut has beautiful wood and intended for finishing work. It is well processed, can be polished and impregnated with chemicals. Heavy and durable walnut wood is resistant to warping and decay.

Aspen has soft wood, in which there are few knots. Aspen lends itself well to processing, but due to its porous structure small parts can break almost during their manufacture.

Poplar also applies to softwoods. Beautiful small details and products are obtained from such wood. But poplar is prone to decay, warps and cracks when it dries out.

Alder of all softwoods, it is most often used in the construction of houses and in the manufacture of furniture. Alder practically does not rot, and therefore it is often used in the construction of log cabins for wells. It is also well used in the construction of pantries - it does not smell and does not absorb smell.

Linden among all softwoods, it is valued in the manufacture of large carved furniture parts. In addition, this is one of the few types of wood that does not warp or crack during shrinkage. Linden has a strong structure, which is not very susceptible to decay.

fruit tree wood

Among the rare species that are used in joinery and carpentry, the wood of fruit trees occupies a large place. Mostly wood from wild trees is used here.

Fruit wood:

- Pear

- Apple tree

- Plum

Apple tree belongs to a number of the most beautiful and durable types of wood. But after drying, the tree warps and dries out very much, so it is preferable to work only with a well-dried apple tree. Just like a pear, it is used for furniture finishing, making household utensils and jewelry.

Plum, like the apple tree, is very susceptible to cracking and warping during drying. Hard and durable wood with many multi-colored veins is perfectly pricked and polished. Most often it goes to the manufacture of jewelry and to the relief decoration of furniture. Turned utensils made of plum wood are also highly valued.

Rare wood

Above, we examined those types of wood that grow with us. But in Russia, imported breeds are also very popular, which are most often used to make furniture and jewelry.

Rare wood:

- The Red tree

- Ebony

- Eucalyptus

- Furnambuc

- Rosewood

- satin tree

Ebony brought to us from Madagascar, Ceylon, the island of St. Mauritius. Although wood cracks and splits well during shrinkage, ebony is considered the most expensive. Its wood is dense, uniform, black in color. Wood with inconspicuous layers of growth rings and vessels is highly valued. Wood with whitish interlayers and macrostructures and cores that stand out against the background of wood is least valued. Wood practically does not rot, does not warp during shrinkage, perfectly absorbs varnish. The only thing that is not allowed to be done with ebony is polishing: from this appearance only gets worse.

Eucalyptus has a strong, heavy wood, which is practically indestructible. This property is explained great content in its structure essential oils, which act in the same way as the resin in pine wood. Eucalyptus belongs to a small number of tree species that are difficult to work with. Most often, the basis of furniture is made from eucalyptus, then it is decorated with inserts from other species or pasted over with mahogany or ebony veneer.

Furnambuc used in the manufacture of mosaics. The most expensive are violin bows and conductor's sticks made from this tree. During storage, fernambuque can change color from yellow with an orange tint to dark cherry or even black. Its wood practically does not rot and, when dry, does not warp. But a tree that has just been cut down dries out, cracks and changes shape. In terms of severity in processing, it is second only to eucalyptus.

Rosewood, like most breeds, is imported into Russia from South America. Rosewood wood has a porous structure and a dense arrangement of fine fibers. The peculiarity of this breed is its color, which, depending on the predominance of any shade, changes from light purple to dark brown with a purple tint. Like fernambuque, it can change color over time. If the wood has not been polished at the end of the work, then the color of the wood can become almost black. The wood itself is perfectly processed, not subject to decay. Most often, furniture and all kinds of decorations are made from rosewood.

satin tree is rare among us, and therefore it is highly valued. AT Russia is coming only for the manufacture of mosaic inserts and decorations. The wood of this breed can have a yellow, red and brown tint. But regardless of the color of the wood, it always contains the smallest sparkles, which, when varnished, give the finished product a satin sheen and gloss of a soft flowing fabric.

wood structure

By making a cross section, you can most clearly see the structure of the wood. Each bar of unhewn wood has a bark - this is the skin of a tree that is not used in work, it must be removed.

Under the bark is a tree growth zone, which is practically invisible to the naked eye. On a fresh saw cut from a growing tree, this cambium layer is very well represented. After you remove the bark, you will see a thin layer of wet greenish tissue - this will be the cambium. Behind the cambium is the actual wood with growth rings.

The wood is also called sapwood. In the center of each tree there is a core, which can merge in color with sapwood or have more dark color. Depending on this, sapwood species are divided, where the core does not have a pronounced structure and the cells are located as densely as in sapwood, and heartwood, where, accordingly, the core is clearly distinguishable. Sometimes sapwood is called coreless.

Heartwood species include all conifers (pine, cedar, spruce, yew, larch) and some hardwoods e.g. oak, ash, poplar.

Most hardwoods are sapwood, or non-core: birch, hornbeam, alder, maple, hornbeam.

In addition to the microstructure of wood, which includes the density of the arrangement of wood cells, the creation of a composition and the possibility of using one or another bar in work is influenced by the macrostructure of wood, represented by growth rings and heart-shaped vessels. The macrostructure also includes the presence of various knots, growths and undeveloped shoots-eyes, which deflect the growth rings and form various twists.

Wood, where annual rings, horizontal and vertical vessels are most clearly distinguishable, seems to be the most interesting for processing. Almost all conifers - hornbeam, oak, elm, beech - have such wood.

Wood defects When working with wood, you should not only pay attention to the location of the fibers. First of all, carefully inspect the bar you have chosen from all sides. The wood with which you are going to work should be not only durable, but also “healthy” - uniform in color, without admixture of quite interesting and unusual colors, without traces of damage by wood grinder worms, and also without traces of rotting that has begun. If your bar has at least one of these signs, then immediately put it aside, otherwise you may suffer from everything during the work, and at the end of the work you will not receive sufficient satisfaction from the work done. Yes, and work can simply come to naught.

Do not use wood affected by fungus. It can be clearly seen even with the naked eye by changing the color of the wood and by splitting the wood fibers at the site of the lesion. The color of wood affected by the fungus can vary from cream and brown to bluish and greenish. The rest of the wood will retain the usual color.

Greenish coating that appeared on separate sections wood, indicates that the wood has begun to rot. Mold infects wood only from the outside, therefore, if you clean the surface with a knife or planer in a timely manner, then the board or bar can still be saved, and then, after drying it, can be used in work.

color rot not as harmless as sound. It affects the wood from the inside, destroying its structure and making it impossible to use it. Wood can be absolutely healthy, but still unusable. Defects can be different. Some of them can completely exclude wood from use, others only limit the possibilities for processing.

The most common defect is the presence of knots. But there are two types of knots. Some of them are firmly grown together with wood and are removed from the array only when the entire area is removed. Others separate easily from the wood. It is here that there is a high probability that during drying finished product it can fall out and ruin the whole picture.

You can close up such a hole using a wedge-shaped plug, which is driven in instead of a knot. In addition, during long-term storage of wood as a building material, knots darken first. The only exceptions are some conifers.

The presence of tars in coniferous and water layers in hardwoods can also be attributed to the category of wood defects. So it is customary to call the places of accumulation of tree sap in the massif of wood. When finishing, you will have to pump out the resin from this place and treat it with a special solution. But it is better if you place the part on the bar so that the pocket is either inside the part or outside it.

Among the defects of wood, which must be taken into account when working, more space occupies such a defect as the presence of cracks. They are formed in the massif of wood during the growth of the tree trunk. Cracks can be different.

frosty cracks can divide the entire trunk into two parts. The cracks themselves go from the outer edge inward and form only in winter during severe frosts.

Compensation cracks occur only inside the trunk, thus forming a gap between annual rings. The reason for the formation of such cracks is a large stress inside the trunk during the period of increased growth.

Metic cracks, like frosty ones, can divide the trunk into two parts. The difference between them is that the frosty ones go from the outer edge to the center, and the metic ones go from the base of the trunk to the top.

Cracks during shrinkage can also form in wood without visible defects. Such cracks go from the center of the trunk to outside across the annual rings.

Also, the defects of wood include the presence of a slope of the fibers. Such a defect can be both natural and mechanical. In any case, thin narrow blanks made of such wood warp very strongly during shrinkage.

At conifers timber, the most common defect is roll. This is a natural defect that occurs when the trunk is compressed during the growth period. Wood fibers in this area are located close to each other, which significantly increases the time of impregnation of wood with antiseptics and chemical dyes. But such wood is very durable and weather resistant, so it can be adapted for upholstery. front door at the cottage or in the apartment.

The presence of growth in wood in itself is harmless, but can create great difficulties after shrinkage. Such a defect occurs when a tree trunk is cut during growth. The resulting wound gradually overgrows, but the annual rings begin to grow differently.

Shrinkage of wood

Various wood defects during work can be avoided by one way or another placing the drawing on the prepared workpiece. But in any case, you need to take only well-dried wood for work, otherwise there is a possibility that after a long and hard work all your efforts will be in vain, in other words, it will crack and warp.

Therefore, before starting work, dry the workpiece well. But you should not immediately saw off pieces from raw wood that will not be needed later. The wood will not dry out any faster. In this case, you can simply ruin the bar - after all, during shrinkage, the fibers are compressed in different directions in different ways.

The smallest change in the size of the bar will occur in the direction of fiber growth. The bar will become even smaller across the growth of the fibers, i.e. in the radial section. Most of all, the bar dries out in the tangential direction.

All tree species can be divided into 3 categories according to their ability to shrink during drying: strongly drying out, moderately drying out and slightly drying out. The first category includes such species as oak, linden, elm, alder, beech, maple and many others. The second category includes: willow, aspen, poplar, pine. Only spruce and larch change their dimensions a little during shrinkage.

Drying wood requires a lot of patience. Can't put right away raw wood to a strong heat source. First of all, after bringing the boards home, hold them for a few days for glazed loggia and only then bring it into the room. If your loggia is not glazed, then put them in the pantry or in the corridor, where the temperature is always a little lower than in the living room, and even more so in the kitchen. Only in these few days, try to keep the workpieces away from the draft. Yes, and direct sunlight should also be avoided on the loggia so that one part of the workpiece has dried and darkened in the sun, and the other is still damp.

Lubricate slightly dried boards from the ends with garden pitch or PVA glue. blanks from valuable breeds wood must be lubricated not only from the ends, but also from the sides, so that cracks do not form during drying. The same rule should be followed when drying the wood of fruit trees. The PVA layer can be replaced with plain paper, which is glued to the sides of the bar on a starch paste.

Lay the bars and boards prepared in this way near the battery central heating or near a fireplace or heater. The boards will constantly need to be turned over and ensure that the temperature in the room is the same, without significant differences. But drafts should also be avoided, otherwise the likelihood of cracks increases.

Depending on the size of the blanks you have chosen, the drying time may vary. Thick and long boards naturally dry much longer than thin and short ones.

If you dry the boards not indoors, but under open air, then you must make a canopy that would protect the wood from direct sunlight and precipitation. The ground under the boards must be carefully leveled so that the boards do not bend during storage and drying. Lay a layer of roofing paper on the ground, then put a few bars so that air can penetrate under them.