We will send the material to you by e-mail

The platband is an ornament and functional part windows on the facade of the building. This tradition has been going on for a long time and does not lose its relevance today. You can make beautiful platbands on the windows in wooden house on one's own. At the same time, many products are made not only from wood, but also from other materials. The creation of such elements requires certain knowledge and skills, as well as suitable tools.

Unusual color and style make carved platbands a real decoration of the building.

Currently, the installation of platbands on windows in a wooden house is again in demand. The photos below allow you to see best examples. This element emphasizes the desire to revive the traditional decor.

To the virtues given element can include the following:

- performs a decorative function and helps to visually expand or stretch the building;

- complements the overall style of the architectural solution;

- protection of the space between the window opening and the wall surface from moisture and dust;

- reduction of heat loss and noise level;

- emphasizes the individuality of the building and the style of the era you like.

Also, this design has some disadvantages:

- wood requires a certain treatment from high humidity and swelling;

- the need for constant processing and regular care;

- not compatible with metal-plastic windows.

Helpful information! When combining wood with metal-plastic, they must be made in a single color scheme.

Do-it-yourself patterns of carved platbands on the window

There are various platbands for windows in a wooden house. Their varieties often depend on the method of fastening to the window.

There are two types of fasteners:

- telescopic products have L-shaped protrusions that coincide with the grooves of the window box;

- overheads are installed on the window frame using building glue or nails with screws.

The original solution is to install carved architraves. At the same time, on the Internet you can find a lot of patterns of carved platbands on the window. With your own hands, such structures can be made only with the help of special equipment.

You can consider the following types of materials for creating such structures:

- wood is considered a traditional material;

- plastic models are resistant to temperature fluctuations and ultraviolet rays;

- MDF is made from wood waste, therefore it is more environmentally friendly than plastic products;

- polyurethane varieties are characterized by practicality.

How to choose the right wood?

Wooden platbands are popular. At the same time, the performance of the product depends on the variety of the selected tree.

The following options are worth considering:

- ash, beech and oak are hardwood varieties. They are durable, but it is difficult to cut patterns on them;

- much easier to handle soft hardwoods- linden, aspen and alder. On their surface, patterns can be cut even by hand. Such surfaces must be carefully treated special formulations;

- it is recommended to create small elements from cherries and apple trees that can be attached to the base;

- characterized by ease of processing and good operational properties pine and birch.

Helpful information! You can use different combinations of wood types. In this case, special protective impregnations should be used.

The secrets of making do-it-yourself window trim templates: stencils and design

You can find various templates for window frames on the Internet. You can print stencils with your own hands. The selected ornament should be combined with the overall style. In this case, do not mix geometric and floral patterns.

When making platbands, it is worth considering the following points:

- wall color palette decorative items must match;

- It is important to choose the correct size. Products should not be too small or wide;

- you need to pick quality option coatings. In this case, special paints and varnishes are used;

- a template is required to create external carvings.

Helpful information! It is necessary to correctly place the drawing on the workpiece. Details should be located along the grain of the wood.

Platbands for windows in a wooden house: manufacturing steps

Before you start creating window decor, you can pick up carved platbands on the windows in a wooden house from the photo. A template is preliminarily made, which must be the same for the design of all window openings.

There are two main ways to create patterns:

- overhead thread is different separate elements patterns that are attached to one base;

- with slotted carving, a through ornament is made that looks like wood lace.

With any method of manufacture should be used. You will also need special tools: a hacksaw for wood, a set of knives and chisels, and a drill. Platbands for windows are made in a wooden house from prepared materials. The process of creating products includes several stages:

- precise measurements are made;

- The selected wood must be dry. The width of the boards depends on the dimensions of the window opening. The thickness of the material must be at least 30 mm when making a slotted thread and at least 10 when making a consignment note;

- the resulting holes are rubbed with sanding paper;

- prepared parts are attached to the base. It uses adhesive composition or special nails.

Helpful information! When installing platbands, self-tapping screws cannot be used, since such fasteners cause cracking.

Mounting Features

The finished platband is mounted to the window opening in the following ways:

- mounting on a blind spike. These items are installed on inside. Under them, special holes are created in the frame. Glue is distributed on the spike and it is inserted into the groove. Such fasteners protect the platbands from dust and moisture;

- a through spike is used. In this case, the junction must be carefully treated with varnish.

Similar techniques are used if the window is wooden. For mounting on metal-plastic, a special liquid glue is used.

What care is needed?

Carved items are primed, varnished or painted. Such treatments are carried out every few years. This will extend the life of the products, as well as maintain their attractive appearance.If plastic or metal products are installed, they do not need special care. It is important to protect products from corrosion and occasionally renew the paint.

Making beautiful architraves with thematic patterns with your own hands will allow you to decorate window openings in an original and unusual way and bring a special zest to the planned architectural style.

Save Time: Featured Articles Every Week by Mail

The tradition of decorating windows with carved platbands has come from ancient times. It was believed that window decoration with fancy patterns not only protects the room from drafts and cold, but also serves as a kind of protective amulet from evil spirits or the evil eye.

A selection of templates for carved window frames

How to make a stencil for a platband

A stencil is a device for applying the same patterns and symbols to the desired surface. Before starting work on the manufacture of platbands, you will need to get stencils and templates. Finding a sketch for a carved platband is not difficult - they can be downloaded for free and in a wide variety on the Internet, purchased in specialized stores or found in magazines.

IN ready-made stencils and templates can be made on paper, cardboard or wood fiber. They only need to be attached to the surface of the future casing and circled. There are several ways to make a stencil yourself:

Stencils and templates are the main assistants in creating carved platbands. In the drawing, you need to take into account which pattern will be chosen for the various components of the casing.

Carved platbands include the following main details:

- top trim;

- vertical slats of the casing or frame;

- bottom bar or profiled window sill.

These are just the main elements, carved platbands can include many more decorative details: a diadem, coat hangers, flowerpots, and so on.

Transferring the contour of the drawing to the workpiece

After the sketch is created, you need to make a stencil directly, onto which all the elements of the pattern for carved platbands are transferred. You can transfer a contour to a workpiece in the following ways:

Cutting a platband according to a template

Cutting a platband according to a template - The most common way is when the pattern is cut out of thick paper or cardboard. The resulting templates are applied to the board and traced along the contour with a pen, felt-tip pen or pencil.

- The stencil can not be cut out, but transferred to future platbands through carbon paper.

- You can push the outline of the sketch through the paper onto the tree with a pen (leaving an inconspicuous trace). You can make the outline clearer without carbon paper by applying a layer of graphite on the back of the sheet with a soft, simple pencil.

You need to place stencils on the workpiece along the fibers of the tree: in the future, the thread of such a casing will not crack. For convenience, the places where the cuts will be made can be made colored.

Old Russian architecture is invariably associated with carved platbands on the windows. This form of design of houses is distinguished by species diversity. A few decades ago, craftsmen with their own style of creating decorative elements lived in each region. Today's return to the roots is accompanied by a revival of interest in window decoration using carved platbands.

Framing purpose

The very word "platband" speaks of its location - "on the face", that is, one of its functions is to decorate the facade of the building. Therefore, people tried to express their individuality through it and decorate the windows with carved frames. In addition to the decorative role, window trims primarily perform a constructive function, closing the gap between the frame and the opening. This prevents dust from entering the house, protects against precipitation, drafts and extraneous sounds.

In the old days, carved platbands were also attributed magical properties. It was believed that the window frame certain form straps protects from the evil eye and serves as a kind of amulet. Therefore, in bizarre patterns were seen various figures and plants that carry a specific semantic load.

IN modern architecture functional purpose platbands for windows is as follows:

- Properly selected carved decoration allows you to visually stretch a low building or expand a narrow wall.

- The opportunity to show individuality and decorate the building in accordance with the trend of a particular era.

- Allows you to achieve a single architectural ensemble between all buildings on the site.

- Protection of cracks from the penetration of external negative factors(precipitation, noise, dust).

- It is one of the elements of thermal protection of the house.

Remark ! Sometimes platbands are the only option for framing a window. This mainly concerns log cabins when the use of other materials is unacceptable due to the loss of harmonious appearance.

Carved finishes, especially those made of wood, have a number of features that should be taken into account during the period of operation:

- Dependence on the influence of atmospheric factors. Moisture and temperature changes invariably damage the decorative design.

- When choosing a frame, you should take into account the properties of the rock from which the platbands are made, and take care of high-quality processing. Timely preventive measures extend the life of the product for the window.

- Difficulties often arise when combining wooden carved elements with modern plastic frames. With this combination, it is preferable to install windows that imitate a wooden texture.

The value of carved elements

The desire to live up to ancient traditions requires knowledge of the meaning various elements carved platbands:

- The sun, as a rule, is placed on the kokoshnik. It symbolizes life and energy.

- The personification of wisdom and fertility lies in the image of a snake.

- The symbol of harmony between spiritual and material aspirations is a cross in a carved platband.

- The feeling of unity with nature is emphasized through vegetation.

- Earrings testify to the hospitality of the owners of the house.

- The connecting element of all times is the silhouette of a bird on the window.

Characteristics of materials and forms

For the production of platbands on windows, natural and artificial materials. Traditionally carved elements were made of weather-resistant wood. Characteristics of the properties of individual breeds will help determine the most suitable type:

- Larch is minimally susceptible to decay processes, but is not suitable for the production of carved frames due to its fragility.

- Aspen, alder and linden are the most convenient species for creating openwork decor on windows. However, flexible and softwood carved platbands need special treatment due to the ability to absorb moisture well.

- Oak, ash or beech window frames are resistant to negative weather conditions, but the processing of carved elements is burdened with difficulties, overcoming which you will get a durable decor.

- A good choice would be birch or pine wood, which allows you to perform a neat carved decor. At the same time, the platbands have sufficient strength for external use.

- Small carved window decorations, which are fixed on the main elements, can be made from cherry or apple.

Advice ! Regular updating of the coating of wooden architraves with waterproof paint or varnish will ensure their long service life.

What other materials are used in the production of linings for windows and what are their features, we will consider below:

- Laminated MDF allows you to accurately simulate the color of any type of wood, but is intended exclusively for indoor use.

- Plastic windows are harmoniously combined with platbands made of similar material(PVC), which is not subject to decay, has a wide color palette resistant to solar radiation. The color of the platbands is selected taking into account the finishing of the house to match or contrast with the facade.

- for windows round shape ideal for products made of polyurethane, characterized by lightness and unpretentious care.

- Metal strips are attached for protection assembly seam, connecting them into a single whole with a profile box.

There are two main ways to install platbands:

- Invoice - the most common method in the design of windows. For fixing, special glue or nails are used.

- The telescopic method involves the L-shaped form of manufacturing the casing, which allows you to fix the product by entering the grooves of the box. Mostly used for finishing doorways. Its characteristic difference is the absence of traces of fasteners.

Patterns and types of thread

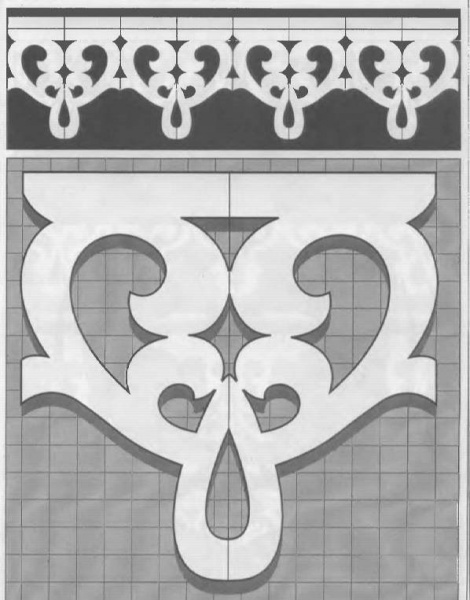

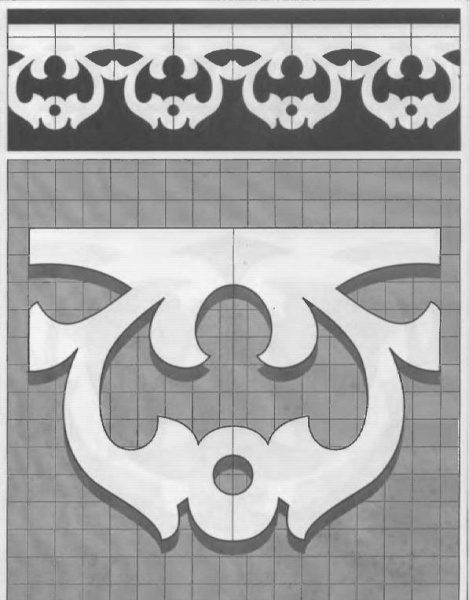

The carved forms of the architraves give the window individuality, but in order to make them, you will definitely need templates. The presence of woodcarving skills allows you to choose a complex ornament. If the ability to work with wood is not enough, it is better to find a light pattern for window trim. We suggest exploring:

- variants of templates of single elements and their general appearance;

- top, bottom and side decoration details.

You can copy them completely or add your own details to the pattern. The picture of the carved platband you like or its fragment must be scaled up taking into account the size of your window. For the manufacture of carved templates, fiberboard, thick cardboard or paper is used. It is desirable to decorate windows with platbands with the same thread. Please note that it is much more difficult to make small carved elements, and they become unusable faster than others. In this case, you will need partial replacement framing.

Warning ! Be sure to take into account the slope at the top of the carved casing. This will prevent the accumulation of snow and ensure timely drainage of water.

The upper part of the window casing is called a kokoshnik, the lower part is called a towel. The contours of plants, images of animals and geometric figures were most widely used in the ornamentation of carved architraves.

The key details of the drawing for any window trim are:

- lower bar or window sill;

- vertical rail;

- top bar.

The scheme can also contain all kinds of hangers, flowerpots or a diadem. Detailed description the names of carved decor elements are shown in the diagram below:

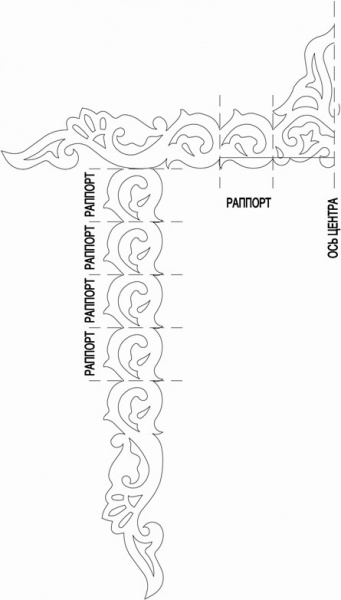

If your windows have different size, experts advise to make a drawing with an intermediate repeat repeating required amount once. For rapport, you can choose one or two elements that repeat alternately. An example of such a scheme is shown in the photo below:

There are several ways to make a wooden carved frame on the windows:

- The greatest decorativeness and delicacy are characterized by slotted platbands. The product is made of light-colored wood or is subsequently coated with white paint. This window design on a darker wall looks sophisticated and elegant, vaguely reminiscent of Vologda lace.

- With overhead threading, separately cut parts are fixed to a solid board by gluing or nailing. This technique allows you to arrange a window with a simple casing. Protruding elements are often covered with contrasting paint.

Sometimes both types of thread are combined.

Manufacturing process

Having decided on the pattern, material, type of thread and method of fastening the platbands, you can directly proceed to the manufacture of carved framing for windows.

Important ! The drawing on the workpiece needs proper placement. To prevent cracking of the thread will allow the location of the elements along the fibers of wooden blanks.

Places of the pattern where it is necessary to make cuts, it is better to mark with color. The work on the manufacture of platbands consists of the following stages:

- Taking measurements from the window.

- For slotted carving, boards with minimum thickness 30 mm, the overhead method allows the use of wood with a thickness of 10 mm. All work is done with dry lumber.

- Blanks are cut out.

- For a snug fit of the carved casing from the inside, the wood is selected to an insignificant depth (1-2 mm).

- The pattern applied using the template is cut out. To form holes, drills of various diameters are used, a jigsaw is needed to make cuts. To make a beautiful cut, the entry point of the jigsaw is marked with a drilled hole.

- All carved elements of the platband for the window are cleaned with sanding paper. Wood dust is removed from blind holes with a vacuum cleaner.

Laid on thread provides for fastening finished elements to a wide casing on nails with removed caps. Strengthen the strength of the connection will allow glue applied from the wrong side of the casing. The use of self-tapping screws is not recommended due to the risk of damage to the carved section of the connection.

Carved platbands are installed on wooden windows using deaf or through spikes. The first option is distinguished by a reliable connection and a complex installation process. The second method is simpler, but less reliable. The installation of carved elements on a plastic window is carried out using liquid nails.

preliminary protective treatment carved architraves and regular preventive care will ensure long-term preservation of the attractive appearance of the window.

For buildings from log cabin carved platbands just beg for decoration window openings. Their independent production- not at all a whim or an attempt to save money, because there are very few really good woodcarvers now.

Required minimum tool

The manufacture of platbands, unlike artistic wood carving, involves the repeated execution of the same type of operations, resulting in a rather primitive repeating pattern. Therefore, most of the work is done with an electric tool: this not only increases the processing speed, but also achieves uniform quality in different areas.

1 - jigsaw; 2 - drill; 3 - belt grinder; 4 - vibration grinder; 5 - manual router

1 - jigsaw; 2 - drill; 3 - belt grinder; 4 - vibration grinder; 5 - manual router

The main work is done with a jigsaw and a drill. The tool must be reliable and of high quality, capable of for a long time be in continuous use. For cleaning and grinding products, it is better to use an electric grinder, at least the simplest belt grinder. Fast finishing of the relief is possible using vibration-type machines.

If you intend to add additional fine details to the edges of your product, you can not do without a router. Descents, chamfers and a figured border can also be done manually, but only with a variety of chisels, cutters and specific skills in working with wood.

How to choose wood

Best suited for platbands hard rocks wood: oak, birch, ash, maple, alder. Because the thickness finished product relatively small (30-45 mm), hard rocks will be less prone to rotting and drying out, therefore, they will retain their appearance longer.

If you plan to decorate carved platbands with flat-relief elements with many small parts, softer rocks with a fine grain pattern should be preferred. Suitable linden, poplar, aspen, walnut and spruce.

Wood for platbands should be selected and, preferably, chamber dried, with a moisture content not higher than 12%. It is not allowed to have traces of warping or other pronounced defects, large branches. Ideally, you should immediately order calibrated boards with a width of 100-150 mm and a thickness of 30-40 mm.

The length of the blanks must be sufficient to completely cover window hole horizontally and vertically with an overlap in each direction by 1.5 board widths. It is important that you first count the number necessary blanks and, in addition to them, they purchased several more boards of the cheapest breed for training and practicing carving skills.

Making templates and stencils

Almost any wood carving begins with drawing a pattern on a workpiece according to a pre-made template or stencil. There are plenty of threading schemes in the network, the main difficulty comes down to transferring lines to the part accurately and without distortion. We will warn you right away: do not chase the high complexity of the drawing. A set of even the most primitive elements in correct sequence and with well-chosen indents takes its modesty and quality of processing.

The first option for marking is the manufacture of a small piece of plastic or solid sheet material, on which a single element of a repeating pattern is applied. Such a template is successively applied to the workpiece and outlined in pencil.

It is also possible to produce a single template. You need to take a strip of paper of the appropriate width, fold it with an accordion several times, and then cut out the pattern according to the principle Christmas tree garland. The resulting tape must be glued onto cardboard or LMDF, and then cut out the desired shapes. This method is welcomed with a significant amount of work.

The resulting stencil is subsequently simply superimposed on the board and outlined with a soft pencil. Ideally, saturated, but precise cut lines and boundaries for further processing should remain. When marking out the details, it is also necessary to take into account the layout of the pattern so that the platbands form a solid and complete contour, and the repeating pattern is not interrupted at random.

Through hole selection

The first step is to trim the edges of the workpiece and select holes in the center. With the edges, everything is simple: we cut out the excess with a jigsaw, stepping back from the marking line 1-1.5 mm outward for further processing. To cut out figures in the center of the plane, we drill a part at the very line of each cutout, then select the inner contour with a jigsaw.

For making large holes, it is reasonable to use core drills. In this case, it is necessary to mark on the template not the contours, but the centers of the circles in which the centering drill bit will be installed. A similar technique can also be used in the manufacture of oval holes or elements with small rounding radii: a complex bend is drilled with the appropriate radius, and everything else is cut out with a jigsaw.

When the excess parts of the workpiece are sawn out, the cut edges must be carefully processed with a rasp and then sandpaper. It is recommended to use bars of square, round and rounded profiles, on which sandpaper. This way you are less likely to "collapse" the edges and you can get right angles on each edge.

Rectangular edges look rather rough, so they are smoothed out with chamfers and slopes of different profiles. The easiest way to diversify the product is to walk along the outer and inner contours of the casing with a figured cutter. But manual processing options are also possible:

- to chamfer, walk along straight edges with a chip, keeping the angle of inclination of the handle to the part constant;

- a semicircular convex descent can also be made with chips, changing the slope of the blade, or use a concave cutter for this;

- concave semicircular pairing is performed with a chisel or a cutter with a rounded edge. Such elements must be cut out in stages, removing small chips layer by layer and carefully controlling the depth of the tool and the tilt of the handle;

- if the descent has a complex profile with several convex, concave and straight elements, this profile is divided into several stages and cut in strict sequence, starting from the widest outer part and ending with the deepest and shallowest tier.

Blind carving: we apply a relief

When you're done with shaping, it's a good idea to diversify the remaining flat pieces with simple ornaments or floral designs. Here are the simplest ways to work:

- A groove (branch, furrow) is made with a narrow chisel or cutter with a square, triangular or concave blade shape. The carving is carried out strictly along the line, the relief is selected with small chips and then polished.

- Sheet - several small grooves that imitate veins cut with a circular knife. Small notches are made from the center between the veins to each of them. semicircular chisel, imitating the body of the sheet, then an external contour is drawn with a thin cutter.

- The flat areas adjacent to the descent can be diversified with a blind carving of a small ornament. For example, cut two grooves from the edge, forming a triangle with it, and punch an asterisk in the center with a notch.

Wood processing and installation of architraves

Due to carved elements wooden product has a large surface shape, due to which it is more susceptible to aging. Therefore, wood should be treated in a special way.

First of all, carvings for placement on the facade should be soaked in an antiseptic composition for 5-8 hours, for which you can dig a small trench in the ground and put it in polyethylene film for temporary bathing. After soaking, the parts are dried for several days stacked with linings after 30-40 cm.

When the wood has dried, it must be carefully sanded, achieving smoothness and finally eliminating all traces of sawing and carving. Protective composition is selected in accordance with the type of facade finish, it can be either alkyd enamel, and polyurethane varnish, tinted or transparent.

Finally, for correct installation platbands, the window opening should be framed with a flat rail 10-15 mm thick and of such a width that its outer edge is not visible through carved pattern along the contour of the platband. The purpose of this plank is to eliminate the remaining irregularities in the wall and provide solid foundation to secure carved element. Often this rail is painted in a color that contrasts with the coating of the casing itself for greater expressiveness of the pattern.

Platbands can be attached with straight and oblique trim, depending on the type and density of the pattern. Oblique trimming is performed with a 45° cut on each side, while the cutting line must pass through identical sections of the pattern and not cross the figures cut inside.

With a straight cut horizontal element located between two vertical lines. Their upper edge should be 1-2 cm above the crossbar if the cut end is straight. It is also possible to manufacture on the edge of the thread according to general scheme if, during the manufacturing process, fitting and fine-tuning of platbands are carried out. The very fastening of the platbands is elementary - for it they use ordinary ruffed nails without a hat. It is only important that the nail pierces the casing and the lath, protruding at least 5 mm from the inside.