Fagus sylvatica

Spreading.

Spreading. Oriental beech (F. orientalis) - Oriental beech grows mainly in the Caucasus and Crimea; European forest beech (F. sylvatica) - European beech - central regions of Europe and Great Britain.

Wood.

Sapwood and heartwood do not differ in color. When freshly cut, the wood is pale brown, but under the influence of external conditions becomes reddish brown. Solid beech wood is typically straight-grained, with a fine, even texture, but density and hardness vary depending on where the trees grow. In a freshly cut state, the wood of the forest beech is similar to the wood of the oak in terms of the main mechanical characteristics. After drying, most characteristics improve and beech becomes stronger than oak in bending, surpasses it in stiffness and shear resistance by about 20% and significantly in impact strength.

Dry density - 700 kg/m3.

End surface hardness - 571 kgf / sq.cm

Technological properties.

Usually beech wood is processed without complications and can give a benign smooth surface. Beech lumber can be turned, easily glued, satisfactorily etched with dyes and polished. Due to the high hygroscopicity, beech boards and other lumber should not be kept in an environment with high humidity. This phenomenon is called "breathing" of wood, in order to avoid it, the temperature and humidity in the room should not fluctuate widely.

Application.

The uses of beech are very diverse - from the production of furniture to the manufacture of household items. Steam-treated beech bends easily, this feature allows it to be used in furniture industry in the manufacture of Viennese chairs. Stairs and parquet, etc. are also made from beech boards.

botanical name

Quercus spp.

Spreading.

Oak grows throughout Europe, including the British Isles, and also enters Asia Minor and North Africa.

Wood.

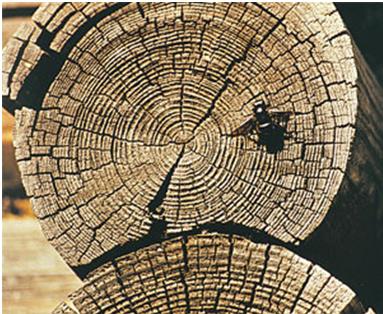

essential external differences wood various kinds oak is not observed. The sapwood is 25 to 50 mm wide, lighter than the yellowish-brown heartwood. On radial sections, a silvery pattern of wide core rays is clearly distinguishable. Growing conditions largely determine the nature of wood. For example, with a slow growing tree, the relative proportion of the dense, compact latewood zone is reduced in each annual ring, making the whole oak wood relatively soft and light. The wood is durable.

Cross cut photo (20*20 mm)

photograph of a radial cut (20*20 mm)

photograph of a radial cut (20*20 mm)

End surface hardness - 622 kgf / sq.cm

Technological properties.

In general, oak wood allows you to achieve good-quality finishing. Oak lumber is satisfactorily etched with dyes, polished, glued, suitable for waxing, accepts nails and screws well, and lends itself well to bleaching and staining.

Application.

For the production of furniture and other products, both solid oak and facing veneer are used. Also oak boards are good stuff for the manufacture of parquet, stairs, railings, etc.

botanical name

Fraxinus excelsior.

Spreading.

Europe, including the British Isles, northern Africa, Western Asia.

Wood.

After drying, it acquires a yellowish-white color. Some trees have a dark brown or black heartwood. irregular shape which is not necessarily a defect. Assortments with black strokes and stripes in the heartwood are often valued more because of the decorative nature of such wood, called "olive ash". Ash wood is usually straight grained, with high impact strength and flexibility. The texture of the wood is large. In terms of the main indicators of the mechanical properties of wood, ash is similar to oak, but has a higher impact strength and splitting resistance.

cross cut photo (20*20 mm)

cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 710 kg/m3.

End surface hardness - 400 kgf / sq.cm

Technological properties.

Despite the increased viscosity, ash wood is successfully processed manually and on machines, giving a smooth surface. Suitable for bonding, staining and polishing.

Application.

Ash is one of best breeds for bending, and sawn timber of this breed is widely used in the production of related furniture, including chairs. Ash wood is also used in the production of plywood and decorative veneer, sports equipment, tool handles.

botanical name

Juglans mandshurica.

Spreading.

Far East.

Wood.

The heartwood is light brown to brownish gray, the sapwood is narrow, light gray in color. The breed is moderately resistant to decay.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 680 kg/m3.

End surface hardness - 360 kgf / sq.cm

Technological properties.

The wood is well processed and can be polished.

Application.

Saw-timber from Far Eastern walnut wood is used in the production of furniture, joinery and turning products.

botanical name

Acer platanoides L.

Spreading.

European part of Russia.

Wood.

Light yellow. Annual layers on cross section are distinguished by a narrow light stripe. The core rays are visible in the transverse and radial sections. Maple wood is dense, hard, shiny, well polished. Impregnation of wood increases its service life.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 630 kg/m3.

End surface hardness - 470 kgf / sq.cm

Technological properties.

Well processed and polished.

Application.

Production of decorative veneer. Manufacture of furniture, musical instruments, carpentry and turning wooden products.

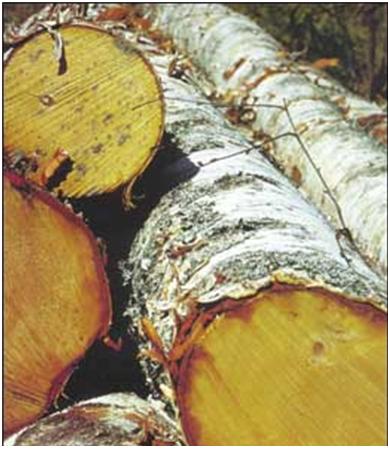

Birch (not currently in use)

botanical name

Betula

Spreading.

The birch range extends from Scandinavia and Northern Europe to the central part of Spain, and also captures the territory of the British Isles.

Wood.

There is no clearly distinguishable core. The wood is whitish to pale brown, with no noticeable hallmarks and features, straight-fiber, fine-textured. Dried birch wood is similar to beech in most respects. mechanical characteristics, surpasses it in compressive strength along the fibers, in rigidity and impact strength.

cross cut photo (20*20 mm)

cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 670 kg/m3.

End surface hardness - 392 kgf / sq.cm

Technological properties.

Easy to handle. When planing and profiling, a clean, high-quality surface is obtained. The wood is satisfactorily glued together, etched with dyes and polished, perfectly turned on lathes.

Application.

Plywood and blockboards, furniture, inventory, accessories, turning products, sliced and peeled veneer, skis, carved toys, butts of firearms.

(not currently in use)

botanical name

lophira alata.

Spreading.

It grows in West Africa from Sierra Leone to Nigeria and Cameroon. Typical tree species of forests in areas with big amount atmospheric precipitation and swampy forests. locals sniffing the bark to treat headaches. Azobe is also used in local traditional medicine to treat back pain, toothache, respiratory problems, stomach problems, and as a remedy for yellow fever.

Wood.

The sapwood is pale pink, sharply delimited from the heartwood in a red-brown to dark brown color, with a somewhat mottled pattern due to white deposits in the vessels. The fibers are usually tangled. The texture is large. The wood is hard and heavy. Azobe wood is very resistant to rot. It is one of the most biostable and durable types of wood.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 960-1120 kg / m3.

End surface hardness - 945 kgf / sq.cm

Technological properties.

Very difficult to process hand tools, easier to machine.

Application.

Azobe lumber is suitable for the construction of critical structures, especially wharves, piers, bridges, decking, railway sleepers, overpasses, as well as for flooring, especially designed for heavy operating conditions, the manufacture of steps. It is considered an ideal wood for all kinds of sea port structures: sheet piles, piles, breakwaters, dams, piers, as well as for any other purpose when wood of high strength and bioresistance is required.

botanical name

Entandrophragma candollei

Spreading.

Solitary trees are found in dense virgin forests from Equatorial Guinea to Zaire. Rarely represented in the western part of the range and more common in the Congo Basin.

Wood.

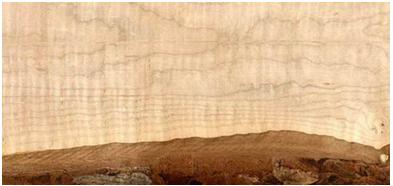

The sapwood is greyish-white to pale brown in color, 25 to 75 mm wide, distinctly different from the dark heartwood. The color of the kernel is reddish-brown, darkening when exposed to external environment, and usually with a purplish tint. The texture is quite large. Fibers from tangled to straight. When the fibers are serrated, a ribbon-like, striped pattern is observed on the radial cuts. The medullary rays often contain small granules of silica. Moderately durable wood.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 640 kg/m3.

End surface hardness - 521 kgf / sq.cm

Technological properties.

Easy to handle. When planing and profiling, tearing of the fibers is possible. Easily etched with dyes and well polished.

Application.

Furniture manufacturing, flooring, interior panels, high end office work, offshore construction and outer skin. Kosipo wood also serves as a raw material for the production of decorative veneer, often with a moire pattern.

botanical name

Pterocarpus soyauxii

Spreading.

Central and West Africa

Wood.

Trees reach 30-40 meters in height, trunk diameter - 0.6-1.2 m. The color can vary from pale orange to dark red. It has a rough texture and fairly large open pores. The fibers are usually straight. It has high resistance and is valued for its strength and durability.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 740 kg/m3.

End surface hardness - 560 kgf / sq.cm

Shrinkage - Radial: 3.3%, Tangential: 5.2%, Volumetric: 7.6%

Technological properties.

Paduk is quite easy to process and glues well.

Application.

It is used in the form of veneer, for the manufacture of parquet, musical instruments, furniture, tool handles.

botanical name

Distemonanthus behthamianus

Spreading.

West Africa

Wood.

Trees reach 38 m in height, trunk diameter is 1-1.5 m. Color is yellow to orange-brown, the color tends to darken with age. The surface is spotty. The fibers are wavy, the pores are slightly open. Annual rings are indistinct, the rays are not visible. Moderately durable wood.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 725 kg/m3.

End surface hardness - 624 kgf / sq.cm

Shrinkage - Radial: 3.1%, Tangential: 5.2%, Volumetric: 10.7%

Technological properties.

Relatively easy to process. Contains silica which will dull the tool.

Application.

It is used in the form of veneer, for the manufacture of parquet, furniture.

botanical name

Peltogyne spp.

Spreading.

Central and South America to the south of Brazil

Wood.

Amaranth reaches a height of 50 m with a trunk thickness of up to 1.5 m. Sapwood is white with light brown hues, sharply separated in color from heartwood. Heartwood - in a freshly sawn tree has a grayish Brown color, however, when exposed to light, it oxidizes and becomes a violet-purple color. If the wood is exposed to sunlight and rain, the purple will turn black over time. This coloration is only superficial - when a thin layer of wood is removed, the original color is restored and preserved until a new oxidation. The uniform texture of amaranth varies in size from fine to medium. The fibers are usually straight, rarely serrated, but always uneven, disordered, which, combined with the variability of gloss and coloring, creates a beautiful striped pattern on radial cuts. One of the outstanding distinctive characteristics amaranth is the ability to withstand impact. Amaranth wood is quite stable and during operation in finished product little to no deformation. Amaranth has a high wear resistance.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density – 980 kg/m3.

End surface hardness - 921 kgf / sq.cm

Shrinkage - Radial: 3.2%, Tangential: 6.1%, Volumetric: 9.9%

Technological properties.

Processing Amaranth is considered difficult both by hand and on equipment, the tool must be as hard and sharp as possible, processing at high spindle speeds and at a slow tool feed is recommended. Easily glued and accepts oils and polishes (impregnations).

botanical name

Microberlinia brazzavillensis

Spreading.

West Africa

Wood.

Trees up to 46 m in height, trunk diameter - up to 1.5 m. The core is light brown or cream in color with dark black-brown stripes, resembling zebra stripes.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 860 kg/m3.

End surface hardness - 662 kgf / sq.cm

Shrinkage - Radial: 6.8%, Tangential: 11.5%, Volumetric: 16.5%

Technological properties.

The texture is rough with large open pores. For a smooth finish, porosity is required. Well processed.

Application.

Due to its high cost, it is mainly used as a veneer.

botanical name

Carpinus betulus L.

Spreading.

Europe from Sweden and to the south, in Asia Minor and Iran, in the Caucasus, in the Carpathians, in the Crimea.

Wood.

Trees up to 20 m high, trunk diameter - up to 1 m. The wood is dull white, without a clear distinction between sapwood and heartwood, often core rays create a mottled pattern on radial cuts. The texture is fine and even. The arrangement of the fibers is usually disordered. The hornbeam is a strong, strong breed.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 735 kg/m3.

End surface hardness - 505 kgf / sq.cm

Shrinkage - Radial: 6.8%, Tangential: 11.5%, Volumetric: 18.4%

Technological properties.

The wood is not durable. It is difficult to process, but allows you to get a smooth surface, sticks together well, suitable for bending with steaming, well turned on lathes.

Application.

Percussion mechanisms pianoforte, spikes, turning products, repair and installation works, billiard cues, blocks, rollers.

botanical name

Prunus serotina Ehrh.

Spreading.

North America.

Wood.

The kernel is pinkish-brown when freshly cut, becoming golden-brown over time when exposed to light. The sapwood is pale yellowish in color. It has a finely porous structure.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 595 kg/m3.

End surface hardness - 490 kgf / sq.cm

Shrinkage - Radial: 3.7%, Tangential: 7.1%, Volumetric: 11.5%

Technological properties.

The wood is durable and resistant to decay. Easily processed.

Application.

Widely used in furniture production.

botanical name

Tilia spp.

Spreading.

Wood.

Trees reach 40 m in height with a trunk diameter of up to 2 m. The color is from pale white to cream, uniform over the entire surface of the wood. Over time, it changes to yellow or light brown.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 535 kg/m3.

End surface hardness - 448 kgf / sq.cm

Shrinkage - Radial: 5.0%, Tangential: 7.5%, Volumetric: 12.0%

Technological properties.

The wood is not durable. It is processed very easily, one of the best breeds for woodcarvers.

Application.

Carving, veneer, plywood, musical instruments.

botanical name

Entandophragma cylindricum

Spreading.

West Africa.

Wood.

Trees up to 45-60 m in height, pure trunk height - 50 m, trunk diameter - 1-1.5 m. The wood is from light brown to dark reddish-brown or violet-brown. The color tends to darken with age. The fibers are tangled. The texture is dense. In terms of bending strength, rigidity and resistance to impact loads, sapele is equivalent to English oak. Moderately durable wood.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 690 kg/m3.

End surface hardness - 604 kgf / sq.cm

Shrinkage - Radial: 4.8%, Tangential: 7.2%, Volumetric: 12.8%

Technological properties.

It is well processed manually and on machines. Sapele wood glues satisfactorily, is easily etched with dyes and polished.

Application.

beautiful material for high quality furniture, office decoration. Sapele lumber is also used in shipbuilding, paneling, flooring, joinery.

botanical name

Tieghemella heckelii, Tieghemella Africana.

Spreading.

West Africa, Tieghemella heckelii (Nigeria, Ghana), Tieghemella Africana (Cameroon, Gabon).

Wood.

Trees reach a height of about 37-45 with a trunk diameter of about 1.2 m. The color of the core varies from blood red to reddish brown. Sometimes the wood has asymmetrical veins of a darker shade. Has a natural shine. The texture is thin and even.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 690 kg/m3.

End surface hardness - 587 kgf / sq.cm

Shrinkage - Radial: 5.5%, Tangential: 7.4%, Volumetric: 10.8%

Technological properties.

When processing has a blunting effect on tools due to the presence of silica, it adheres well and polishes to mirror shine. Very durable wood.

Application.

Manufacture of doors, table and chair legs, outdoor finishing works, doors, window sills, boat building, floor coverings.

botanical name

Khaya, spp.

Spreading.

West Africa.

Wood.

Trees reach a height of 55-60 m, trunk diameter - 1.5-1.8 m. The wood has a reddish-brown core. The fibers may be straight, but are usually tangled, forming a textured striped pattern on the surface of a radial cut.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 530 kg/m3.

End surface hardness - 559 kgf / sq.cm

Shrinkage - Radial: 3.7%, Tangential: 6.6%, Volumetric: 10.3%

Technological properties.

Density and compressive strength are medium, flexural strength is low. Easy to process, good adhesion, excellent polishing. Moderately durable wood.

Application.

Used for a wide range of carpentry work. production of stairs, floor coverings, decoration of offices, boats.

botanical name

Acer saccharum

Spreading.

Northeast North America

Wood.

Trees 25-35 m high, trunk diameter - 0.6-1 m. Unlike most other hardwoods, hard maple mainly uses sapwood, not the core. The sapwood is usually white or light cream in color. The fibers are usually straight, but can also be wavy. It has small evenly spaced pores. Maple has a beautiful texture. Relatively easy to process both manually and on machines. It may “burn” a little at high speeds of the machine, for example, a milling cutter. It lends itself well to turning, gluing and painting. Has no specific smell. It is applied to the manufacture of floors, veneer, paper, musical instruments, cutting boards and decks, workbenches, baseball bats, etc.

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Dry density - 705 kg/m3.

End surface hardness - 540 kgf / sq.cm

Shrinkage - Radial: 4.8%, Tangential: 9.9%, Volumetric: 14.7%

American black walnut

botanical name

Juglans nigra

Spreading.

Eastern US

Wood.

Trees up to 37 m high, trunk diameter - 1 m. The color of the core can vary from light brown to chocolate brown with darker brown stripes. The sapwood is pale yellow-gray to almost white. The fibers are usually straight, but may be woven. The wood is annular, large pores of early wood pass into smaller pores of late wood. Usually easy to process if the fibers are straight and regular. Glued, stained and finished well (although the walnut is rarely dyed).

Cross cut photo (20*20 mm)

Radial cut photo (20*20 mm)

Deciduous trees include beech, birch, oak, ash, maple, walnut, hornbeam, linden, alder, aspen, pear.

feature hardwood wood is the fact that it does not swell when exposed to moisture and does not shrink under the influence of sunlight. In addition, in comparison with conifers, it has increased strength, which affects the more complex processing process.

Consider one of the representatives - this is a beech. It is mainly used in the manufacture of furniture, as it has the unique property of becoming elastic as a result of heat treatment, which allows it not to give crevices, being in a warm room for a long time. Therefore, furniture made of beech from the Linwood factory retains its original appearance well. long time.

Birch is considered the cheapest representative of hardwoods. Distinctive property which is the high strength due to natural factors, the main of which is widespread in the northern latitudes, where the most prominent representative is the Karelian birch, which has a beautiful yellow-red structure.

The most famous representative of this category is oak, distinctive feature which, is high strength and hardness. These qualities of oak make it possible to save products from rotting. This unique wood can stay in water for a long time, as a result of which it develops new qualities used in the manufacture of furniture and parquet, this is the so-called " bog oak". The value of products from such oak increases several times.

Wood with a pronounced fibrous structure and an unusual white-brown color is inherent in ash. We have already considered the features of the breeds listed above, in this case we are dealing with unique features ash - it becomes flexible under the influence of hot steam, which allows it to be easily processed. The disadvantage of ash is rapid wear during friction and rapid decay.

Maple is indispensable in the manufacture of musical instruments, and the brilliance and density of maple are its calling card. The drying process of maple is quite meticulous and demanding, but in order to convey the entire palette of musical sounds, it is necessary to carefully observe the process of impregnation and polishing of maple musical instruments.

Walnut to match oak is distinguished by extraordinary strength and hardness, so the Dana mebel factory uses it in the manufacture of luxury furniture.

Special medicinal properties lindens, along with a pleasant color, put this species wood into one of the most popular in the decoration of baths and saunas. The softness of linden has found application in the manufacture of various crafts in the form of spoons, mugs, ladles and other utensils.

The most common material used for interior decoration of saunas and baths is alder, primarily due to the resistance of this wood, to different kind mechanical influences, as well as the relatively low cost of alder lining. Pleasant red - brick color of wood adds warmth to the room, fine pattern of the structure well emphasizes all elements of the interior.

How construction material wood has a number of positive properties: relatively high strength with a small volumetric weight, sufficient elasticity and low thermal conductivity.

Under favorable operating conditions, wooden buildings and building parts are preserved for a very long time, several hundred years. Due to these qualities and relatively low cost, wood various breeds widely used in construction.

Heartwood, also coré - the name of a physiologically inactive zone developing in many tree species in the center of the trunk section, usually more dark color than the outer part, lighter sapwood. Occurs as a result of the secondary metabolism of dead parenchyma in the inner part sapwood.

real core contains mostly colored, for the most part phenolic substances (core substances) that impregnate cell walls and generally increase the durability of wood. In addition, the tree breaks the connections between cells, so that capillary exchange between them is no longer possible. Heartwood is biologically dead.

ripe wood- this is also heartwood, which, however, does not differ in color from sapwood. For example, podocarp produces light but durable mature wood (core), while mature spruce wood is short-lived. There are heartwood, sapwood and ripe wood species. Heartwood and heartwood ripewoods form a true core, while ripewoods and sapwoods can form a false core.

|

|

|

|

Cross section of a yew trunk (the dark core differs in color from the light sapwood) |

False core in beech |

Many non-core (sapwood And ripe woody) deciduous trees do not always develop a core, but depending on external conditions (usually as a result of damage) they form the so-called false core. This wood does not have the inherent durability of heartwood and is often distinguished by non-uniform coloring, variety in shape and size. Differs in inconsistency in the time of appearance in the tree.

It is considered a defect of wood and reduces its value, however, a false core without rot does not significantly affect strength. It has almost the same properties as the real kernel, different in different breeds tree. False core with rot is unevenly colored, develops pale and grayish tones, black lines.

On a transverse section of the trunk, it can be central or displaced. It is usually brown or brown in color, sometimes with a lilac, purple or dark green tint. On a cross section it can be rounded or stellate.

Surrounded by a dark, rarely lighter than the rest of its part, a protective border, which can not only cover the false core, but also divide it into parts (zones). It can be simple or homogeneous, as well as two-zone, multi-zone (with zones in the form of rings) and mosaic, when there are many sections in the core that are adjacent to each other and separated by a protective border.

Sound rocks(forming the true core)

Pine(lat. Pinus) - a typical sound tree species. The heartwood (reddish) is clearly distinguished in pines from the sapwood (yellow-white). If the sapwood is not removed from the core, then the wood must be treated with chemical protection.

Oak(Quercus). In this wood, only the heartwood is used, since the sapwood is short-lived, although it is possible to use wood with sapwood, provided that it is treated with protective agents.

Ebony(a variety of ebony) has a black heartwood and light sapwood, is very hard and is also expensive.

podocarp forms light but durable heartwood (mature wood)

Ash(lat. Fraxinus excelsior) and elm form a yellow-brown core, the sapwood must be removed.

ripe woody species(may form a false nucleus)

- cherry kernel(lat. Prunus avium) is not a true heartwood, but a false heartwood and is short-lived. Since the color difference in this case is very pronounced (the heartwood is red and the sapwood is white), the sapwood is simply cut off for critical applications.

- Beech(lat. Fagus sylvatica) often forms a mottled red heartwood in old age, which was previously considered completely unacceptable, and today finds use in furniture making as "heart beech".

- ate(Picea) - non-nuclear, ripe wood species.

In addition, all wood is divided into wood coniferous And deciduous breeds.

Coniferous breeds.Wide application in construction conifers(pines, spruces, larches, less - cedar and fir) is explained by their large territorial distribution, height and straightness of trunks, increased quality compared to some hardwoods, in particular resistance to decay.

Fig.1. Pine wood

Pine- heartwood, brownish-red heartwood, yellowish-white sapwood. Pine occupies about 1/6 of the area of all forests in Russia.

There are ore pine, growing on elevated sandy places, and myand, growing on low places. The ore pine has a dense, small-layer resinous wood. In myand pine, the wood is large-layered, loose with a wide sapwood and therefore lower quality than that of ore pine. Pine is used to make wood load-bearing structures, poles, piles, sleepers, carpentry, plywood, etc.

Fig.2. spruce logs

Spruce occupies 1/8 of the forested area. Greatest economic importance have two types of spruce - European (ordinary) and Siberian.

Spruce wood has a uniform White color with a slight yellowish tint, wide sapwood and mature wood, not differing in color from sapwood. Spruce wood is soft, light, like pine, but with a lower content of resinous substances, which reduces its resistance to decay. The presence of spruce in wood a large number hard knots makes it difficult to machine.

Spruce is used for the same purposes as pine, but taking into account its reduced resistance to decay. Fig.3. larch wood

Fig.3. larch wood

Larch It has a reddish-brown heartwood and a narrow white sapwood.

Larch wood is thin-layered. The strength, hardness and average density of larch are higher than those of pine and spruce, by about 30%. It is characterized by increased rot resistance, but is prone to cracking. Larch is especially valued in hydraulic engineering and bridge building; sleepers and mine racks are made from it. Larch grows mainly in Siberia and Far East, which limits its use in the central zone of the country.

Fig.4. Cedar wood

Cedar has a light brown heartwood and a wide sapwood, slightly different in color from the heartwood. Cedar wood is soft and light, its mechanical properties are lower than those of pine. Cedar is used in the form of roundwood and lumber, for joinery and furniture finishing - in the form of decorative plywood.

Fir in wood it is similar to spruce, but does not have resin passages. It easily rots, therefore, in construction they are used on a par with spruce, but they are not used in wet conditions operation.

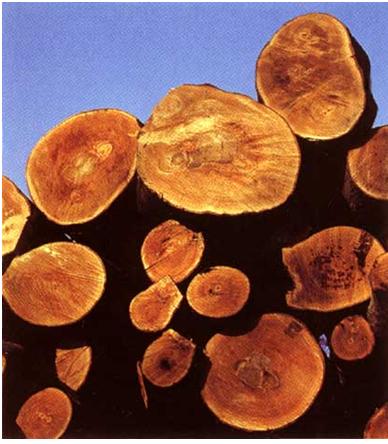

Rice. 5. Timber storage

Coniferous species include: pine, spruce, larch, fir, cedar, yew, cypress, juniper. characteristic feature The structures of coniferous wood are resinous passages, which are thin channels filled with resin - tracheids, occupying up to 95% of the total trunk volume.

These channels are hollow cells that conduct water from the roots to the crown. It is tracheids that give wood mechanical strength, which largely depends on the gluing intercellular substance - lignin.

The amount of lignin, and hence the quality of wood, largely depends on the place and conditions of tree germination.

Deciduous species. Hardwoods have trunks that are less regular and more tapered than conifers. In construction more wide application received oak, ash, birch, aspen, alder, beech, linden, poplar.

Oak- an annular vascular rock with a pronounced core from light to dark brown in color and a narrow light yellow sapwood. Oak wood is characterized by high strength and resistance to decay, beautiful texture and color, but gives significant shrinkage and is prone to cracking.

In construction, oak is used for the manufacture of critical structures in hydraulic structures, in bridge building, as well as for the manufacture of parquet, cut plywood, joinery products (window frames, doors, etc.) and critical parts of load-bearing structures, especially those working under a load directed across the fibers (support pads, gaskets, dowels, etc. ). For finishing and decorative works Valuable is the bog oak of black or dark gray color, which is obtained by prolonged exposure of the oak under water.

Ash- heartwood, in appearance and structure of wood resembles oak wood, but of a lighter color. Ash wood is distinguished by high strength and toughness, low tendency to cracking, beautiful texture, it is well preserved in air and in water, but easily rots in conditions of variable humidity. Apply on a par with oak, but in conditions that are not dangerous for decay.

Birch is the most common hardwood species in our forests. The species is sapwood, has white wood with a slight yellowish or reddish tint, is hard and durable, but easily rots, especially in conditions high humidity. Plywood, some joinery, etc. are made from it. Karelian birch, which has a wavy arrangement of fibers, is widely used in finishing works and furniture production.

Aspen- sapwood, like birch, grows everywhere. Aspen wood is uniform white in color, soft, light, less durable than birch. When dried, it does not warp and crack a little, but when wet, it easily rots. In construction, it is used for the construction of temporary structures, as well as for plywood.

Beech- ripe wood species. Beech wood is white in color with a reddish tint, very durable, with a beautiful texture on a radial cut, it bends well, but is prone to rotting in conditions of high and variable humidity, and when dried, it warps and cracks. Beech is used for the manufacture of parquet, plywood, sleepers, etc., as well as in furniture production.

Alder- sapwood with soft wood prone to decay. Use like birch.

Other hardwoods (linden, maple, poplar) are used in construction as local materials and mainly for temporary and non-critical buildings and utility and auxiliary products, as well as in other sectors of the national economy.

|

Pine- the most common coniferous breed. Pine trunks have relatively correct form and at the age of 120-150 years reach a height of 30-40m. Its wood is easy to plan, saw, glue, paint and varnish well. They are used in housing construction, in furniture, plywood and other industries. |

|

Spruce ranks second in distribution. Its trunks are round and straight, at the age of 120-150 years they reach a height of 30-40m, and sometimes 50m. Advantages spruce wood- homogeneity of the structure, white color and low resinousness, the disadvantage is a large branchiness. The walls of houses are cut from spruce, floors are laid, doors, bindings, boxes, platbands, skirting boards, and furniture are made. |

|

Fir- it is characterized by increased warping and cracking, lower density than pine, so fir is less often used in carpentry than pine and spruce. |

|

Siberian cedar- a tree species similar in mechanical properties to the pine It has a straight trunk with a diameter of up to 2m. Cedar wood is sticky, soft, but dense and durable, resistant to decay, well processed. |

|

Larch quite suitable for the manufacture of joinery. Its wood has great strength (30% higher than pine) and resistance to decay, but heavier than pine. |

|

Of hardwoods, oak, ash, aspen, birch, maple, and beech are mainly used in construction and decoration. |

|

Oak has high strength. It is used to make floors, doors, bindings, various pillars, and is used for sheathing houses. However, oak is difficult to process, especially sawing, planing, chiseling, drilling. |

|

Beech distributed in the southern regions of the country. Plow blocks, parquet, veneer, plywood are made from it. Processing a beech is difficult. |

|

Maple refers to hard rock wood with beautiful texture. In places of mass growth, they are used in the form of logs and boards for construction works, as well as for the manufacture of pads of various plows. |

|

Birch has a thin-layer structure, solid, very homogeneous in structure. Used for the manufacture of plywood, wood-laminated plastics, chipboard and fibreboard, parquet, furniture, etc. |

|

Aspen And Linden- used as roundwood for log cabins, and boards and bars - for laying floors and ceilings, making partitions, furniture. Aspen and linden wood is unstable to moisture, therefore it is not recommended for the manufacture of bindings and external doors. Linden wood is widely used for outdoor carvings (platbands and cornices). |

|

Ash has a beautiful texture and cracks a little, is used for the manufacture of stairs, railings, tool handles. |

|

In addition to the listed wood, hornbeam, walnut, pear, mountain ash are used in construction and decoration, and imported tree species are also used for making furniture: sequoia, red And ebony, rosewood, backout. |

Perhaps the most widely used and favorite material for carpentry and homework is, of course, wood. It is light and at the same time durable, has electric, sound and thermal insulation properties. It can be cut, hammered, drilled, glued, painted, metal and other fasteners are well held on it.

Don't forget the unique decorative properties. However, due to its biological origin, wood also has various defects - heterogeneity of the structure, the ability to dry out, swell, rot, warp, crack, ignite ... processing.

Trees of different species are divided mainly into two large groups - coniferous and deciduous. Of the latter, furniture and various crafts are usually constructed, and the carpenter usually works with coniferous wood, which is less prone to decay and warps less, sticks together firmly, cuts and paints better. Let's not make a mental cut in the trunk and delve into physical and mechanical properties wood, the reader will find information about them in any special reference book (luster, color, density, humidity, etc.). Harvesting wood (for example, at the country house or personal plot), the master must ensure that it does not have frost holes and other cracks, large knots, rot, wormholes, cancer growths, resin "pockets", or eliminate such defects.

What kind of wood will the craftsman prefer? Looking for what. That's why a brief description of our most common tree species necessary.

Pine. It has a fine and even texture, relatively strong, easy to process. It is easy to drive a nail into it, to screw in a screw. However, it often gives chips and needs careful deresining.

Spruce. Its wood is softer, lighter and whiter than pine, cuts and glues better, is less resinous, but does not hold antiseptics well, is knotty and short-lived.

Larch. Very nice creamy brown texture, but resinous and hard to work with. At quick drying cracking from the inside.

Juniper. The texture of this shrub with a rather thick trunk is also beautiful. The wood is strong but easy to work with a pleasant smell. Like thuja, juniper is usually used for fine carving in crafts and inlays.

Oak. It has a very hard, heavy, durable, rot-resistant wood. When using adhesives, fasteners, there are no particular problems. At home, oak is used for furniture, parquet and floorboards, tool handles, and doors. It is very difficult to process bog oak (which has lain in water for a long time and has a color from brown-green to black).

Ash. Similar in texture and properties to oak, the wood is hard and viscous, resilient, warps little and bends well. Indispensable for ax handles, handles of heavy tools, sports equipment.

Maple. Dense and hard almost white wood, well processed. Beautiful texture, especially on a radial cut. Blanks are easy to polish and etch. Maple, which has an even structure, imitates many rare tree species.

Birch. Moderately hard, with an equal density structure, lends itself to any tool (it often splits when processed with a chisel). The material perfectly absorbs varnishes and paints, imitates under valuable breeds. At the same time, birch warps, is unstable to decay and is of little use in places with high humidity.

Linden, aspen, poplar. They are white or yellowish softwood, which, when dried, does not crack or warp, cuts easily and cleanly (the exception is dry aspen: it is difficult to process. But it glues perfectly, is resistant to wood-boring beetles and retains strength in water for a long time). Poplar wood is resistant to rotting, but is well imitated as mahogany or ebony.

Alder. The wood is light, reddens in air, resistant to high humidity. Like the linden great material for plywood. Black alder wood, which grows in abundance along the banks of swampy reservoirs, is successfully imitated to look like mahogany.

Elm. Wood young tree yellowish, becoming red-brown with age. Successfully etched under mahogany.

Pear, cherry, white locust. The wood of these species is very dense, with a beautiful texture, well processed, painted and polished (pear, for example, takes mordant well when stained like ebony). Used for crafts, small tools.

Would please everyone walnut- and it cuts perfectly (but is planed with difficulty), and it does not give chips, and the texture is amazing, - but it is not very common with us.

Wooden houses from a log from the project before construction "on a turn-key basis". Projects wooden houses with pictures: typical and individual, use of the northern forest, own production rounded log.

The article is protected by copyright and its reprint is allowed only with a direct link to the site

Thank you for adding this article to: