Today, the hardness of a tree is determined using several methods. There are density ratings for all trees. Based on the hardness, they determine where and what kind of wood to use.

The hardest woods

According to the obtained hardness data, a list of the hardest trees has been compiled. It included white acacia. This tree grows in large quantities in Europe, anywhere from North America.Brazilian cherry, scientifically called jatoba, is second in hardness. It should be noted that this tree has nothing in common with plants of the genus "cherry". Sucupira grows in South America. Its wood is not only practical, but also decorative, as it has inclusions of light veins that contrast with the reddish-brown wood. It is known that fungi and pests of sucupire are not terrible. Despite the fact that wood is difficult to process, it is well polished.

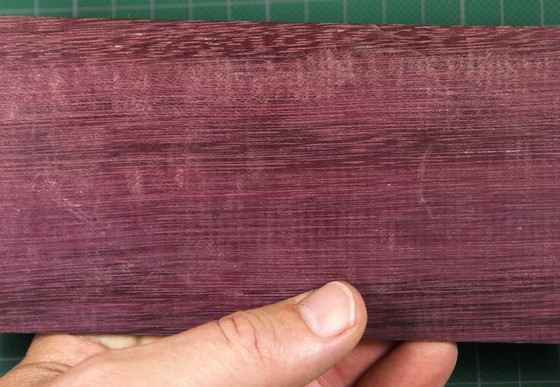

There is such wood from the category of hard ones, like African turbidity. It is unusual that in structure it is similar to teak, and in color it resembles walnut. AT Central America there is an amaranth tree, which has a dense but flexible wood that has a red-violet hue and a large expressive structure. Amaranth is difficult to process and varnish, however, single accessories and expensive furniture are made from its wood.

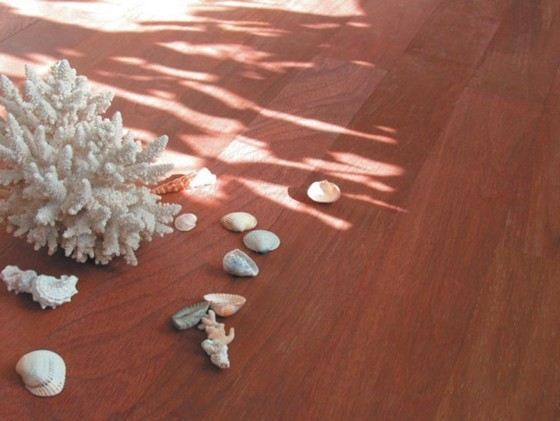

Merbay is another type of hardwood. It is easy to process, easy to polish and resistant to moisture. These properties make it ideal for the production of parquet, bathroom decoration. The well-known Canadian maple growing in North America, otherwise called sugar maple. This is solid wood is the symbol of Canada.

Yarra is an Australian eucalyptus. Due to the similarity of its wood with mahogany, the tree is also called Australian mahogany. Wood is considered solid rosewood. His homeland is Brazil. It is an indispensable material for the manufacture of musical instruments and furniture for presentable objects.

The hardest tree in Russia

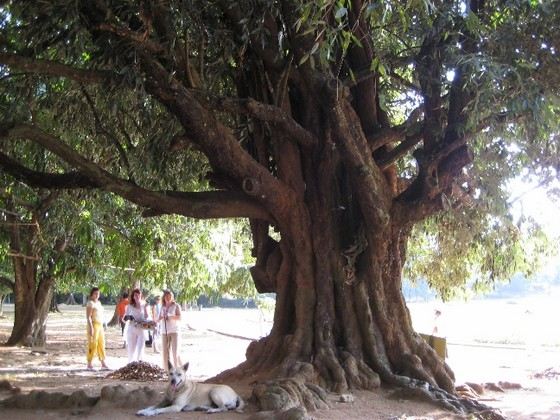

Russia is rich in forests. Birch Schmidt - a resident of the reserve "Kedrovaya Pad", located in Primorye, is the hardest in the country. This birch is one of the representatives of the so-called iron trees. Due to the extremely hard wood, bullets bounce off it, it instantly sinks in water, has the property of self-preservation, does not rot and is stronger than cast iron. It is believed that bearings for machines can be made from this tree.

The birch got its name in honor of the botanist who discovered it by the name of Schmidt. This tree grows on the slopes of ravines at the exit of rocks, as it loves rocky soil. The birch always has an inclined state of the trunk. Usually it is comb-shaped and does not exceed eighty centimeters in girth. Iron birch reaches a height of twenty-five meters, but the crown begins only at a height of eight meters. These trees are considered long-lived. On average, the Schmidt birch lives about three hundred and fifty years.

What is hardwood made of?

Hardwoods are used in many areas, depending on the species. So from the Brazilian cherry, which is called jatoba, canes, billiard cues, furniture, parquet are made. But in shipbuilding, this wood is not used, as it deteriorates in sea water.

Acacia wood has a yellow tint. She was known even to cabinetmakers, as she does not rot and does not wear out. Acacia wood is used to make parquet, which is considered stronger than oak, and over the years it becomes more beautiful.

Marbau wood, due to its increased hardness, is used during construction. public buildings, and also make parquet from it. It is used in the design of wet rooms, as it is not afraid of water.

Previously, not only hunting tools were made from durable ash wood, but also military weapons, spears and clubs were made. Beech wood is known to bend easily when steamed. This property is indispensable in the manufacture of rounded furniture, including Viennese chairs. Beech is used to produce rifle butts, weaving shuttles and even musical instruments. In addition, plywood and containers are made from beech, beech parquet and measuring instruments are known.

The tree with the strongest wood

It is reliably known that the most durable, in other words, “iron” wood, is in trees, which are called “iron trees”. It is so strong that sometimes it exceeds iron in this indicator. Even nails and machine parts can be made from it. There are several types of trees and they grow in different parts planets. Here are some examples of these miracle trees.

The Schmidt birch, whose wood is one and a half times stronger than cast iron, grows in Primorsky Krai, another owner of iron wood grows in Brazil - this is an Amazonian tree, in Africa such a representative is called azobe. Taxus (or yew) also belongs to iron trees, it is absolutely not subject to rotting, it is also called “non-rot-tree”. Azerbaijan and Iran - motherland iron tree called temir-agach, and Persian parrotia grows in the Northern Irish and Transcaucasian forests.

Trees are champions not only in strength, but also in size. According to the site, the largest tree in the world has reached a height of more than 150 meters.

Introduction

A bunch of various breeds wood should not be used in one design (unless it is caused by the need to document the original in the manufacture of a museum model), as this complicates the work. Using the same materials (two or three types, such as pine and birch veneer), the modeler gains experience in working with them, which allows him to create good flying models. The lightest indoor models are sometimes made entirely of straw, and many models are made of balsa.

Some ubiquitous woods, such as pine and linden, have become versatile in aircraft modeling and are well-accepted by modellers.

conifers

Wood conifers is one of the main materials in the construction of flying models of all types. When choosing a material for the manufacture of certain parts, it should be remembered that before painting with nitro-varnishes, coniferous wood products must be completely puttied or primed. Otherwise, due to uneven absorption of paint, the layered structure of the tree will show through. Coniferous wood products are poorly polished.

The physical and mechanical qualities of wood of various species are shown in the table below.

Common pine. Pine has a resinous straight-grained wood of white or color pink dream large quantity knots.

Pine - the most common material for the manufacture of many parts of flying models - has high mechanical properties and is well processed by cutting tools.

Pine bends well. Laths with a section of 2x3 mm, soaked in water room temperature within 6 hours, it can be easily bent along a radius of up to 30 mm without causing cracks. It is even easier to bend slats boiled in water for 15-20 minutes. After drying, the slats stably retain their shape.

The least resinous wood with straight fine layers should be selected.

Spruce. spruce wood white color slightly glossy, low resinous, knotty, but straight-layered between knots. These sections make excellent slats for flying model frames. Spruce is easily pricked, bends as well as pine.

Spruce (a kind of spruce), which has a straight flexible wood of white or pink color, was widely used in foreign wooden aircraft construction. In flying models, the spruce is used to make frames.

Fir. Fir wood is soft and light, of light tones, almost white with a pink or yellowish tinge. In terms of its qualities, the wood is close to spruce wood.

hardwood

Wood hardwood It is widely used for making many parts of flying models, such as propellers, bosses, fuselages, turned parts, blanks and all parts of non-flying models.

From varieties hard rock with beautiful texture panels, sub-layouts and exposure details are performed. Most rocks are well polished and varnished.

Linden is one of the lightest breeds. The color of the wood of the southern linden is white, the northern one is yellow-pink. Its wood is soft, fine-fibered; cuts well and polishes well. Linden is stained, but not deeply, with water and alcohol dyes.

Under the outer part of the linden bark is a fibrous layer of bast. This is a valuable material, glue brushes are made from it. The ends of dry bast plates smooth the pile after pickling and staining on the wood surface during finishing.

Linden is used as the main material for the manufacture of non-flying models. In flying models, propellers, ribs, fuselages, bosses, blanks, fairings are made from linden.

Poplar wood is porous, soft and resilient. It is used if there is no linden.

Aspen has a soft, fine-grained wood, white in color. In terms of its qualities, aspen is better than poplar; it is also used as a substitute for linden.

White birch wood, dense, strong. young tree flexible, old fragile. Handles well for lathe and polished. It is painted with nitro-lacquers, water and alcohol dyes. Finished in walnut and mahogany. When dry it shrinks a lot.

Made from birch the best varieties aircraft plywood, veneer for gluing monocoques and the so-called flower shavings. Produce screws for models with reciprocating engines, parts for mock-ups, handles for tools.

It is rarely used in the designs of flying and non-flying models.

Karelian birch is a variety of common birch. It is distinguished by a reddish-yellow color and frizziness. Particularly strongly entangled fibers on the sags at the butt and knots of branches give in the cut and veneer beautiful drawing. Such wood is especially appreciated; it is used for finishing artistic stands for models and layouts.

Alder. Alder wood is straight-grained, brittle, without pores, with very small layers, has a color from white to brown. Alder is softer and lighter than birch. It is well processed by cutting tools, gives a clean surface, well polished. Alder can be dyed various colors- under a nut, mahogany and other breeds. Alder bends badly, is prone to fungal diseases and wormholes. She happens to be best material for the manufacture of non-flying museum and tactical models. It is used for coasters and all kinds of crafts. Alder wood is fragile, so it should not be used for the manufacture of propellers and other critical parts of flying models.

Maple has a solid uniform beautiful wood white, difficult to prick, well polished and stained with mordants and dyes.

Nut. Walnut wood is hard, brittle, has a color from light gray to Brown with very beautiful layers, homogeneous, perfectly polished, varnished and finished with wax. Due to the natural play of colors and the beauty of the structure, walnut parts are usually not stained. In aircraft models, walnut is used for the manufacture of screws, all kinds of stands and as a finishing material.

Beech wood is pinkish-white in color, fine-grained, well processed by cutting tools and well polished. In the steamed form it bends well. Beech is often used to make propellers for models with reciprocating internal combustion engines.

The disadvantages of beech include a tendency to change shape, cracking, warping.

The hornbeam, or white beech, has white wood, very hard, difficult to process. Well polished, it is the best material for aircraft piston engine propellers.

Oak. In flying models, oak is not used, it goes only to the underlays and Finishing work. Oak wood is light brown in color, durable, well stained with water mordant (mordant) in various tones - from light to brown-black. Oak products are varnished or waxed.

Its wood must be gradually dried over a long time, as it is prone to cracking.

Ash wood is similar to oak wood, has high mechanical properties, is hard and viscous. When folded, it bends easily. Ash is trimmed in the same way as oak.

Balsa. rare breed, its dry wood is extremely soft and light.

Balsa does not grow on the territory of Russia. Her homeland is the equatorial part South America, Trinidad, Burma.

Balsa is extremely simple and easy to process. With the same weight, balsa structures are more rigid than, for example, pine.

For processing balsa, a special tool is used, which has a small sharpening angle and a thin blade.

Balsa is poorly polished and stained with opaque paints and varnishes, satisfactorily - with water dyes and alcohol mordants.

Balsa can be used to make all parts of flying models, such as ribs, helicopter blades and propellers for rubber models.

Some modelers in the recent past considered balsa to be an indispensable material, which is wrong. Balsa fibers are very weak, easily crushed, and swell from water.

Density and physical mechanical properties Balsa woods are very heterogeneous. Freshly cut balsa contains up to 95% water, it is very heavy, but quickly loses water after felling and drying. In the ridge at the butt and in the core, the wood is dense and rather strong, the density can reach up to 0.3 g/cm3, the young sapwood is very light, with a density of 0.01 g/cm3. Accordingly, with the density, the strength also changes. These qualities oblige the modeler to be extremely attentive to the selection of sections of rails and other parts of flying models.

Red tree. Under this name, there are many species with reddish wood. These include brazil tree, acatu, gambia, sequoia; from those growing in Russia - yew. Of these species, some are deciduous, others are coniferous. All of them have different density and various mechanical properties.

Mahogany grows mainly in Africa, the Antilles and America. It is found in small quantities in Transcaucasia.

Mahogany wood is valued for its beautiful color, texture, and water resistance. It is processed with cutting tools easier than walnut, it is well polished.

pear wood has various colors- from light pink to red, fine texture, very dense and uniform. The density and mechanical properties of the pear are different, depending on the age and variety. The pear is perfectly processed by cutting tools, it is well polished.

Boxwood (Caucasian palm from the Buxus family). Boxwood wood is pale yellow in color, homogeneous, dense and very hard, well turned and polished. It is used in the manufacture of small ingots for stamping organic glass and celluloid. In addition, miniature models and crafts are made from it, in which special strength and edge sharpness are needed.

The tung tree is grown in the People's Republic of China to produce tung oil, a valuable raw material in the paint and varnish industry. It also grows in the subtropics of Russia, has a fairly strong homogeneous wood, about two times lighter than linden, that is, its density is about 0.25-0.3 g / cm3. Tung wood can be crafted good designs flying models, making propellers, edges, blades. Chinese aircraft modelers widely and successfully use tung wood.

Bamboo is a tree-like cereal that grows in subtropical countries. There are more than two hundred types of bamboo, some of them reach a height of 40 m and a diameter of 50 cm. The structure of the bamboo stem is the same as that of cereal straw. In the designs of flying models, dried bamboo stalks with knees of the greatest possible length and diameter are used.

The most valuable are thick stems of yellow-white color with long knees with a diameter of 50 - 60 mm.

The business part of the wood is very strong and resilient. Bamboo splits perfectly along the fibers and bends over the flame without prior steaming.

Cane. Along the banks of rivers, lakes and swamps, many types of reeds grow, bearing various local names - reeds, reeds, etc.

Reed, like bamboo, belongs to the family of perennial grasses. In terms of mechanical properties, reed stands between bamboo and cereal straw.

Reed is the best material for fuselage rails of schematic flying models, as it resists torsion well and has high rigidity at low density. Reed is used for kite rails, braces in the frames of large flying models.

Twisted stems straighten over the fire.

You should choose straight, fully mature stems with a diameter of 8 to 10 mm, white or light yellow. Greenish-gray hues at the root indicate that the cane was cut early and began to rot. Since the reed ripens in late autumn, it is convenient to cut it after the water bodies freeze.

Chiy is a perennial grass, reaching 3 m in height. It grows in Kazakhstan and Kyrgyzstan. Chia stems with a diameter of 1 to 5 mm are used. Chiy has a thin, strong outer shell and a soft, white core. In terms of its qualities, it is much better than reed and second only to bamboo. Chiy can be used to make stringers, porch roundings, braces, ribs and other details.

Small schematic models can be made entirely of chia.

The disadvantages of chia, like all cereals, include its nodularity and inconsistent thickness.

Straw. For the construction of indoor models, dry straw of ripe rye is used. With success, you can also use dry stems of other cereals: timothy grass, bent grass, bluegrass, fescue.

In the construction of larger flying models, straw is used only in the manufacture of light truss braces, as it resists compression well.

In order to increase the strength and straighten the straw, it should be strongly stretched in the hands, in this position, warm up over the electric stove and cool without reducing the tension.

Table "Physical and mechanical qualities of wood of various species"

|

bulk density, g/cm³ |

compression along fibers, kgf/mm² |

stretching along fibers, kgf/mm² |

bending, kgf/mm² |

Growing areas |

Note |

|

|

Scotch pine |

European part of Russia, Western and Eastern Siberia, Far East, Central Asia, Crimea |

Flying model frames |

||||

|

European spruce |

european part of Russia |

Pine Substitute |

||||

|

Siberian cedar |

Eastern regions of Russia |

Pine Substitute |

||||

|

Does not grow in Russia |

Model frames |

|||||

|

Eastern regions of Russia, Caucasus |

Spruce substitute |

|||||

|

European part of Russia, Siberia, Altai, Caucasus |

Various parts of tactical models, screws, all kinds of blanks |

|||||

|

Central and southern strip of Russia |

Linden substitute |

|||||

|

Linden substitute |

||||||

|

European part of Russia, Altai, Transbaikalia |

Museum and tactical models, power units of flying models, screws, pads and tool handles |

|||||

|

European part of Russia, Transbaikalia, Altai, Caucasus |

Museum and tactical models |

|||||

Its color is yellow or olive green, the layers are straight and sharply visible. It is processed well only in its raw form, while in the dry it is difficult to process with cutting tools; does not crack and does not warp; remarkably resistant to friction; almost insensitive to atmospheric influences; under the influence of light, the acacia changes its color somewhat and becomes very beautiful with time.

Durable, hard and at the same time elastic acacia wood is used by furniture makers. Including make a beautiful veneer for veneer MDF boards or products from low-value wood species.

Acacia wood is an excellent flooring material. We compare their service life with ash or larch parquet. In addition, excellent doors are made from it, which are stronger than oak (an 80 mm thick acacia door cannot be shot from a PM pistol from a distance of 10 m.

Thoroughly dried and varnished parts retain their shape and dimensions better in dry rooms. Acacia wood is ideal for glued and screwed joints. For finishing products from it are equally well suited as paints and varnishes based on organic solvents, and water-soluble varnishes and paints, but the natural texture and color always look better.

One of the difficulties in working with acacia is due to the fact that it is initially prone to cracking, so it needs gentle drying modes, which increases the time. Another difficulty is that acacia has a multidirectional texture - the fibers in the wood are located towards each other, like mahogany - which makes processing much more difficult. But the result is worth it. Acacia wood is an exquisite material for interior decoration rooms, creating a beautiful contrasting background for dark furniture.

Birch is the most common finishing material in the northern part and partly in middle lane Russia. Its wood is the lightest, homogeneous, fine-grained, dense, hard, well cut. It sharpens, pricks, saws and plans excellently. It is convenient to use it for small crafts, since birch reacts to temperature and humidity and can warp in large products. Dries slowly and hard; does not rot quickly, especially in a dry place, but is highly susceptible to wormholes. A very beautiful veneer is cut from the smelting. The best birch tree gives in the period of 40-50 years, and then the good qualities progressively decrease. Old wood is easily identified by its darker color.

Beech (red beech) - in Central Europe it is the most common type of wood. But beech wood growing in the mountains is of better quality. In some conditions, especially in underwater structures, it is not much inferior in strength to oak. Beech is a champion among other common ornamental wood species, especially for being well planed, processed on a lathe, and bent in a steamed state (in this it is second only to walnut. Resistant to splitting, but not resistant to cracking. It is an excellent ornamental material for interior decoration, cut very good, although dry wood crumbles and pricks in fine carving across the fibers.In everyday life it is used for the manufacture of drawing rulers and squares, shoe lasts, parquet, furniture (especially cots and playpens. These objects, which have served their time, can be used for carving Beech is not suitable for house carving, as it is extremely hygroscopic and warps when wet, prone to wormholes and decay.In order to prevent the attack of worms, finished beech products are smoked or steamed.To make the tree less warped, it is cut down in the middle of summer, and then, after a year , sawn into boards, which are placed in water and kept in it in those several months.

The color of the wood is reddish-brown with many large and darker spangles; in old age it darkens and turns into brown, and therefore is not used at all for elegant products. Steam-treated beech bends easily. This feature is used in furniture industry in the manufacture of Viennese chairs - the famous bent Viennese furniture, for which there is no more suitable tree. But even in this case, the beech is etched and stained in order to change the nondescript natural wood. When steamed, the beech easily bends, and after drying it retains its shape for a long time. The rawer the tree, the easier it is to process; it is very poorly polished, but it takes color well and imitates walnut especially well.

White beech or hornbeam, has a whitish-gray wood, very hard and strong, with lighter sheen on a smoothly finished surface. Annual layers in cross section have an irregular wavy shape. Sapwood is as hard as seasoned wood. While the wood is damp, it warps a lot; but after thorough drying almost completely does not change its shape from atmospheric influences; as it dries, the hardness of the hornbeam increases so much that the processing of hornbeam wood requires the sharpest tools. With cutting tools, the hornbeam is almost equally processed both along the fiber and from the end.

Thanks to these qualities, the hornbeam is used in carpentry - machine and model business.

In the carpentry and furniture business, the hornbeam has no use, since it is ugly in appearance and too heavy, and it is also very poorly polished. The hornbeam takes color perfectly, and therefore it is sometimes used to fake under ebony. This is most often done by turners, since the hornbeam sharpens very easily and well.

Cherry - in Russia it is common in the south and in the middle lane. The wood is dense, strong and elastic, but it is well processed and cut in all directions. By structure mature tree elegant and decorative amazing. Dry Cherry tree strong and hard, easily pricked and planed. As a finishing material, cherry is one of the most valuable and decorative species, and since the early Middle Ages (according to interior items that have come down to us) it has been used to decorate works of art and architecture. Musical instruments, stairs were made and are still being made from it, the famous Turkish chibouks are made from some varieties of cherries, growths and root nodes are valued by turners. It is used exclusively for the manufacture of expensive furniture. Cherry furniture is distinguished by a special aristocracy, even relatively recently created items look like rare antiques. It accepts polish and paint perfectly, it is especially well painted under mahogany. In house carving, the use of cherry is limited, in particular, by the small size of the blanks. But using the decorative texture of cherry in small panels or rosettes is perhaps tempting.

Elm (elm, birch bark, elm) - varieties of the same tree species. The most common species is the common broadleaf elm, distinguished by its heavy, light wood that darkens with age. The wood of old trees is dirty pink in color, dotted with many veins and dashes. Despite the distinctness of annual layers, the tree is very dense and slightly porous. It does not crack at all and warps very little. Resilience and flexibility are remarkable; elm is used to make wheel hubs and rims, sleigh skids, large-sized wooden screws, as well as all kinds of products that require endurance during shocks and impacts, but do not require smooth surface and elegance of decoration. The ability of the elm to bend (yes, given its light tone) is used for making curved contours and framing in decorative panels, house carving ornaments. All trees of this family, due to viscosity and fine fiber, are pricked, planed, smoothed and polished extremely poorly. As a result, they are very rarely used in furniture business.

Hornbeam - wood is light, grayish-white, shiny, heavy and hard. It cracks a lot and warps when it dries. The extraordinary hardness of the hornbeam, resistance to abrasion and splitting from impact (only white acacia is ahead of it in this. Due to its good staining with black dyes, high strength and hardness, hornbeam wood is used as an imitation of ebony. To avoid deformation and cracking, it requires long and careful drying.

Pear - wood is obtained mainly from the wild, due to the thickness and height of the trunk of a forest plant, which the garden pear usually does not reach, although the latter has no worse wood. The color of young wood is yellow - white, and old - brownish. The structure of the wood is dense, without noticeable pores and annual layers. The pear is planed and cut in all directions equally well. From soaking in water, and then slow drying, the pear tree noticeably hardens and turns brown. In the modeling business, it is used to make expensive carvings, and in the manufacture of expensive furniture, it is used to fake ebony, which is much more durable than pear. The pear is excellently polished. The only downside to her being prone to wormholes is.

Oak is a hard and strong wood of brownish-yellow color with strong noticeable annual layers, in the spring part of which there are many pores. A special characteristic of oak can be frequent and thick core rays. The wood of young trees is hard, flexible and greyish. brown. In older trees, the wood is yellower and more brittle. There are many varieties of oak, but we will divide them only into two groups: the first will include varieties that grow in the south and differ in appearance in that their acorns sit directly on the branches, and also in that the leaves turn yellow in autumn, but only fall from the tree. in winter or even in spring, when young ones appear. This variety is called winter oak and its wood is valued more than the other group. It goes mainly for parquets and characteristic wooden furniture decorated with carvings. The best wood gives oak in the period of 80-150 years of age, taken from the black forest, i.e. from dense forests. Pure oak forests do not produce good trees, as their trunks are squat, thick and gnarled.

Another group of oaks is known under the name of spring oaks and differs mainly in that their acorns sit on long petioles, which winter oaks do not have. The wood of spring oaks is somewhat more viscous, knotty and grayer - in general, it is lower in quality than the wood of the previous group.

Planed and sawn oak is quite difficult, it is pricked easily, and the polish takes very badly because of the sponginess.

Oak is especially resistant to water, where it takes on a completely black color, which raises its value as a material for expensive furniture.

Spruce - in appearance somewhat similar to pine tree, but differs from it in greater softness, pallor of annual layers and a large number of small knots. Spruce does not differ in especially good qualities, and it owes its wide distribution to its cheapness and similarity to pine.

In products that are directly affected by atmospheric changes, spruce quickly rots. It warps a little and this is almost her only good quality. Spruce is planed, sawn and pricked easily.

Karagach (elm, elm, birch bark) - varieties of the same tree species. The most common species is the common broadleaf elm, distinguished by its heavy, light wood that darkens with age. The wood of old trees is dirty pink in color, dotted with many veins and dashes. Despite the distinctness of annual layers, the tree is very dense and slightly porous. It does not crack at all and warps very little. Resilience and flexibility are remarkable; elm is used to make wheel hubs and rims, sleigh skids, large-sized wooden screws, as well as all kinds of products that require endurance during shocks and impacts, but do not require a smooth surface and elegance of finish. The ability of the elm to bend (and taking into account its light tone) is used to make curved contours and framing in decorative panels, house carving ornaments. All trees of this family, due to viscosity and fine fiber, are pricked, planed, smoothed and polished extremely poorly. As a result, they are very rarely used in furniture business.

Chestnut (wild / horse) - gives a very beautiful, almost completely white, but, unfortunately, very soft wood. The wood of old trees loses its whiteness and turns yellow or red. Chestnut is processed very easily, but soon rots and loses strength. It also paints well and at the same time it lasts longer from damage. Due to the above reasons, he plays a role only in haberdashery and artistic - amateur works.

An edible chestnut gives a tree that is completely opposite in properties to a wild chestnut. It is hard, brown (similar in color to oak), very durable, not warping or cracking. Polishing takes very well. His appearance is not particularly attractive, and therefore is rarely found on sale.

Cedar is a kind of pine (Siberian pine. The tree is soft, prickly, pinkish-brown in color, with a pleasant smell. Since ancient times, it has been used to make furniture, in construction, as well as pens and pencils - sometimes called pencil - does not warp and is not at all susceptible to wormhole.

Maple - gives a whitish wood with many small sparkles, giving the tree a silky look. The tree is dense, dense, of medium hardness and almost never cross-layered, as a result of which it is pricked and planed perfectly. In that case, if we add to what has been said that maple warps a little and resists moisture well, it will become clear why it is so highly valued by carpenters. Expensive models of carved ornaments are prepared from it. Maple takes polish very well; painted in different colors is also good, because it is used to fake acacia and boxwood, to which it is close in its structure (but not in density.

Mahogany (mahogany, amaranth) is the most common and well-known of all tropical trees, under the name of which the most diverse and heterogeneous breeds are sold, having a common color and partly appearance textures. It is easy to process, and although redwood is quite soft, it still belongs to the category of the most desirable joinery materials. The reason for this is not so much in its beauty, but in the persistent resistance to atmospheric influences and the perfect immutability of form. Therefore, it goes to the manufacture of expensive furniture, grand pianos and pianos.

In Russia, there is not even half of all varieties and varieties of mahogany, so it is pointless to present the details of its merchandising. Most often we have a bad yellow-orange variety, known as a sugar, or chest, tree. Its smell is weak and rather pleasant for humans, disastrous for insects. Therefore, the best chests and wardrobes are made from sugar wood. This tree is called sugar because American sugar was transported in boxes from it, and these boxes were then sold as carpentry material.

Linden - gives light, white wood with barely noticeable annual layers. Works well, especially with cutting tools. It warps very little, is not afraid of dampness, but, unfortunately, is prone to a wormhole. The best tree gives the southern linden; from it are prepared mainly foundry models and all miscellaneous products under gilding.

Little is used in turning, except for handicrafts and children's toys. From linden, characteristic furniture under white colored polish is good. Linden is painted very poorly, as it is distinguished by remarkable impermeability. Honey, for example, flows through the walls of any wooden vessel - one linden does not let it through.

Larch - belongs to the category of the most best trees both in construction and carpentry. The wood is reddish in color and is remarkably durable. It is much more stable than oak and is equally hardy both in water and in air. The reason for this should be sought in a large amount of resin. Larch is processed very smoothly and well; almost does not warp and is not subject to a wormhole.

Juniper - grows everywhere in the middle lane, but is very rarely tree-like, and its ordinary shrub never gives thick pieces of wood suitable for larger products. Young plants produce almost white, and old ones whitish-yellow, not too hard, very thin-layered, dense and flexible with wavy growth rings and very hardy. To rare properties juniper wood is attributed to its pleasant sandarach smell, .

See more information about children's furniture

A large number of tree species grow in Russia, but when using some of them, their strength must be taken into account.

Acacia

It has the hardest wood of all trees growing in Russia. Has an olive green or yellow. Works well only when raw. But in dry form it is practically not cut. various tools. When dry, it does not warp or crack. Possesses fine wear resistance, practically is not exposed to atmospheric influences. Over time, under the action of UV rays, it changes the color of the structure and acquires a very attractive and refined color.

Thanks to its durable and hard, but elastic wood, it is popularly used to perform facing works. This is an excellent material for the manufacture of finishing veneer.

Acacia wood makes excellent floor coverings. Their service life is much longer than that of larch or ash parquet. Acacia makes excellent interior doors.

Birch

The most popular finishing material. Differs in light uniform texture. Due to its fine structure, it has dense hardwood. Perfectly lends itself various types machining in different condition. Responds quickly to temperature fluctuations and high humidity. Starts to warp. Mainly used for making small items. It makes a very attractive veneer. Requires the use of effective wood impregnations.

Oak

It has a fairly hard and strong wood, which has a yellow-brown color with clearly defined growth rings. Oak wood is used, which is 80-150 years old and grown in black forest. Oak has excellent water resistance. Under its action, it acquires a perfectly black color. Wood with this color is in great demand for the manufacture of luxury cabinet furniture.

Linden

It has an exquisite white texture with subtle growth rings. Perfectly handles various cutting tool. Linden is impervious to dampness, as a result of which it practically does not warp. But easily wormholeed.

Linden products practically do not stain, as they are distinguished by excellent water resistance. Mainly used to produce furniture with white texture and finishing materials, type lining for a bath.

This is the Siberian version of the common pine. Its wood is soft, has a pinkish-brown hue and a pleasant smell. Does not warp under the influence of moisture. It is in great demand for the manufacture of furniture. Larch belongs to the category of the most popular species coniferous trees used in the construction and carpentry industries. The wood is highly durable with a reddish color. It is much more durable than oak. Larch is distinguished by excellent endurance to water and adverse atmospheric factors. This is facilitated by the high content of gum in the structure of its wood. It is perfectly processed, after it a smooth, perfectly flat surface is obtained.

Thanks to a large number gum larch perfectly resists the formation of colonies of mold, rot, wood-destroying insects.

Conclusion

Comparing all breeds, we conclude that stronger than wood oak and Siberian larch in Russian Federation there is no other breed. This conclusion confirms the fact that best boards for the floor in the Russian Federation are made from oak wood and boards from Siberian larch.