The tasks of the heating system include optimal and uniform heating various premises in winter, so the connection of the radiator must be made in accordance with all the rules.

Purpose of the heating system

In a private house or apartment, it should be set from 18 to 25 degrees. In winter, this indicator can only be achieved with a high-quality heating system. Its efficiency must correspond to the area of the building, must be correct scheme.

Heating appliances compensate for heat losses, which are mandatory in any room, as heat escapes through windows, doors and even communication elements.

It is especially necessary to pay attention to what heater connection schemes exist, and choose desired option. It is advisable to make a choice at the stage of building a house or apartment.

The best is the connection of heating radiators to central system, because in this case we obtain an effective and reliable system providing uniform and constant heating in winter. Many private houses are located far from the city, so it is not always possible to use a connection to centralized heating.

That's why you have to create your own autonomous systems, which:

- must have high efficiency;

- if desired, you can do it yourself;

- numerous nodes must be correctly formed and adjusted;

- installation must be carried out in accordance with all requirements and conditions;

- there must be a reliable and correct strapping systems.

To ensure uniform and high-quality heating of the premises in the house, it is important to know what elements affect it:

- Proper network wiring, which affects the efficiency of heating and how evenly the rooms will heat up, and the price for heating also depends on this.

- The right equipment for the system, for which you need to make calculations that will determine what efficiency, power and other parameters the main elements should have. It depends on the fuel consumption.

- Correct installation the main components and elements of the heating system, which include pipelines, radiators, fittings, a boiler with a pump. If any actions are not performed correctly, the heating will work poorly or stop functioning altogether.

Read also: Power and number of sections of aluminum radiators

Before installation of all heating elements, you need to calculate and select the connection scheme for heating radiators. It is necessary to choose batteries that will have the desired efficiency and other characteristics. Other installation materials must be purchased. The work itself should be carried out independently only after carefully studying the instructions.

How to choose a scheme

First you need to know what are connection types heating radiators:

- (serial connection);

- (parallel connection).

The piping itself to the batteries can be done in the following ways:

The piping itself to the batteries can be done in the following ways:

- bottom;

- unilateral;

- diagonal.

All have their own characteristics. Some nodes are mounted in various ways.

If it is supposed to carry out the installation of a serial circuit, then there should not be more than 12 sections on one battery in the gravitational network. If a circulation pump is used, then there should not be more than 24 sections. In this case, you can achieve the highest efficiency of the system and high safety of its use.

Installation rules

Before connecting the radiator, the following requirements must be considered:

- the distance from the floor to the battery should be approximately 10 cm;

- from the window sill to the radiator, the distance is 10 cm;

- all nodes must be connected in accordance with the requirements specified by the manufacturers;

- from the wall to the product should be more than 2 cm.

Work process

When connected the following steps must be taken:

- At the place where it is supposed to mount the device, it is necessary to apply markings that will indicate future areas for the brackets.

- Brackets are fixed to the wall of the room.

- On the radiators themselves, piping is carried out, which involves the installation of shut-off and control valves. Usually Mayevsky cranes are used for this.

- Other additional components and elements are installed, which include plugs or valves.

- The radiator itself is mounted, for which it is attached to the brackets. It is important to properly adjust the device so that there are no distortions or other problems.

- The battery is connected to the pipeline in one of the ways: diagonal, lower or one-sided.

- The structure is pressure tested, then water can be let in to check the tightness and correct operation of the equipment.

- Use of heating.

Incorrect inclusion of heating radiators - factor that most often causes problems during operation.

Errors in the installation of other components and the wrong choice of system type also have a negative impact on the use of heating devices.

How to properly connect batteries in an apartment building

Connection options depend on the number of pipes used to connect the boiler to the radiators. There are two methods:

- One pipe comes out of the boiler, makes a circle along the harness, simultaneously entering the batteries, and returns to the starting point. This installation method is easy to implement.

- The first half of the system exits the heater, visits all radiators, connecting with them only once. At the extreme, the most distant, it stops and the second part begins. The latter also passes through all the batteries, connecting on the other side. Its end point is the cauldron.

The choice will depend on the budget, as both options have advantages over the other. Single-pipe is easier to install and cheaper, which is why it is used in apartment buildings. Two-pipe is more complicated and more expensive, but more reliable, therefore it is recommended for private buildings.

Schemes for the correct connection of radiators to the heating system

Pipes leading to radiators in three ways:

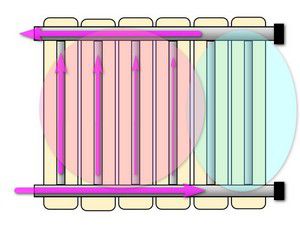

- Diagonal variant implies a supply connection with the upper axis on one side of the battery, and a return connection with the lower one on the other. This type is characterized high efficiency operation and rapid heating of sections, regardless of their number and distance from the boiler.

Photo 1. Scheme diagonal connection heating radiator. The supply circuit is on the top left, the return circuit is on the bottom right.

- lower connection is made along one axis. To do this, the supply is cut from one end of the radiator, and the return from the other. This method is used less frequently than others due to poor performance.

Photo 2

- Lateral also known as unilateral. Pipes lead from one side to vertical plane. This method is in great demand in small spaces and apartments.

Each type of connection can be used because they independent of the heating system. But in the work of different combinations there are nuances that it is desirable to observe.

Reference. Single-pipe wiring is better combined with bottom and side connections, and two-pipe - with diagonal.

Wrong connection methods

Radiators are usually mounted without problems, but the same cannot be said about some components of the system.

Thermostat head

Errors during installation of the device lead to a drop in performance. The most common problems are:

- Vertical head placement make sure that it does not stick out to the side, interfering with walking or cleaning. This causes the bellows to heat up as the coolant rises up from the valve. To correct it, it is necessary to stop operation, dismantle the device, then reinstall it, placing it horizontally.

Photo 3. Incorrect vertical connection of the thermal head to the battery (left), correct horizontal placement (right).

- Placing the thermal head in a niche or similar confined spaces. This leads to a decrease in convection: heat settles in a closed volume, accumulates and is incorrectly reflected from the surrounding walls. Thus, the heating efficiency is reduced.

- Installing curtains so that they cover the thermal head. This factor leads to an incorrect determination of the temperature in the room by the device. The bellows stops working when it is needed. Solution to this problem — removal of the sensor on the wall, not covered by unnecessary objects. Most thermal heads are allowed to be mounted at a distance of up to two meters from pipes.

- An important role is also played by the quality setting of the device. It is recommended to invite a specialist who will check the correct operation and, if necessary, change the characteristics.

You will also be interested in:

bypass

Problems with the device usually arise when radiators are replaced by an unskilled person. This is especially true in cases in which cast iron is exchanged for another material.

The two most common mistakes are:

- Mounting on supply bypass pipe ball valve designed to let water into the system. The entire coolant should not pass through the device: only a small part, which is enough for operation.

- The bypass is connected to the piping through a mixer with a three-way valve. Theoretically, this allows you to regulate the heat transfer of the boiler, but in practice it leads to damage to the device.

Both errors are easy enough to fix by changing the principle of connecting the bypass. There are also a few rules to note:

- It is forbidden to install a bypass on a free pipe in apartment buildings.

- Forbidden installation shutoff valves and valves.

- Allowed reduction of pipes by one typical size.

- In a non-volatile gravitational system pump needed, and it is connected exclusively to the bypass.

Attention! These problems concern only apartment buildings in which they lead to imbalance of the whole system. The consequence of such errors is a decrease in the amount of heat that neighbors receive along the highway.

Serial connection of radiators - the most popular and economical option heating of the room, thanks to which an autonomous, independent of the central, heating system is created.

Necessary tools

To form such a connection of heating devices, the following components will be required:

- Pipes: for the main line, it is advisable to choose a pipeline made of steel, galvanized or metal-plastic with appropriate diameters 2.2 cm, 2.2 cm and 2.6 cm. Also allowed to use polypropylene pipes, but not in a system with three or more radiators. Branch pipes departing from the main line are made of the same materials, but have smaller diameters.

Photo 1. Metal-plastic pipes different diameter in section: a layer of metal is visible between two layers of plastic.

- Radiators: choice necessary equipment carried out on the basis of personal preferences and expert advice. For such a scheme the most optimal counts 5 batteries, and for more of them, a well-calculated project is required.

- Thread sealing tapes on batteries.

- thermostatic valves to regulate the heating of radiators.

- Fitting for connecting pipes.

The direct components are also expansion tank and heating boiler.

Preparatory actions

Before starting the process calculated detailed project heating systems for everyone specific premises.

Then choose one of the options serial connection: horizontal or vertical based on the characteristics of the living space and personal preferences.

Then, focusing on the selected type of circuit, you need to decide on the coolant. For vertical decoupling, it is better to use antifreeze diluted in water, and for horizontal decoupling, plain water.

How to connect two heating radiators, diagram

- Initially in serial connection the location of the heating boiler is determined. It is usually located in basement on a special fire platform. An expansion tank is firmly fixed above it.

Attention! Height expansion tank relative to the boiler should be at least three meters.

- Wherein competent chimney adjustment is thought out: the draft must be sufficient, and the smoke itself should go outside without remaining inside the room.

- After produced main pipeline connection. It is important to avoid bends when laying.

- Passes along the perimeter of the whole house a pipe parallel to which all the batteries run.

Photo 2. Scheme of serial connection of batteries in a single-pipe system with a boiler and a circulation pump.

- Radiators are placed under window openings.

- Such a circuit should be closed on the heating boiler.

- And it is also necessary provide an element through which the system will be filled water and its drain.

- AT sequential circuit connections, can be completed with taps and thermostats each battery.

With vertical binding included in the diagram for forced circulation coolant circulation pump, and with horizontal- a slope of the supply pipe is created, and a Mayevsky crane is mounted in front of each radiator to remove excess air from the system.

Pros and cons of connecting batteries in series

pros serial connection:

- low cost consumables;

- allowed use of any kind radiators;

- if necessary the pipeline is brought into the "warm floor";

- coverage of heating devices of the entire perimeter rooms;

- easy installation;

- a small amount of consumable material.

Minuses:

- complex design process;

- high heat loss coefficient: due to the characteristic elongation of such a line, the coolant cools towards the end;

- in the absence of a circulation pump, stagnation occurs liquid moving along the radiators and reducing the efficiency of the system as a whole;

- without thermostats on batteries lack of control over the heat supply.

Any heating system is a rather complex “organism”, in which each of the “organs” performs a strictly assigned role. And one of the most important elements are heat exchange devices - it is they who are entrusted with the ultimate task of transferring thermal energy or to the premises of the house. In this capacity, the usual radiators, convectors of open or hidden installation, the systems of water floor heating that are gaining popularity are pipe circuits laid in accordance with certain rules.

You may be interested in information about what is

This article will focus on heating radiators. Let us not be distracted by their diversity, structure and specifications: on our portal on these topics - enough comprehensive information. Now we are interested in another block of questions: connecting heating radiators, wiring diagrams, installing batteries. Correct installation heat exchangers, rational use embedded in them technical capabilities- This is a guarantee of the efficiency of the entire heating system. Even from the most expensive modern radiator there will be a low return if you do not listen to the recommendations for its installation.

What should be considered when choosing radiator piping schemes?

If you take a simplified look at most heating radiators, then their hydraulic design is a fairly simple, understandable diagram. These are two horizontal collectors, which are interconnected by vertical jumper channels through which the coolant moves. This entire system is either made of metal, which provides the necessary high heat transfer ( a prime example-), or "dressed" in a special casing, the design of which assumes the maximum area of contact with air (for example, bimetallic radiators).

1 - Upper manifold;

2 - Lower collector;

3 - Vertical channels in the radiator sections;

4 - Heat exchanger case (casing) of the radiator.

Both collectors, upper and lower, have outlets on both sides (respectively, in the diagram, the upper pair B1-B2, and the lower B3-B4). It is clear that when a radiator is connected to the pipes of the heating circuit, only two out of four outlets are connected, and the remaining two are muffled. And from the connection diagram, that is, from relative position the pipes for supplying the coolant and exiting the "return" largely depend on the efficiency of the installed battery.

And first of all, when planning the installation of radiators, the owner must figure out exactly what kind of heating system is functioning or will be created in his house or apartment. That is, he must clearly understand where the coolant comes from and in which direction its flow is directed.

Single pipe heating system

In multi-storey buildings, a single-pipe system is most often used. In this scheme, each radiator is, as it were, inserted into the “gap” of a single pipe, through which both the coolant is supplied and its removal to the “return” side.

The coolant passes successively all the radiators installed in the riser, gradually wasting heat. It is clear that in the initial section of the riser, its temperature will always be higher - this must also be taken into account when planning the installation of radiators.

There is another important point here. Such a one-pipe system apartment building can be organized according to the principle of top and bottom feed lyre.

- On the left (pos. 1) the top supply is shown - the coolant is transferred through a straight pipe to top point riser, and then sequentially passes through all the radiators on the floors. This means that the flow direction is from top to bottom.

- In order to simplify the system and save Supplies often another scheme is organized - with a bottom feed (pos. 2). In this case, radiators are installed in the same series on the pipe ascending to the upper floor, as well as on the pipe descending. This means that the direction of the coolant flow in these "branches" of one loop is reversed. Obviously, the temperature difference in the first and last radiator of such a circuit will be even more noticeable.

It is important to deal with this issue - on which pipe of such a single-pipe system your radiator is installed - the optimal tie-in scheme depends on the flow direction.

A prerequisite for piping a radiator in a single-pipe riser is a bypass

The name “bypass”, which is not entirely clear to some, refers to a jumper that connects the pipes connecting the radiator to the riser in a single-pipe system. What is needed for, what rules are followed when installing it - read in a special publication of our portal.

The single-pipe system is widely used in private one-story houses, at least for reasons of saving materials for its installation. In this case, it is easier for the owner to figure out the direction of the coolant flow, that is, from which side he will be supplied to the radiator, and from which side he will exit.

Advantages and disadvantages of a single-pipe heating system

Attracting with the simplicity of its device, such a system is still somewhat alarming due to the difficulty of ensuring uniform heating on different radiators of house wiring. What is important to know about how to mount it with your own hands - read in a separate publication of our portal.

Two-pipe system

Already on the basis of the name, it becomes clear that each of the radiators in such a scheme "relies" on two pipes - separately for supply and return.

If you look at the two-pipe wiring diagram in high-rise building, the differences are immediately visible.

It is clear that the dependence of the heating temperature on the location of the radiator in the heating system is minimized. The direction of the flow is determined only by the relative position of the branch pipes cut into the risers. The only thing you need to know is which particular riser acts as a supply, and which one is the “return” - but this, as a rule, is easily determined even by the temperature of the pipe.

Some apartment residents may be misled by the presence of two risers, in which the system will not cease to be one-pipe. Look at the illustration below:

On the left, although there seem to be two risers, a single-pipe system is shown. Just one pipe is the upper supply of coolant. But on the right - a typical case of two different risers - supply and return.

The dependence of the efficiency of the radiator on the scheme of its insertion into the system

Why was it all said. what is placed in the previous sections of the article? But the fact is that the heat transfer of the heating radiator very seriously depends on the relative position of the supply and return pipes.

| Scheme of inserting a radiator into a circuit | Direction of coolant flows |

|---|---|

| Diagonal radiator connection on both sides, top inlet | |

|  |

| Such a scheme is considered the most effective. In principle, it is she who is taken as the basis for calculating the heat transfer of a specific radiator model, that is, the battery power for such a connection is taken as a unit. The coolant, without encountering any resistance, completely passes through the upper collector, through all vertical channels for maximum heat dissipation. The entire radiator warms up evenly over its entire area. | |

|  |

| Such a scheme is one of the most common in multi-storey building heating systems, as the most compact in vertical risers. It is used on risers with an upper supply of coolant, as well as on return, descending - with a lower supply. It is quite effective for small radiators. However, if the number of sections is large, then the heating may be uneven. The kinetic energy of the flow becomes insufficient to propagate the coolant to the very end of the upper supply manifold - the liquid tends to pass along the path of least resistance, that is, through the vertical channels closest to the entrance. Thus, in the part of the battery farthest from the entrance, stagnant zones are not excluded, which will be much colder than the opposite ones. When calculating the system, it is usually assumed that even with optimal length battery, its overall heat transfer efficiency is reduced by 3÷5%. Well, with long radiators, such a scheme becomes inefficient or will require some optimization (this will be discussed below) / | |

| One-way radiator connection with top inlet | |

|  |

| A scheme similar to the previous one, and largely repeating and even reinforcing its inherent shortcomings. Used in the same risers single pipe systems, but only in schemes with bottom supply - on the ascending pipe, so the coolant is supplied from below. Losses in the total heat transfer with such a connection can be even higher - up to 20 ÷ 22%. This is due to the fact that the difference in density will also contribute to the closure of the movement of the coolant through the near vertical channels - hot liquid tends upward, and therefore it is harder to pass to the remote edge of the lower radiator supply manifold. Sometimes this is the only connection option. The losses are compensated to some extent by the fact that in the ascending pipe the general level of the coolant temperature is always higher. The circuit can be optimized by installing special devices. | |

| Double-sided connection with bottom connection of both connections | |

|  |

| The scheme of the lower, or as it is often called the "saddle" connection, is extremely popular in autonomous systems private houses due to opportunities hide the pipes of the heating circuit under decorative surface floor or make them as invisible as possible. However, in terms of heat transfer, such a scheme is far from optimal, and possible efficiency losses are estimated at 10–15%. The most accessible path for the coolant in this case is the lower collector, and distribution along the vertical channels is largely due to the difference in density. Eventually top part heating batteries can warm up much less than the bottom. There are certain methods and means to minimize this disadvantage. | |

| Diagonal radiator connection on both sides, bottom inlet | |

|  |

| Despite the apparent similarity with the first, most optimal scheme, the difference between them is very large. Efficiency losses with such a connection reach up to 20%. This is explained quite simply. The coolant has no incentives to freely penetrate to the far section of the lower radiator supply manifold - due to the difference in density, it selects the vertical channels closest to the battery inlet. As a result, with a sufficiently evenly heated top, in the lower corner opposite to the entrance, stagnation often forms, that is, the surface temperature of the battery in this area will be lower. Such a scheme is used extremely rarely in practice - it is even difficult to imagine a situation where it is absolutely necessary to resort to it, rejecting other, more optimal solutions. | |

The table deliberately does not mention the lower one-sided connection of the batteries. With him - the question is ambiguous, since in many radiators that suggest the possibility of such a tie-in, special adapters are provided, which in fact turn bottom connection one of the options listed in the table. In addition, even for conventional radiators, you can purchase additional equipment, in which the lower one-sided eyeliner will be structurally modified to another, more optimal option.

I must say that there are also more “exotic” tie-in schemes, for example, for high-height vertical radiators - some models from this series require a two-way connection with both connections from above. But the very design of such batteries is thought out in such a way that the heat transfer from them is maximum.

The dependence of the heat transfer efficiency of the radiator on the place of its installation in the room

In addition to the scheme for connecting radiators to the pipes of the heating circuit, the place of their installation also seriously affects the efficiency of these heat exchange devices.

First of all, you must comply certain rules placement of the radiator on the wall relative to adjacent structures and interior elements of the room.

The most typical location of the radiator is under window opening. In addition to the general heat transfer, the ascending convection flow creates a kind of " thermal curtain”, preventing the free penetration of colder air from the windows.

- The radiator in this place will show maximum efficiency if it total length will be about 75% of the width of the window opening. In this case, it is necessary to try to install the battery exactly in the center of the window, with a minimum deviation not exceeding 20 mm in one direction or another.

- The distance from the lower plane of the window sill (or other obstacle located on top - a shelf, a horizontal wall of a niche, etc.) should be about 100 mm. In any case, it should never be less than 75% of the depth of the radiator itself. Otherwise, an insurmountable barrier to convection currents is created, and the battery efficiency drops sharply.

- The height of the lower edge of the radiator above the floor surface should also be about 100÷120 mm. With a clearance of less than 100 mm, firstly, considerable difficulties are artificially created in carrying out regular cleaning under the battery (and this is a traditional place for the accumulation of dust carried by convection air currents). And secondly, convection itself will be difficult. At the same time, “pulling up” the radiator too high, with a clearance from the floor surface of 150 mm or more, is also completely useless, since this leads to uneven distribution of heat in the room: a pronounced cold layer may remain in the area bordering the floor surface air.

- Finally, the radiator must be at least 20 mm away from the wall with brackets. A decrease in this gap is a violation of normal air convection, and in addition, clearly visible dust marks may soon appear on the wall.

These are indicative indicators that should be followed. However, for some radiators, there are also recommendations developed by the manufacturer on the linear parameters of the installation - they are indicated in the product manuals.

It is probably unnecessary to explain that a radiator located openly on the wall will show heat transfer much higher than one that is completely or partially covered by certain interior items. Even too wide window sill can already reduce the heating efficiency by several percent. And when you consider that many owners cannot do without thick curtains on the windows, or, for the sake of interior design, they try to cover up unsightly, neither their eyes, radiators with the help of facade decorative screens or even completely closed casings, then the estimated battery power may not be enough to fully heat the room.

Heat transfer losses, depending on the installation of a heating radiator on the walls, are shown in the table below.

| Illustration | The influence of the shown placement on the heat transfer of the radiator |

|---|---|

| The radiator is located on the wall completely open, or installed under the window sill, which covers no more than 75% of the depth of the battery. In this case, both main heat transfer paths - both convection and thermal radiation - are completely preserved. Efficiency can be taken as a unit. |

| A window sill or shelf completely covers the radiator from above. For infrared radiation, this does not matter, but the convection flow is already facing a serious obstacle. Losses can be estimated at 3 ÷ 5% of the total thermal power of the battery. |

| In this case, not a window sill or shelf on top, but the upper wall of a wall niche. At first glance, everything is the same, but the losses are already somewhat greater - up to 7 ÷ 8%, since part of the energy will be wasted on heating the very heat-intensive material of the wall. |

| The radiator is covered from the front decorative screen, but the clearance for air convection is sufficient. The loss is precisely in thermal infrared radiation, which especially affects the efficiency of cast iron and bimetallic batteries. Heat transfer losses with such an installation reach 10÷12%. |

| The heating radiator is covered with a decorative casing completely, from all sides. It is clear that in such a casing there are gratings or slot-like holes for air circulation, but both convection and direct thermal radiation are sharply reduced. Losses can reach up to 20 - 25% of the calculated battery power. |

So, it is obvious that the owners are free to change some of the nuances of installing heating radiators in the direction of increasing the efficiency of heat transfer. However, sometimes the space is so limited that you have to put up with the existing conditions regarding both the location of the pipes of the heating circuit and the free area on the surface of the walls. Another option - the desire to hide the batteries from the eyes prevails over common sense, and the installation of screens or decorative casings is a matter already decided. This means that in any case, it will be necessary to make adjustments for the total power of the radiators in order to guarantee that the room required level heating. Correctly make the appropriate adjustments will help the calculator below.