To determine the value of ventilation in the bath know its purpose:

- Rapid heating of the room, uniform distribution of heat. Savings in heating costs.

- Constant air renewal during soaring. This is necessary for the comfort and health of vacationers.

- Rapid removal of moist air. Implementation of mandatory drying of the premises.

- Preservation of the building for a longer time. No fungi or mold appear. Objects are not deformed, do not change color under the influence of moisture.

No or insufficient ventilation unpleasant odors gradually accumulate in the room, the air becomes damp. Fresh air is not supplied, it becomes difficult to breathe. There is a risk of carbon monoxide poisoning. Without ventilation, all the warm air will gradually go up, and the cooling air will accumulate below.

Proper ventilation system in the baths

In baths made of natural logs any punching of holes to provide ventilation is considered superfluous. The lower crowns of the walls are laid with the installation of holes through which a moderate amount of fresh air passes. If there is a stove-heater in which the blower is simultaneously designed to bring air out, you can limit yourself to its presence. They let in air through the open door, a gap of 5-7 mm is enough.

Ventilation is designed for regular entry into the bath of fresh air, outflow of cooled and moist. For fresh air flow need to build vents. If they are not, then you can use the vents, doors. The hood also takes place through special openings; a furnace blower can be used; a chimney is of great importance in the outflow of steam. In order to be able to fully control the air exchange, the openings are equipped with shutters, by adjusting which you can stop or resume the flow and exit of air.

There is a wide range of ventilation systems:

- For inlet and outlet located opposite each other, one level is used. In some cases, the low placement of the inlet helps to retain heat for a longer time. To activate the air exchange, a fan is installed, an air duct or a deflector can also be used. You can not place holes with an exact match in level. As a result of the rapid release of air, accumulations of cold at the bottom and warm in the rest of the bath can form.

- The air currents directed by the operating ventilation device lower the pressure inside the duct. Exhaust air is drawn out due to a decrease in pressure inside the bath. To raise the pressure again, fresh air is supplied.

- The vents can be arranged in this way: the supply air is 30 cm from the floor, the outlet located opposite does not reach the ceiling by 30 cm. Fresh air immediately heats up from the stove, rises, gradually leaving the room.

To ensure constant control over the speed and volume of incoming and outgoing air, dampers are created. It is advisable to make them retractable, slightly opening to the required distance. The length of the duct is determined by the dimensions of the bath, as well as the maximum volume of required incoming air.

When the room is only heated with a preheated stove, all openings should be covered. When the temperature becomes optimal for vaping, the valves open a little and are immediately regulated so that the air exchange does not change the temperature in the room. Both inlet and outlet openings must have a connector close to the same. To make the influx of fresh air stronger, you can slightly increase the outlet.

The inlet connector must not be larger than the outlet. This leads to a reverse draft, which contributes to the release of fresh air from the bath, and not its active circulation.

Ventilation in the Russian bath

In a classic bath, created according to the Russian model, no special holes, so air exchange should be performed in a more natural way. Normally, conventional ventilation is used to supply fresh air. You can open the door leading to the street and the window opposite to it. Sometimes forced exhaust is used with the door open. To better get rid of the accumulated dampness, you should sweep the leaves from the broom in a timely manner. Benches and other wooden objects can be dried when wet, sometimes sheets are swept. These procedures will not allow the formation of heavy steam, remove unpleasant odors and decay products from the room.

After the bath is ventilated and dried, need to start steaming. To do this, pour water on the stones in small portions. The prepared steam quickly rises and remains there for a long time, so it may turn out that it is already very hot at the top, and still cool at the bottom. With a strong temperature difference, you can wait until the steam sinks or use artificial methods to lower it.

It is enough to work with brooms to create movement in the steam room, the air will immediately mix. Waves with a towel or broom should be carried out closer to the ceiling.

You can make a fan: on the wooden handle there is a stainless steel loop, on which the fabric is stretched. Horizontal or vertical movements are made by this device to move warm and cold air. Sometimes they begin to use it in the manufacture of steam. To do this, one person pours water on the stones, and the second works with a fan.

in the steam room

In classical bath ventilation schemes, it is assumed air flow in the steam room from below. The hole is usually located below half a meter from the floor. The hood can be placed close to the ceiling by equipping a hole on the opposite wall. The regulation of the level of humidity and heat of the air is carried out by extending or closing the shutters.

The best option, especially for a small steam room, is to create an air inlet next to the stove. This is necessary to instantly heat the incoming fresh air. This arrangement will not allow strong drafts to form, helps to avoid a large temperature difference in different parts of the steam room. The heat from the steam room can not only be taken outside, but also moved to other rooms for their high-quality heating.

Proper ventilation works by bringing fresh air under the box. Air masses leave the device through the top opening. The steam room warms up quite evenly until the warm air reaches the bottom of the box. Hot air will gradually displace colder air, providing warming before leaving the room. The steam room simultaneously heats up and dries out.

In the bathhouse

The ventilation channel is directly connected to the duct, the diameter of which usually exceeds the chimney by no more than 20%. With such parameters, oxygen fills the room, and does not leave it. Air intake from the underground is not needed.

The walls of the stove, if it is in the dressing room, should be close to the floor. Shelves are not necessarily placed in a strictly horizontal position. They are able to slow down the rise of heat to the ceiling. For better absorption of warm air, it is better to equip the stove with several chimneys.

Sometimes during the heating of the bath in the room a large amount of smoke is formed and retained. This means that the air inside the dressing room is colder than in the environment. Cold air is somewhat more massive than warm air, so it often creates a shell in chimneys. In order to push out this air, it is necessary to equip an additional door for burning ash.

Forced ventilation

Ventilation in the bath with the help of electronic systems is carried out if it is impossible to provide good air circulation in natural ways. Fans can be installed on both supply and exhaust openings. They accelerate the movement of air masses, providing the room with fresh air, quickly removing moist.

Ventilation in the bath with the help of electronic systems is carried out if it is impossible to provide good air circulation in natural ways. Fans can be installed on both supply and exhaust openings. They accelerate the movement of air masses, providing the room with fresh air, quickly removing moist.

Exhaust ventilation

In the design of this ventilation is always present exhaust fan. For air circulation, a supply air is also necessarily constructed. Sometimes cracks in the walls are used for fresh air to enter, windows or doors are slightly opened. The advantage of exhaust ventilation is to reduce the pressure in the bath. The action must be compensated by a constant flow of air from outside.

Ventilation with a powerful hood perfectly removes harmful gases, humid air with an unpleasant odor. It is possible to build such a ventilation system not only in the steam room, but also in showers, washing rooms, departments with a pool or in bathrooms. Usually, the basic set of the exhaust ventilation system includes a fan and a box. If the device is too noisy, a silencer can be used.

Forced ventilation

It is installed according to the exhaust principle, however the fan must be placed on the inlet. When the supply ventilation system is activated, an increase in pressure in the room is observed, which should be compensated in a timely manner by the release of air through the hood or gaps in the walls, floor, ceiling, through the windows, the door.

Supply fans are not considered convenient if they will operate in cold temperatures. In winter, they supply icy air, which must be additionally heated by pre-installed air heaters. If it is necessary to purify a large amount of incoming air, filters can be used.

Supply and exhaust ventilation

Combination of artificial inflow and exhaust air is often equipped with recuperators, silencers, filters. Additional devices provide comfort while in the bath, at the same time there is a constant, good air circulation. In order not to worry about ventilation, you can equip it with an automatic control unit.

Creating a design for supply and exhaust artificial ventilation often causes difficulties. It is necessary to calculate the optimal air exchange in all rooms of the bath at the design stage. The amount of outgoing air must match the incoming air. Sometimes air flows are not specifically balanced. In order to prevent the spread of excessive humidity or unpleasant odors from a certain room, the pressure is artificially reduced in it. To do this, the hood is mounted with greater intensity than in other rooms.

When arranging ventilation in the bath, you should take care not only of the steam room, but also of other important rooms. To save heating costs, you can use the warm air generated in the steam room, taking it out not to the street, but through other rooms. By adapting the ventilation system to specific requests, you can make the most successful option.

Floor ventilation in the bath is an urgent need. Constant dampness of the flooring will inevitably lead to rotting of the material, even with a concrete base. And floors with areas of rot, mold, fungi become a source of various infections and unpleasant odors. And the durability of such an element will be short. To ventilate the floor of a bath means to increase its service life without repair, to exclude an unhealthy effect on the human body and to ensure the comfort of the bath procedure.

Rot on the floor in the bath indicates a lack of ventilation

Problem Features

The floor in the bath is in extreme conditions. Active moistening of the material goes both from below (from the side of the ground) and from above during the operation of the establishment. Particularly difficult conditions are created in the steam room, where saturated heated water vapor, in contact with the flooring, cools and condenses. The resulting water penetrates into the material, creating a favorable environment for various harmful organisms. The destructive process is accelerated by an elevated temperature, which at the floor surface can be 30-40 degrees.

Not much better conditions in the washing department. Here, streams of water (both warm and cold) pour onto the floor from showers and various containers for watering. Moreover, water is mixed with detergents, which increases the aggressiveness of the impact.

A more favorable environment arises in the dressing room and the rest room. However, in these rooms, one should not discount the possibility of steam from the steam room through the open door, as well as moisture from wet feet.

Ventilation of the floor in the bath prevents the appearance of fungus and rot, and also draws out excess steam

Ventilation of the floor in the bath prevents the appearance of fungus and rot, and also draws out excess steam From the side of the soil, moisture is caused by natural conditions. The most dangerous is the presence of high-lying groundwater and a rise in the water level during prolonged precipitation, snowmelt and flood situations. In principle, drainage systems and waterproofing layers in the floor structure are intended to protect against the effects of this moisture, but they cannot completely exclude the penetration of moisture from below.

nuance! Do-it-yourself ventilation of the floors in the bath is considered an effective way to deal with the problem of dampness.

By providing an influx of fresh air, it accelerates the drying of the material between bathing procedures. It does not allow condensation to accumulate on the surface, does not allow microorganisms to actively develop, and removes polluted air from the room.

Principles of organization of ventilation

Floor ventilation in bath rooms can be carried out by various methods. One of the most important elements of the system is the creation of ventilation spaces in the floor structure, which eliminates the accumulation of moisture inside, between the layers. The main system can be based on several characteristic structures: ventilation under the floor in the sauna, general ventilation of the sauna room, blowing warm air.

Structurally, any ventilation of a room should include an inlet for fresh air mass and an outlet for polluted air. To do this, all bath rooms are equipped with inlet and outlet ventilation openings (vents). In addition, if necessary, air ducts (air ducts), dampers, protective grilles are installed to ensure air supply at the right time and in the right direction.

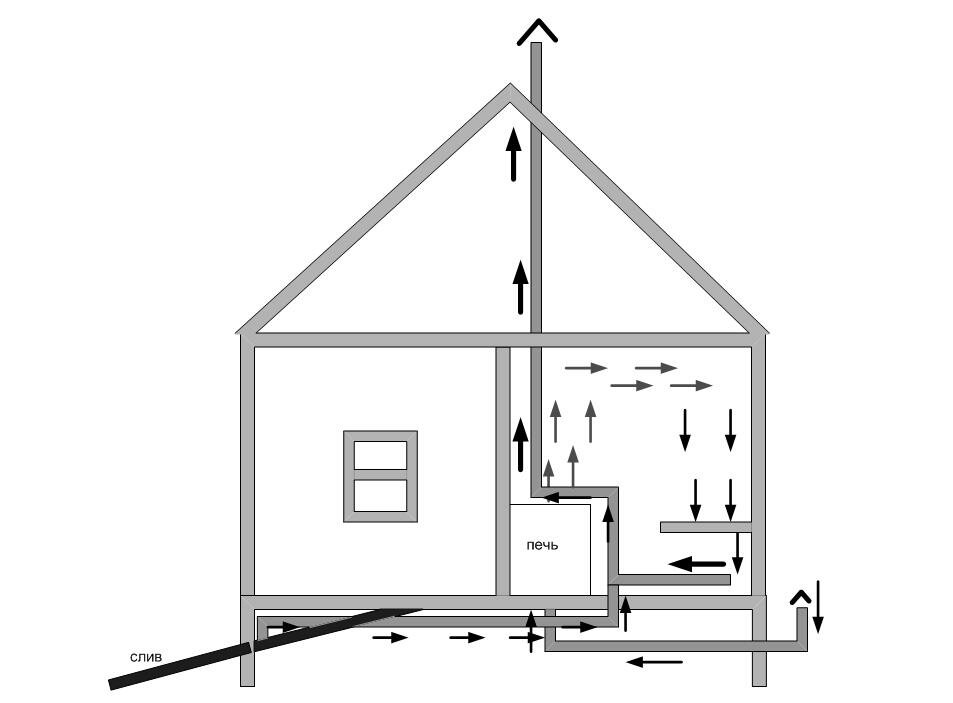

By the nature of the provision of air flow, this process can be natural and artificial (forced). The first option is considered classical, in which the movement of the air flow occurs spontaneously in accordance with the laws of convection, i.e. as a result of a temperature or pressure gradient. When such floor ventilation occurs in the bath, the flow pattern has a characteristic appearance (Fig. 1).

Nuance! In a natural scheme, the inlet vent should be located as low as possible (under or near the floor).

The air, heating up, will rise up, and this is where the outlet should be located. It is not recommended to ventilate the floor in the bath through the attic, i.e. through an opening in the ceiling. A closed space is formed in the attic, where all harmful secretions gradually accumulate, which can then return to the bathhouse through the hole, but already in a concentrated state.

Figure 1. Natural ventilation occurs due to the difference in air pressure in the steam room

Figure 1. Natural ventilation occurs due to the difference in air pressure in the steam room Forced ventilation of the bath floor is based on the use of special equipment that creates an adjustable air flow in the required direction. It is possible to use the following types of artificial ventilation:

- Exhaust type: the influx of fresh air from the outside occurs naturally, and the outlet vent is provided by an exhaust fan, which forcibly draws out the exhaust air mass.

- Supply type: forced supply of fresh air is carried out using an inlet air fan, while its removal from the bath room occurs naturally through an appropriate vent.

- The supply and exhaust type combines the listed technologies, combining the forced supply and exhaust air.

- The general exchange system is a complicated version of the previous ventilation. A unified air circulation scheme is created using air ducts, which makes it possible to control the volume, direction and speed of the air flow.

There is an option for outflow ventilation through the floor in the bath to the outside

There is an option for outflow ventilation through the floor in the bath to the outside System design features

When arranging floor ventilation, a number of specific conditions must be taken into account. The efficiency and comfort of the system is due to the following requirements:

- prevention of floor cooling during the bath procedure, it is especially important to ensure the absence of drafts (should not pull on the legs);

- the volume of air mass must be sufficient to perform the tasks;

- fast, optimal drying should be ensured, especially in the presence of wooden floors, when dampness is unacceptable, but excessive drying is also bad, which can cause cracking of the wood;

- arrangement of ventilation should be carried out at the construction stage of the bath, when vents of the desired shape and size are created, pipes are laid, distribution channels (gaps) are formed.

When providing forced ventilation through the floor, it is necessary that cold air is not drawn along the floor.

When providing forced ventilation through the floor, it is necessary that cold air is not drawn along the floor. The quality and characteristics of ventilation depend primarily on the location of the vents. When choosing a place for them, it is necessary to take into account climatic conditions (humidity and air temperature), wind conditions (“wind rose”), the landscape of the site, the presence of polluting sources, as well as internal factors - the type and location of the furnace, the design of doors, the presence of windows and vents.

Most often, the inlet for floor ventilation is placed in the following places, at 3 different levels:

- lowest level: in the foundation or under the floor covering;

- directly under the stove or at the level of its base;

- in the wall at a height of 35-45 cm from the floor (best behind the stove).

The most common options

Most often, when organizing floor ventilation in a bath, the following fairly simple solutions are used:

- You can ventilate the bath under the floor by creating an air draft under the floor covering. To do this, the inlet is equipped below the level of the upper flooring, and the flooring itself is raised above the subfloor by 3-5 cm. A gap of 10-15 mm is left between the flooring boards.

- Ventilation according to the Basta system. The air flow is provided under the furnace, while the outlet is arranged on the opposite side. Under the floor, the air mass is directed through a box lined with aluminum foil. The size of such an air duct corresponds to the size of the chimney duct. Thus, hot ventilation of the floor in the bath is ensured.

- Ventilation stand. Such a system is often used in a washing room. In this case, an asbestos pipe is installed, which is brought out of the bath roof, which creates good air draft. Such a riser is usually equipped with a deflector.

Ventilation according to the Basta system in the steam room

Ventilation according to the Basta system in the steam room Features of the underfloor system

Ventilation mounted under the floor of the bath has a number of advantages. In addition to helping to eliminate condensation and ensure the drying of the floor covering, the airflow hidden below cannot cause drafts, which means that the system can also be used during the bath procedure.

For effective ventilation under the floor, it is important to properly equip the drain system, i.e. constantly remove wastewater outside the bath. Ventilation is provided by the arrangement of 2 holes in the foundation. They are located on opposite walls, but not directly opposite each other. In general, the option is considered optimal when the air flow passes along a complex path, covering the maximum possible area. The vents are equipped with valves that allow you to adjust the fresh air supply time and flow rate. It is necessary to single out one of the varieties of the outlet vent - a vertical hole through the entire thickness of the foundation to the ground. Moisture drainage is also provided through this channel.

The ventilation channel under the floor is formed by jumpers (lags), which are usually used as a bar measuring 6-8 x 10-15 cm. These logs are mounted on a concrete screed, made with a slope to drain the drain. The boardwalk is laid on top of the joists, and the boards are fastened with a gap, which ensures a free outflow of water. The shutters on the vents open taking into account the outside temperature. In summer, they can be open all the time, but in winter, active ventilation should be carried out only when there are no people in the steam room.

Arrangement of warm floors

One of the most comfortable and effective options is to make a warm floor in the bath with ventilation. To solve this problem, it is necessary to direct heated air into the ventilation ducts. In bathing conditions, it can be obtained using an oven. You can use a two-section pipe, which will provide ventilation for both the premises and the underground. This pipe is directed through the sauna stove, and the air flow is divided in 2 directions: into the steam room and under the floor. It is desirable to provide such a system with forced exhaust.

In the locker room of the bath, you can build a warm floor with ventilation

In the locker room of the bath, you can build a warm floor with ventilation advice! Underfloor heating with hot air ventilation must be well insulated from the ground surface to reduce the cooling of the channel from soil water (especially in winter).

For this, waterproofing and an effective heat-insulating layer are laid. In the system under consideration, the external decking is superimposed with a tight fit of the boards to each other, without a gap. The outlet of the system is combined with the chimney, which increases the draft. The inlet and outlet are equipped with valves.

Ventilation of the floor in the bath is considered an important element of its arrangement, which helps prevent rotting of the material and increase the service life of the entire structure. With the help of ventilation, you can provide warm floors, which will increase the comfort of bath procedures. The ventilation bath system can be provided with your own hands, but for this it is necessary to take into account the specific requirements and recommendations of specialists.

State norms for ventilation of premises are regulated by SNiP 41-01-2003, the document establishes the minimum frequency of air exchange in rooms, depending on their purpose and features of use. In residential premises, ventilation must perform two tasks - to provide favorable indicators of the percentage of oxygen in the air and to remove exhaust gases.

SNiP 41-01-2003. Heating, ventilation and air conditioning. Download file

SNiP 41–01–2003

For a bath, ventilation tasks become more complicated, it must additionally remove moist air as quickly as possible (fast drying of wooden structures is ensured) and regulate the temperature in the steam room. There are cases when it is necessary to quickly reduce the temperature in the steam room before taking procedures by small children, the elderly or large people. The stove continues to give off heat for a long time, it takes a very long time to wait until the bath cools down on its own. With the help of room ventilation, you can quickly set the desired temperature and maintain it within the specified limits all the time people stay in it.

What are the types of ventilation and the method of their calculation

Ventilation can only exist when there is an inflow of fresh air and an outflow of used air into the room. Often you can find the concept of "supply" or "exhaust" ventilation. These are not quite correct concepts, there cannot be only supply or only exhaust ventilation, it is always only flow-exhaust. Why are these terms used? Thus, it is emphasized that the supply or exhaust of exhaust air is carried out in a forced way, and, accordingly, the removal or supply of fresh air occurs in a natural way.

When calculating the parameters of ventilation systems, the initial data take into account the volume and purpose of the premises, the presence of special conditions in them in terms of air indicators, the presence or likelihood of the presence of carbon monoxide or other chemical compounds harmful to health. Based on these data, state regulations establish the frequency of air replacement within an hour, it can vary from 1 ÷ 2 to ten or more.

Next, engineers determine the parameters and location of the channels to ensure the necessary intake and removal of air, taking into account weather conditions and the climatic zone. If natural ventilation cannot provide the required frequency of air changes, then forced systems are used that supply / exhaust air with electric fans. Baths have their own characteristics of each type of ventilation, consider them in more detail.

General rules for ventilation in the bath

The principles of the ventilation device in the bath largely depend on the architectural features of its design. If the floors have slots for draining water, then supply air can also be supplied through the same slots, there is no need to make a special hole.

Quite often, small windows are installed in the bath - when opened, they “turn” into exhaust holes. In addition, if the furnace firebox is located directly in the steam room, the room can be ventilated even easier - open the firebox and, by changing the position of the damper, adjust the air change rate.

These are the simplest options for a steam room (by the way, the most efficient and low-cost ones), but there are cases when the furnace firebox is located in another room, there is no window, and the floors are solid without gaps. It is on such a bath that we will focus in our article. Why do you need to do ventilation in the bath?

- For better mixing of air throughout the volume. Natural convection of air masses is not able to equalize the air temperature along the height, the difference in indicators under the ceiling and near the floor can reach tens of degrees. This negatively affects the comfort of taking water procedures.

- For the supply of fresh air. If one person is steamed in the steam room, and the residence time does not exceed 20 ÷ 30 minutes, then the oxygen concentration in the air will not have time to drop to critical values. And if several people steam at the same time in the steam room for a long time, then the influx of fresh air becomes mandatory.

Quite often, developers fall into two extremes: in order to save heat, they generally refuse ventilation or make it too strong and unregulated. Both extremes have negative consequences, ventilation should not be neglected, it is cheap, and the positive effect is very impressive. But it should be done correctly, taking into account the features of the premises, the requirements for the temperature in the steam room, the materials for the manufacture of walls and cladding.

In the event of a complete lack of ventilation, the risks of oxygen starvation increase and, if the furnace firebox is located directly in the steam room, carbon monoxide poisoning. In the case of strong unregulated ventilation, the heating time increases significantly, warm air is quickly removed from the room. But that's not all the problems - the rapid removal of warm air automatically causes an equally rapid influx of fresh air - the floors will always be very cold, and this increases the risk of colds.

Uncontrolled ventilation is fraught with cold floors

The influx of fresh air in the steam room is arranged in two places: behind the stove or under the sun loungers.

There are many air movement patterns on the Internet, most of them are made by amateurs, you should not pay attention to them. Follow only two conditions: air inflow at the bottom, exhaust at the top, placement of channels diagonally across the room.

This is quite enough to ensure normal circulation and air mixing. Everything else is reasoning about nothing, they can only confuse inexperienced developers, significantly complicate the ventilation system, make it expensive and unreliable. There are options with two multi-level exhaust valves, with two supply valves, etc. The air outlets are located at different heights.

One under the very ceiling, is used only for complete ventilation of the bath after the completion of water procedures. The second is done 30 ÷ 40 centimeters below the first and is used during washing. Some craftsmen connect them together with internal air ducts, install several control dampers, etc. We assure you that these complications do not have any visible effect on the comfort of staying in the steam room.

A few words should be said about the ventilation ducts in the bath, they are often suggested to be used in steam rooms. In large buildings, ventilation ducts are used to connect several different rooms to a common ventilation system, no matter if it is natural or forced. This is quite justified from both technological and economic points of view.

And what other rooms can be connected to the steam room with ventilation ducts? Weird question. Then why make complex channels under the wall sheathing? Wouldn't it be easier to make ordinary holes in the walls and insert ordinary pieces of pipes and grates with elementary valves into them? Of course, we will talk about a real, effective, simple and cheap way to install ventilation, we will not lay any channels anywhere. This is a universal option, perfect for both "budget" and expensive exclusive pairs.

Video - Ventilation in the bath

Natural ventilation of the bath

The most accepted option for most baths, minimal in cost and safety, and quite effective. The specific location of the ventilation openings should be taken into account, taking into account the size of the premises, the location of the shelves, the stove and the material of the building. The general rule is that the holes should be located at different heights, as a rule, the inlet (supply) 20 cm from the floor and the outlet (exhaust) 20÷30 cm from the ceiling. When choosing holes, you need to consider where the holes will be located on the outer walls. It is desirable that they do not stand out too much on the facade walls.

The dimensions of the holes are approximately 300÷400 cm2, it is better to make them larger than smaller. In case of too rapid air exchange, leading to a decrease in the temperature in the steam room, the channels should be covered with control dampers. To improve the appearance, it is better to use decorative grilles, they can be purchased at specialized stores or made independently.

Somewhat complicates the ventilation system, requires the installation of electrical equipment. Another problem is related to the microclimate in the steam room. There, high temperature and humidity are the main enemies of any electrical equipment. Fans must have a reliable protection of the housing from moisture; during connection, the recommendations of the Electrical Installation Code must be strictly observed. And in order to comply, you need to know them.

The advantages of forced ventilation - the rate of air change in the room is significantly accelerated, the control parameters are expanded. Natural ventilation is very dependent on weather conditions, in some cases it can become ineffective. Especially if the wind is at right angles to the exhaust vent. Forced ventilation works with the same efficiency in any weather and regardless of the direction and strength of the wind.

How to make ventilation in the bath with your own hands

Initial data. The architectural features of the bath do not provide for air to enter through the cracks in the floor, doors, windows or the furnace. It is necessary to make holes for both entry and exit of air. There is no internal and external wall cladding, the bathhouse is built of sawn timber.

Step 1. Decide on the location of the input and output channels.

We have already mentioned that it is better to place the inlet channel near the stove at a distance of about 20 centimeters from the floor level. Exit channel diagonally under the ceiling. This position of the inlet and outlet openings will ensure the distribution of air flows throughout the volume of the room. Also, the inlet air will not cool the flooring. Channels should be easily accessible. There are recommendations to make an exit hole in the ceiling. We are opponents of such a decision, humid air will certainly cause great damage to the entire truss system.

Step 2 Purchase or make your own grates and valves.

They can be of various sizes and geometric shapes: round, square or rectangular. At the same time, take into account the materials of the future cladding of external and internal walls, consider how the decorative grilles will be attached to them.

Important. Be sure to install grilles with adjustable gaps, only they can provide smooth adjustment of the frequency of air changes in the room.

And one more thing - from the outside of the bath, the holes should also be closed. Moreover, the closure should be as airtight as possible, to prevent moisture from rain or snow from getting on the log house crowns.

Step 3 Make holes in the walls.

The most time-consuming operation, you have to work manually. Pre-in the marked places, you need to drill holes around the perimeter. The closer they are to each other, the easier it is to gouge the wood later. When the holes are drilled, take a chisel, a chisel and a hammer in your hands and begin to destroy the timber bridges remaining between the holes. Ventilation holes should be made 1-2 cm around the perimeter more than the inserted pipe. The fact is that then this pipe must be insulated to prevent the appearance of condensate on wooden structures.

Use only a sharp chisel and a chisel - the timber will have to be cut across the fibers, this is quite difficult. If the thickness of the beam is 20 centimeters, then it is better to make half the depth of the hole from the inside of the bath, and the second half from the outside. If you have extensive experience using a gasoline saw, then you can cut a hole. But we immediately warn you that it is very dangerous to work with a gasoline saw in such conditions. You will have to cut with the end of the tire, while grabbing the tree with the lower part of the chain, the saw will be pulled out of your hands. This way of using the saw is strictly prohibited by safety regulations, remember this.

If there is a need to dilute the inlet in the wall and in the bath, then buy a pipe with an elbow. It is advisable to use not round pipes, but rectangular ones, they take up less space under the lining of the inner walls of the steam room.

Be sure to seal the joints of the elbow and pipe with silicone and wrap with adhesive tape for reliability.

Scotch metallized

Step 4 Lay foil or polyethylene film and mineral wool around the perimeter of the holes, the wool layer should be dense, without gaps. It will not be possible to make the edges of the hole absolutely even, carefully make sure that the waterproofing is not damaged by the sharp protrusions of the timber.

Step 5 Insert the pipes into the holes in the log house. They should enter with little effort, quite tightly. In order to increase the reliability of sealing and fastening, be sure to walk around the perimeter of the hole and pipe with foam. Mounting foam eliminates all invisible gaps in thermal insulation between the pipe and the wall and firmly fixes it in the desired position.

We recommend foaming the holes and after wall cladding, the foam will eliminate the gaps between the wall and the vapor barrier. During the expansion of the foam, the vapor barrier will press tightly around the uneven hole, all possible small damages will automatically close.

The pipe to the hood may not be insulated, warm air comes out through it. But we advise, just in case, to do all the operations for her. First, you will lose a little time and money. Secondly, you will make additional and reliable protection against penetration of atmospheric moisture to wooden structures.

When both holes are prepared, you can start upholstering the walls and install decorative grilles with adjustable throughput parameters.

Important. We strongly advise you to ventilate the space between the wall cladding and the aluminum foil during the installation of steam room ventilation. The work is performed according to the above algorithm with one difference. Ventilation should be either permanently closed (during the adoption of water procedures) or permanently open (during the airing of the bath). Using foil as a wall vapor barrier has many benefits. But there is one problem - the difficulty of removing condensate between the skin and insulation. An ordinary hole solves all problems and completely eliminates damage to wood.

Video - DIY ventilation

How to make a hole in a log house with a crown

If you do not want to make holes for ventilation by hand, you can drill them with a special metal crown. They are sold in stores and are inexpensive. The only problem is that the crown requires a powerful low-speed drill or a hand-held drilling machine, ordinary drills can quickly fail due to a heavy load. Another limitation is that the maximum diameter of crowns is rarely more than 120 mm. But for most baths, small volumes of this size are enough.

Step 1. Choose a drill bit of the appropriate diameter and secure it in the chuck. Mark the drilling site.

Step 2 To lighten the cutting force, be sure to lubricate the bit with machine oil. Lubrication should be repeated periodically. Once the bit is about two-thirds deep, stop drilling, remove the bit and re-lubricate its inner and outer surfaces.

Step 3 Mark the center of the hole with any thin drill. Insert a crown into a shallow hole and start drilling the timber.

Step 4 Drill as long as the bit height allows. Carefully monitor the operation of the electric tool, do not allow heavy loads. Loads are regulated by the force of pressing the crown to the bar.

Step 5. The crown does not work further - take it out and gradually remove the cut wood with a chisel or chisel. It is removed quickly, start gradually chipping holes in the corners. Don't cut the log across the grain with the chisel, only chip it along the grain, it's much easier to do the job.

Repeat the steps until the hole is through. If the timber is so thick that the drill cannot go through it on one side, go to the other. To do this, you need to find the center of the already made hole as accurately as possible. The crown has its own centering drill, but its length may not always be enough to reach the reverse side. You will have to find the center yourself. To do this, install a thin wood drill in the drill, insert it into the existing hole from the center drill of the crown and very carefully make a through hole. The more precisely you drill the center, the easier and faster it will be to work on the other side of the wall.

Video - How to drill a hole with a crown

Bath ventilation with heating

A rather original way of arranging ventilation, not only fresh air lends itself to the bath, it is immediately heated. This is very important in winter, as it is possible not only to increase the comfort of your stay, but also to speed up the heating of the premises and save firewood.

The air intake is made at the bottom of the bath and is fed into the air intake duct with the help of electric fans.

The stove has a metal chimney, a special screen is installed around the chimney, air from the duct enters the screen channels. The screen performs two functions: it protects the limbs from burns and serves as a radiator for heating the air coming from the duct. The heated air exits the screen into the steam room.

If desired, you can slightly improve the design. Install a tee with a damper on the air duct. This will allow you to take both air from the bathhouse and from the street - the possibilities for regulating the parameters of the microclimate in the room are significantly expanded.

Video - Ventilation in a steam room with heated air

Ventilation in the bath: how to do it

Ventilation in the bath is essential. First of all, ventilation is designed to ensure the safety of people who take bath procedures.

Everyone knows that when you breathe, you inhale oxygen and exhale carbon dioxide. In a tightly closed room, he will begin to suffocate after a while. And in the steam room, where the temperature is high and the concentration of water vapor, this will begin to happen even faster.

Relaxing on a shelf, you can simply not have time to get to the saving door of the bath. The price of the wrong ventilation device can be too high.

The second important factor is wood decay. Enjoying bath procedures and benefiting from them, smelling rot and mold, is very problematic. Therefore, proper ventilation in a Russian bath is a guarantee not only of its benefits, but also of the health of vacationers.

Experts believe that such a ventilation device in the bath can be considered correct, in which the air in the room is replaced three times in one hour. The ventilation scheme in the bath is selected depending on the type of structure and materials used in the construction of the walls.

General principles of ventilation in the bath

The correct arrangement of the bath and ventilation in it, regardless of the type of structure, is based on the following basic principles:

- Fresh air that enters the steam room should not violate its temperature regime;

- The already exhausted air, which contains the most carbon dioxide, should be removed from the room;

- The location of the air in the steam room should be layered: the hottest - under the ceiling, on the bench - the most comfortable and cold - near the floor.

Note!

There should be no draft in the steam room!

If all these principles are followed, then bathing procedures will bring the maximum effect for which they are calculated - the restoration of mental and physical strength.

Ventilation device in a free-standing wooden bath

Wood is considered an ideal building material for a bath. Wooden walls "breathe", so the issue of air exchange is partially solved in a natural way.

However, even in a wooden building in a steam room, ventilation is necessary. At least for quick drying of the tree after taking bath procedures.

An important role in the air exchange processes is played by the operation of the sauna stove. When water is poured onto the sauna heater, a column of hot steam is created, which rises up. As it cools, it lowers, pushing the used air out of the steam room.

Together, the above factors allow you to create the necessary humidity and temperature in the steam room, and ensure normal air circulation.

Let us consider in more detail the ventilation device in wooden baths. The main tasks for us, of course, will be to ensure the inflow of fresh air and the removal of already exhausted air. Our instructions will help you cope with these tasks.

Ensuring air flow

The correct frame is laid in such a way that the lower crowns are free. With this installation, it is possible to access fresh air from the street.

In addition, in any case, there will be gaps around the steam room door that are sufficient for it to enter. The stove in such baths is placed closer to the door so that it immediately heats up.

If the steam room is designed for 6 or more people, a separate air duct is brought to the heater, which supports the combustion process. If you make this duct double, then the problem of fresh air supply is solved once and for all.

Exhaust air removal

If the heater is heated directly from the steam room, then the exhaust air is thrown through the furnace into the chimney of the bath. If the oven is properly installed, no additional holes are required.

In order to dry the room after the end of the bath procedures, a small hole can be cut in the wall (up to 200x200 mm). At the time of heating and work of the steam room, it is closed with a special plug.

If there is a window in the steam room, such a hole is not needed. Sometimes a window from the steam room is cut through into the washing room, and either a through hole to the street or another window is already made in the washing room. Thus, when drying, two birds with one stone are immediately killed, both the steam room and the washing room are dried.

Thus, the myth that ventilation is not needed for a wooden bath is confirmed when the following conditions are met:

- The steam room is calculated for 2-4 people;

- The lower crowns of the log house are laid freely;

- The stove-heater is heated directly from the steam room;

- There is a hole or window in the wall for ventilation.

Actually, such family baths are usually built on personal plots.

Ventilation device in a free-standing brick bath

A brick structure, as well as a structure made of foam concrete, expanded clay blocks and other capital structures, is another matter. Ventilation in a brick bath is more complex.

The first difference is that the floors in a brick building must be ventilated. The thing is that the floors in the bath are constantly in contact with water, and if they are deaf, then you will have to change the boards about once every three to four years. You can not even talk about unpleasant odors and mold.

The ventilation of the floor in the bath is laid even at the stage of foundation construction. To do this, special holes are made in the foundation on opposite sides. These holes will provide through air circulation under the floor and dry the log.

The second difference is the obligatory presence in the steam room of special supply and exhaust openings. There may be several. Two air inlets are made at floor level and covered with bars so that rodents do not penetrate.

There are 4 most popular schemes for the ventilation device in the bath, from which you can choose the most suitable for you.

- Scheme No. 1. The air inlet is located behind the stove at a distance of 50 cm from the floor. An exhaust hole is cut in the opposite wall no higher than 30 cm from the floor. A bath fan is installed on it, which will circulate air.

According to this scheme, the air in the steam room is heated evenly, the incoming air is heated from the stove and rises. Cooling, it goes down and exits through the outlet. The lower it is located, the stronger the air flow will be. When using a fan, a ventilation valve can be installed on the outlet.

- Scheme No. 2. Suitable for those baths where the stove is heated from the steam room. In this case, the inflow is done directly under the stove. The flow of fresh air is sucked in by the stove, supporting combustion, and provides an inflow directly into the room.

The exhaust hole is located above the floor and a corrugated pipe is connected to it, which rises up to the level of the roof and goes outside. In other cases, the ventilation duct is made in the wall.

Note!

If the walls of the bath are made of expanded clay concrete blocks, then it is best to lay the ventilation ducts during construction.

- Scheme No. 3. According to this scheme, ventilation for the bath is arranged through cracks in the floor. In this case, the supply hole is made in the wall near the stove at a height of 30-50 cm from the floor. The air, heated up, rises and exits through the cracks between the floorboards into the basement. From the basement space, it is thrown out with the help of a special pipe.

Note! For the normal functioning of this type of ventilation, it is necessary to leave gaps between the floorboards of 5-10 mm.

- Scheme No. 4. This scheme is suitable in cases where the stove also heats other rooms.

Fresh air is sucked in by the stove through holes in the floor and, passing through the firebox, goes into the steam room and into the washing room. It is removed from the premises through the holes located below, above the floor level.

There are also combined ventilation schemes, but for their do-it-yourself device, consultation with a specialist is necessary.

To clearly understand how ventilation is arranged in the bath, the video in this article will help you.

How to mount ventilation in a bath in a steam room

Russian bath is very beneficial for health. The fundamental point in its construction is well-equipped ventilation in the bath in the steam room. In this room, as a rule, very high temperature and humidity. Properly organized air circulation is a necessary condition.

Often, many homeowners doubt whether ventilation is needed in the bath in the steam room. The proposed material will allow you to correctly answer this question and solve all the problems with the arrangement of ventilation without much difficulty and without significant material costs.

Ventilation in the steam room is necessary for air circulation

Ventilation in the steam room is necessary for air circulation Why do you need ventilation in the steam room

Proper ventilation of the sauna steam room helps to solve the following problems:

- maintaining a comfortable indoor temperature;

- health safety;

- the preservation of the wood used for the interior decoration of the steam room.

Ventilation products in the steam room help to regulate the temperature, and keep the wood from dampness and fungus longer

Ventilation products in the steam room help to regulate the temperature, and keep the wood from dampness and fungus longer If the ventilation of the steam room in the Russian bath is not properly equipped, the appearance of such negative factors as:

- rapid cooling of heated air;

- accumulation of gases during the adoption of procedures;

- premature decay of finishing materials;

- the appearance of harmful microbes, bacteria, mold, fungi;

- bad smell.

The proposed material will describe in detail what should be properly organized ventilation in the steam room of the bath, video and photo materials will clearly illustrate all the key points.

Basic principles of steam room ventilation

A specific scheme for arranging ventilation is usually selected taking into account the architectural features of the building itself, the size, number of rooms, etc. In this case, it is necessary to strictly observe the basic principles for arranging ventilation systems for steam rooms in Russian baths. If they are violated, various negative phenomena can occur that create a serious threat to the health and life of vacationers.

The fresh air inlet is located just above the floor level. In order for the incoming air to warm up immediately, the inlet is located in the immediate vicinity of the furnace.

The outlet for used air is located under the ceiling. The main thing is that the inlet and outlet for air be equipped on opposite walls.

Important! Under no circumstances should these holes be placed at the same level! The air in the interior space will not fully circulate. There will be a temperature difference that creates a serious health hazard.

The dimensions of the inlet and outlet holes are identical. They are selected depending on the dimensions of the internal space of the steam room. For 1 cu. m of air requires 24 cm of pipe diameter. If necessary, arrangement of additional air outlets is allowed.

The ventilation of the steam room is arranged in such a way that the exhaust air is completely replaced every 3-4 hours. This is required by sanitary and fire safety standards.

The vent in the bath is equipped with valves to regulate the air flow

The vent in the bath is equipped with valves to regulate the air flow The ventilation device in the steam room of the bath requires the mandatory placement of a valve system. You can use special blinds for this. This will allow you to control the amount of air entering and exiting. If necessary, the bath can be heated or cooled very quickly and without much difficulty.

You need to think about how to make ventilation in the steam room of the bath already when drawing up a project. This will allow you to correctly place all ventilation pipes, openings, etc. during construction. This will allow you to properly equip the mines, lay pipes and perform all other work. It will be much more difficult to equip the air circulation system after the completion of construction work.

Before building a bath, it is necessary to consider the location of the ventilation ducts in the bath

Before building a bath, it is necessary to consider the location of the ventilation ducts in the bath Varieties of ventilation systems for the steam room

Ventilation in the bath in the steam room (see photo) is used in 3 types - natural, forced (i.e. mechanical) and combined. The choice of a particular system is made taking into account factors such as:

- the size of the steam room and the dimensions of the building as a whole;

- it is possible to correctly place the exhaust pipes;

- the material from which the bath was built;

- use of the bath all year round or only in the summer season.

Warm air is lighter than cold air. Therefore, with properly equipped ventilation in the bath in the steam room, heated flows rise to the ceiling and are gradually drawn out through the vent. The air coming from the outside is immediately heated from the stove and passes into the room without creating a temperature difference. Here is the basic principle by which ventilation works in the bath in the steam room.

natural ventilation

The natural ventilation system provides air exchange due to different levels of pressure and temperature in the internal space (in the steam room) and outside, i.e. on the street. When the exhaust air exits through the outlet, the internal atmosphere in the room is discharged, creating conditions for drawing in cold air through the bottom inlet. In this case, special attention should be paid to the insulation of the bath. Otherwise, high-quality heating will not work.

Natural ventilation in a steam room in a frame bath is most often used for small buildings built from breathable material, i.e., from wood. Additional elements of the ventilation system in this case are small gaps in the log walls. The main advantage of natural ventilation is its low cost.

Forced and combined ventilation

A mechanical or forced ventilation system in a bath in a steam room is necessary if:

- the total area of the bath is large;

- the building was built of brick, cinder blocks, stone;

- the steam room is very large;

- exhaust pipes cannot be placed correctly;

- heavy duty oven.

Do-it-yourself forced ventilation of the steam room of the bath is mounted without any problems. It uses:

- fans;

- supply valves;

- deflectors.

Forced ventilation in the bath is suitable for large rooms

Forced ventilation in the bath is suitable for large rooms Nuance! The ventilation system in the bath in the steam room, heated with a geyser, requires the arrangement of a separate ventilation duct.

The combined ventilation system is equipped using elements of both systems described above. Fresh air enters naturally, i.e. through the lower inlet. Extraction of exhaust air masses is provided by mechanical devices.

How to choose a steam room fan

A classic duct-type fan for a steam room is not suitable. High temperature and humidity are detrimental to such devices. In the steam room, fans of a special design are used. The material for their manufacture is glass-filled polyamide. Such models are resistant to moisture and can withstand temperatures up to 130 ° C.

Glass fiber reinforced polyamide is an ideal material for steam room fans

Glass fiber reinforced polyamide is an ideal material for steam room fans The fan model is selected in accordance with the technical specifications.

It should be remembered! Ordinary room fans can only be used for the final drying and airing of the steam room after the adoption of procedures and subsequent cleaning.

If you have money, you can install a self-regulating system for ventilation in the bath in the steam room. This device will automatically provide air inlet and outlet, temperature, humidity level. It is advisable to purchase such systems only from trusted manufacturers.

Basic schemes

What can be the ventilation in the steam room of the bath, the diagram, video and other materials attached below will show clearly. You just need to choose 1 of the 4 attached options and correctly perform all the necessary work.

According to scheme A, the fresh air inlet is arranged below the stove. The outlet channel is mounted on a directly opposite wall under the ceiling.

The exhaust pipe is installed vertically. Its length is calculated so that the upper edge of the pipe rises slightly above the roof ridge. This will ensure the normal functioning of the ventilation system during strong winds.

Scheme A of the location of ventilation in the bath

Scheme A of the location of ventilation in the bath Properly selected sizes of pipes for exhaust air will ensure the natural circulation of air masses. Additional adjustment is provided by the installation of dampers.

The use of scheme B is assumed only if only 1 of the walls of the steam room can be used for arranging ventilation. Air openings are located opposite the heater. The inlet hole is raised 30 cm from the finished floor. The outlet window is lowered 20 cm from the ceiling.

Scheme B Arrangement of ventilation ducts in front of the heater

Scheme B Arrangement of ventilation ducts in front of the heater The air passing through the bottom inlet is heated by the furnace and rises in the direction of the air outlet. Mechanical pulling devices are necessary for the normal functioning of the system.

According to scheme C, it is possible to provide ventilation not only for the steam room, but also for the underground space. The inlet hole is arranged in the wall behind the heater. It must be raised above the finished floor by 20 cm.

Scheme C with air supply under the floor of the bath

Scheme C with air supply under the floor of the bath The heated supply air passes into the basement through the cracks of the leaking floor. Then it returns to the steam room and moves towards the exhaust opening. From here, the exhausted air masses go outside.

For a constantly used bath, ventilation according to scheme D can be used. In this case, the inlet is arranged at the bottom, but opposite the stove, and not behind it, as in other options. Height above the floor - 20 cm. Extraction of exhaust air is provided by means of a blower and a chimney.

In order for the ventilation in the bath in the steam room to work effectively, it is necessary to choose the right location for the stove. It is most convenient to equip it inside the steam room. If the stove is located in an adjacent room, the efficiency of the ventilation system and the heater itself will be noticeably lower.

Preparatory work

To arrange ventilation in the steam room, it is necessary to prepare the following materials:

- brick and/or stone;

- cement and sand;

- ventilation ducts;

- finished valves or material for their manufacture;

- a metal sheet;

- lining for lining the box;

- fixing material - nails, screws, self-tapping screws.

To work, you will need the following tools:

- hacksaw;

- Bulgarian;

- a hammer;

- screwdriver;

- tape measure, level, plumb;

- construction mixer;

- drill or perforator;

- a set of spatulas;

- container for mixing the solution;

- technical knife;

Work is best done in special clothing. Wear gloves and a respirator if necessary.

Supply ventilation installation

The inlet channel for supplying fresh air is located in the immediate vicinity of the furnace of the sauna stove. It is desirable that the inlet is located above a sheet of metal sheathing that protects the wood from the accidental ingress of small coals.

First, you need to make a box from a suitable material. Its dimensions should exceed the dimensions of the chimney by about 20%. The outer opening of the box is located on the outer wall. It is undesirable to place it in the basement.

If the firebox is located in the actual steam room, a convection box is additionally equipped. At the wall in which the air inlet is located, you need to lay out a podium of bricks placed “on edge”. They are laid out in 3 rows - under the wall, in the middle and on the edge.

The masonry for the oven is arranged to a height of 25 cm. It must be brought to a brick screen and must be blocked. In order for the newly incoming air to pass directly into the furnace, it is better not to lay the last 2 bricks. The butt is lined with bricks.

The convection box is mounted to the end. At the end, a blower is equipped. Under it is a protective substrate for the safety of the floor covering.

When the podium is completely ready, you can start installing the furnace. To evenly distribute the load, it is desirable to use a corner made of metal.

After the final installation, stone or brickwork is arranged around the furnace. To form a gap, it is moved 5-6 cm from the furnace. Next, a special screen is installed. It needs to form holes for the passage of hot air.

Installation of outflow ventilation

The outflow box is installed in the diametrical opposite from the inlet. It is raised above the finished floor by 30 cm. The internal area of the box is approximately 1.25 m².

Through the wall, the outflow duct is led to the ceiling and an external outlet is equipped for it. You can remove the exhaust air to an adjacent room. In this way, it will be possible to warm it up without extra costs.

Outflow ventilation can be placed on top of the ceiling

Outflow ventilation can be placed on top of the ceiling To avoid accidental burns, the chimney box must be lined with a brick or stone casing. At the same time, a special hole with a door must be left below, which will be a blower. An additional hole, equipped on top, will allow the use of the chimney as a heat pump, this will create both heating of the room and proper air circulation.

How to ventilate a Russian bath

The correct ventilation device in the steam room of the Russian bath does not involve the use of any mechanical devices. Otherwise, the heated air will be expelled very quickly. Efficiency and pleasure from bathing procedures will decrease significantly.

In the Russian bath, natural ventilation is used, where the outflow of air is carried out through the window.

In the Russian bath, natural ventilation is used, where the outflow of air is carried out through the window. Therefore, the Russian bath must be carefully cleaned, ventilated and dried after each use. For ventilation, a special window is installed in the wall opposite the door. You can use a mechanical extractor. The door must be kept open for ventilation.

It is necessary to remove leaves from brooms and random objects from the beds. Then you need to wash all surfaces and dry them with towels and / or a special absorbent cloth. This will protect against the formation of mold and the reproduction of harmful microorganisms. After cleaning, airing and drying, the steam room is ready for further use.

The steam room in the Russian bath is combined with a washing room, so it needs to be dried after each use

The steam room in the Russian bath is combined with a washing room, so it needs to be dried after each use How to warm up a Russian bath

First you need to fire up the oven. The outlet openings must be kept closed. Only input opens.

Having warmed up the room to the desired temperature, you need to open the valve of the lower air outlet pipe. This will ensure proper air circulation. The temperature will not drop.

In order to warm up the stove, it is necessary to open the valve in the stove of the Russian bath

In order to warm up the stove, it is necessary to open the valve in the stove of the Russian bath Passing into the box from below, the heated air will gradually displace cool air masses to the outlet. When passing through the box, they will provide additional heating of the room. In parallel, the ventilation of the steam room will also take place.

If ventilation is not working properly

During the use of the steam room, it is necessary to periodically check the health of the ventilation system. With good air circulation in the steam room, it is always easy to breathe, the body heats up evenly, the temperature and humidity are maintained at the required level.

If the ventilation in the bath in the steam room was installed incorrectly or became unusable over time, signs such as:

- abundant condensation on vertical surfaces;

- mold, especially in the corners;

- putrid smell;

- uneven air heating;

- drafts;

- slow setting of the required temperature;

- excessively rapid heat loss;

- an unpleasant internal atmosphere that makes it difficult to breathe.

Mold in the steam room indicates a lack of ventilation

Mold in the steam room indicates a lack of ventilation If at least 1 or 2 of the above factors are present, then the ventilation in the bath in the steam room is not properly equipped. Another option is clogging and / or damage to the system, the need for urgent repairs and / or thorough cleaning of individual elements or the ventilation system as a whole.

Clogging of ventilation ducts disrupts its operation

Clogging of ventilation ducts disrupts its operation From the foregoing, it becomes clear that it is inexpensive and not very difficult to properly ventilate the steam room of the bath. However, this requires careful observance of all technologies. The attached video "How to make ventilation in the steam room of the bath" will help to avoid mistakes.

Do you need ventilation in a modern bath?

Do you need ventilation in the bath? This question is questionable by many people. On the one hand, sanitary standards indicate the need to update the air in any room where a person is located, but, on the other hand, ventilation can cool the bath, where it is so difficult to maintain the necessary heat. The bath is a very specific institution, and one should thoughtfully approach the solution of the problem.

Steam room ventilation

The bath includes several rooms, different in their functions. Therefore, it is important to understand whether ventilation is needed in a Russian bath.

The heart of any bath is the steam room. If we consider the Russian bath, then it provides an environment of saturated water vapor with a humidity of up to 80% and a high temperature of 60-65 ° C. The classic steam room is a small isolated room. At the same time, several people can be in it for a sufficiently long time.

People inhale oxygen and exhale carbon dioxide, which can accumulate in a closed space in the absence of fresh air. In a stagnant steam room environment, an excessive concentration of carbon dioxide, sweat, bacteria and germs occurs, accompanied by unpleasant odors.

Attention! The answer to the question of whether ventilation is needed in the bath in the steam room is unambiguous - it is necessary.

The second problem is the destruction of the material of construction. The Russian bath is most often built of wood, and wood rots when exposed to moisture for a long time, especially in a confined space at high temperatures. Saturated water vapor condenses on contact with any colder surface, which causes the presence of water in the material. As a result, microorganisms that destroy wood actively develop, mold and fungi develop. If proper drying of structural elements is not ensured, then decay will quickly render the structure unusable. This problem is not limited to wood. A process with varying degrees of intensity is characteristic of any building material, incl. concrete.

An analysis of the conditions that arise during the operation of a bath steam room indicates that there is no need to doubt whether ventilation in the bath is necessary. Only the influx of fresh air will avoid sanitary problems and the destruction of the material in the steam room.

Features of other rooms

When considering whether ventilation is needed in the bath, do not think that only the steam room should be ventilated. All bath rooms are in difficult conditions.

The washing department is a constant stream of heated water, often mixed with detergents. Shower cabins can be installed here, and this causes water splashing and active wetting of structural elements. When you open the doors from the steam room to the washing room, clouds of steam rush, which condense on the walls and ceiling. In this room, the accumulation of moisture is the same acute problem as in the steam room, although the air temperature is much lower.

The dressing room plays the role of a dressing room; a furnace firebox can be located here. There are no high temperatures in this room, and the humidity may rise slightly when opening the doors to the steam room or the entrance doors when it is damp outside. A big problem is created by the furnace furnace, from which, with any chimney, the combustion products of the fuel still come out.

In more favorable conditions, there is a rest room. It provides normal temperature and humidity. However, ventilation does not interfere here either. After taking a bath procedure, you want to relax in a calm environment, and inhaling fresh air is one of the conditions for comfort.

Bath ventilation principles

Ventilation in the bath is necessary for the influx of fresh air, elimination of unpleasant odors, drying of the construction material and prevention of decay. Its arrangement is dictated by sanitary standards and technical parameters. There are no regulatory documents for private baths, therefore their owners must take into account the recommendations of specialists.

On a note! When operating a bath, you can apply the tips from the manual "Methodological recommendations for the design of baths and bath-health complexes" for public institutions, tk. their foundations take into account the basic requirements for comfortable operation.

This document proposes the following mode of air renewal in bath rooms:

- steam room - up to 5 times per hour;

- washing - 8-9 times per hour, and in the presence of an isolated shower - in it up to 11-12 times per hour; rest room - 2-3 times per hour.

- There should always be fresh air in the bath, in which only the aroma of wood, medicinal herbs and a steamed broom is felt.

- Cold air in the winter season cannot be supplied near the floor; it is better to supply it at the top, where the air mass warms up quickly.

- Before each visit to the steam room, the environment in it should be completely updated.

- Between bathing procedures, a good drying of all structural elements (floor, walls, ceiling, shelves) is necessary.

- Oxygen is burned out by a red-hot stove, so its replenishment must be ensured, with the simultaneous removal of carbon dioxide and carbon monoxide.

- When arranging ventilation, it is necessary to take into account the laws of air convection, when the heated mass always rushes up, displacing the cold down.

Features of ventilation arrangement

Ventilation in the bath can be natural and forced. In the first case, it is provided by the free circulation of the air mass coming from the street. The movement of air occurs due to the difference in temperature and pressure. This method is considered the most common in Russian baths. Forced ventilation requires the installation of air intake and exhaust devices. They allow you to suck in the required amount of air from the outside and direct it to the right place.

On a note! A simple and effective option for refreshing a steam room is the so-called salvo ventilation. It provides air flow through the open front door, and stale air exits through the window on the opposite wall.

Such operations should not be carried out if there are people in the steam room, but between ventilation procedures they give a quick effect. The duration of salvo ventilation is 3-5 minutes.

More complex options include special air inlets. There are several schemes for bath ventilation with different locations of these holes:

- classic: the inlet is made near the floor at a height of 25-35 cm behind the stove, and the exit is on the opposite wall near the ceiling 30-35 cm lower;

- with a constantly working stove: the entrance is near the floor on the wall opposite the stove, and the exit is provided through the stove chimney;

- when using an exhaust fan: the entrance is behind the stove at a height of 0.3 m from the floor, and the exit is on the opposite side a little lower (20-25 cm from the floor), which ensures air circulation throughout the room;

- entrance and exit on the same wall, both equipped with fans: one opening near the floor, and the other near the ceiling.

Ventilation in the bath is necessary in all bath rooms. It will provide comfort, sanitary safety and reduce the risk of damage to the structure from moisture. When arranging the system, it is necessary to take into account the recommendations of specialists.

Often to ensure ventilation can be limited to aeration. It is necessary to make holes with dampers, it is advisable to choose the recommended places so that the air circulation is soft and constantly maintained. If necessary, you can use forced air exchange systems.

Above the oven

Opening for outside air equipped above the heater. An outlet is made in the opposite wall, it should be lower than the entrance. The warm stream will rise as a jet of cold air and exit through the hole. Due to the constant exit of warm air, cold air cannot enter through the outlet.

Behind the oven

The air inlet can be positioned at the bottom of the wall behind the stove. The stove will heat the incoming, cold air, so there will be no drafts or sudden temperature changes. Output channels can be built in the floor. They can pass through the underground, passing into the ventilation pipe that leads the air to the street. The air outflow created according to this scheme saves heat, helps to reduce heating costs, and gives comfort to those in the bath. The main advantage is the additional heating of the subfloor. It dries well, so mold and various fungi do not grow in it.

Under the stove

The hole is being made next to the stove as low as possible. When cold air passes by the stove, it heats up, so it rises. Exit holes are made in the corner opposite the furnace. To create the first, you need to measure 1 meter from the floor, and the second is built under the ceiling. They are connected by a ventilation box, which can be brought to the roof, for example, through the attic.

Hood under the floor

The hole for the forced draft must be equipped from the back of the oven. From the level of the heater, it should rise by 1.5 m. The hood is installed under the floor, at a distance of about 30 cm. A fan is mounted in the exhaust hole. All incoming air will be heated absolutely evenly. First, the air masses are heated from the furnace, rise up. After cooling, they rush down, go out into the street. To keep warm for a longer time, you need to make the exhaust hole as low as possible.

Other popular options

- If there is no other possibility, you can make an air inlet anywhere on the wall near the stove, and the outlet is also in a free location, but in the opposite wall. To speed up air circulation, you can install a fan for the outlet.

- The location of the inlet and outlet openings on the same wall opposite from the furnace. The air will enter through the one built at a height of 30 cm from the floor, and exit through the one installed 30 cm from the ceiling. This scheme is great for baths with only one external wall.

- The inlet is placed at a distance of 30 cm from the floor behind the stove, and the outlet is also at a height of 30 cm, but on the opposite side.

- Option for baths with a continuous cycle. The blower of the heater is used as an exhaust hood, so there is a need to equip only one hole for air inflow. It must be placed opposite the brazier at the height of its level.

One of the main elements of ventilation for the bath is a chimney. Warm air escapes better through a chimney than through ventilation holes. To freshen the air as quickly as possible, you need to open the chimney along with the equipped holes.

The temperature in the bath should not be allowed to drop lower than the street temperature. In this case, there is a risk of smoke in the room in which the stove is located, usually a steam room. Cooled air forms a plug, it can be released by opening all dampers on the ventilation openings, connecting the chimney. Sometimes you have to use a special opening for ash disposal.

Video on how to make ventilation in the bath with your own hands.

Do-it-yourself steam bath ventilation

In the steam room, it is desirable to install a stove-heater. It provides the main ventilation system. Air from the steam room passes through the blower, so its circulation is already well ensured. A blower is used instead of a special exhaust device. For maximum air outflow the oven must be installed at a level lower than the finished floor. To start ventilation, you only have to slightly open the front door or window. The disadvantage of this method of ventilation is that it is maintained only during the combustion of the furnace. If the device is inoperative, the hood stops completely.

In the steam room, it is desirable to install a stove-heater. It provides the main ventilation system. Air from the steam room passes through the blower, so its circulation is already well ensured. A blower is used instead of a special exhaust device. For maximum air outflow the oven must be installed at a level lower than the finished floor. To start ventilation, you only have to slightly open the front door or window. The disadvantage of this method of ventilation is that it is maintained only during the combustion of the furnace. If the device is inoperative, the hood stops completely.