The main component of a carpentry home workshop is a circular saw. It is intended for primary processing of materials by manual or automated method. Due to the high cost of factory equipment, craftsmen most often come to the conclusion that it is best to make this machine with their own hands.

Requirements for household circular machines

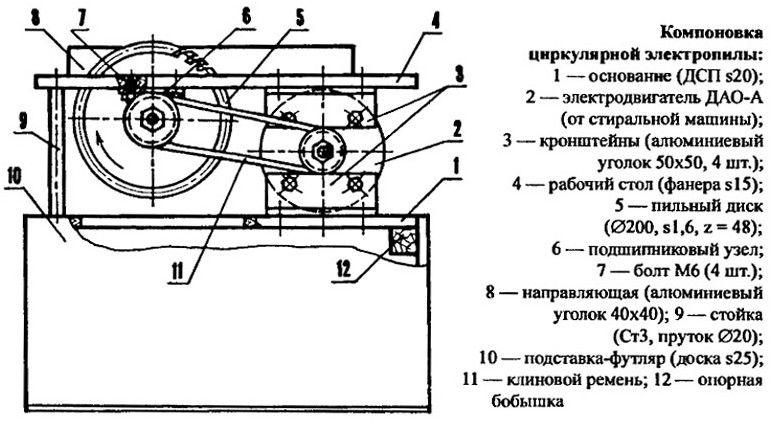

Structurally, a home-made circular saw should not differ from factory models. They consist of a support table, in the center of which there is a slot for a saw blade. In addition, the design contains measuring components, elements for fixing the workpiece and for ensuring the safety of work.

Before manufacturing, it is necessary to familiarize yourself with the basic requirements for its components. It is important that they fit each other not only structurally, but also in terms of technical parameters. To do this, you can take a diagram of a typical design of a factory woodworking machine.

Complete set of woodworking saw equipment:

- table. Must have sufficient stability, the surface of the countertop is perfectly flat;

- power point. The main parameters of the electric motor for rotating the disk are power and number of revolutions;

- additional components. These include stops for fixing a wooden workpiece, rulers for measuring.

The advantage of home-made models is the ability to choose its dimensions, performance and other technical parameters. In the process of drawing up a manufacturing scheme, you can choose the optimal height of the table, the dimensions of the tabletop, and the characteristics of the electric motor. This does not have a hand tool for woodworking.

Requirements for woodworking discs directly depend on the parameters of the workpiece, the type of wood and the required productivity speed. This is calculated on an individual basis.

Materials for the manufacture of a circular machine

After drawing up the optimal drawing for the manufacture of stationary equipment with your own hands, you need to select consumables. To do this, you can purchase rolled metal or use existing components.

The main problem is the choice of the power unit. Some recommend installing a factory-made hand saw. However, often they do not have the necessary power to process large volumes of wood. In addition, the limitation on the diameter of the disk will reduce the functionality of the equipment. Therefore, it is best to choose drawings in which there are two separate blocks - an electric motor and a shaft for mounting the disk.

The connection of the load-bearing elements of the desktop is carried out by do-it-yourself welding. Mechanical components will not provide a proper indicator of reliability, as backlash will form due to constant vibration.

- table. For legs, you can use steel corners 30 * 30 or 40 * 40 mm;

- countertop. It is made of dense chipboard, although experts consider the use of a steel sheet to be the best option. In this case, a lattice structure is made in the upper part of the table;

- electric motor. You can use any household model of a 220 V asynchronous power plant, the power of which does not exceed 1.5 kW, and the maximum number of revolutions is 2400 rpm;

- a system of pulleys for transmitting torque on a shaft with a disk. Pulleys are best taken from the factory. A tensioning system must be provided.

To fix the workpiece along the length, it is necessary to provide a support bar. It should shift relative to the plane of the disk, thereby adjusting the width of the board being processed with its own hands.

Before welding, all steel blanks must be cleaned of rust. Painting is carried out only after the final manufacture of the saw machine with your own hands.

Assembling a homemade circular machine

After preparing the components, you can begin to assemble the structure on wood. Drawings are drawn up in advance, on which all the parameters of the elements are indicated: dimensions, welding places, mandatory processing zones.

First, the frame of the saw machine is assembled with your own hands. It is necessary to provide places for mounting the shaft with the disk and the electric motor. Pulleys should be located on the outside. This is necessary for the periodic tightening of the transmission belts and the prompt implementation of repairs.

According to the diagram, a slot is made in the center of the tabletop through which the disk will pass. The edges of the material must be processed, but the countertop must be even. The plane of the disc must be strictly perpendicular to the surface of the table. Recommended slot dimensions: width - up to 5 cm; length - up to 400 mm.

The motor control unit is located in front of the cutting area. This will help prevent chips from getting into electrical components.

To get acquainted with an example of making a circular saw with your own hands, it is recommended to watch the video material: