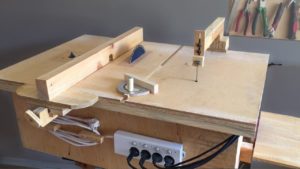

Many joiners have a large number of different saws. Some can be worked without additional devices, but the circular will be difficult to use manually. A table for a hand-held circular saw, made by yourself, is a very real way to save money and provide yourself with a comfortable cut of a large number of materials. Moreover, it is not difficult to make it, the main thing is to draw up the drawings correctly and provide yourself with the necessary tools.

A circular table made from a manual circular saw with your own hands will provide comfort when cutting, as it will be made based on your desires. The work surface will be a convenient size, which is difficult to find in a store where there are mostly standard worktops. Moreover, there are situations when the need for a router table arises unexpectedly and the purchase option is completely eliminated. Do not despair, using the advice of skilled carpenters, you can create a model that will be no worse than the store version.

1

2

3

Circular saw table features

Making a table for a circular saw with your own hands is very simple, especially if you have at least a little experience in carpentry. Experienced craftsmen can assemble it even without diagrams. The design consists of two main parts:

- legs;

- smooth work surface (tabletop).

Additional departments in the form of boxes are not required, but such projects can be created if desired.

1

2

Remember that the saw itself must be securely fastened under the table, and only the blade should remain on the surface. The opening of the table for a circular saw should be a few centimeters larger than the blade so that the sawdust can easily fly down without clogging the mechanisms.

The table for the miter saw with your own hands must be made as strong as possible. Since the greater the power of the tool, the greater the load will fall on the surface. Be sure to consider this fact when choosing a material and a place for its installation. Knowing how to make a table for a circular saw, you can save a lot of money and please yourself with a more convenient use of the tool.

Inventory and requirements for the work process

Of course, the master himself decides what the table for the miter saw should be like with his own hands. Mandatory requirements include:

- safe and durable fastening of the saw;

- flat and smooth working surface of the tabletop;

- Easy access to start and stop buttons.

Homemade table can be made of wood

The stores mainly offer stainless steel products. But tables for a milling cutter and circulars made of wood are in no way inferior to them in quality, and the service life of the material does not decrease.

You can make a table for a manual circular saw with your own hands using the following tools in your work:

- boards for legs and countertops;

- wood glue;

- self-tapping screws and a screwdriver;

- jigsaw;

- plane.

In addition, you need a tape measure and a pencil, as well as wood varnish for protective properties.

Stages of work

A circular saw is quite a dangerous tool. The saw table must be positioned so that the saw is exactly in the center, without shifting the center of gravity. Based on the diagrams drawn up on the board, markings are made with a pencil, and then the base is cut with a jigsaw. After that, the resulting countertop must be carefully sanded to give smoothness.

After the work done, the tabletop is turned over and markings are applied on the inside to deepen under the sole of the circular. The grooves are created with a milling cutter. The saw is installed in a homemade table, carefully fastened and tested for strength.

When making a table for a circular saw with your own hands, do not forget about the stiffeners. They significantly strengthen the structure, especially in conjunction with self-tapping screws.

The legs for the manual circular are attached last. The dimensions, as well as the height, depend on the master, the main thing is to fasten them to bolts and self-tapping screws with high quality. You need to put them slightly by surprise, and control the strength with the help of the same stiffeners.

Working with electronics

Making a do-it-yourself circular table with standard drawings is quite simple, but you also need to take care of the power supply. If the master is well versed in electronics, then the best option would be to bypass the start and stop buttons, and fix them in a convenient place. A more simplified option is to pull the start button of the saw blade and turn it on with the power cord. But this method is not very safe, since in an emergency the equipment will not be able to turn off automatically.

Safety at work

Remember that there should not be any foreign objects on the table on which the cut takes place. If the saw blade is out of balance with your own hands, you should immediately fix the problem.

Be sure to use protective goggles for your safety.

Do not hold wood material close to the saw blade, it is unsafe. Be sure to wear protective clothing, goggles and gloves for work. Remember that it is not enough to make a circular table with your own hands, you also need to monitor its condition in order to be safe.