Some building materials from which walls are erected immediately imply the need for exterior decoration of the house: the picture is very unsightly. Others may lose their appeal over time. And the third case is extensive fissure formation, which is “treated”, but the results remain visible. In all these cases, the question arises: "How to sheathe the house from the outside." Moreover, most often it is required to “sheathe” - without the use of a solution or other similar means that require a lot of money and time. I want to do everything quickly and, very preferably, inexpensively, and even, if possible, with my own hands. Oddly enough, but the choice of materials and technologies is, and considerable.

Basic Rules

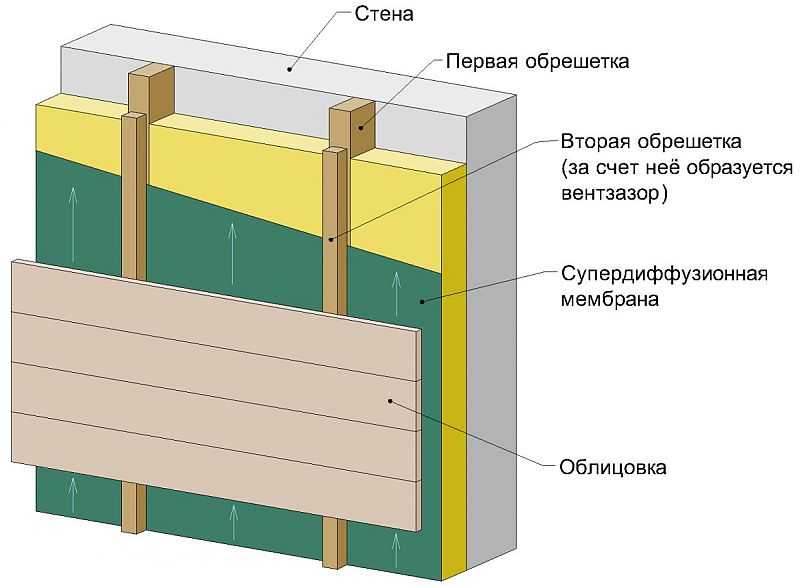

When choosing materials for cladding a house from the street, be sure to remember that in order to maintain normal humidity in the premises, the vapor permeability of materials must decrease from inside the room to the outside. That is, the exterior finish should conduct steam better than the material of the walls. Then the increased humidity, which is typical for our homes, will be removed through the walls in a natural way (explanations in the photo).

If this principle is violated, moisture will accumulate at the boundary of materials with different vapor permeability. It condenses, creating conditions for decay, the development of fungi and mold. In winter, it freezes, destroying the material of the wall and / or decoration. Sooner or later, such a system will have to be dismantled and redone.

The trouble is that only wood meets this requirement. Most of the other materials for the exterior of the house has a low vapor permeability. The problem is solved in two ways:

Today, the second option is becoming more and more popular. Very effective heat-insulating materials have appeared that allow to reduce heating costs by several times. But they have very low vapor permeability (expanded polystyrene and extruded polystyrene foam). When using them, only the second humidity control scheme is possible. When choosing how to sheathe a house, consider these points.

wood paneling

Wood in construction and decoration has been used for centuries, and it looks like it will be relevant for a long time to come. All thanks to the excellent appearance and the ability to regulate the humidity in the room. This is perhaps the only material that will easily remove excess moisture, no matter what material the walls are built from.

Wooden sheathing can have a completely non-standard look: different colors and sizes, different directions. It's simple and the effect is amazing

The most popular wall cladding materials are block house and timber imitation. There is also a lining for exterior decoration - it has a greater thickness, compared to the one intended for the rest, it is no different.

The block house imitates the surface of a rounded log - the front part has a rounded shape. Imitation of a bar is very similar to a planed bar. Both types of cladding are attached to the crate, then sanded and coated with protective impregnations, optionally varnished or painted.

What lumber looks like for exterior cladding of a house

If you can’t decide how to sheathe a house of foam blocks on the outside, consider wood cladding. In this case, a crate (metal or wooden) is nailed to the walls. If necessary, a heater is laid between the planks - basalt wool (styrofoam or polystyrene foam cannot be used), and then the wooden sheathing is nailed.

This building is sheathed with imitation timber. Under the skin there can be a brick, a log house, a frame or any of the building blocks

If you need the cheapest option, for most regions of Russia this is an ordinary planed board. Its thickness is from 40 mm, it is stuffed in the same way as a lining or a block house on a crate, the lower end of the upper board goes 10-20 mm onto the one located under it. It turns out the principle of the bump. So you can cheaply veneer a country house or even a residential one. With proper processing, such a lining has a very good appearance.

What is the cheapest way to sheathe a house outside? For central Russia - a planed wooden board

The disadvantages of such a finish are the same as for any wood: it can be damaged by pests, rot, without proper care it quickly loses its decorative effect, becomes dark and ugly. If you want to sheathe a house and not think about it for years, this is not your choice. Wood paneling requires maintenance, and, most often, annual maintenance.

Siding

In some regions, boards and other lumber are not the most affordable materials. In this case, it is cheaper. This is the option when, after finishing once, you can forget about it for a long time.

If you are thinking about how to decorate a house from a bar from the outside, perhaps your option is siding.

Since the sheathing is nailed to the crate, the facade is ventilated. If you need to inexpensively finish wooden walls (from timber, logs, shields), siding is one of the options. It can also be used for building from any other material: foam block, aerated concrete, slag filling, etc. This cover is universal.

Vinyl

Siding is made from polyvinyl chloride (PVC) and is therefore also called vinyl siding. It is a strip of material with a width of 205 and 255 mm, a thickness of 1.1 mm and 1.2 mm. On the longitudinal edges there is a lock on one side, on the other - perforation for fasteners (self-tapping screws are more often used).

The siding is also attached to the crate. It is recommended to use a special metal one, but impregnated wooden blocks are quite suitable. Only regular starting and side lanes will be needed. The only caveat: the self-tapping screws need to be “short” a little, leaving a backlash in order to compensate for temperature changes in materials. With this installation, the siding will not crack from the stresses that have arisen.

The advantages of this material for exterior cladding of the house: low prices, easy installation.

The disadvantage of vinyl siding: it quickly fades in the sun, so it is advisable to use soft colors. It has a fairly wide operating temperature range: from +50°C to -35°C, but even in slight frosts it becomes brittle and easily damaged.

Another point: the houses sheathed with siding, which have a broken configuration, look good. If the building is rectangular, without architectural excesses, it does not have the most attractive appearance (in confirmation of the photo below).

If the building is just long, without reliefs and ledges, wall cladding with sadding will not embellish it very much.

Metal

Metal siding is a strip of thin aluminum or galvanized steel, which is coated with a protective and decorative coating. It has the same mounting system as vinyl.

Sheathing a house with metal siding is simple: you can do it yourself even without much building experience

The coating may be of polymers. Differs in reliability, resistance to burning out, other climatic factors. Its disadvantage is the limited choice of colors. The second coating option is powder coating. The color gamut is much wider, the paint lasts for years without signs of flaking.

If you are looking for something to clad the outside of the house so that the finish is reliable and bright, one of the metal siding options may suit you. It can be bent, broken very difficult, installation is not very difficult: you need good metal scissors, self-tapping screws, a screwdriver or a screwdriver. All installation features are the same as for vinyl, with the only difference being that metal can also be mounted at low temperatures.

It is not easy to harmoniously decorate a building sheathed with metal siding

From the point of view of durability, this is a good option, but from the point of view of aesthetics, it is difficult to work with it: it looks too “productive”. The building no longer looks like a residential building, but a warehouse or some kind of workshop.

basement

This is one of the varieties of vinyl siding, but it has a completely different configuration, appearance and greater panel thickness. It was developed specifically for decorating and protecting the plinths of buildings, but it was so well liked that it was also used for facade cladding. External design - for brickwork of various types and colors, with or without drawings, wild stone. Sometimes the imitation is so successful that you can understand that in front of you is not a brick cladding, but a vinyl cladding, you can only touch the wall.

Mounted, like other types, on the crate, there is perforation and locks. The difference is that the basement siding panel does not look like a long rectangle, but a certain section of the wall with curly edges. These curly edges are joined. Accordingly, the crate must be adjusted to the size of the fragment. When installing, first the edge of the panel is brought into the lock of the already installed one, matches are achieved, and then fixed. The main thing - during installation, do not tighten the screws too much, leaving the siding to move with temperature changes.

The crate can be made of treated wooden bars (protective impregnation) or from drywall profiles (galvanized). How to mount basement siding on the base, see the video. Similarly, it is attached to the wall. Area difference.

Fiber cement boards and siding

Relatively recently, a new cladding appeared on our market: fiber cement boards and siding from the same material. They consist of wood fibre, quartz, mica, cement, may contain chlorine and asbestos (some materials used only for exterior decoration). This mixture is molded into sheets, then dehydrated in several stages, and fired using some technologies. Then a protective and decorative coating is applied to the surface:

The coating can be smooth - glossy and matte, can imitate brickwork, wood and other finishing materials. Mounted on mounting rails, fastened to the wall with clamps. This material may suit you if you do not know how to sheathe a frame house from the outside: it creates a solid surface, the panel joints are sealed and precipitation will not get inside.

This house is also lined with fiber cement boards.

How to fix fiber cement boards, see the video.

Fiber cement siding is made using the same technology, only it is molded into long strips. They are basically standard: 3600*190*12mm. This material is cut with an electric jigsaw, installed on a wooden crate with an overlap (according to the cone principle) and nailed to it or screwed with self-tapping screws.

Thermal panels

Thermal panels are a material that performs two functions at once - cladding and external insulation of houses. A layer of decorative coating is applied to the thermal insulation layer at the factory. It is similar to marble or natural stone, does not burn, has low water absorption characteristics.

This finishing material is made on the basis of foam, mineral wool or extruded polystyrene foam. Depending on the type of insulation, the installation method is selected: polystyrene foam and polystyrene are glued to the appropriate composition. The joints are closed with a special aluminum bar or rubbed with paste.

Based on mineral wool, they are mounted only on a special system of profiles, the joints are also sealed.

A very attractive idea is to immediately insulate the house and revet it. Excellent appearance, and the characteristics of such a cladding are impressive. It’s just a pity that there is little operating experience and there are no reviews yet: it appeared quite recently.

There are also clinker thermal panels. Clinker tiles are glued to the insulation. The material is not cheap, but the characteristics are impressive, as is the variety of finishes.

Another option for thermal panels - with clinker tiles

The choice of materials with which you can sheathe the house at any time - in winter or summer - is considerable. There are expensive options, there are cheaper ones. In any case, in addition to cost, be sure to consider vapor permeability. Then you do not have to deal with mold and dampness.