Starting the construction of a bath, you need to understand that one of the important stages of work will be the creation of high-quality ventilation. Moreover, this applies not only to the steam room, but also to other premises (for example, a dressing room). The time spent taking bath procedures should bring only moral and physical satisfaction. Air ventilation in the dressing room is necessary to protect the wooden bath from decay. Self-made ventilation will minimize the effects of high humidity and extend the life of the entire building.

The work of ventilation in the dressing room is carried out due to the flow of air through special vents or door (window) openings. In the first case, flow control occurs with the help of special sliding plugs.

The ventilation system of the dressing room must meet several requirements:

- Ensure absolutely equal inflow and outflow of air;

- The movement of air masses should occur only from the living room to the utility room (for example, from the dressing room to the toilet). Otherwise, comfort may be disturbed by foreign odors;

- The ventilation grill must be located at least 2 meters from the ground;

- Hot air that will come out of the steam room is recommended to be used for heating the entire bath. This will save some of the resources. At the same time, in the dressing room it is better to ensure the joint operation of forced and natural ventilation;

- Air circulation in the room should be carried out as efficiently as possible - according to the three-time exchange formula. Thus, if the volume of the dressing room is 5 squares, then in one hour it must “take in” at least 15 m2 of clean air.

Do-it-yourself ventilation in the dressing room

Before creating a ventilation system in the bath, it is required to develop a scheme for the movement of air in the room. But for the dressing room, this requirement can be neglected.

Self-creation of the ventilation system in the dressing room occurs in a certain sequence:

- Even at the construction stage of the bath, it is necessary to consider the location of the door from the steam room to the dressing room. It is better if it is located near the stove, which will ensure the safety of the high temperature regime;

- On the opposite wall from the steam room, you need to create a rectangular hole 20 × 15 cm and equip it with a sliding plug;

- Install a fan in the vent, designed to accelerate air exchange;

- An outlet with a fan can be replaced with an exhaust pipe through which humid air will be vented;

- Then you need to cut out the vent, designed for the influx of fresh air masses. It should be located at a height of 50 cm from the floor;

- If the firebox "goes" into the dressing room, then under the floor covering it is necessary to equip a ventilation duct.

How is additional ventilation of the dressing room

Fresh air enters the pre-bath room through the lower vent, located 50 cm above the floor covering. And the recycled heated air is discharged through a ventilation pipe, an upper vent or even a window in a window opening.

Signs of improper ventilation

Improper arrangement of the ventilation system threatens with many troubles. For example, the temperature in the room will rise for a very long time, and in some cases, it is simply impossible to raise it to the required levels. In addition, there is a high probability of carbon monoxide concentration and excess humidity.

The fact that ventilation was created incorrectly is indicated by several signs:

- Accumulation of condensate on walls and ceiling;

- There is no greasy coating on the exhaust pipe;

- There is an unpleasant, musty smell in the room;

- When a burning splinter is brought to the vent, the flame does not deviate to the side.

When constructing a dressing room, it is necessary to take care not only of its ventilation, but also of insulation. The room should be provided with a comfortable temperature and the absolute absence of drafts.

The parameters of the dressing room should be sufficient so that at least 2-3 people can fit in it. Approximately 1.3 squares are calculated for each visitor. Failure to comply with this requirement will result in significant inconvenience.

Conclusion

Dressing room - a room that plays an important role in a comfortable visit to the bath. In this regard, it is necessary to take care of its functionality and comfort, which cannot be provided without creating a high-quality ventilation system. Good ventilation will have a beneficial effect on the health of visitors and ensure the long-term operation of the premises.

Qualitatively equipped ventilation in the bath solves two major problems:

- providing people with the necessary amount of fresh air during procedures;

- a quick decrease in humidity and drying of the bath after they are completed.

At the same time, the required temperature is maintained, comfortable conditions are provided, the risk of musty smell, fungus, mold is eliminated, and fuel consumption is reduced. If proper ventilation is not organized in the bath, then its wooden structures become unusable in just a couple of seasons.

Reliable ventilation of the bath protects from the effects of carbon monoxide gas during stove heating.

If necessary, ventilation can solve the problem of quickly adjusting the temperature. In some cases, sick people or children require an accelerated decrease in temperature and its further maintenance at a new level.

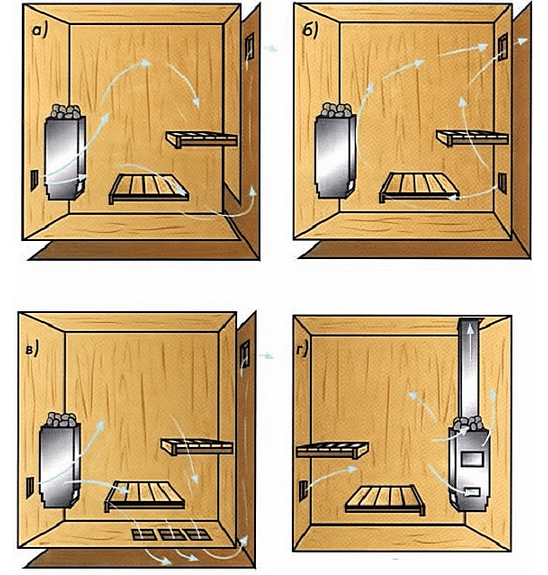

According to current standards, high-quality ventilation of the bath should provide an air exchange rate of 5 ... 10 room volumes per hour.

Natural or forced supply and exhaust air exchange using a fan can be used. Natural ventilation for a bath is characterized by simplicity, no energy costs, and reliability. Its feature is the obligatory presence of air inlet / outlet vents with a control damper device.

The combined version uses a fan - to intensify air exchange. For a mechanical type of ventilation, the control is carried out by humidity and temperature sensors.

Efficient ventilation - necessary in all areas of the bath

Proper ventilation for a bath should comply with the following principles:

- when designing a bath is selected

- arrangement of ventilation ducts, inlet and outlet vents is carried out during construction;

- the area of the exhaust opening necessarily exceeds the area of \u200b\u200bthe inflow opening, otherwise it will not be possible to achieve access to the required amount of fresh air;

- the calculation of the area of the ventilation hole is made from the dependence of 24 cm2 of the area of the vent per one cubic meter of the volume of the room;

- it is forbidden to place the exhaust and inflow openings on the same straight line in order to avoid violating the correct air circulation;

- be sure to equip the ventilation valves for the bath at the inlet and outlet openings.

The presence of adjustment of the free section of the inflow and outlet allows:

The presence of adjustment of the free section of the inflow and outlet allows:

- significantly accelerate the achievement of the desired temperature of the steam room with closed ventilation;

- achieve comfortable conditions by adjusting the intensity of air exchange;

- adjust to weather conditions.

Combined ventilation in the bath requires the use of fans with a protection level of at least IP44 with a heat resistance of about 130 degrees.

Do-it-yourself ventilation in the bath - device features

Proper and effective ventilation in the dressing room is organized according to the following rules:

- hourly productivity should be three times the volume of the dressing room;

- the inflow must correspond to the air outlet;

- air movement is directed from the residential area to the economic one;

- the most effective is the combined air exchange with an exhaust fan;

- the ventilation grill is arranged at a two-meter level from the ground.

Consider how ventilation is performed in the dressing room of the bath with your own hands:

- the door from the steam room should be as close as possible to the stove to ensure a comfortable temperature regime;

- on the opposite side of the steam room, they make an outlet 0.15x0.2 m with an adjustable damper;

- install an axial exhaust fan;

- the supply vent is performed at a height of half a meter above the floor;

- under the floor of the dressing room, an air duct for the exit of hot air from the steam room is equipped, improving heating.

It is extremely important to ventilate the floor in the bath, allowing it to dry quickly and ensure the durability and reliability of the coating. Basic rules for its implementation:

It is extremely important to ventilate the floor in the bath, allowing it to dry quickly and ensure the durability and reliability of the coating. Basic rules for its implementation:

- in the subfield they make a cement screed with a slope to the drain pipe;

- brick pedestals are used to fix the floor log;

- the foundation of the bath under the flooring should have air holes on opposite sides, but not opposite to each other;

- when laying the flooring between the boards, gaps of about 8 mm are provided;

- equip the mark of the finishing floor above the level of the blower of the furnace;

- Ventilation vents in the subfield must be provided with control dampers and protective grilles.

5 best ventilation schemes for a bath

The best results are given by the ventilation of the bath - the scheme of which corresponds to one of the five main options.

According to the first air exchange scheme:

- an air inlet is made behind the stove 50 cm above the heater mark;

- the exhaust outlet with a fan is placed on the opposite wall at a level of about 250 mm above the zero mark;

- the cold air stream warmed up by the stove goes under the ceiling, cooling down, it goes down to the hood hole;

- uniform heating of fresh air is guaranteed.

According to second scheme for air exchange:

- air supply and exhaust openings are made on the same wall opposite the furnace;

- the inflow vent is located at the bottom 200 ... 300 mm from the floor, and the hoods at the top 200 ... 300 mm below the ceiling;

- put a fan in the exhaust hole;

- in the process of circulation, the flow of cold air goes to the stove, is reflected from it upwards and under the ceiling goes to the hood.

The scheme is used when there is only one external wall used for air inlet/outlet openings.

According to the third scheme ventilation in the steam room is carried out as follows:

- the supply outlet is placed behind the stove 200 mm above the floor;

- the hood hole is placed on the opposite wall also 200 mm above the floor mark;

- to intensify the hood, a fan installed in the exhaust vent is used.

This scheme is characterized by fast, uniform air heating, freshness and comfort.

Fourth scheme used for steam rooms with a leaking floor:

- an inflow hole is made behind the heater 200 ... 300 mm above the floor;

- the air is heated, passing the heater, and falls under the floor;

- from there, the exhaust air goes up through the ventilation pipe and is discharged over the roof.

During the continuous operation of the furnace, the steam room is ventilated according to the fifth scheme:

- an air inlet is made opposite the heater on the far wall;

- air outlet is carried out through the furnace blower.

Often ventilation in the steam room of the Russian bath is performed according to the sixth scheme:

- the inflow occurs through an outlet in the lower part of the wall behind the heater;

- two exit holes are made on the opposite wall;

- exhaust openings are connected by a flexible pipe and equipped with dampers;

- during procedures, the upper opening is closed;

- for quick ventilation and drying of the steam room, both vents open.

Given the sensitivity of wood to high humidity, for ventilation of a bath from a bar is necessary:

Features of sauna ventilation

While the principles are similar, sauna ventilation has some peculiarities. The following air exchange rates are recommended for different sauna rooms:

- shower room - 50;

- massage room - 5;

- steam room - 5;

- rest room - 3.

Air supply and exhaust openings located on opposite walls are spaced diagonally.

Most often, ventilation for a sauna is performed according to two schemes:

- Includes an air inlet behind the stove above the floor. From the opposite wall, two exit holes are made connected by a ventilation duct. The first outlet is made 100 cm above the floor, and the second below the ceiling. This arrangement improves the uniformity of air exchange throughout the volume of the steam room.

- Provides a supply outlet at the furnace slightly above its level. The hood hole in the opposite wall is arranged 50 cm lower. For efficient exhaust, a fan is installed at the outlet.

Bathing in a bath is a process of cleansing not only the body, but also the soul, it is an ancient ritual that has its roots in ancient times. Going to take a steam bath with a good company is a synonym for a pleasant stay with a useful purpose.

Dressing room - a bath room in which it is also important to ensure proper ventilation

Happy owners of home saunas should try hard to provide the building with all the elements necessary for its quality work. The article talks about such an installation detail as ventilation in the dressing room, because proper ventilation must be provided to each room.

Why is it needed and why is it useful

A small room that opens the entrance to the bathhouse, which serves as a kind of corridor and a changing room, as well as a resting place, is called a dressing room. The floor in it is usually made of moisture-resistant wood, and the ceiling is endowed with a heat-saving function. The walls of this room are insulated with wool.

The area of the dressing room is calculated according to the principle of 1.3 m2 and more per person. If seasonal summer buildings do not need additional insulation, then year-round ones require certain conditions of maintenance in the cold season.

In addition to heating, ventilation must be present in the room. It performs the function of protecting the dressing room from excessive moisture, dampness, and various fungi, thereby preventing rotting of the wood from which the building is made. The influx of fresh air replaces the remote one. An improperly equipped ventilation system and insufficient heating can lead to the formation of condensate in the dressing room.

Visitors to the baths expect a long and comfortable pastime, and a well-installed ventilation system will help ensure it. One ventilation to maintain a sufficient temperature in the room will not be enough.

High-quality equipment will require a lot of money, but it's worth it. On cozy winter evenings, sitting in a warm sauna, you will not regret the money spent. The influx of fresh air is provided by a ventilation circulation, and this allows a person to breathe normally in the steam room.

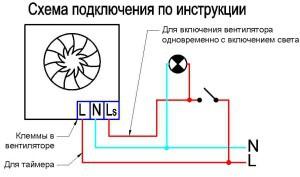

Depending on the process regulator, the ventilation in the bath is of the following types: natural, mechanical and combined. The first, according to the principle of operation, is based on the difference between internal and external pressure, the second - on the operation of special devices, and the mixed one - on the operation of fans.

Make sure the system is functioning correctly. Ventilation should not:

- incorrectly distribute air flows, directing coolness to the wrong destination;

- break the usual degree of the bath;

- eliminate the necessary air.

Failures and even life-threatening situations can result from system malfunctions. In addition, the comfort conditions and the smell in the room will leave much to be desired.

Unpleasant smells, disturbed comfort conditions and even an increased risk of endangering the life of visitors are the consequences of improper ventilation.

Principle of operation

In addition to windows and doors, air enters the building through special vents. Sliding plugs help regulate the air circulation process. Intensive ventilation can be created by installing a fan in the exhaust opening.

What parameters should air ducts have for the successful operation of the system:

- size - 15-20 cm;

- the upper air should rise 2 m above the floor;

- the lower one is 50 cm, located on the opposite side from the upper one.

It is easier to provide ventilation for a small room, but sacrificing space is also not an option.

The operation of ventilation in a bath building directly depends on the operation of the stove. The furnace is located in the underground channel. Its function is the passage of air and further heat exchange. Through a pipe, it is connected to a metal sheet with a fuse lined with bricks. This will make the air in the sauna fresh. The ventilation box is protected from damage by a special grille.

For the purpose of a more detailed acquaintance with the device of the ventilation apparatus, it is proposed to view its diagram.

Self-installation of ventilation

If you decide to equip the air regulator with your own hands, you should carefully read the theoretical information and watch the necessary videos. Be sure to use the scheme when working on the arrangement of ventilation.

It is recommended to start with the floors. Some owners believe that this part of the room does not need ventilation, but this is not entirely true. Since the floor is constantly wet, without intervention, it can gradually deteriorate. Therefore, it is worth doing a few vents in it. The distance between the floorboards should be about 1 cm.

Do not forget that after each session the floors must be dried. The best option for a well-established air circulation in the steam room is when the ventilation duct is laid right next to the metal sheet. The box can be no more than 1/5 part larger than the chimney. It is most rational to place the firebox directly in the steam room.

Below are five basic options for ventilation schemes for dressing rooms. To determine which one is right for you, read each in more detail.

- The location of the inlet is behind the stove, the outlet is opposite it. For uniform heat transfer, a fan is installed in the outlet. The outflow of air occurs through the hood.

- Both holes are located on the same wall: the upper one is at a distance of 30 cm from the ceiling, the lower one is at the same distance from the floor. The fan is also present in this variant. The heated air from the oven goes to the exhaust and leaves the room.

- The entrance is behind the stove at a height of 20 cm from the floor, the exit is opposite it. Through the fan, cold air is sent from the steam room to the street.

- This principle is good for a bath with floors and slots for water drainage. The inlet is located behind the stove 30 cm from the floor, cold air makes its way through the floor to the ventilation pipe before leaving the room.

- If your bath has a constantly running stove, make a hole directly opposite it. The air in this case will be drawn out through the chimney and the firebox.

To adjust the temperature in the steam room and change the quality of the steam, experts advise installing plugs that can close the inlets.

Now you know how to make ventilation in the dressing room. It is not necessary to purchase an expensive Finnish installation. The main thing is to carefully follow the instructions and act according to the given scheme. Proper ventilation in your room is the key to success.

During the construction and repair of baths, attention is paid primarily to structural materials, stoves, insulation and waterproofing. It is assumed that natural air circulation will be sufficient for high-quality ventilation of the premises in the bath. But this is absolutely not the case, and if you approach the matter superficially, you can face serious problems.

Peculiarities

Ventilation in the bath can be done in various ways.

Depends on her presence:

- distribution of heat flows inside;

- comfort and safety of washable;

- period of operation of the building.

Water and steam are continuously concentrated there, the tree actively absorbs them. Even if you dry the building periodically, without establishing a constant movement of air, the effect will not be strong enough. In order to avoid dampness, it is required to create a pair of ventilation windows - one serves to bring in clean air from the outside, and the other helps to exit the heated one, which has absorbed a lot of water. Choosing the location of the openings, they change areas that are especially intensively ventilated. The use of a pair of outlets in the steam room and dressing room sometimes improves the orientation of the air flow in the required direction.

Of course, the size of each window and the ability to adjust the clearance are of great importance. They put valves that open fully or partially. The calculation of the volume of ventilation openings is repelled, first of all, from the area of \u200b\u200bthe bath rooms. If you make them too large, mold will never appear on the floor and in the sink, but the steam room will heat up for a very long time, and an unusually large amount of fuel or electrical energy will be consumed. Too narrow windows will not allow the air inside to cool or become dry.

All deviations from normal parameters are strictly unacceptable, which allow you to exclude the occurrence of powerful temperature changes - this not only creates discomfort, but can also provoke health problems. It is impossible to completely eliminate the difference in the temperature of the flows; it is only necessary to limit their magnitude. Normal ventilation systems are formed during the construction of the bath, while making channels and preparing openings. Windows are mounted only after the decorative cladding of the building has been completed. Therefore, you will have to enter information about the arrangement of ventilation ducts into the bath project.

In most cases, the ventilation openings are made strictly the same. The outlet can be made larger than the inlet, but according to safety rules, it cannot be smaller than the first. For the same reasons, sometimes they resort to paired exit windows. As control elements, it is worth using not doors, but valves, when closing which it is impossible to preserve the gaps. When the steam room is heated for the first time, the valves are closed 100% until the air reaches the desired temperature.

The use of elements with controlled position is also useful because the amount of air flow must be adjusted according to the season. When there are negative temperatures outside, even a very small trickle of air brings a lot of cold. Therefore, you should not open the ventilation windows completely. The cross sections of such windows should average 24 square meters. cm per 1 cu. m of internal volume. But these are only preliminary figures, and if in doubt about the result obtained, it is worth contacting qualified heat engineers for calculations.

It is categorically impossible to place ventilation windows at the same height or even directly opposite each other, since this will not allow all the air in the bath to be heated sufficiently. In addition, such a design will not allow the air masses to be evenly mixed, which means that it will be necessary to thoroughly calculate the accuracy of the location of the ventilation elements. Exhaust windows are recommended to be placed just below the ceiling, because the air immediately rushes up after heating.

Types of ventilation systems

The ventilation device in the bath varies according to the design of the room and its total volume. Natural ventilation is based on the difference in temperature and pressure inside and outside. In order for it to work efficiently, the air inlet is organized near the stove, at a level of 25-35 cm from the floor. The outlet is made on opposite walls about 15-25 cm below the ceiling. But it is important to consider that such a scheme is not good enough for steam rooms, since it is relatively cold down there, and always hot upstairs.

The natural movement of air in such a situation is too difficult to organize, you will have to very carefully and accurately arrange the components of the ventilation system. A forced circuit does not always require the use of electronic control systems, with complex panels and so on. There are simpler options when ventilation windows, placed in a special way, are complemented by an exhaust fan. The combination of such components is especially effective when the bath is located inside the house, the windows are not placed inside the outer wall, but are connected to the exits by a long ventilation box. Duct fans must be selected very carefully, because the conditions for their operation in baths differ from the usual parameters.

The peculiarity of such devices lies in the increased waterproofing of electrical circuits and main mechanical parts, in adaptation to work at high temperatures without consequences for technology. The state of supply ventilation and its arrangement in each room is adapted to individual characteristics and to the type of bath. It follows that the time spent on calculations and thinking through the project is not wasted - it will save a lot of money and time, get the best result sooner.

As already known, the bulk of the projects involve the location of the introductory windows near the furnaces at 0.25-0.35 m from the floor. With this design, the stove transfers heat to the air coming from outside, and a flow occurs that moves in the direction of the hood. Having overcome the entire distance, hot and street flows eventually cover the entire volume of the steam room, and the area where the upper shelf is located is heated the most.

In the second option, by installing an exhaust fan, it is possible to mount the inlet and outlet openings on the same wall. The air flow is directed first in the direction of the heating device. Having received a thermal impulse, it begins to rise towards the ceiling and moves in a wide arc that covers the entire room. This approach will be effective if the bath is built into the house and has only one outer wall, while there is no need to arrange a ventilation duct.

If a bath with a leaking floor is created, the introductory window is placed in the same place as in the first case., right next to the stove. When the heated air gives off heat in the upper lobe of the steam room, it cools and descends to the floor, leaving through the holes in the flooring. This technique improves the evaporation of water accumulating below and allows you to delay the failure of the wooden floor. The hood is placed either in the next room, or in isolated channels that do not allow air to return to the steam room. The complexity of the flow path makes the use of a fan mandatory. This option is used very rarely, since it is not easy to calculate everything exactly, it is not easy to foresee the details properly.

Another type provides for a continuously operating furnace, the blower hole of which replaces the hood. For the inflow, a window is made under the shelf opposite the furnace itself and at the same level. Cold air displaces the heated mass upwards, and when the heat-releasing parts of the flow descend, they go into the blower channel. There are even more complex systems when a pair of supply and a pair of outlet ventilation windows are placed (always with a forced circulation type). It is quite difficult to adjust complicated complexes, but their effectiveness is higher than in the simplest cases.

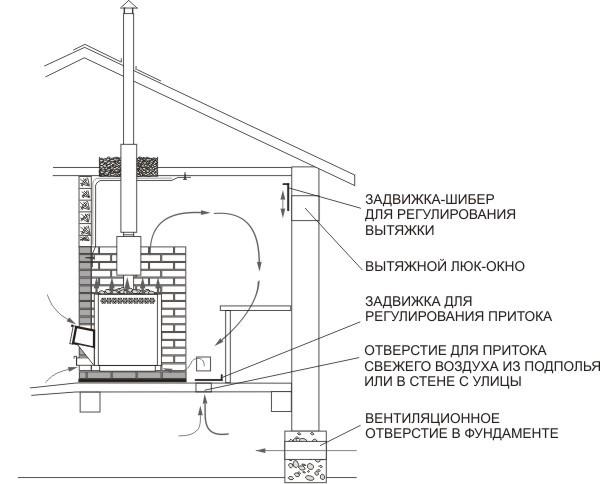

The Bastu system is the placement of air inlets(with adjustable valves) behind or below the oven. The organization of vents under the stove is not required, although it is highly desirable. Through these openings, air from the underground part of the bath enters the room, which is connected to the external atmosphere by the foundation vents. When a bath is made in a previously finished room, you need to choose a room with a pair of external walls; when preparing the basement, choose an angle that meets the same requirements. The dimensions of the inlet and outlet are calculated according to the general rules.

How to do it right?

Installation of ventilation implies that when the pipe is brought out, it is protected from the penetration of snow, dirt, rain and melt water. When this does not work out, you can organize a ventilation duct or direct the pipe up, passing it through the ceiling and roof. In the latter case, the channel is covered with an umbrella to prevent the penetration of the same precipitation and falling leaves. To arrange high-level ventilation means to ventilate and dry all rooms, structural parts of walls, floors, attics and under-roof spaces.

It is not difficult to find a step-by-step guide for installing ventilation in a bath, however, the simplest option is the use of asbestos-cement pipes and gratings, selected according to the diameter of the channel. If we talk about the technical design, the use of supply valves is recognized as the most effective and convenient design in frame-type walls. First, the valve is disassembled and circled on the wall with a circle marker where future ventilation ducts will pass. To obtain holes in the skin, a drill is used, and large-diameter drills are taken, into which a jigsaw knife can easily pass.

- using the jigsaw itself, cut out a circle;

- remove wooden parts;

- take out the insulation and vapor barrier material;

- using a long drill, they pierce the outer skin (this must be done in order to avoid mistakes when placing the outer lobe of the valve);

- mark a suitable hole outside and make it using long drills;

- saw off valve tubes along the thickness of the wall.

Then you need to mount the tube in the hole with your own hands and fix the inner segment of the valve with self-tapping screws, only after which you can put the outer part of the product. Installation of valves is recommended in the washing department and in the dressing room.

When preparing a new building, it is imperative to calculate both the size of the openings and the required fan power. It is possible to establish ventilation even when it was not originally done. A common mistake is to rely on burst ventilation and the use of stove draft to dry the air. In principle, this scheme works, but it has serious drawbacks. So, when opening windows and doors, instead of lowering the temperature, steam is released into adjacent rooms.

It does not go outside, but turns into condensate. The heating of the air is reduced only for a short time, and very soon it becomes uncomfortable again in the bath. To use the effect of stove draft for ventilation, holes are needed, but they should be made only at the bottom. This will ensure the flow of air from neighboring rooms, where fresh portions will come from outside. The damper and the doors of the furnace itself help to adjust the ventilation, to increase the flow they are opened to the limit, and to weaken them they are partially covered (to avoid the ingress of carbon monoxide).

A simple calculation can only be made with respect to forced ventilation, and the natural flow of air is much more complicated and subject to a number of different factors. Among them, special attention should be paid to the strength and direction of the wind that blows in a particular area. If the outlet is on the side from which strong winds are directed, this can lead to the inflow of the supply mass into it (the so-called backdraft effect or its overturning).

Prevention of such a negative phenomenon seems simple - it is the lengthening of the channels output in the right direction or the use of turns in them. But each turn complicates the work and reduces the speed of exit or entry of air. The solution would be to orient the inlet to the side where the wind mostly blows, while placing the outlet on the opposite side or on the roof (with a tall chimney).

Do not use a ventilation duct in a block wall, in such cases, mount it on the inner wall and partition. According to experts, the best air duct is the one built from galvanized pipes. Plastic structures can be mounted with care, carefully evaluating the temperature range allowed for them. The gap from the pipe to the walls of the hole is filled with mineral wool or more modern heaters. Mounting foam helps to eliminate gaps at the inlet and outlet.

The method of fastening the ventilation grilles is selected according to the material that serves as the base. Checking the quality of ventilation is very easy - a fire or a smoking object is brought to the hole. This will additionally find out how fast the air is moving. Most often, only an extractor hood is placed in the dressing room, supplemented by a fan.

When the furnace firebox is brought into the dressing room, it is necessary to make a special ventilation channel based on galvanized steel, passed under the finishing floors and supplying air directly to the furnace door. It is necessary to create a channel before the finishing floor is laid. One edge of the pipe is inserted into the hole and fixed in it with mounting foam, sealed with a grate. An adjustable plug is installed on the edge suitable for the furnace.

Good ventilation is one that avoids condensation on the ceiling surface. As for the subfloor, work on it begins with the preparation of a cement screed, which is tilted towards the sewer. The foundation is equipped with a pair of holes (in opposite walls, but not directly opposite each other). Air flows should go under the floor along the most intricate trajectories. The holes are closed with valves, which will allow you to adjust the rate of movement of the jet according to the current season.

In the bath, which was originally built without floor ventilation, it is required to drill a concrete base down to the ground. This will prove to be a decent replacement for full drainage when there is no desire to work on installing drain pipes. The ventilated floor must be decorated with jumpers, which are pipes or a wooden beam with a section of 11x6 or 15x8 cm. The logs are covered with processed and well-polished oak boards.

How to choose?

In the Russian bath, unlike the usual washing, it is necessary to provide with the help of ventilation the following conditions:

- temperature in the steam room - from 50 to 60 degrees;

- relative humidity - not lower than 70 and not higher than 90%;

- very fast drying of any wooden surface after washing;

- operational decrease in humidity while excluding drafts and opening doors;

- the same air quality in the steam room, as well as in the relaxation room, regardless of the season;

- preservation of all the traditional properties of the Russian bath.

No ventilation devices will help escape carbon monoxide if there is a constant supply. You will have to continuously monitor the completeness of the combustion of firewood, and only after the attenuation of all the coals, close the chimney. The organization of air flow in a chopped log bath occurs through the crowns of the walls.

This approach, for obvious reasons, is not suitable for a brick building. When the walls are sheathed with boards or clapboard, you will definitely need to use ventilation holes, otherwise the negative effect of dampness will be excessively strong. In most cases, a hole of 200x200 mm will be enough to bring pipes outside. The choice of plastic or metal should be made in accordance with the specific project and operating conditions of the ventilation system.

A bath of foam blocks must be ventilated inside the walls. The layers of waterproofing and cladding are separated by a ventilation gap, for external cladding it is 40-50 mm, and inside the bath - 30-40 mm. A typical design involves the use of battens, which already help hold the wall cladding. In addition to in-wall ventilation, all rooms are equipped with an air intake at the bottom (most often behind stoves) and an outlet (near the ceiling). The advantage of an active air freshening system is that it can be placed anywhere.

In most cases, baths made of foam blocks are ventilated in a salvo way, that is, at the same time opening the front door and the window most distant from it. Only a professional calculation is guaranteed to make it possible to find out whether artificial ventilation is needed or whether the natural circulation of air masses is enough.

Accessories and materials

A fan heater for a bath must have a certain level of thermal protection (not lower than IP44), its body is always made of heat-resistant materials. Modern devices have very high power and operate almost silently, the volume is no more than 35 dB.

As ventilation holes in attics, you can use:

- special windows;

- aerators;

- spotlights.

A well-equipped ventilation system, other things being equal, guarantees, firstly, a long service life of the building and finishing materials involved in the arrangement of the serviced premises, and secondly, the comfort and safety of visiting the latter for the user. Particularly relevant is the issue of arranging full and sufficiently effective ventilation in the bath, due to the characteristic temperature and humidity conditions and additional requirements for such buildings.

Prices for bath fans

bath fan

Video - Requirements for ventilation in the bath

The choice of the optimal type of ventilation system for servicing a bath is a topic for many hours of discussion. For example, there is natural ventilation. The cost of money, time and effort for its arrangement is minimal - the work literally comes down to drilling holes in the walls, installing boxes / pipes and valves / gratings.

Ventilation damper and grille

Ventilation damper and grille  Ventilation grilles for baths and saunas

Ventilation grilles for baths and saunas

However, it is impossible to use natural ventilation to serve all the premises of the bath. Of course, one could save money, but the disadvantage of such a solution will become obvious with the arrival of the first winter: along with the influx of fresh air from the street, cold will come in, and everyone knows the combination of frosty air with humidity - everything around will simply freeze. Therefore, natural ventilation in some rooms must be combined with other existing options in other rooms of the bath.

If the bath is equipped with a washing room or even a private pool, natural ventilation will definitely not cope with the maintenance of such premises - you will have to equip an exhaust system. And in general, the presence of a forced inflow / outflow of fresh air will be useful for both visitors to the bathhouse and its premises. Recommendations regarding the optimal composition of the air exchange system are given in the table.

Table. The choice of ventilation system for different rooms

| room | Recommended type of ventilation | Scheme | Description |

|---|---|---|---|

| Steam room, dressing room or rest room | Under aeration it is necessary to understand the organized natural air exchange. The option is most optimally suited for use in a bathhouse: air is supplied from the bottom of the furnace (for other rooms - 25-30 cm above the floor), exhaust air is removed through an opening in the upper part of the room. The work of air exchange is based on elementary physical laws: cold air from the street displaces warm air masses, which have less weight, up the room. Aeration is ideal for use in rooms with high heat dissipation rates. The presence of additional moisture contributes to an even more pronounced increase in the efficiency of the system. |

||

| Wash room, bathroom, pool room | The system is equipped with a fan and, if necessary, cleaning filters. Mechanical exhaust ventilation is ideal for use in the washroom, pool room and other damp and high traffic areas of the bath. A mechanical extractor effectively removes unpleasant odors and excess moisture, which makes the air in the serviced room safe and clean. It is impossible to use only exhaust ventilation - air rarefaction is formed. To compensate for the rarefaction, air is supplied from the street or other rooms. Along with this, the presence of forced ventilation will eliminate the likelihood of drafts. The supply ventilation system can be either natural or mechanical. In combination with mechanical exhaust ventilation, it is more expedient to use a mechanical supply system, because. the potential for natural inflow may ultimately be insufficient to compensate for the resulting rarefaction. At the heart of mechanical supply ventilation is a blower fan. Additionally, it can be equipped with an air heater, which will eliminate the inconvenience and solve the problems of ventilation of the serviced premises during the cold season. Additionally, the supplied air can be humidified or purified using appropriate devices. A mechanical system is more complex in arrangement compared to its analogue, which works according to the laws of physics: in addition to fans and air ducts, the system may include additional equipment and devices (diffusers, air distribution grilles, automation equipment, silencers, etc.). This gives an excellent opportunity to arrange an air exchange system that fully meets the wishes of the user. |

In vestibules, warehouses and other premises of a similar purpose, a natural hood is made.

Regardless of the type of ventilation system chosen, the bath must have conditions for simple ventilation. Install adjustable windows in all rooms, the location of which allows this.

Video - Types of ventilation systems

Instructions for self-calculation of air exchange

For the calculation, an elementary formula is used:

W (required volume of fresh / exhaust air) \u003d k (coefficient indicating the frequency of air exchange) x V (volume of the serviced room, determined by multiplying the width of the room by the length and height).

That is, first you must calculate the volume of each room and find for it the required indicator of the volume of clean air (in calculations it is customary to denote Wpr, i.e. inflow) and a similar indicator of exhaust air (indicated as Wvt, outflow). In this case, multiplicity factors must be taken into account. The calculated values are rounded up - the last digit in the number must be 0 or 5.

Next, the summation of all Wpr is performed. A similar action is carried out for the found Wvt. The amounts received are compared. If the total value of Wpr exceeds the total indicator Wpr, it is necessary to increase the exhaust volume for rooms with a minimum air exchange value, if vice versa, increase the inflow by the missing value. That is, at the output, the sum of all Wpr should be equal to the total value of the found Wvt.

The results of the calculations will allow you to determine the optimal cross-sections of the installed air ducts and choose the appropriate type of ventilation system. Thus, with the calculation of the volume of premises and other related data, there will be no particular problems. For greater convenience of subsequent processing, enter the found values in a simple table, as in the example presented.

In the given example, the total value of Wpr is less than the sum of all found Wvt by an indicator equal to 110 m3. In order for the balance to be maintained as a result, it is necessary to ensure the flow of clean air in the missing amount. This can only be done in the waiting room. Thus, the value of 55 m3 for the dressing room, given in the table, must be replaced with an indicator of 165 m3. Then the balance will be struck.

Proceed to the calculation of the installed air ducts and the drawing up of the structure of the equipped ventilation system.

The ventilation system is designed in such a way that the air moves through the installed air ducts with the following speed indicators:

- ≤ 5 m/s in main channels and ≤3 m/s in existing branches - for mechanical ventilation systems;

- ≤ 1 m/s - for air exchanges operating according to the natural principle;

- 2 m/s - for natural air exchange directly in the steam room.

When choosing the cross-section of air ducts, consider the above indicators. As for the profile of the box / pipe, this moment is determined by the design features of the air exchange and the bath itself. For example, air ducts with a circular cross section are easier to install than their rectangular counterparts, and it is much easier to select the required connecting fittings for round air ducts.

The relationship between the diameter of the air ducts and other significant indicators is shown in the following tables.

For example, we will work with round ducts. We select the necessary sections according to the corresponding table, focusing, at the same time, on the indicators of the table An example of calculating ventilation.

Estimated air consumption is 165 m3/hour. The air flow at this flow rate should not move faster than 5 m/s. In accordance with the table above for round ducts, we select the section according to the specified data. The tabular value closest to ours is 221 m3/h. Air duct cross section - 125 mm.

Air duct with insulation

Air duct with insulation  Flexible ducts

Flexible ducts

In the same order, we determine the optimal sections for all branches of the system in the serviced premises, remembering that in them the air flow should move at a speed not exceeding 3 m / s (in vestibules and closets - 1 m / s, in the steam room - 2 m / s). sec):

- steam room: calculated Ww is 60 m3 / h, which requires the installation of an air duct with a cross section of 125 mm;

- shower room - Ww is 50 m3 / h, air moves at a speed of 3 m / s, a 100 mm air duct is suitable;

- toilet - the indicators are similar to the shower room;

- pantry, vestibule, etc. - indicators (except for the speed of air movement) are similar to the shower and toilet.

Important! In the shower room (washing room, room with a pool), an increased level of humidity is noted. When determining the cross-section of the duct for this room, it is necessary to make an upward adjustment (in this example, 125 mm).

For greater convenience, enter all the information received in the table. As an example, you can use the template below.

Important note! In the table above, the extract volume exceeds the clean air supply. This happened because the sections were determined by the nearest flow rate, and the diameter of the air duct in the washing room was deliberately increased. In practice, such an approach will only benefit - the margin for outflow and inflow will not be superfluous.

SNiP 2.08.01-89. Residential buildings. Download file

Sanitary and epidemiological requirements for residential buildings and premises. Sanitary and epidemiological rules and regulations SanPiN 2.1.2.1002-00. Download file

Building codes and regulations of the Russian Federation heating, ventilation and air conditioning heating, ventilation and conditioning SNiP 41-01-2003. Download file

The cross-sectional area of the ventilation window is determined in accordance with the volume of the served room: 24 cm 2 for every 1 m3.

It remains to figure out only the optimal height of the ventilation holes:

- for the influx of fresh air - an average of 25-30 cm above the floor (in the steam room - near the stove);

- for the outflow of exhaust air - about 15-20 cm below the ceiling, as a rule, on the wall opposite to the supply air.

Popular bath ventilation schemes

Separate consideration deserves only options for arranging ventilation in the steam room - in the rest of the rooms everything is done according to the standard scheme, for example, like this:

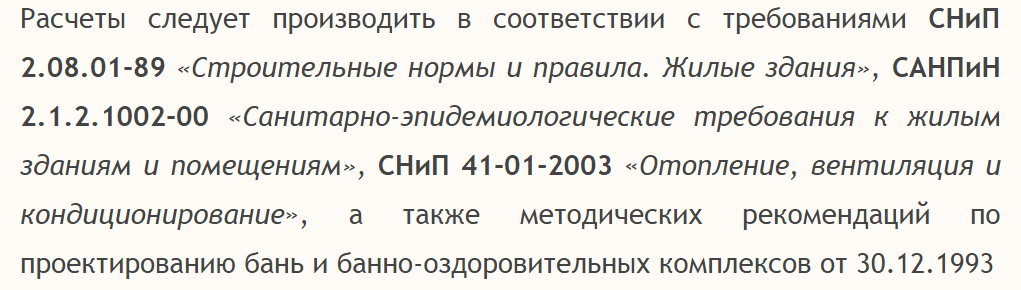

Air exchange in the steam room can be organized in accordance with 4 main schemes presented in the following image.

Scheme "a". The most popular option. The window for air flow is next to the stove, at a distance of about 25-30 cm from the floor. The incoming clean air gradually displaces the exhausted warm upwards to the opposite wall. On it, about 15-25 cm below the ceiling, there is an exhaust hole.

Scheme "b". Both holes are on the same wall. The circuit will only work if an exhaust fan is installed. Fresh air enters through the lower opening, equipped in the wall opposite to the stove. The air will rush in the direction of the stove, and then, covering the space of the steam room with an arc, move to the hood and be discharged outside the bath.

Scheme "in". The option is suitable for steam rooms with a leaking floor. The inlet opening is located as in scheme "a". Having warmed up in the upper part of the steam room, the air descends to the floor, passes through the gaps in the boardwalk, contributing to more efficient drying of the boards, and then is removed through the exhaust hole, usually equipped in another room. Also, the hood can be carried out through a separate insulated channel.

Scheme "g". Option for baths with a constantly working stove. In this case, the function of the hood is performed by the blower hole of the furnace. The supply window is arranged under the shelf, in the wall opposite to the furnace. The height of the inlet must correspond to the height of the furnace blower. Fresh air rushes to the stove, displacing the air masses heated by it to the ceiling. Cooling down there, the air descends and is removed from the bath through the blower.

In order for the operation of the air exchange system to be as efficient and high-quality as possible, before starting its installation, study and remember a few simple tips.

If your bathhouse has a bathroom or even a kitchen, equip them only with exhaust ventilation - this solution will eliminate the possibility of unpleasant odors spreading to other rooms. Alternatively, you can equip other rooms with forced ventilation, and equip the bathrooms with a natural exhaust - in this case, the air will move towards the bathrooms.

When calculating the performance of fans, it is recommended to reduce the total capacity of the supply units by 5-10% of the total performance of the exhaust units. In this case, the exhaust air will be completely displaced by the incoming air masses, and a 5-10% reserve will compensate for the inflow of air entering through windows, slots, etc., which will help to maintain a balance.

In rooms with only natural ventilation, it is recommended that opening windows be made - this will increase the efficiency of fresh air intake and reduce the risk of fungi, mold, rot, etc.

Important! If your bath has a non-standard configuration, the ventilation system project will also be individual. When compiling it, the features of the composition of the premises, their design, design features, etc. should be taken into account.

The main stages of independent arrangement of the ventilation system

Any ventilation system in any room is equipped in approximately the same sequence. Differences are present only in the characteristics of the air vents and their locations, as well as the configuration of the system (mechanical, unlike natural ones, are supplemented by various kinds of devices).

For example, the following arrangement of ventilation elements can be used.

Or its somewhat modified counterpart, shown in the following image.

Recommendations regarding the choice of the location of each opening, the type of air exchange system for different rooms of the bath, as well as the procedure for determining the characteristics of ventilation elements, were discussed earlier.

Along with this, the procedure for arranging ventilation may vary depending on which design option you prefer. There are few solutions available:

- independent ventilation in each room. An easier option. Work is limited to the installation of transoms, vents, fans and other necessary elements, if provided for by the project. Fans can be mounted both in windows and in separate channels brought outside through the wall;

- centralized system. More difficult option. Requires ventilation ducts. It is used mainly in private homes - in the case of a bath, this option will be too costly and time-consuming;

- "hybrid" option. Some rooms are ventilated individually, some are combined into a joint system.

An appropriate option for use in the bath is independent ventilation - the owner can choose the optimal characteristics of fans and other elements for each room, saving money, time and effort on the activities necessary to combine the channels into a single system.

Important! The location of some bath rooms may not allow to equip independent supply and exhaust ventilation. In this case, it will not be possible to avoid laying ventilation ducts. Alternatively, the boxes can be placed in the attic, and the ventilation holes can be arranged in the ceiling or connected to the channels equipped in the walls (the option is more complicated if the laying of such channels was not provided for by the project at the construction stage of the bath).

In most cases, the first option is used: ventilation pipes of the required length are led out through openings in the ceilings of the serviced premises and either equipped with their own fan, if necessary (easier to implement for an unprepared user, the procedure is similar to that given in the following table), or connected into a single circuit and connected to a common hood (may require the involvement of specialists).

Remember: the maximum efficiency of the ventilation system is ensured by using as short and straight air ducts as possible - up to 3 m with natural air exchange and up to 6 m with electric fans.

The procedure for arranging an independent ventilation system is given in the following table.

Important! The example considers instructions for arranging a mechanical ventilation system using fans. The order of installation of natural air exchange remains almost the same: only the stages of laying wires and installing fans are excluded.

Table. Arrangement of ventilation

| Stage of work | Explanations |

|---|---|

| The operating procedure remains the same for the supply and exhaust openings. Only the height of their arrangement and location change (possible options were considered earlier), as well as the type of fans used (supply or exhaust). The characteristics of the latter are selected on an individual basis, taking into account the volume of the serviced premises, the required air velocity in the air ducts, the required air exchange rate, etc. - all these moments were consecrated in the theoretical part. We equip the holes in the following order: - we outline the center and contours. We make the markup so that the diameter of the hole as a result is slightly (usually a 2-3 mm gap) exceeds the diameter of the installed pipe (recommendations for choosing the diameters of the ducts were given earlier); - Using a perforator, make a hole in accordance with the markings. We hold the working tool horizontally, but with a slight downward slope; - carefully take out the cut material (a hammer and a chisel will help us with this), after which we carefully clean the finished hole from dirt and dust. |

| The ventilation pipe (ventilation duct housing) is placed in the prepared hole, but before that it (if mechanical / forced ventilation is planned) must be equipped with a fan. Useful recommendation! Initially, buy ready-made kits for arranging ventilation, including, in addition to related accessories, a ventilation duct / pipe and a fan with an appropriately sized case - this way you will avoid difficulties during the assembly phase. The pipe with the fan is placed in the prepared hole, and the remaining gaps are filled with mounting foam. |

| The fan is an electrical appliance, therefore, it must be connected to the mains. Let's do this while the mounting foam dries (at least 10-12 hours). The procedure is standard: - the contours of the strobe for the cable are cut out in the wall using a grinder. Excess material is removed using a chipper; - a hole is prepared in the wall for installing the switch box (for example, you can use a puncher). The box is installed (pre-read the instructions specifically for your switch). The switch itself will be mounted after finishing; - the wire is laid in a strobe. We use alabaster to fix the cable; - connect the wire to the switch and fan. We must first study the connection diagram recommended by the fan manufacturer in the attached instructions, because. it may differ for different devices. For example, one of the most commonly used schemes is given. |

| It remains only to bring the whole structure into its proper form. To do this, we do the following: - get rid of excess dried mounting foam with a knife; - putty strobes; - we mount adjustable ventilation grilles on both sides of the pipe. For fastening we use self-tapping screws. If provided, we install additional elements at the appropriate stages of work (for example, an air heater, a filter, etc.). Each of these devices is mounted individually - we first clarify these points in the manufacturer's instructions. |

Video - Arrangement of ventilation holes

Video - Do-it-yourself ventilation in the bath - scheme