The airbrush has been successfully used in many industries for a long time. In addition, this useful tool can be found on construction sites around the world. The spray gun plays an important role in the arsenal of the home master. Let's figure out what spray guns are, which sprayer to choose for repair.

The first spray guns appeared at the end of the nineteenth century. Interestingly, they were used in medicine - for the treatment of various preparations of open wounds, as well as for inhalation of the throat and upper respiratory tract. The invention turned out to be incredibly successful and quite versatile, so its author, American Alain DeVilbiss, left medicine and organized the production of spray guns. In 1907, Alain and his son patented a manual spray gun for industrial and domestic use.

As you can see, this tool has a long history. For many years, it has been appreciated not only by furniture makers, industrial painters and car repair workers, but also by builders involved in finishing work. Previously, there were no household spray guns in our country, almost none. You have probably seen how women from the ZhEK used to whitewash the entrances with spray guns with a hand pump and a long metal fishing rod. Do you remember the Soviet blown vacuum cleaners, they also had a plastic nozzle in the form of a lid attached to them? We connect a half-liter can of paint and ...

Now everything is a little different, the tool has evolved noticeably, it has become more functional, more productive and more technologically advanced. Modern sprayers allow you to perform a huge amount of painting work in a short time, in addition, they provide the highest quality of the finished coating. If you need a smooth, uniformly painted surface, then there is no alternative to the spray gun at all. Neither a roller (even with the smallest velor coat), nor even a brush, will give such a result. The spray gun will be indispensable when processing large areas or when painting profile, curved, volumetric parts.

At the moment, there are many options for the paint sprayer, which differ not only in price, but also in a special design, different principles of operation. Accordingly, their purpose is different. All spray guns are divided into two main categories:

- Pneumatic.

- With electric motor, airless.

What is the difference between an electric spray gun and a pneumatic one?

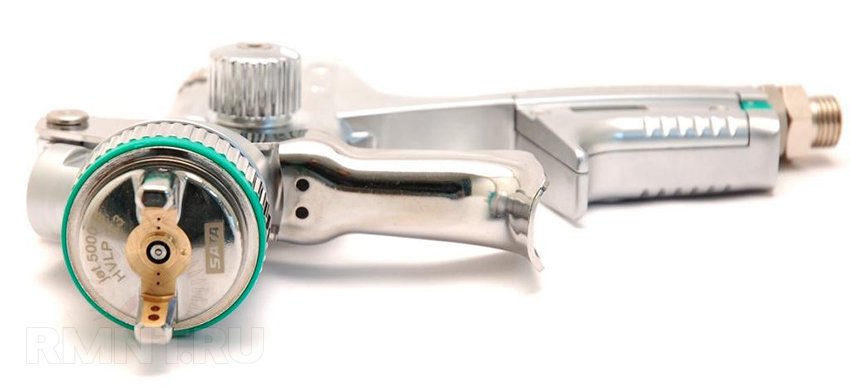

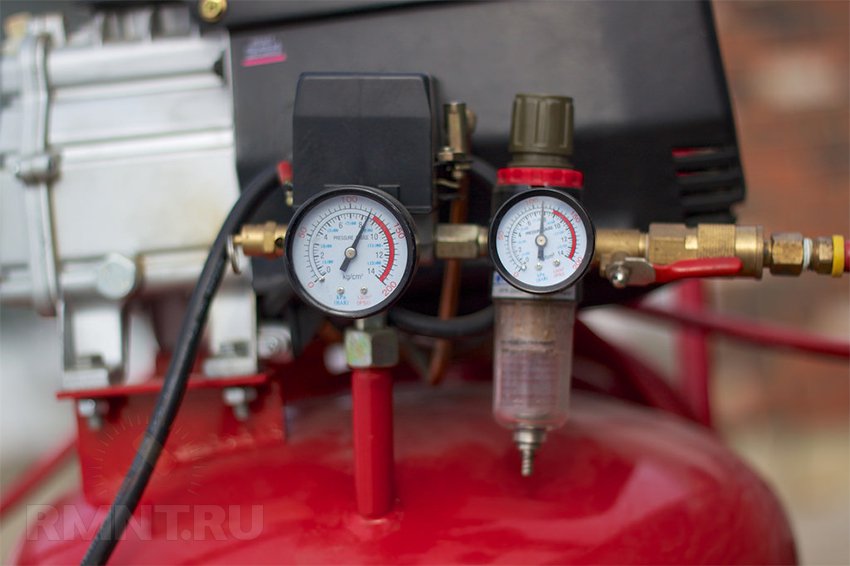

To be honest, they don't have much in common. It's all about design and how it works. A spray gun that runs on compressed air is called pneumatic. Naturally, for its operation you need a compressor with a receiver. By means of a hose, a spray nozzle in the form of a pistol with a tank is attached to the compressor - in fact, this is the spray gun. The compressor, using electricity, pumps air and supplies it to the spray gun. Pressurized air breaks the paint into tiny particles and pushes it out of the nozzle, forming a so-called torch.

Properly selected, high-quality "compressor-spray gun" kit costs a lot of money, so pneumatic spray guns are mainly used by professionals.

An electric spray gun (more precisely, it will be called “with an electric motor”) does not form compressed air, the paint is sprayed simply under pressure - using a built-in pump. Naturally, paint materials cannot be pulverized properly due to the lack of air flow. The quality of the coating performed by such a device is significantly inferior to the result available when using even the cheapest pneumatic analogues. True, in return we get a compact, inexpensive, easy-to-maintain tool that does not require any additional equipment, air purification tools. He is able to seriously make life easier for the home master, who periodically encounters painting work. The vast majority of experts consider electric paint sprayers to be household.

In fairness, we note that there are electric spray guns with a minicompressor. It's kind of an intermediate option. Here, a compressed air stream is also used for the spraying process. The compressor is clearly designed for the performance of your gun, it is made in a separate casing, they are connected by a special high-pressure factory hose. The spaced gun that we hold in our hands is much lighter than the usual monoblock electric model (there is no electric motor). Such specimens are close to traditional pneumatics in terms of the quality of painting, however, they are not cheap either - the price tag starts from 500 conventional units. Be careful, through television (all sorts of “purchases from the couch”) are now actively distributing low-grade stylization for this class of professional instrument.

Our combat kit: FIAC COSMOS 2.4 plus MIOL 80-864

At one time, our team also faced a question of choice. We decided not to play roulette, and followed the example of our more experienced comrades - we purchased a worthy, one might say, typical Italian mid-range compressor FIAC COSMOS 2.4. They paired him with a simple high-pressure pistol from a well-known Kharkov company - MIOL 80-864. The set turned out to be well balanced, there was never a case when the compressor turned off for “resuming”, or the thermal relay worked due to overheating. Its productivity of 240 l / min easily covers the "gluttony" of the gun, which is estimated at 75-210 liters per minute.

There were doubts about the capacity of the receiver - which one to take, 24 or 50 liters. As usual, we made a choice in favor of compactness, low weight - and did not regret it. The COSMOS 2.4 is only 65 cm long, weighs 30 kg, has good ergonomics and is very easy to transport across the floors of our facilities. Despite the minimum volume of the receiver, the pressure of 4-6 bar (the working pressure of our gun) COSMOS 2.4 keeps stable, without failures during active parsing, since its automation is set to the range from 6 to 8 bar. The Fiats developers used the engine not the weakest (1.5 kW), but it works stably and not too loudly. Its aluminum body with pronounced ribs dissipates heat well, and the built-in fan also contributes to this. It is quite natural that the Italian device has a clear pressure adjustment, a high-quality pressure gauge, a really working safety valve, and sensitive thermal protection. Our compressor has one drawback: after a working shift, a few drops of oil are found on the floor - apparently, some kind of gasket is “sweating”. But we decided not to intrude on the motor, because it has not let us down for several years in a row, we just always put something on it.

A little about the MIOL 80-864 pistol. We don’t paint cars, we don’t varnish windows / doors, so we didn’t bother much and bought an inexpensive high-pressure sprayer. But the quality of the coating that it allows you to get will completely and completely suit any builder. At the same time, it works quite quickly, the hiding power is good, a small percentage of paint transfer does not scare us (the consumption is better than from a brush or roller). It is light, maneuverable, lies well in the hand, however, there is a little lack of rubber or something like that on the handle. Sometimes you want to have a larger tank (a 0.6 liter tank is included in the kit), but logic tells you that then you will need to hold more paint in your working hand. The manufacturers installed a nozzle on the pistol with a diameter of 1.5 mm, and it completely satisfies us, we see no point in buying other sizes. We spray with this gun not only water-soluble paints, varnishes, but also more viscous materials - primers, drying oil, sometimes enamels. In general, we thought that we were buying a disposable (“break down - throw away - buy another”) pistol in order to understand the principles of working with an airbrush, but it has been pleasing us for several years.

From the very beginning, the compressor and gun were connected with a MIOL 81-333 polyurethane coiled hose. However, he turned out to be not very convenient for working "in place", he constantly got confused and strove to catch on to something. As a result, it was replaced with a regular straight hose from old stocks. The problem has been fixed.

Our pneumatic kit turned out to be very budgetary. He copes with all the tasks easily, the best for construction is not needed. Basically, all maintenance comes down to removing moisture from the receiver and regular cleaning of the gun (no more time than washing or preserving the roller). Now it's hard for me to understand how some people who are seriously involved in repairs do without a spray gun.

How to choose a gun for a pneumatic spray gun by spray technology

If in spray guns with electric motors, the manufacturer has balanced the performance of the gun and the blowing motor in a single monoblock tool, then in the case of pneumatics, we can independently choose (we are forced to choose) both the parameters of the spray gun and the characteristics of the compressor. What is most interesting, the main part is the spray gun (gun), and based on its performance, a compressor is selected.

There are three types of spray guns depending on the working pressure and the volume of air consumed. They were simply named: HP, HVLP, LVLP.

HP technology (an abbreviation from English "big pressure") is used in low-price tools. At the moment, for a number of reasons, she has receded into the background, or to be more precise, into the background. What is its feature? The main thing is a high level of working pressure, reaching 5-6 bar, with a relatively small air flow. Such an airbrush allows you to paint quickly, but high pressure is an obstacle to perfect quality. The main disadvantage of HP-technology is the low percentage of material transfer. Interesting term, isn't it? It means in what percentage the paint gets on the object, and how much of it evaporates with the air flow. So, these devices transfer no more than 45-50% of paints and varnishes, we throw the rest under pressure, as they say, into the wind. It turns out that not only expensive paint is wasted, but the air in the working area is also polluted. As a result, in some countries, environmental organizations have banned the use of such spray guns. These tools are good for their simplicity and their budget cost. High pressure guns are perfect for most maintenance and construction jobs involving spraying a variety of formulations.

HVLP technology (“a lot of air - low pressure”) is rightfully considered the most effective. The air at the inlet to the gun is under high pressure, and at the outlet it is sufficiently discharged (0.7-1 bar). The ink transfer rate rises to over 65%, which naturally improves the quality of the work. All this is due to the excellent stability of the torch, the specific design of the spray gun, its high-tech nozzle and special air channels. HVLP pistols are very economical, but they are not cheap either.

LVLP (Low Air, Low Pressure) spray guns have the best transfer rate of up to 80%, respectively, mist losses are reduced to 20%. At the same time, they do not require a large amount of air, so the requirements for compressor performance are not the most stringent. You need only about 180-200 liters per minute. Oddly enough, the speed of work will not suffer, the quality of spraying will also be on top.

There are a few more nuances. For example, the location of the container for paints and varnishes. The top location of the tank gives a good weight distribution, and the speed of work. Containers located on top have a small volume (up to one liter), they are usually made of nylon or plastic, often transparent (they allow you to control the level of the material). The lower tanks are larger (1 liter or more), they are often made of metal. During a break, the gun can be placed on such a container.

Airbrush manufacturers often offer interchangeable nozzles of different diameters - from 1 to 3 mm. For spraying construction mixtures, nozzles with a hole of up to 6-7 mm can be used. Depending on the type of sprayed material, its grain size and viscosity, in fact, the nozzle is selected. Nozzles with an opening of 1.4-1.7 mm are considered universal.

It is worth paying attention to the possibility of adjustments that affect the spraying process. These are limiting the stroke of the needle (the amount of paint supply), setting the parameters of the outgoing air, adjusting the shape of the torch. Some models are equipped with a manometer.

How to choose a compressor

The compressor is the most important part of a pneumatic spray gun, so in order to assemble a truly capable kit, you need to correctly select it. There are several indicators that compressors differ from each other, some of them are traditional for most models, while others make us think seriously.

Engine power most compressors on the market, fluctuates between 1.2-1.8 kW. This is quite enough to ensure good performance of the entire unit. The motors on average compressors are even outwardly very similar, one might say, identical. Unscrupulous manufacturers may claim too much power when their compressors actually produce neither more pressure nor more air. They are driven by the desire to make the product more purchasable, it is not worth spending extra money for non-existent or unnecessary watts.

The volume of the receiver in 24-50 liters is already a tradition. For construction purposes, this is what you need - the accumulated air will be enough to perform most types of work, while the device remains moderately compact and light. But if the compressor will be used in any production, in intensive mode, then the budget option can not be dispensed with - you need to pay attention to a larger volume of the receiver (100-500 liters). In fact, a larger receiver size can somewhat offset/increase the overall performance of the compressor.

Operating pressure. Usually you don’t have to choose here - the vast majority of compressors compress the air in the receiver up to 8 bar, after which the automation turns it off. Manufacturers set the lower threshold (switch-on threshold) to 6 bar, upon reaching this indicator, the motor turns on and “pumps” the missing volume of air into the receiver. More advanced units pump 10 or more bar.

Performance. And here is a closer look. This concept displays how many liters of compressed air the compressor produces per minute. Why is it so important? We have already said that guns differ in spray technology, for normal operation they need different amounts of air, different pressures. Let's say HVLP spray guns "consume" a lot of air (from 180 to 550 l / min). If the compressor is selected incorrectly, then the pressure drops too quickly, even with the engine constantly running, it “floats” at the outlet - the quality of the spray deteriorates noticeably. You will have to take frequent breaks for swapping. If the motor seems to cope, but works at the limit, then it may overheat and again turn off the automation (thermal relay), in addition, we have premature wear of the piston group.

Interestingly, manufacturers indicate the inlet capacity (how much air is sucked in). In practice, there are losses of air during its compression, and they amount to 35%. Experts believe that for a guaranteed correct calculation (the actual volume of air at the outlet), we must multiply the declared performance by a factor of 0.65-0.7. It turns out that common 206x0.65 = 133.9 l / min. Most manufacturers are a little more loyal in this matter, they offer to make calculations with increased productivity - at least 15% of the gluttony of the gun.

There is only one conclusion: compressor performance is the most important indicator that must be taken into account with a margin.

Important options for compressors include: the presence of an automatic shutdown in case of overloads, pressure adjustments with a pressure gauge and a safety valve, built-in filters and cooling fans, an ergonomic layout with comfortable handles and wheels (for compact mobile models).

Electric spray gun: manual or floor

Electric (airless) sprayers are available in both manual and floor versions. A manual spray gun is the most affordable and most common version of this class of power tools. Because of the characteristic sound and vibration, it is also called the "buzzing gun". In this case, the entire unit is arranged in one unit, consisting of a motor with a piston pump, a pistol grip, a reservoir and a spray nozzle (valve, nozzle ...). Many companies produce such a tool, some of them have succeeded more, some less, but the fact remains - these are household spray guns for do-it-yourself work. The Bosch company did not deceive the consumer and sells all its painting tools in green "household" cases. The vast majority of handheld electric spray guns have a relatively low paint consumption efficiency (transfer), the spray quality often leaves much to be desired. However, we cannot but be captivated by the high speed of painting, ease of operation, compactness and low price of such a tool.

Floor spray guns are already produced by a limited number of companies: Campbell Hausfeld, Wagner, Earlex. Such units are distinguished by high technical characteristics inherent in a professional tool. They have a more powerful and heavier motor (you don’t need to hold it in your hands), a productive pump, an extended set of adjustments, a greater margin of safety, which allows you to use the tool for commercial purposes - for painting serious volumes (wooden and metal structures, ceilings, walls ...) . We control only the gun connected to the high pressure hose - the power plant and the tank are installed separately on the bed (for example, the Wagner Paint Crew model).

Characteristics of electric spray guns

As we have already said, the developers have already balanced the main indicators of the tool related to performance, they all turned out plus or minus similar. It makes no sense to choose specific instances based on minor differences in engine power or pump operating pressure. Believe me, extra watts will not play a role, but the rest is worth understanding in detail.

First of all, when choosing an electric spray gun, pay attention to what compositions it is intended for spraying. Some of them can only work with water-soluble paint materials, others are more versatile, they can easily cope with solvent-based paints and varnishes, oils, viscous compounds.

The presence of adjustments is a very important position. Most manual electric spray guns have a minimum of adjustment options. As a rule, this is a rough setting of the supply volume of the painting material and the shape of the torch (Black & Decker BDPS200 or Fiolent KR1-260). More advanced models may have electronic feed adjustment, the ability to preset working pressure, change in piston speed, and several spray modes. Floor sprayers are usually always more functional (Earlex HV500 SprayPort).

Pay attention to the type of tank. The most convenient tanks are made of transparent plastic, located below - they have a larger volume and allow you to control the amount of remaining liquid (BOSCH PFS 65). For extensive jobs, the built-in tanks will be too small, so it makes sense to look at models with the ability to draw paint from a free-standing tank. By the way, floor spray guns have large tanks of 7-10 liters or suck the composition directly from the bucket (Wagner ProjectPRO 117).

Some manufacturers make special extensions for their spray guns or long guns, sometimes with a swivel mechanism. This makes it possible to paint most surfaces without ladders and scaffolds. Imagine that you need to process the ceiling, but the tool needs to be kept at a small distance from the plane. Speaking of distance, there are spray guns with a laser pointer that shows the working distance - very convenient for beginners. Here again, the Wagner company (Wide Shot model) excelled.

Floor sprayers can have different hose lengths - from 1.5 meters (Miol HVLP 79-560 - shoulder version) to 60 meters, sometimes this difference greatly affects convenience and performance. The paint composition can be transported over a limited distance. For example, the DP Airless DP-6820 can feed material 30 meters horizontally and 15 meters upwards.

It is very important how high-quality plastic is used for the manufacture of the spray gun, how many metal parts the manufacturers used (it is better if the needle is made of metal), how well all the elements of the tool fit, especially the moving ones. There are usually no repair kits for electric sprayers; a breakdown will immediately entail the replacement of the tool.

The vibration of a hand-held electric spray gun can be very strong. Before buying, turn on the tool, take the opportunity to compare several models, this will also allow you to decide on the ergonomics of the product that is right for you. Pay attention to the weight of the tool.

Give preference to products of a well-known, time-tested brand. Overpaying for a brand will most likely save you a lot of hassle and downtime.

We all love to paint, because it is at this stage that the objects of our work acquire their special features, a finished look. The sprayer is the tool that will bring true pleasure from work, you just need to choose the right one for your specific purposes.