The airbrush is a device with more than a century of history, which in its modern form is used in a variety of industrial fields. Its versatility allows you to successfully paint various surfaces both in the factory and at home. Picking up such a tool is not always easy, because it is available in a large assortment.

A modern spray gun for painting is much more productive and functional than its predecessors. The manual spray gun allows you to evenly and smoothly paint large areas.

What are spray guns

In order to determine which spray gun to choose, you need to know the main differences between different models. They consist in the price, the design of the spray gun device, the principle of operation and purpose. Usually they are all divided into two groups: pneumatic and airless with an electric motor. But it can be said that there are three separate groups.

- The pneumatic spray gun runs on compressed air, therefore it is equipped with a compressor with a receiver. It is to the compressor that a special spray nozzle is attached, which looks like a pistol with a tank. It pumps air and feeds it into a spray gun, where it breaks the paint into small particles and pushes it out in the form of a torch.

- Electric spray gun, that is, equipped with an electric motor. Such a spray gun does not form compressed air, since the paint is sprayed under pressure here. The built-in pump provides this, but its ability to grind materials is limited.

- An intermediate option, that is, electrical devices with a minicompressor. Here, too, a compressed air flow is used, but the compressor is calculated according to the performance of the gun. It is performed in a separate casing, and the high pressure hose serves as a connecting element.

Deciding on an appointment

If you need a professional spray gun, then pneumatic will be the best option. Here it is important to choose a compressor to match the spray gun and this kit is not cheap. But he is out of competition in terms of results.

Electric devices are cheaper, but without air they are not able to grind paints and varnishes well enough, in which they are inferior to all pneumatic devices. However, they have their own advantages:

- compactness

- cheapness

- no need for additional equipment

- ease of maintenance.

Although the best spray gun for professionals is a pneumatic one, an electric one is also suitable for those who like to make at home. It is unsurpassed in terms of cheapness and ease of use. The combined model is also quite a convenient option. His gun is lighter than the electric monobloc, and the quality of the result is very high. Of course, cost is not its strong suit. For the home or garden, you can choose a convenient cordless spray gun.

Choosing a pneumatic spray gun

To the question “which spray gun is better”, professionals unequivocally answer that it is pneumatic. It exists in three versions:

1) Conventional, i.e. high pressure - a good choice for painting at a distance of up to 30 cm, as it provides quick and convenient painting. Its disadvantages are high cost, high energy consumption, more than half of the material is sprayed onto the surrounding planes.

2) HVLP, that is, a low pressure spray gun with a high volume. This is a popular device for painting at close distances (less than 15 cm) and it is quite economical, as everything else is sprayed only about 40% and this is relatively small.

3) LVLP - spray guns with a small volume at low pressure. The fact that only 30% is sprayed around the product makes it the most economical.

4) RP, Trans-Tech is the best device in many ways. It is very economical, as it requires the least amount of electricity, and also provides consistently good coating quality. In addition, it is easy to use and consumes little air, and thanks to this, dust does not get on the surface in the future when painting. This spray gun is available in a wide range of models.

Looking at compressors

All spray guns work due to the presence of a compressor, and they differ in several main ways. Most often, devices with a receiver of 24-25 liters are purchased with a volume and power in the range of 1.1-1.8 (kW). The pressure in them does not exceed 8 bar, and the performance is measured 206 liters per minute. There are other models that have the following characteristics:

- The volume of the receiver, that is, the tank where air accumulates and then a certain pressure is created. For cheap models, this figure is from 24 to 50 liters, while expensive ones can hold 100, 200 or more liters. Their technical characteristics are generally much higher, but the cost is many times higher.

- Engine power, which is of great importance and can sometimes be exaggerated by manufacturers. Usually it is about 1.1-1.3 kW. For an additional 0.5 kW, indicated in the characteristics of the product, you can overpay a lot, but this almost does not manifest itself in work. The air in the compressor from this does not swing faster.

- Pressure - a parameter that is standardly in the limit of 8 bar, at which the compressor turns off. When the pressure drops to 6 bar, i.e. during use, the compressor automatically turns on and continues to pump up the missing volume. In expensive models, this threshold may be higher - 10 bar, etc.

- The performance is usually indicated at the inlet and means the amount of air intake in liters per minute. But at the output due to losses (up to 35%), this figure is different. You need to know what is the need for air. Then the number indicated on the compressor must be multiplied by 0.65 and see if it suits you.

Choosing an electric spray gun

You need to pay attention to the quality of the material of the product. First of all, this is the quality of the plastic, and secondly, the number of metal elements. In the store, for this, you can ask to unwind the nozzle, look at the needle - both components must be made of metal.

You also need to pay attention to the vibration, which should be at a level that is comfortable for you. It is also important to see what types of paints can be sprayed using this device.

How to use the spray gun correctly, you can learn from the following video:

www.mebel-raduga.ru

How to choose a spray gun for home?

This is familiar to many: paint flows from a brush, drips onto the floor, onto hands, and splashes fly in all directions. The result is not always satisfied: smudges, stains, adhering villi. Not all places can be painted over well, especially in relief areas (for example, on batteries or gratings). Would you like to avoid these troubles? It's possible!

This is familiar to many: paint flows from a brush, drips onto the floor, onto hands, and splashes fly in all directions. The result is not always satisfied: smudges, stains, adhering villi. Not all places can be painted over well, especially in relief areas (for example, on batteries or gratings). Would you like to avoid these troubles? It's possible!

An airbrush is a tool for applying paint to a surface. It works as follows: under pressure, the composition from the tank is fed through the tube into the nozzle and sprayed. Fine particles of the coloring matter settle on the treated surface in a thin layer, without creating smudges.

Compared with a brush or roller, this method allows you to achieve a more uniform and high-quality application of varnish, primer or enamel. On average, with the help of a spray gun, from 0.2 to 0.5 liters of liquid can be applied per minute. It's amazing how quickly you can update the color of even large surfaces!

More than a coloring tool

He is able to perform a whole range of work in the apartment, in the country, in the garage:

- Priming and painting walls.

- Ceiling whitewash.

- Application of car enamels and anti-corrosion agents on the car body.

- Lacquering of wooden products and furniture.

- Treatment of plants with liquids that protect against pests.

- Implementation of original design ideas, for example, applying stencil drawings.

- Disinfection of the premises with various detergents.

Before buying, you need to know for what purposes you need an airbrush.

Pneumatic spray gun - powered by compressed air from a hand pump or compressor. With the help of such a productive tool, it is possible to apply substances of different viscosity, even metallic paint, which has aluminum particles in its composition. These tools are classified as professional equipment and are usually used in construction, manufacturing, and auto repair shops.

In the case of an electric spray gun (also called "airless"), the pressure to supply paint is created by an oscillating diaphragm, which is driven by a connecting rod mechanism. Such a tool does not require connection to the compressor, it is enough to have a 220-volt outlet nearby. With its help, paint, varnish, anti-corrosion and other compounds are easily and quickly applied to the surface.

Compared to pneumatic tools, airless tools are much easier to use and therefore suitable for home use. In this article, we will focus on household sprayers and talk about them in more detail.

Benefits of Electric Sprayer

So that you have no doubts about the advisability of such a purchase, consider the advantages of this technique:

- Ease of use. It has a simple design, so it is easy to assemble and disassemble. You will be able to control the flow of liquid and quickly top up the paint.

- Compactness. Such spray guns are small-sized and have a small tank volume (from 0.6 to 1 liter), so they do not take up much space during storage and transportation. As a rule, they weigh up to 2 kg, so your hands will not get tired during work, and you will quickly paint large surfaces.

- Mobility. By connecting the electric sprayer to the outlet, you can freely move around the room with it, and if you have to paint on the street, then just use an extension cord. The tool is small in size, so it is convenient to transport it, you can take it to the country house or to the village.

- Profitability. Due to uniform spraying, the paint lays down on the surface in a thin layer. When applied, smudges and drops are not formed, so it is not wasted. Some manufacturers equip tools with a built-in adjustment system, thanks to which you can set the flow rate of the composition.

What spray gun is suitable?

The right choice of tool is the key to effective work. Buy a compact sprayer that will handle painting surfaces and won't take up much storage space. Almost all electric spray guns are household, but some of them can also be used by professionals (for example, in a carpentry workshop). Regardless of whether you want to paint a car bumper with it, carry out design work in an apartment, varnish wooden furniture or spray plants, you can find the right option for you on our website.

For painting walls or ceilings

Most spray guns have a bottom tank. In this case, the liquid is supplied from the bottom up, so they are suitable for vertical wall painting.

Often buyers ask this question: “Can I paint or whitewash the ceiling with a spray gun?” If you try to do this with a tool with a lower tank, then nothing will work, because when tilted, the substance will not flow from the container into the nozzle. Especially for these purposes, devices with a top location of the tank are provided. The paint is fed from top to bottom, so you can easily apply it to the floor, ceiling, bench, table top.

If you need a universal approach, then pay attention to sprayers with a curved delivery tube, for example, Energomash KP-96400 and Bosch PFS 65. By turning the tube 90 degrees, you can adjust the tool to a vertical or horizontal surface. In this case, the location of the tank will not play a role.

Operation without refueling

Electric sprayers are usually equipped with containers with a volume of 0.4 to 1 liter. If you paint small objects, for example, radiators, grates, benches, wooden blanks, then purchase a tool designed for 0.5 - 0.7 liters. You will not get tired while working. It is also suitable for spraying plants in the country. Both men and women can work with it.

Painting walls, ceilings in an apartment or car requires a lot of liquid, so the tank needs a volume. The best solution would be a spray gun with a capacity of 0.8 or 1 liter. You will quickly cope with the application of the composition on large surfaces, since you do not have to frequently top up the composition.

Staining speed

The more powerful the sprayer, the less time it needs to do the job. For example, you need to paint a wall. One tool will do it in 15 minutes, another will take a little more.

A paint sprayer with an external pump is a composite structure of a “gun”, a connecting flexible hose and, in fact, a pump, which is located in a mobile plastic case with stable legs or wheels. High power (280-350 W) allows you to quickly paint large surfaces. For example, using a Bosch PFS 65 spray gun, you can paint up to 5 square meters in 10 minutes. meters of wall. The disadvantage is that these models are heavier than usual and take up a little more space when stored. These spray guns are powered by an outlet, but the energy to squirt the paint comes from compressed air pressure. Therefore, they are called fine spray systems, and they can be used not only at home, but also by construction teams, and also come in handy in small carpentry workshops.

The paint sprayer with a built-in pump has a pressure supply mechanism, which is located in the “gun” body. The tool is not as productive, but more compact. Its power is enough for drawing pictures, painting walls, radiators, gratings, etc. A significant advantage is the affordable price.

The paint sprayer with a built-in pump has a pressure supply mechanism, which is located in the “gun” body. The tool is not as productive, but more compact. Its power is enough for drawing pictures, painting walls, radiators, gratings, etc. A significant advantage is the affordable price.

See for yourself: by replacing the traditional paint brush with an electric paint sprayer, you will be able to perform various paint jobs much faster and better. After all, why buy new garden furniture or another new wallpaper when you can simply update its color? Believe me, sometimes this is enough to “breathe life” into an object that is already familiar to us. And you will cope with this task in a matter of minutes using a sprayer. We are sure that you will find exactly what you need in the product catalog of our website.

www.vseinstrumenti.ru

How to choose a pneumatic spray gun (paint sprayer)

Large and complex surfaces are more convenient to paint with a spray gun. The airbrush will help you quickly and efficiently paint the ceiling and walls, the fence and the radiator, the car bumper and the old chest of drawers. The main thing is that the tool be of high quality, otherwise it will ruin all the work. How to choose a pneumatic spray gun?

When buying equipment, you need to take into account many factors - the materials that will be sprayed, the desired quality of painting, the qualifications of the master. If there is a compressor, then the spray gun should be selected according to its power. Otherwise, you first need to select a paint sprayer, and already to it - a compressor.

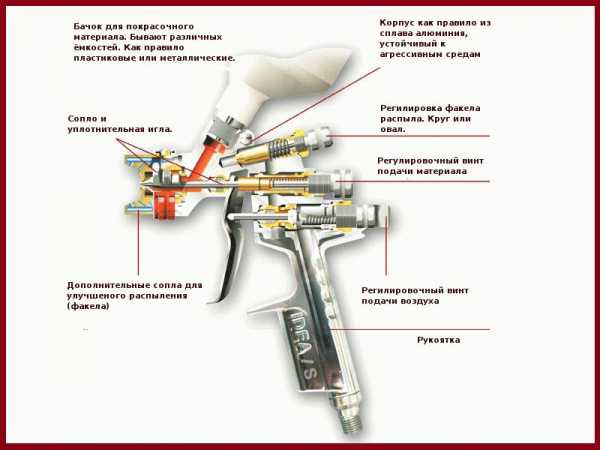

The structure and principle of operation of a pneumatic spray gun

Before choosing a pneumatic spray gun, you need to understand its design. This atomizer looks like a metal gun, which is connected to a compressor with a flexible hose. The "gun" is equipped with a container for paint (a bulk tank), a conical nozzle (nozzle or nozzle) and a sealing needle. It also has adjustment screws.

Pneumatic spray gun device

Pneumatic spray gun device Important! The compressor for the pneumatic sprayer must be equipped with a reservoir.

How does such equipment work? The compressor pumps air up to the pressure specified in the settings. When the painter pulls the trigger, the valve opens and compressed air enters the spray gun. Here, thanks to the pressure difference, the paint is "pulled" out of the tank and sprayed into tiny particles. A jet of colorful “fog” flies out of the nozzle of the spray gun, which paints the desired surfaces. This jet is called a torch, and it can have a different cross-sectional shape (round or elongated).

In almost all spray guns, the speed of the air supply and the material being sprayed can be adjusted. Many models are equipped with several nozzles of different diameters.

Types of pneumatic spray guns

Sprayers are divided into three types according to two basic characteristics - pressure and air flow. The type of spray gun is easy to recognize by the markings on the body.

The values in the table refer to specific sprayer performance:

- The transfer percentage indicates how much ink reaches the surface to be painted. Low transfer means high material consumption. The rest of the paint is simply sprayed into the air. Here, its particles dry out and settle on the painted surface in the form of dust, deteriorating the quality of the coating.

- The air flow indicates which compressor is needed for this paint sprayer. Its performance should be 20-40% higher than the consumption of the atomizer.

Important! At high flow rates, the requirements for the purity of the supplied air increase. Filters should be used to prevent oil drops from the compressor from entering the spray gun with air.

- The outlet pressure determines the spray radius of the paint particles. At high pressure, a wide torch is obtained, and painting can be done from a greater distance.

The quality of paint spraying depends on the characteristics of the spray gun.

The quality of paint spraying depends on the characteristics of the spray gun. Which spray gun to choose?

Each type of atomizer has its pros and cons:

- HP allows you to paint evenly and quickly, but due to the formation of a large amount of paint dust in the air, it does not give an ideal painting quality. When applying glossy materials after drying, you will have to polish the surface. To work with such an airbrush, you will need good personal protective equipment.

Advice! HP is the best option for the beginner and for spraying inexpensive materials. This is a simple and inexpensive spray gun for home use.

- HVLP paints better and consumes material more economically, but requires an expensive powerful compressor and clean air.

- LVLP gives excellent painting quality - with such equipment you can do without polishing the painted surface. But its use requires a certain skill from the operator. The torch of this atomizer is narrow, and the material is fed very quickly. Therefore, LVLP requires a steady hand: the spray gun must be kept close to the surface, moved quickly and evenly so that smudges do not form. Such a sprayer is expensive and suitable for painting furniture, doors, car body parts.

Nozzle diameter

Nozzles for spray guns are available in the form of interchangeable nozzles. Nozzle diameter affects the size of material particles emitted from the atomizer. The thinner the nozzle opening, the finer the paint is sprayed. Thick, viscous formulations require larger diameter nozzles. Nozzles should be selected for a specific material.

If the spray gun is not equipped with a replaceable nozzle, it is worth choosing the most universal diameter that is suitable for all planned jobs.

The diameter of the spray gun nozzle affects the type of material being sprayed

The diameter of the spray gun nozzle affects the type of material being sprayed On a note! The most popular nozzles are with an average diameter (1.3–1.7 mm). For example, a 1.5 mm nozzle is best suited for home repairs, and 1.4 mm for painting a car.

If the spray gun is of high quality, it is usually equipped with a set of nozzles with a diameter of 1-3 mm. Often, nozzles are also included in the kit, giving a different shape of the torch.

Tank capacity and location

As a rule, pneumatic paint sprayers are equipped with bulk tanks of 0.8–1 l. These are containers that are attached directly to the "gun". Thus, the master constantly holds the entire volume of paint in his hand. If you need to paint very large surfaces, use specialized tanks up to 100 liters. They are attached to the spray gun with a hose.