The drying process is the initial moment in the entire preparation of the semi-finished product (wood) before processing.

A drying chamber for lumber and wood is an excellent solution to the task, you can do it yourself. In order to avoid deformation of logs, drying is carried out in specialized conditions, which are carried out exclusively in a dryer.

What is drying for?

From time immemorial, when performing any wood crafts, timber cut down a few years earlier was used. Products from wet or under-dried boards will warp or become covered with numerous cracks.

When the tree dries, it shrinks, the raw wood material will “behave” over time, huge wide gaps will form in the log house. In under-dried semi-finished products, a fungus is likely to start. But it is also not advisable to overdry the tree, because it will begin to absorb water, which will lead to swelling.

What are the modes of drying chambers?

There is a whole list of drying modes for wood materials. In self-built machines, the regime from the lowest to the highest changes gradually, removing all excess water from the semi-finished product. The drying process is carried out based on the following characteristics of the material:

- tree species;

- overall dimensions of the semi-finished product;

- final and initial level of humidity;

- unit specifics;

- lumber quality indicators.

The drying operation can be characterized by high temperature or low temperature. The second case is notable for the fact that the primary drying is carried out at a regime that does not reach 100ºС.

Low temperature conditions can be as follows:

- soft - after drying, semi-finished products have their original properties, without changing strength and color;

- moderate - the color changes slightly, strength characteristics decrease slightly;

- accelerated - in the process of subsequent processing (fracture, sawing, cutting), increased fragility is possible, the color fades.

Changing the temperature regime during low-temperature processing is carried out in three stages.

Processing in high temperature mode is carried out in two stages. The second stage begins when the moisture level of the semi-finished product drops to 15%. Such a technological process is used if it is necessary to further design secondary structures.

The main types of drying chambers

Drying of wood semi-finished products in industrial volumes is carried out in specialized dryers. Moisture is removed from the wood due to heated air, which subsequently goes into the atmosphere. The device provides the passage of a full cycle of lumber drying. The machine body can be:

- solid / prefabricated metal;

- made with building materials.

The latter are mounted directly in carpentry workshops in the form of a structure, or as freestanding. The walls are made using reinforcement and concrete mortar. Alternatively, bricks can be used. Large factories make a system of cameras, combining them into whole modules with centralized control and communications. Air moves inside the dryer in a horizontal plane or vertically transverse.

Heat sources in the dryer:

- radiant source from specialized units;

- hot shelves;

- electric current that passes through raw semi-finished products;

- high frequency electromagnetic field.

The chambers are completed with the main and auxiliary equipment. Main systems:

- supply and exhaust equipment;

- heat sources;

- humidifiers.

According to the principle of operation, dryers are divided into:

- convection equipment;

- condensing equipment.

In convective machines, semi-finished products are "washed" with hot air waves, heat is directed by the convection method. The time for completing a full cycle varies from 5 to 13 hours. Similar units are mounted on large-scale sawmills.

Chamber-type dryers are more compact; a constant temperature and the environment as a whole are maintained throughout the volume. This type of dryer will allow you to dry any type of wood material to the required condition, which is why many entrepreneurs who are associated with the need to dry lumber choose chamber dryers.

Based on the technology of the drying process, the moisture that is released from the wood settles on the cooling elements, is sent to containers and then drained. The efficiency of such a unit is quite impressive, but time-consuming, leads to large heat losses. The pricing policy of machines and the profitability of condensation drying are lower than those of convective drying.

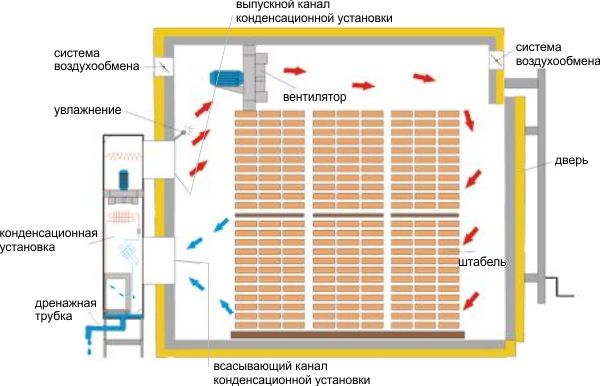

Drawing

Drying chamber for lumber: step by step instructions

To build a dryer with your own hands, you can not use the technical documentation. It is only necessary to provide:

- the area where the camera will be installed;

- insulating materials;

- source and communications to create high temperature;

- blowing.

The area of a machine built personally, as a rule, is not more than 10 square meters. A square-section room is more suitable for moving warm air currents. It is preferable that at least one of the walls of the equipment be concrete, the others can be made of wood. Inside the chamber without fail gives in to warming. An excellent insulating material is wood shavings. If there is no foil at hand, then it can be replaced with penofol.

A separate extension for the dryer can be constructed from aluminum sheets, such a design will last a very long time. The base is made on the basis of profiles, it is covered with sheets of metal, which is further insulated. The thickness of the insulation must be at least 150 mm. The floor is covered with roofing material, a thick layer of shavings is poured on top, which will be excellent as heat saving.

The heat source can be supplied as a heating pipe system. The temperature of the liquid in the pipes should be at the level of 60 ... 90ºС. For an oversized chamber, a two-burner stove will be quite acceptable. If the source is right in the room, it must be overlaid with a brick. The brick is able to perfectly collect heat in itself and send it to the lumber drying machine.

The continuous circulation of the liquid is important, which is provided by the compressor or the whole station. The room must be equipped with wet and dry thermometers.

For more convenient loading of semi-finished products into the chamber cavity, you can use a rail trolley.

Video: do-it-yourself drying chamber for lumber.