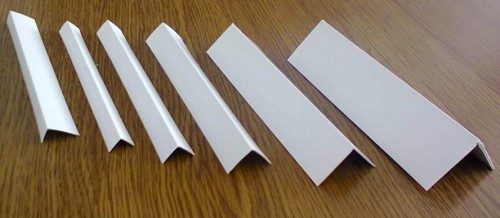

External corners must be aligned and reinforced during the repair process, for which it is necessary to use a perforated corner of various sections. Today we will talk about fixing a perforated painting corner on an external plaster or plasterboard corner, as well as clarify the stages of work and the materials necessary for this.

Materials and tools

The corner has a central stiffener and side strips with perforations, which helps the element to be securely fixed on the edges of the outer corner. You can fix the corner on gypsum plaster or starting putty, as a rule, a putty mixture is used to fix it on drywall, and a gypsum plaster composition is used to fix it to plaster. External corners are not only vertical corners at the junction of two walls, but also sections of plasterboard ceiling structures, as well as window and door slopes.

Instruction

To work, in addition to the corner and the material, you will need metal scissors, a spatula and a level. First, the perforated element is cut at an acute angle with the edges with scissors, then a small amount of Rothband or Start putty is kneaded and installation begins.

When fixing to the corner of the GKL, a minimum amount of putty is required, it is applied with a spatula along the edges of the outer corner, the corner is applied to the base and pressed tightly. The remains of the mixture that have made their way through the perforation are removed. In this case, you can do without a level, because the plasterboards are attached evenly and there is no point in doing the same job twice. With perfectly even corners of the GKL structures, the corner is fixed with a stapler.

When attaching the corner to the plaster, most often the corner must be trimmed, so the gypsum mixture is applied with strokes of greater thickness, the corner is applied without pressure and only then is pressed with a level until it is completely aligned vertically. Since in some places of the outer corner the corner protrudes above the surface of the side walls by 3–4, and sometimes by 5–7 mm, after fixing the element of the pit on the wall, it is necessary to close it with a gypsum mixture using a spatula wide from 40 cm.

Putty and plaster for fixing the corner should be kneaded only in a plastic bucket, first pouring water into it and then adding the dry mixture and kneading it with a mixer. The consistency of the mixture is from "thick sour cream" for gypsum boards and gypsum boards to liquid plasticine for plaster corners with large differences.

Conclusion

In conclusion, we note that in addition to painting, there are plaster corners, which instead of perforation have a rigid mesh on the sides, they are used only in plaster work, fixing directly into the mortar body at the corner and plastic elements for curved corners.

Below you can find a video on attaching a perforated corner.

The topic of today's article is an arched corner. We will talk about the types, purpose and methods of fastening this finishing element.

To begin with, let's define the terminology: which corners are called arched and what is their difference. In general, such angles serve to design curvilinear structures from various types of finishing and building materials.

The main purpose of these elements is to protect the decorative coating of corners. They prevent peeling and abrasion of paint, wallpaper, etc. Also, these corners, as it were, highlight the shape of the structures they are attached to. For example, arches, plasterboard niches, figured ceilings.

Types and purpose of arched corners

decorative corners

Stucco arched corners

- This type of auxiliary finishing materials has perforations (holes) on its entire surface. One side of such corners has petals (similar to incisions). Thanks to this design, they bend perfectly.

- Basically, the perforated arched angle is used to give a smooth edge to curved structures. For example, when installing plasterboard arches, figured suspended ceilings, graceful partitions.

- Corners for plaster are made of plastic. The most common length is 3 meters.

Fixing arched corners

Fixing decorative arched corners

If you decide not to install an interior door and made a semicircular opening (see Arched openings), then you need to “ennoble” it - attach an arched decorative corner along the entire contour.

There are several ways to do this:

- Stick with glue.

- Fasten with screws.

- Pin with carnations without caps.

Let's take a closer look at each of these methods.

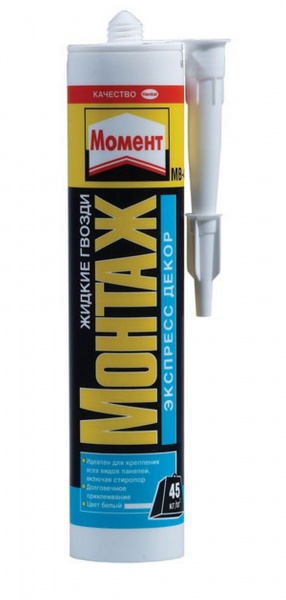

Most often, PVC corners are glued to the wall with glue. For example, liquid nails or titanium.

Should know! No need to use liquid nails for heavy structures! They may contain solvents that can corrode plastic. The best option is Express-Decor class glue.

Before you start gluing the corners to the surface, it should be prepared:

Should know! In no case do not stick plastic corners on the wallpaper. Even if the latter are firmly attached to the wall.

- All loose materials must be removed.

- If you have already pasted wallpaper, then remove them from the place where the corner will be pasted as follows: attach the pvc arched corner to the “native” place tightly and mark its edge with a pencil on both sides. Then remove the corner and carefully cut and remove the wallpaper with a sharp clerical knife.

Now you can start gluing. If you decide to use liquid nails, then it is better to take them in a tube (for a gun). From such packaging it will be more convenient to apply glue. Just buy the gun itself.

Apply glue to the corner in a small layer along the entire length and attach to the wall. Move the corner a little so that the glue spreads over the surface. Then remove the corner and wait five minutes.

After that, firmly press the corner again and fix it to the wall with masking tape.

Should know! For white corners, buy white glue, and for colored corners - colorless.

How to glue an arched cork corner: follow all the surface treatment steps described above. Glue must be used special - contact, for cork products.

Fastening arched corners to studs and furniture brackets has a number of disadvantages.:

- Lost aesthetics, as the fasteners will be visible.

- At the moment of tightening the self-tapping screws (shooting the staples) possible cracks. on the surface of the corner.

- If the fastener is tightened, then corner may be bent..

Fixing perforated arched corners

Perforated corner fasteners include the following procedure:

- Should firmly press the corner to the surface and shoot it with staples using a construction stapler on both sides.

- Next, a solution is prepared from gypsum plaster (or base putty) and applied with a spatula to the corner. In this case, you need to press the plaster more tightly.

- Immediately after applying the plaster mortar, it is necessary remove excess.

- After the plaster has dried, sand it with a special mesh or sandpaper.

Should know! The use of gypsum-based plaster "VOLMA-Sloy" will be optimal. It is very elastic and rubs off easily after drying. It is also possible to apply ready-made putty with a coating thickness of 3 mm.

Since the arched perforated corner is flexible, it will perfectly hide all design flaws of any form of curvature.

All of the above steps will help you secure the arched corners yourself.

If you still have questions on this topic, then you can watch a video about fixing corners for arches, as well as read other articles.

Now we will consider a fairly simple screed - a furniture corner. They are produced quite a lot of varieties that differ in appearance, the number of screws and material (plastic, metal), but the concept is always the same: a corner fixed with screws.

Consider the installation process using the example of a plastic corner with a removable cover. It seemed that there was nothing to discuss at all - screw the screws and it will hold! But no!!! Even here there is a trick. If you screw the corner incorrectly, then it will not tighten anything and a gap will form between the parts.

The first step is to determine the size from the edge to the center of the hole (this size is individual for each corner). For the considered corners (with a removable cover) 15 mm.

Now we determine the location of the parts to be tightened: one of them necessarily rests on the second.

We need a detail number 2. We set aside all such details separately and proceed to the markup (for this it is convenient to use a carpenter's square.

We need a detail number 2. We set aside all such details separately and proceed to the markup (for this it is convenient to use a carpenter's square.

The marked pencil marks are easily smeared, so it is advisable to immediately deepen them with an awl or (as I have been doing lately - with a dowel by hitting it with a hammer). It is necessary to postpone not 15 mm, but 16 !!!(It will become clear why later.

We put a corner opposite the hole and wrap a self-tapping screw into it - the self-tapping screw is screwed into the hole marked with an awl much better. The corner installed in this way does not adjoin the edge of the part with its edge, but is 1 mm away from it.

Now, when we attract the second part, this millimeter will be covered by a deformable corner (and plastic is still quite a plastic material), but the tension of the material will allow the parts to be pulled together without gaps.

We have considered the main ties with which furniture is assembled, now let's move on to the consideration of the simplest, but extremely common modules. Let's start with the drawer.

After any repair, for example, wallpapering, installing doors or windows, finishing work remains, including attaching corners to slopes. They will protect walls and other surfaces from mechanical damage that occurs from careless touch, for example, when moving furniture, and give the interior an aesthetic look. They are used to hide corner joints, which is especially important when using different materials. Most often, hard PVC is chosen for finishing, which is manufactured by the method of “hot” bending of the sheet. You need to know how and with what to glue such corners on the slopes so that the product lasts as long as possible.

Wall plastic corner

Buyers choose plastic corners for slopes for the following positive qualities:

- ease of use - when mounting and cutting out the desired size and shape, which is done with scissors or a knife, and the burrs and ends are ground with appropriate paper;

- smooth out irregularities, forming an angle of 90 ° in the places of finishing;

- strength - protect the corners from damage, while remaining unharmed themselves;

- resistance to moisture, ultraviolet, temperature changes;

- light in weight, which is also important for ease of installation;

- long service life - 20-25 years, during which they do not lose their qualities, including color;

- affordable cost;

- do not require staining;

- unpretentiousness in care, in which they are easily washed with home remedies.

It is worth mentioning the shortcomings of the material:

- melts in case of fire, releasing harmful substances;

- at the end of the term fades;

- when in contact with sharp objects, unaesthetic scratches remain.

Varieties of plastic corners

Before gluing a plastic corner, you need to understand its types in order to choose the right option. A wide range of colors is provided for the product, which includes plain versions, as well as wood, marble, metals and other natural materials.

They are made in different shapes and sizes. The most popular two options are in the shape of the letter L with the same or asymmetrical width of the shelves (from 10 to 50 mm wide, from 2 m long), and curvilinear, which are used for similar openings (arches, etc.), due to for which they are called arched corners. They are produced in two versions - for angles of 90° and 105°. Standard length - 3 m.

Plastic corners in different sizes

They are also made in a T-shape, which hides the joints between the slope and the wall cladding. The most rare option to use due to the increased cost is removable. Such a corner is made with a latch, which allows you to carry out repair work without removing the profile. It is easily bent, and at the end of the process it falls into place.

More corners are classified by type of finish - external and internal. The latter are made with double-sided color.

Important! The wider the sides of the finishing material, the greater the load it is able to withstand, which is especially important on curved openings.

Types of adhesives

Before gluing the plastic corner, choose the right product for the procedure. Today, there are four positions to choose from, with the characteristics of which you should familiarize yourself with before work - how to apply, how long it takes to set, whether it is suitable for the material, etc.

Types of glue for plastic corners

- Liquid Nails.

They have good durability. This glue spreads easily over the surface of the plastic corner. Apply dotted or zigzag. Liquid nails are able to connect glued products for more than 20 years without losing their properties. The setting strength after complete solidification is 40 kg / m 2. It has anti-corrosion properties, does not damage or contaminate plastic. When buying, give preference to a colorless composition, especially if you have to work with light surfaces.

- Silicone sealant.

It is used to connect corners with wallpaper, as well as tiled and ceramic walls, if acrylic is present in the composition. It is distinguished by the absence of toxic chemicals and high adhesive performance.

- Polyurethane adhesive. Durable, flexible and leaves no residue. Hardens quickly.

- liquid plastic. Suitable for work only on plastic surfaces (for example, window slopes). Fast acting, high strength and reliability.

You need to apply glue from the inside of the part, closer to the middle. The gaps between dotted drops are 1-1.5 cm.

Glue application example

There are also self-adhesive corners that are glued immediately after measuring and creating the required size and shape. To do this, remove the protective tape and press the product against the protruding corner.

Preparatory work

Before finishing the walls with plastic corners, the work surface should be cleaned of dirt, dust and other debris. To apply glue, purchase a glue gun, and for installation, additionally the following tools:

- scissors or a hacksaw for metal;

- square (preferably metal);

- stationery knife;

- roulette;

- masking tape.

You may also need a miter box, with which blanks are made with an angle of 45 °. But if the tool is missing, you can cope without it, using certain skills and our recommendations.

Tools

Degrease the place of attachment of the corner and the part itself with a weak solvent or white spirit. The workpiece must be clean. Avoid moisture.

Options for mounting corners on the walls

Before gluing the corners, decide on the installation method. There are two of them.

- To wallpaper.

This option is suitable for wallpaper with a shallow relief, but be careful when finishing the slopes on deep embossing, as gaps can form in which dust collects due to loose corners.

- With a strip cut on the wallpaper to apply the adhesive directly to the wall. To do this, follow this action plan:

- attach a corner to the installation site, align and press against the wall surface;

- using a sharp knife, cut off the wallpaper on both sides of the overlay;

- apply glue to the plastic corner and install in the intended place;

- fix the corners with adhesive tape designed to set the adhesive composition;

- After 24 hours, you can remove the tape.

If you are not sure about the accuracy of cutting blanks, you can first try on the part to the place of finishing, and mark the place of the cut with a pencil.

markup

How to glue a plastic corner on a door and window slope

Before you put the corners on the slopes of windows or doors, you need to check the quality of the surface finish. This is done using a level, bar or hard ruler. If the slope surface is strongly curved, and this cannot be corrected, then it is better to install flexible plastic corners here.

Slopes are of three types:

- drywall;

- wallpapered;

- painted after plastering.

Regardless of the choice, the installation technology is the same in each case. Only the choice of adhesive composition is important so that it fits both the plastic and the finishing surface.

- Measure the height to make blanks. Leave a margin at the top. The cuts are made with metal scissors. You will end up with a 90° angle on the inside and a 45° angle on the outside.

notch example

- Put the part on the glue, and wait for the setting.

Press the corner firmly

- Now measure the width, and cut off the required size with a margin to make a pairing with the side strips.

- The front blank is cut at an angle of 45 ° from two ends.

- Try on the corner to the side slopes to make marks in place with a cutting knife.

- Take a ruler, attach it to the glued part and cut off the excess.

- Now apply glue to the top plank and attach it to the corner. Secure with tape for a day all the elements.

An example of fixing the corners with tape

If the slopes are trimmed with wallpaper with a three-dimensional relief, then you first need to cut strips for plastic corners on them. Be careful not to leave drops on their surface after glue or liquid nails.

How to attach corners to the ceiling

Here you will need additional preparation and tools - a sponge and a soapy solution, with which glue residues are removed. In addition to leveling the surface, it must be primed. Next, you should measure the dimensions and cut the required blanks. The beginning of sizing is done from any corner of the room. For this, it is better to use liquid nails. Apply adhesive to the corner and press firmly against the wall and ceiling. Putty the joint, and then rub it with sandpaper.

Useful tips will help beginners when installing their own hands.

- Be precise when laying out so that there are no gaps between the joints. To prevent this, you can increase the length of the workpiece by 0.5-1 mm. They will still fall into place due to the elasticity of the material.

- It is not recommended to fill the joints with silicone, as it will darken over time, and it will stand out against the background of the slope.

- To be safe, do not glue the corners immediately, but first attach them with tape and take the necessary measurements.

- To create the correct shape for the arch, use a building hair dryer.

- When processing areas in openings where the angle is not 90 °, but more or less, measurements are required to be taken in place and cut off with a knife.

Plastic corners serve as reliable protection for slopes from damage, and also give aesthetic completeness to the entire interior. Among the wide range of shapes, sizes and colors, it is easy to choose the best option for a specific design. And it’s also easy to attach them yourself, owning all the necessary tools and work skills. Strengthen the knowledge gained by watching the video.

A huge selection of finishing materials allows you to decorate walls, ceilings, doorways of an apartment or house in the most daring and interesting decor options, but there is one condition. You need to think in advance how to strengthen and protect the corner lines of the walls. The peculiarity of modern wall decoration is such that the outer corners of the walls are the first to age and lose their appearance.

In some cases, protective plastic wall corners are simply indispensable, as in the case of tiling or wall panels. Therefore, people who are knowledgeable in major repairs, choosing a finish, be sure to look after plastic corners to protect the corners of the walls.

Where and how profiles are used to protect wall corners

You have to get acquainted with the first version of the profile corner at the stage of plastering or leveling the surface of the walls using drywall. Installing a plastic corner under the wallpaper makes it possible to solve two problems at once:

- Strengthen the finishing layer of putty;

- To give the outer corner an ideal geometry, at least visually, the junction line of the two planes looks quite even.

Everyone who at least once had to glue wallpaper on walls with crooked corners will appreciate all the benefits and practicality of the simplest plastic profile.

Note! With the help of a wall plastic corner, you can easily bring out the outer and inner corners even on the most uneven walls.

The main difference between corner profiles and decorative plastic corners is that the mounting option always has perforations along the entire length. The corner does not need to be glued, it is simply imprinted into a layer of putty or plaster mass. Even professional plasterers always use a plastic corner in their work.

But the use of mounting profiles for leveling walls does not solve the problems of the appearance of corner edges, both internal and external, especially if the walls are finished with light trellises. Therefore, plastic corners are often installed in addition to the perforated profile.

What does it give:

- Complete corner protection. No matter how carefully the owners treat the decorative trim at the corner joints of the walls, after a few months, a maximum of a year, traces, scratches and chips of the lining will appear;

- Eliminate cracks and gaps between wall panels, especially at wall corners and skirting boards, on curved surfaces;

- A radical improvement in appearance. Colored plastic corners for walls will help to transform and significantly refresh wall decor at minimal cost.

In this case, it is not necessary to be limited to the outer corners of the walls, although it is they, as they say, that are in sight and require protection in the first place. Often, a plastic corner on the corner of the wall has to be installed after the fact, it is worth rearranging the furniture once with the transfer of the most dimensional interior items. Scuffs and dirt can still be removed or washed, but chips and deep scratches on the walls have to be hidden.

Internal corners also have to be closed in order to mask the transition from one type of finish to another, for example, while lining the corridor walls with drywall, MDF or DFP panels, and living rooms with wallpaper and wall slabs.

Plastic profile for sealing corners

For decorative purposes, corners made of PVC, polystyrene, polyurethane and even silicone are used. If the walls of the room are finished with wood or tiles, then you will need a corner made of a similar material; a plastic profile for such a decor looks unnatural. For all other cases, the list of the most suitable materials invariably leads the PVC corner, it remains the most in demand. Almost everyone who faced the problem of finishing and protecting the corners of the walls with an overlay profile is unanimous in their choice, this is a PVC profile.

The exceptions are metal and MDF corners used as flashings, covering the line of the window opening from the side of the street. At the same time, a plastic outer corner made of polyvinyl chloride is often used for balcony doors.

The reason for the popularity of the PVC profile is determined by three important properties:

- Beautiful appearance, there are practically no problems with the selection of the desired shade of colored plastic corners to protect the corners of the walls;

- Plastic material is highly flexible and "democratic" during installation. No problems with gluing, as in the case of polystyrene or polypropylene corner profiles;

- Easy processing when adjusting the size of the corners. The material can be cut without problems with scissors, a "bread" knife or, best of all, with a sheet of metal.

Note! Good machinability of the material does not exclude the possibility of profile cracking, especially if the plastic corner has been stored for a long time on a balcony or in a garage at low temperatures.

In this case, before cutting the plastic corner, it must be kept for an hour at room temperature.

Size of plastic corners

The advantages of the plastic corner include the low cost of the material. Depending on the height of the shelf, the price of a plank 2.7 m long ranges from 50 cents for a 10x10 mm size to $1.7 for a 50x50 mm profile. For cladding home walls and corners, a corner with a shelf of 20 mm and 15 mm is usually used, their cost is in the range of $ 0.7-1 for a standard bar of 2.7 m.

PVC profiles are represented on the market by three types of plastic corners:

- Standard equal-shelf version, in which both shelves are the same size;

- Double corner or T-profile used for decorating interpanel and tile joints;

- L-shaped or arched plastic corner with different shelf heights.

No matter how hard the craftsmen try to align the planes of the walls, all the same, over time, a gap forms in the corner, which must somehow be masked by installing a plastic corner on the corner of the wall. Otherwise, an ugly line of transition from one type of finish to another will remain. For the case when you need to close the joint between wallpaper and decorative plaster on the wall, the smallest profile, 10x10 mm, is quite enough. The same size of the shelves is selected for the outer corner for the plastic plinth. The largest profiles, 50x50 mm, are used for installation at the corners of building facades, sizes 20x20 and 25x25 are the most popular for interior work.

Options for using a corner profile for finishing corners

At first, most apartment owners are rather reserved about the use of a corner profile when decorating corners and the junction line of walls. First of all, it is the well-established classical opinion that the use of PVC materials in an apartment should be limited and used primarily where it is simply impossible to do without it. For example, for entrance doors in the bathroom or in the kitchen.

It is possible to destroy distrust of plastic corners only if people see with their own eyes the difference between wall decoration without a corner and after installing a plastic corner profile. The difference in perception even with the simplest decor is significant.

Finishing the slopes of doors and windows

The most obvious example of the advantages of installing a PVC corner profile are the windows and doors of a modern apartment.

With the replacement of an old wooden window frame with a double-glazed window, as a rule, it is necessary to plaster the slopes in a new way, look for a way and material to close the resulting external corner to the walls of the room.

Traditionally, window slopes are made on the basis of drywall sheets, with the outer corner reinforced with a perforated metal corner, photo.

This makes it possible to perfectly align the planes and achieve the most even angular line, but still the edge will remain a risk zone. The window is used quite often, so even curtains or curtains often cause damage to the edge. If finishing the slopes using MDF or PVC panels, then you simply cannot do without installing a plastic corner on the slopes. First of all, you will need to close the end of the cladding panel, otherwise the entire decorative effect of using the finish will be smeared. The dimensions of the plastic corner for slopes depend on the height and width of the window opening.

A plastic corner for drywall and wallpaper is selected 20x20 mm, for a corner at the transition of an MDF plate - wallpaper sets a corner profile measuring 25x25 mm. In the latter case, if desired, you can hide the installation of a protective profile, for this you just need to choose the right colored plastic corners for the slopes. Polyvinyl chloride is quite difficult to paint, so the repainting option is used if the entire window with slopes and corners is planned for painting.

In addition to finishing the outer edge, it is necessary to install plastic flashings between the window frame and the plane of the slopes, as well as close the line of intersection of the window sill with the walls. For these purposes, it is best to use a T-shaped profile with a deflection in the central part.

At first glance, the line of intersection of the slope and the window sill may not be covered with a plastic corner, but this is not entirely true. The plastic window sill springs quite strongly even under a small load, so after a few months the material with which the corner joint is sealed can simply spill out of the gap, so it is better to close it with a corner profile in advance.

The same plastic corners are often used for decorative sealing of the seam line between the bathroom and the tiled wall. PVC is ideal for damp bathroom environments.

The second section of the walls, where it is almost impossible to do without installing a decorative plastic corner, are entrance doors. If the front doors are changed in a house or apartment, this means that the owners will have a large front of work on finishing and decorating the vestibule and door slopes. Since the front door always remains the dustiest place in the house, the slopes of the doorway, with rare exceptions, are traditionally finished with MDF, clapboard and PVC panels, most often under wood or natural stone.

After the walls of the door vestibule are plastered and puttied, the lining can be laid. Any master can confirm that after finishing work, the ends of the cladding panels will remain visible at the angle of intersection of the walls of the corridor and the plane of the slopes. They must be closed in order to achieve a finished appearance of the doorway and to exclude the accumulation of dirt and dust in the cracks.

If the lining of the vestibule was carried out by directly sticking PVC tiles or panels onto a plastered surface, then in order to close the gaps, a plastic corner with a shelf width of 30 mm will suffice. For a decorative finish laid on a pre-stuffed crate or galvanized profile, you will need a corner plastic profile 40-50 mm in size.

arched doorways

Among the many design options for an interior opening, the arched scheme is considered one of the most beautiful and expressive. The arch is most often assembled on the basis of a metal frame lined with plasterboard sheets, or laid out from lightweight wall foam blocks.

One of the problems that one has to face when assembling an arched arc is related to the inflexibility of drywall and galvanized profiles. Both of them are almost impossible to bend in a smooth curve. In order to get an arc, the supporting frame has to be recruited from a dozen short segments - chords. The filing of the inner surface of the arch is also recruited from short pieces of drywall.

You can simplify the task, for this, the decoration of the arch with a plastic corner is performed in the form of several rectilinear sectors, photo.

There are two ways to solve the problem of the most smooth profiling of the arch:

- Installing a finished arched plastic corner photo. It will only be necessary to adjust the dimensions of the opening to the finished profile, install and fix the polypropylene frame;

- Run the overlap of drywall wall sheets with a curved arc cut out according to the template. The inner part of the slope is blown out with polyurethane foam, and the edge is sheathed with a decorative plastic arched corner.

The use of a decorative plastic profile allows you to close the joint and the corner transition from drywall to slope. This method of arranging an arched passage is cheaper and easier. But there is one condition, you need to know exactly how to bend the plastic profile under the arch. At first glance, bending a soft PVC profile is not difficult. One of the simple descriptions of how to bend a plastic corner onto an arch is shown in the video.

An ordinary plastic corner is not suitable for these purposes. Any attempt to stick or nail it to the edge of the drywall results in the decorative profile moving away from the wall at the top and breaking into two pieces. You have to cut one of the shelves of a regular corner into segments 25-30 mm long or, more conveniently, use a special plastic corner for the arch.

Most often, a 17x5 mm profile is used for an arched doorway. Due to the reduced side shelf of the plastic profile, the corner bends almost without distortion, which means that when laying the material on the adhesive, the risk of delamination from the edge of the wall will be minimal.

If the radius of the arc of the arched opening is small enough, the plastic profile has to be bent so much that even a special decorative corner begins to warp. In this case, you can use the "hot" method of bending. The corner is fixed at one end of the arch with a clamp or clamp. Next, the polyvinyl chloride profile is heated with a hairdryer to a temperature of 60-70 ° C and pressed against the edge of the drywall. While the material is cooling, it is rolled into place with a soft paint roller.

Advice! If it was not possible to bend the desired arc profile for two or three warm-ups, then the bending must be stopped, since the material becomes rigid and brittle after several heating cycles.

Before gluing the plastic corner on the arch, it is necessary to determine the contact points of the profile to the wall surface in order to apply glue in these places. If you do this "blindly", most of the adhesive material applied to the plastic profile will be used up uselessly.

Do-it-yourself plastic corner installation

The process of laying a decorative profile on a corner or on the edge of an arch is not difficult, it requires accuracy and careful handling of plastic. PVC is easily scratched and loses its glossy sheen. Often, the front of the plastic corner is sealed with paper to avoid damage and contamination with glue. After the adhesive base has hardened, the surface of the corner can be polished with a soft cotton cloth.

One of the advantages of using a PVC profile is the fact that during production, the coloring of the material occurs throughout the mass, any scratches and abrasions do not lead to a change in color or shade. So you can polish the material an infinite number of times.

How to stick a profile on a corner joint

Working with a corner profile is no different from similar operations with a polyurethane glazing bead or plinth. Initially, before gluing the plastic corners to the slopes, you need to do a little preparatory work.

First, with a tape measure, we measure the length of the PVC profile for each slope angle. Since the window opening has a rectangular shape, all plastic corners will be joined together at a right angle. We will cut the junction line at an angle of 45 o. For other structures - arches or polygonal vaults, the angle of the cut will need to be determined at the place of the sticker.

After marking, you need to cut off the plastic strips according to the measurements taken. This should be done as carefully as possible, since the corner is quite thin, only 1-1.5 mm, so the material can be easily split if it is cut incorrectly.

Experienced craftsmen cut the profile with a construction knife under the ruler or well-sharpened scissors. If there is no relevant cutting experience, then it is better to use a carpentry tool for corner cuts. PVC is ideally cut with a conventional hacksaw blade.

After cutting, carefully remove the burrs and perform a final fitting of the cut blanks at the place of the sticker. To do this, you need adhesive tape and a building level. Having attached a blank of a plastic corner to the place of gluing, we align its position according to the level and fix it with several strips of adhesive tape. Install the upper corner bar in the same way.

Only by setting all the cut-out segments of the corner “roughly” and aligning them with the building level, it becomes clear how correctly the corner was washed down. Usually, for amateurs, a gap of 1-3 mm wide forms on the junction line. It is clear that it is impossible to glue a plastic corner with such slots.

Advice! When cutting a corner profile, add an allowance of 2-3 mm to the calculated size. This margin, when fitted, will help correct the situation without any special consequences.

To get rid of the cracks at the joints of the walls, you will need to once again clarify the passage of the gash line along all three blanks. To do this, draw a corrective line with a pencil and disassemble the design to adjust the corners. The cut line can be cut with scissors or sharpened with a piece of sandpaper wrapped around a wooden block.

How and what to glue

It remains to stick the plastic corner on the corner edge of the slope. First of all, you need to choose how to glue the plastic corner to the wall. In salons and hardware stores, the liquid nails adhesive composition will be recommended as the most suitable means. Of the positive characteristics, only convenient packaging in the form of a tube can be called.

Everything else - on the conscience of the manufacturer. With this composition, you can glue light polyurethane bovelacchi or a plastic corner measuring 10x10 mm to the tile joint. In addition, the white adhesive mass becomes beige-gray over time, so traces of glue are very clearly visible on the seams and joints.

The slopes on the windows, on the entrance doors must be glued with silicone, it can be transparent, but if desired, you can easily choose the color version of the sealant. Not all adhesive materials adhere well to the smooth surface of the PVC corner. Silicone sealant is a pleasant exception, it does not drip or shrink.

But the main advantage is in obtaining a strong and elastic seam. If you have to stick something on a door frame, on light partitions that vibrate with every slamming of the doors, choose silicone. Any other adhesives that give the strongest and toughest seams do not withstand vibrations and chip off, especially when it comes to a plastic corner.

The technology of sticking a corner plastic strip is quite simple. We apply glue with thin lines on the inner surface of each of the shelves. If the glue is very thick, then the adhesive mass can be applied to the wall with short oblique lines or dots. You can not cover the entire surface of the wall with a continuous layer. Firstly, it will be impossible to press such a plastic profile into place, and secondly, 50% of the adhesive mass will be squeezed out uselessly outside the corner. Too liquid glue will simply flow out from under the plastic strip.

Carefully place the prepared plastic corner with glue on the place of gluing. To make the adhesive seam strong, you need to gently press the bar into place. A small amount of adhesive mass can be squeezed out from under the plastic profile, but do not rush to remove it - first you need to level the corner. The PVC profile is very flexible, and it will not be possible to trim it with your hands, so the laid corner is brought into a straight line state using a metal ruler and a building level. So that until the glue dries completely, the plastic corner does not fall off the wall and does not slide down, you need to fix it with several strips of adhesive tape.

We glue the next plastic profile bar in the same way, but before laying it in place, it will be necessary to apply a small amount of glue to the joint line. After precipitation, part of the adhesive will come out at the joint, all excess can be removed only after the final drying of the adhesive mass. Until the glue has dried, any attempt to remove excess glue will result in stains on the wallpaper.

Sometimes there is a problem with the length of the arched corner. The maximum length of the plastic strip is 3 m. This may not be enough if the arched opening is made for the entire width of the room, the length of the corner profile on such an arch can reach 3.5-4 m. In this case, the arched arc has to be finished with a small piece. It is best to make the central part of the arc solid, add two small segments on the sides, and seal the joint line with silicone sealant in the color of the plastic material.

After a couple of years, due to shrinkage processes, the seams may diverge a little, but still the arch will retain its original showiness. If you increase the length of the plastic corner on one side, then the junction will be perceived as a stain, and spoil the impression of the whole structure.

Conclusion

Plastic corners are successfully used not only for residential premises. For example, for a dacha or a bathhouse lined with clapboard, for a country house made of timber, protection of the corner joints of the outer walls always remains relevant. This is not so much a matter of aesthetic appearance of the building as an urgent need for protection from moisture penetration. In this case, under the plastic corner 50x50 mm, two load-bearing wooden slats are stuffed, on which the plastic corner profile is glued.