The circular saw is a convenient and productive tool that is present in the workshop of every real man. If you work with lumber in large volumes, then you will need to do it for a circular saw.

Of course, you can make an individual order in a furniture company. But you can build such a table on your own, having the necessary drawings, materials and tools.

Design The table consists of only two elements:

If desired, the craftsmen can add the product:

- drawers;

- racks.

Important: the circular saw is mounted under the table, only its disk is located on the tabletop. The hole for the saw should be slightly larger than the blade. Thus, sawdust will not clog the mechanism.

Such a piece of furniture should be strong enough and reliable. Keep in mind, the greater the power of the saw, the higher the load on the table surface will be.

To benefits homemade table for a circular saw, you can also add:

- comfort and convenience in work;

- saving money;

- high labor productivity;

- the ability to make a product based on personal needs and characteristics of the workshop.

Material

You can make a circulation table on your own from different materials. The most common are considered:

You can make a circulation table on your own from different materials. The most common are considered:

- or chipboard;

Each individual option has its own merits. Chipboard, plywood and MDF are easy and simple to work with. In addition, these lumber are available at an affordable cost. But products made of wood have higher strength and technical characteristics.

Attention: before proceeding with the assembly of the product, all its wooden elements are treated with antiseptic compounds.

Drawing and dimensions

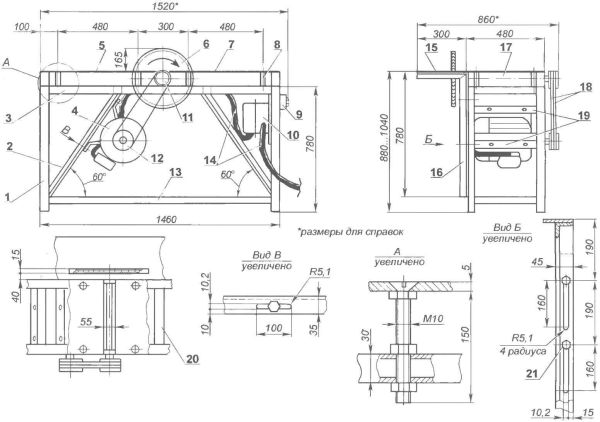

Before starting work, it is recommended to make a drawing of the product. On it, indicate all dimensions, materials of manufacture and other important information. You can make a high-quality drawing of any piece of furniture using special computer programs..

When drawing a table, be sure to consider the size of the circular saw. Each brand of tool will have a specific size.

If during the workflow you like to leave materials on the table, then tabletop dimensions must be at least 120 by 120 cm.

Tools

To make a practical and comfortable table, you will need different tools and materials:

- lumber (plywood, chipboard, MDF and others);

- boards for legs;

- furniture glue;

- paints and varnishes;

- self-tapping screws;

- drill;

- milling cutter;

- electric jigsaw;

- circular saw;

- Ruler and pencil.

How to make a table for a manual circular?

The manufacture and assembly of a table for a circular saw is divided into certain stages:

Finishing

After the manufacture and assembly of the circulation table, to simplify working moments, on the table it is desirable to mark. It is she who will help facilitate the cutting of materials.

After the manufacture and assembly of the circulation table, to simplify working moments, on the table it is desirable to mark. It is she who will help facilitate the cutting of materials.

To extend the life of the product and increase its aesthetics, a do-it-yourself table can be primed and varnished. These manipulations will also prevent the lumber from sliding on the surface and protect the product from high moisture.

Safety in use

Keep in mind that working with a circular saw is a dangerous business. To avoid injury during the work process, it is necessary to constantly monitor the position of the saw table, its strength and stability.

Each time before switching on the equipment, check that it is securely in place.

Attention: It is strictly forbidden to hold the cut material with your hands while the saw is running. Otherwise, your fingers may be damaged.

To prevent bouncing wood particles from getting into your eyes, work recommended with protective goggles.

A photo

Depending on what materials you used and how you solved the issue of finishing, you might end up with something like this:

Useful video

We advise you to watch a detailed description of the manufacturing process in the following video:

Conclusion

In conclusion, it is worth noting that making a table for a circular saw on your own is not so difficult. And its presence will greatly simplify and even expand the functionality of using a circular saw.

In contact with