When developing a project for a private building, you must immediately decide how to sheathe the house from the outside. After all, it is the correct finishing of the facade that will make the house not only presentable, but also warm, so you need to carefully choose materials for its insulation and decoration. Without a solid finish, the house will look ugly and sloppy, and will not be protected from destructive external influences, such as moisture, active solar radiation, wind, thermal changes, etc.

On the modern construction market there is a very large assortment of insulating and decorative materials, from which you can choose suitable for every taste and financial possibilities.

Requirements for facing facade materials

So that dampness does not appear in the house, it is comfortable and warm, and the house looks aesthetically pleasing from the outside, the cladding materials must meet certain requirements.

Based on them, and it is worth choosing the right option. So, the lining should have the following qualities:

- Have low thermal conductivity to keep the heat inside the house.

- Possess vapor permeability - no condensation should form inside the insulation layers.

- Differ in moisture resistance - do not absorb or retain moisture inside the material.

- To have absolute or increased heat resistance - the skin must withstand high temperatures, under their influence not be deformed and not ignite.

- Possess inertness to chemical influences - do not change its characteristics when such substances enter it.

- Be protected from the influence of microorganisms, do not serve as a breeding ground for insects and rodents.

- Do not decompose or lose physical properties under the influence of ultraviolet rays.

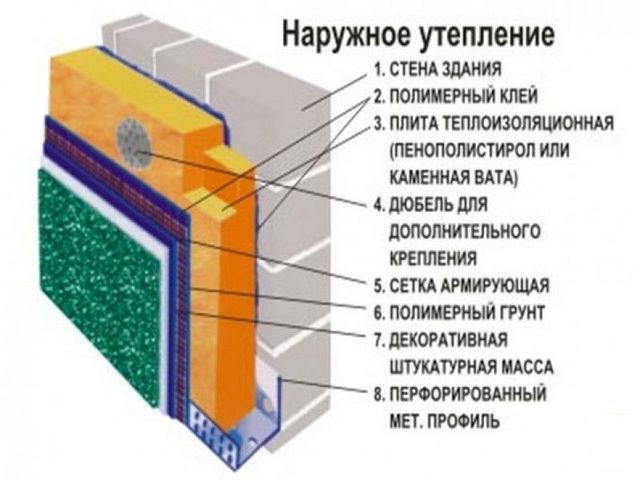

In order for the sheathing to be effective in all matters, it is necessary not only to securely attach decorative material to the walls, but, following the technology, cover them with a whole system of layers, each of which will play its role.

There are two main systems for home insulation, and the choice will depend on what material is planned to be used for decorative finishing and on the insulation used. In one of their systems, the insulation is attached directly to the wall with glue, in the other - along the created crate.

Plastering a house

When using insulation boards with a sufficiently high density, for example, foam plastic, fiber cement or tightly pressed glass wool in mats, which will later be covered with plaster on top, wall lathing is not needed.

Most often, this principle is applicable on even brick or reinforced concrete walls. In this case, the lining is done as follows:

- On the wall of the house at the height at which insulation will be installed, a metal holder profile is fixed, selected according to the thickness of the selected insulation boards. The profile is leveled to a perfectly flat horizontal line.

- The walls are cleaned of dust, and, before applying the adhesive, wetted with water for better adhesion.

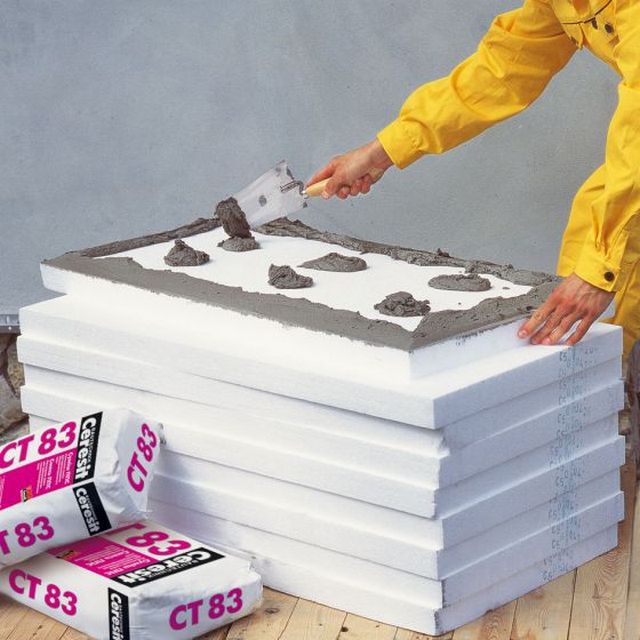

- Next on insulation boards pre-diluted special glue is applied.

- The first row of plates is installed on a metal profile and firmly pressed against the wall.

- The next row is installed on the first one according to the brickwork system - in dressing.

- Having fixed two or three rows of plates with glue, each of them is additionally fixed with dowel fungi.

- Further work continues according to the same system to the very top. Then the insulation is installed in the same way on other walls.

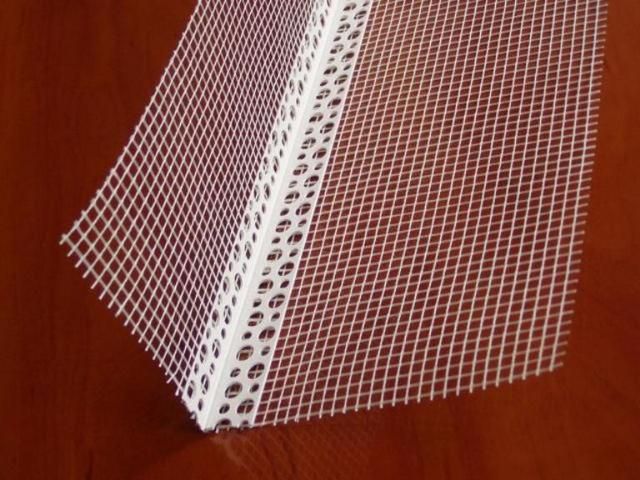

- When the layer of glue under the insulation dries, it is necessary to glue all the corners of the building, window and door slopes with reinforcing mesh corners. They are fixed on the same glue, its excess is removed with a spatula.

- After the corners have dried, the serpentine reinforcing mesh must be fixed on the entire insulated surface.

- The surface on which the sickle cloth will be glued is smeared with a thin layer of glue. A reinforcing mesh is fixed on top of it, smoothed with a spatula, and excess glue is also removed.

- When the surface dries well, it must be covered with polymer plaster, with a layer of 2-3 mm.

- The final stage will be the imposition of decorative plaster, selected in the appropriate style of the building.

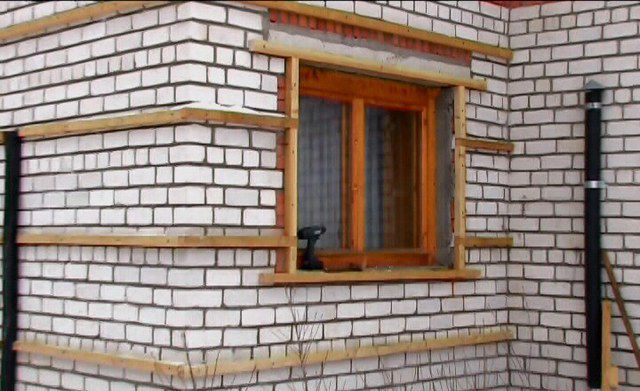

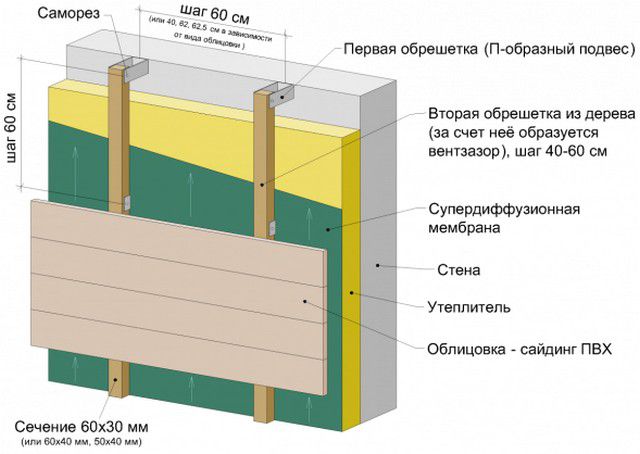

Sheathing a house using crates

Insulating facade system using lathing can be installed in one or two layers. The position of the frame bars will depend on how you plan to install the decorative trim.

- To install the crate correctly, it is better to first mark the wall. In this case, it is necessary to take into account the width of the insulation mats.

- Then bars or metal profiles are mounted on the surface of the walls.

- If a wooden wall is sheathed, then before laying the insulation, a vapor barrier film should be fixed to the entire surface of the walls.

- Next, insulation mats are laid between the bars of the crate. If necessary, they are fixed to the wall with fungal anchors.

- After installing the insulation layer, stretch it on top superdiffusion membrane, fixing it on the bars of the crate with staples of the construction stapler.

- Next, you can install decorative cladding material.

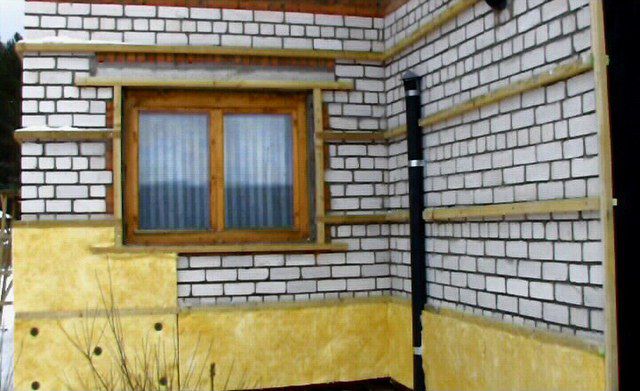

Another option for installing the crate is done in a slightly different way.

- Markings are also made on the wall and suspensions are fixed along it at a distance of 40-60 cm from each other. Their edges-holders should protrude from the wall by the thickness of the insulation and wooden bars that will be attached to them.

- These elements will be fasteners not only for the bars, but also for the installed insulation.

- Insulation mats are marked and cut in those places where they will be put on metal elements.

- Then the insulation is mounted on the wall, and a diffuse membrane is stretched and fixed on top of it.

- Next, wooden crate bars are installed in the hangers, they tightly press the insulation against the wall and fix them in metal holders with self-tapping screws.

- A decorative sheathing material is also installed on top of this system, using the installed sheathing bars as guides.

Types of decorative trim

Modern materials make it possible to make an imitation of brickwork on a wooden wall, or vice versa - to transform a brick house into a wooden frame. To do this, use such facings as siding made of different materials, wooden lining, block house, thermal panels, ceramic or stone tiles and others. It is necessary to find out in advance how each of the skins is attached and how it looks in the end - this will largely determine which insulation system to choose for it.

Clinker thermal panels

Clinker thermal panels are one of the modern materials for insulation and facade design.

They relatively recently appeared on the construction market, and have already gained wide popularity. This is not at all surprising, since they have many positive qualities.

- One of the main advantages is that this material immediately performs two functions: it is insulation and decorative trim.

- The panels perfectly imitate brickwork, and are produced in various colors, so they can be matched to any style and taste.

- They give the surface absolute accuracy and aesthetics.

- This type of sheathing is convenient and relatively easy to mount on the wall.

- Thermal panels can be used for covering any wooden or brick surface.

- The light weight of the panels makes it possible to do without additional strengthening of the foundation of the old building.

- Since the materials have a low percentage of water absorption, the facade can be washed from the hose with water under high pressure.

- The density of the connection of the panels on the wall does not allow cold air to penetrate to the wall of the house.

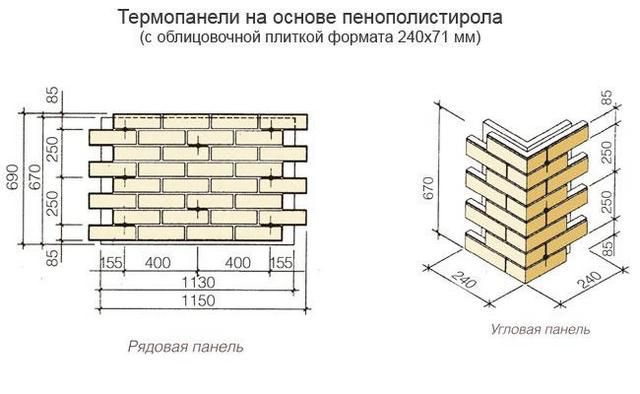

Thermal panels have a polyurethane foam or polystyrene foam base, on which clinker tiles are pressed. A warm substrate increases the thermal insulation qualities of the panels by two to four times, and creates an optimal vapor permeable microclimate for walls, which allows you to save the material from which the house is built for a longer period.

The structure of the panels - a layer of insulation and decorative brick-like tiles

- Clinker tiles protect the insulation base from external factors such as wind, precipitation, direct solar ultraviolet rays.

- Clinker panels are very securely attached to the wall and can last 45-60 years without repair work, without losing their original appearance.

- The panels are assembled in a single plane using the available locking joints (ridges and grooves), which ensures tight adhesion.

- Straight, wall thermal panels and corner elements for them are produced, which facilitate the task of decorating the corners of the building, making them absolutely neat, not differing from the general appearance of the walls.

- Thermal panels are reinforced with plastic guides that prevent deformation and mechanical stresses of the facing material.

Installation of thermal panels

- Before starting the installation of panels on the wall, it is necessary to revise it for various bulges, significant recesses and chips, which can greatly interfere with quick installation. Therefore, it is necessary to bring the surface of the walls in a perfectly even state.

- When installing panels on surfaces that have large irregularities, for example, the walls of a log cabin, they are laid on a crate of wooden beams.

- In this case, it is very important to correctly calculate the location of the elements of the crate so that the fastening of the panels is successful. Each of the panels to be fixed must have at least three battens to create the necessary rigidity of the skin.

The diagram clearly shows the attachment points to the wall or crate and the dimensions of the panel itself and the protruding locking ridges.

- After the wall surface is completely sheathed, the seams between the individual tiles are filled with a special grout. This finally isolates the insulation from external influences, gives the design of the walls the appearance of natural brickwork.

Video: cladding a house with clinker thermal panels

House siding upholstery

Another fairly popular way to transform the facade is It is produced in various forms, imitating wooden and stone wall coverings.

It is produced from different materials using two technological processes - monoextrusion or co-extrusion. The first of them is the molding of siding panels from a homogeneous mass, and the second is manufacturing double layer elements. The top layer of the material is protective against external influences, and the bottom one is the base of the panel.

A truly high-quality siding has a whole range of advantages:

- It is resistant to mechanical impacts such as impacts and scratches, while at the same time having good elasticity.

- The material is fire-resistant, resistant to thermal shocks. High operational qualities of material allow to use it in various climatic conditions.

- The siding is not subject to formation of colonies of microorganisms, damage by insects.

- High-quality material is not seriously affected by ultraviolet rays, so it does not lose its original appearance for many years. The service life of siding is about ten years.

- The panels provide reliable protection for the walls of the building from wind and precipitation.

- The material does not require special care and is well put in order with a jet of water under strong pressure. The surface itself does not absorb dirt.

- Siding sp is special to give any facade an aesthetic appearance. Numerous shades and the possibility of their combination open up great opportunities for design solutions.

- The material is non-toxic, and therefore harmless to human health.

- In addition, compared to other materials, siding is quite easy to install and affordable.

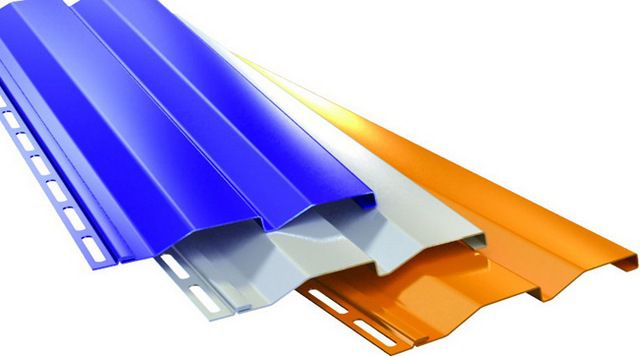

Types of facade siding

saydi ng facade claddings are made from vinyl, aluminium, thin steel, cement-cellulose pulp and based on wood raw materials.

- Aluminum and steel siding is mainly used in industrial facilities, but is also used for finishing private houses. The material is produced in a variety of colors, so it will perfectly decorate any facade of the house.

- The cladding material is made from wood fibers and their binding components by pressing raw materials under high pressure, and then coated with protective paints. This siding is also well suited for cladding the facades of private houses.

Fiber cement siding - great for plinth sheathing

- Cement-cellulose version of the facing material - most often used for lining the basement sections of the building.

The most common is vinyl siding.

- The most popular and affordable is vinyl siding. It is widely used for finishing private buildings, and it justifies itself with a long-term operational period and other positive qualities. Since this material is acquired and used more often than others, it is worth considering in more detail.

Vinyl siding

This type of siding is made in the form of stacked strip panels with a perforated edge through which they are fastened with nails or self-tapping screws. In addition, there is a lock-latch on the strips for pairing adjacent panels with each other.

The material is produced in the form of one, two or three "boards", which simplifies and speeds up the installation of siding on the wall.

The pattern of the siding can also be different. Often this is the usual “lining”, but other types are rapidly gaining popularity, for example, “ship board” or “herringbone”. The surface of the material can imitate the texture and color range of different materials. Panels can be mounted in a horizontal and vertical position, but for everything to go well, you need to foresee the location of the crate bars.

Vinyl siding at the production stage is often covered with paint that contains titanium dioxide, which keeps the surface in its original state for many years and gives any color a pastel softness. At the same time, you need to know that the bright shades of the material indicate the absence of this component, so such coatings lose their original color much faster.

Installation of siding panels

Installation work of installing siding horizontally begins from the bottom of the house. Adjacent panels overlap each other and snap into place. The panel is fixed to the crate with nails along the upper part, through special holes.

During installation, you should strive to minimize the number of vertical joints. If the dimensions of the wall do not allow this (longer than the standard dimensions of the panels), a special docking profile is used, installing it strictly vertically from the bottom to the top of the wall.

During the installation of siding on the walls, additional decorative typesetting elements are also installed, which will give the facade completeness - external and internal corners, spotlights, ebbs, window and door slopes, etc.

Video: installation of facade siding

Block house

The block house is made of natural wood and is a board with a semicircular surface. A house sheathed with this material imitates a log cabin.

There are two longitudinal grooves on the flat side of the block house board, which are designed to relieve stress from the load and improve ventilation. In addition, for easy installation, there is a groove on the bottom edge of the panel, and a spike on the top edge.

Block house panels are available in several standard sizes - from 3 to 6 m in length, from 20 to 45 mm thick and from 99 to 220 mm wide.

For the manufacture of this sheathing material, conifers are mainly used, such as pine, spruce, larch. With proper processing and qualities, raw materials, this wood will serve for many years as a facade cladding. Wood is naturally endowed with excellent qualities that people began to skillfully use to build and decorate housing.

What are the main advantages of this facade material:

– ecological cleanliness inherent in natural wood;

- lightness and strength;

— resistance to high and low temperatures;

- ease of installation;

- the ability to "breathe" - this creates a special comfortable microclimate in the house;

- affordability in price compared to a solid log.

The material is easily attached to the crate of the insulation system and is perfect for finishing not only facades, but also interior walls.

Block house installation

- The first thing to do is to adapt the wood to the conditions in which it will be fixed to the facade. To do this, the block house panels are laid out on a prepared base, for example, spread polyethylene, and left for a day.

- Then each panel must be completely covered with the first layer of antiseptic.

- After it dries, as a rule, all the flaws of the material appear, such as roughness and irregularities. They must be removed with sandpaper.

- A second layer of antiseptic should be applied to the leveled surface. On sale are similar products that already have dyes in their composition - they will help protect the wood from exposure to ultraviolet rays. If such processing of the material is used, then it no longer needs further painting or varnishing.

- The block house is attached to the crate, starting from the bottom of the wall of the house. The first panel is laid up with a spike - this is done so that during precipitation water does not get into the groove of the panel.

- In places where you have to screw the board through, the screw must be recessed and masked. As a composition for covering such holes, you can use wood glue mixed with fine sawdust. You can close the hole with a dowel, the cut of which is aligned and tinted in the color of the panel.

- Installation continues along the "groove-thorn" system throughout the entire plane of the wall. The material is fixed with self-tapping screws to the crate.

- At the corners, the panels are joined through installed corner boards or through a cut at an angle of 45 degrees.

- If it is necessary to lengthen the panel, its two segments are connected with a bar of the same width as the boards themselves. It is fixed on the reverse side, and then the joint is sealed with the mentioned mixture of glue and sawdust.

Video: facade cladding with a block house

It should be noted that, in addition, a metal and vinyl block house is produced, which imitates the shape, texture and color of natural wood. Its cost is usually lower than that of panels made from natural quality wood. Artificial material will last a long time and also decorate the facade well, but it still cannot replace the warmth and beauty of the texture of natural wood.

There are other materials for cladding the walls of a private house - it is simply impossible to tell about all of them on the scale of one article. Follow the publications of our portal - each type of facade decoration will definitely be given special attention.