Today we will consider the main issues regarding the choice of such installations.

- What are the advantages and disadvantages of aeration plants?

- Is it worth separating "black" and "gray" drains?

The operation of these stations is based on the aerobic process of biological wastewater treatment. In other words, organic matter is decomposed by microorganisms that use atmospheric oxygen for their life, with which the drains are saturated with a compressor or a drainage pump.

What are the benefits of aeration plants?

- High degree of wastewater treatment, reaching 95-98%. In this connection, VOC manufacturers allow the possibility of diverting treated process water from their facilities to the relief - into a village drainage ditch, ditch, nearby forest, reservoir, etc. This is a significant advantage of VOC over septic tanks that require post-treatment of wastewater in soil filtration facilities (about septic tanks from , and for them we have described in detail in our articles).

- Aeration plants are the best option for autonomous sewerage, when clay soils are in the area - with poor filtering ability. That is, when it is very difficult to arrange filtering facilities. Or when there is simply no place for them on the site. So, the option with a septic tank disappears.

- Aeration units are suitable for areas with heaving soils and high groundwater levels (GWL). Such units are manufactured from plastic - most often from polypropylene or fiberglass - in the factory. Therefore, they have a durable and sealed body, equipped with stiffeners and protruding elements. This allows VOCs to avoid deformation and extrusion to the surface.

- Compared to septic tanks, aeration plants are less likely to have to be cleaned of excess sludge. But you still need to pump it out.

What are the disadvantages of aeration plants?

- Quite high cost, especially quality products.

- The relative complexity of the design: there are moving elements.

- Energy dependence. Although the cost of electricity for the operation of VOCs is relatively small, when the electricity is turned off, the installation quickly ceases to function normally.

- Unstable work, subject to intermittent residence in the house, which means uneven flow of effluents.

- The need to store the installation for the winter if it is not expected to live in the house at this time of the year.

- VOCs require regular service (often 3-4 times a year), which can be a hassle for homeowners.

- Compared to septic tanks, aeration plants are not as “omnivorous”: there are serious restrictions on what can be dumped into the sewer. Most often, it is impossible to dispose of the remains of vegetables and fruits, spoiled food, construction debris, filter flushes, a large amount of drains with chlorine-containing preparations, etc. there. But you can dump toilet paper, kitchen drains and drains from dishwashers or washing machines.

Sergey Shemaev CEO of Septico

During the conservation of the aeration installation for the winter, it is strictly forbidden to pump water out of it, otherwise the station may be deformed or squeezed onto the surface of the earth. To avoid this, always leave the unit filled with clean water.

What is the difference between the installations of different manufacturers?

Two main types of VOCs can be distinguished, depending on whether aeration is carried out using a compressor or a drain pump. There are much more stations of the first type on the market. This is due to the time-tested efficiency of fine bubble aeration provided by the compressor.

Installations of this type are represented by the trademarks Tver, Topas, Astra, Evrolos (PRO series), Eco-Grand, BioDeka, etc. In general terms, the principle of their operation is similar. Drains sequentially pass through several chambers.

First, they settle in the receiving chamber, then they enter the aerotank - a chamber where they are saturated with atmospheric oxygen. Air is supplied through a fine-bubble aerator connected by a tube to a compressor. Thanks to oxygen, there is an intensive reproduction of microorganisms already contained in wastewater. Some models of VOCs are supplemented with bioreactors (loads) that promote the reproduction of these microorganisms. As a result, activated sludge is formed, which destroys the organic compounds present in the wastewater.

Further, the clarified water with sludge particles is sent to another settling tank, where the sludge settles and again enters the aerotank. And the purified water enters the next chamber, from where it is discharged outside the station - by gravity or forcibly, using a pump. Depending on the installation model, the liquid is moved either by airlifts (jet pumps), or combined - by gravity and airlifts. In some VOC models, additional settling chambers are provided, as well as a bioreactor (loading) in a non-aerated chamber. A biofilm of anaerobic microorganisms is formed on the bioreactor. All this is designed to improve the quality of cleaning.

In most stations of this type, the compressor and control unit are located inside the unit itself. This moment causes criticism from opponents of compressor stations. They remind that the possibility of VOC flooding cannot be ruled out. For example, when there is a power outage and the pump stops working, forcibly pumping water out of the installation. Flooding will lead to a breakdown of the compressor and control unit, the replacement of which will cost a lot.

However, in some LOS this problem is solved due to the fact that the compressor is taken out into the house. However, you need to be prepared for the fact that a constantly running compressor will make noise, although not strong. A compromise option is to place the compressor and control unit in an electrical box mounted on a rack located next to the station.

Peter Kukhanovich Head of Sales Department, Trading House "Engineering Equipment"

Placing the compressor of an aeration unit in a dry, heated room has a number of advantages. First, the compressor is not affected by moisture. Secondly, it is unaffected by toxic gases generated in the treatment plant that can corrode the copper parts of the compressor. All this ensures a long service life. Thirdly, a compressor located in a heated room guarantees high-quality wastewater treatment in the winter.The fact is that the biological processes necessary for cleaning proceed at a water temperature not lower than +8°C. If the compressor is outdoors, it will supply cold air to the unit in winter. And therefore, there is a possibility of a decrease in the temperature of the water in it and, as a result, a deterioration in the quality of cleaning. If the compressor is located in the house, then it will only supply warm air, and this problem is excluded. Moreover, when the compressor is located on the street, and in winter there are arrivals in the house and the drains flow unevenly, there is a risk of water freezing in the installation during severe frosts. When the compressor is placed in a heated room, this will not happen.

Aeration plants of the second type are represented on the market by the trademarks Kolo Vesi, Eurolos (BIO series), etc. In such stations, also multi-chamber, wastewater is first clarified and then saturated with oxygen. Saturation occurs due to the fact that the effluent is sprayed by a submersible recirculation drainage pump onto the sprayer, after which it flows through the biofilter with a load. The biofilter is located in the mouth of the installation. It has a large surface area thanks to the voluminous loading elements made of synthetic material. In fact, the biofilter performs the function of a mechanical wastewater aerator. Passing through the biofilter, the effluents are cleaned by microorganisms in the form of activated sludge and biofilm on the feed. Then the effluents are additionally settled and discharged outside the station. All overflows between the chambers of the station are gravity. The control unit is moved outside the LOS.

Among the advantages of such installations are a simpler design in comparison with the first type of VOC, reliability due to the absence of a compressor, the ability to operate in septic tank mode during a power outage due to the gravity flow of wastewater between the chambers (although in this case, sewage is cleaned much worse). Critics of such stations argue that the efficiency of aeration due to the pump is lower than due to the compressor, which is why the quality of cleaning in "pumping" installations is worse. The manufacturers deny this. At the same time, it can be noted that the market is looking for solutions aimed at improving the aeration of the treated liquid in plants of this type. So, stations have recently appeared where additional aeration is provided due to the ejector.

Konstantin Feldmanhead of the wholesale department of the company "Eurolos"

The new technical solution lies in the fact that the clarified wastewater supplied by the recirculation pump is divided into two streams: the first is sent to the biofilter sprinkler, and the second to the ejector provided in one of the settling chambers. Thanks to the ejector, the amount of oxygen that saturates the water increases. The use of an ejector made it possible to achieve a more stable quality of cleaning, as well as speed up the process of reaching the station's operating mode at startup.

We add that some manufacturers of "pumping" aeration plants recommend adding bioactivators to the water at the initial start-up or after a long downtime of the station to speed up the release of VOCs to the declared mode of operation.

How to determine the required volume of aeration installation?

To determine the required volume of VOC, the following points should be considered:

- Productivity of installation (l/days). It is always indicated in the technical specifications of the VOC.

- The number of people permanently living in the house. The daily norm for water consumption is approximately 200 liters per person (according to SP 30.13330.2012 "Internal water supply and sewerage of buildings"). Knowing how many people are in the family, you can calculate the daily volume of wastewater that will need to be diverted to the sewer. Thus, for a family of five permanently residing in the house, an installation with a capacity of about 1000 l / day will be optimal. As a rule, manufacturers allow short-term excess of the volume of effluents by 20-30% per day, for example, when guests come to you for the weekend. But a long-term increase or decrease in the volume of wastewater will lead to a deterioration in the quality of treatment.

- Many installations are critical to volley water discharge. Therefore, often in their characteristics the maximum allowable volume of one-time drains from various plumbing fixtures is indicated.

Often, homeowners want to direct the "black" drains from the toilet to the aeration unit, and dispose of the "gray" drains from the bathroom and kitchen in some other way, for example, to drain directly into the filter well. At the same time, the savings consist in the acquisition of a smaller aeration unit. We do not recommend doing this, since "gray" drains are also dirty, and dumping them into the ground without cleaning means harming the environment. And the filter well will quickly become clogged. In addition, when separating wastewater, the aeration plant will not receive the nutrient medium it needs in the required volume, sludge will not form normally, which means that it will not be able to treat wastewater with high quality.

In we will talk about how to properly position the aeration unit on the site and how to properly mount it. And also we will touch upon the acute question - is it possible to divert water from the aeration installation to the relief?

Country life can be not only useful and harvesting, but also pleasant. So that nothing overshadows your stay in your favorite area, it is necessary to solve all domestic problems. Often in holiday villages there is no centralized sewage system, so water must be drained and treated locally. The same problems can arise with the supply of electricity and water. The owners of the site are faced with the question of how to install septic tanks for summer cottages, which one is better and more efficient.

Finding a system for local sewerage is quite easy, as manufacturers from different countries have developed various options for every taste. Nevertheless, it is necessary to navigate in a variety of models, materials and prices in order to find the ideal septic tank for your site, which will satisfy all parameters.

The systems differ in some ways:

- operating principle.

- materials used.

- weight and volume.

- performance and device.

How to choose a septic tank for a summer residence and a country house

Before you purchase and install, or you can make a septic tank yourself in your backyard, you need to consider a few basic small but important issues that the owners must determine:

- type of residence - seasonal or permanent.

- how much resources are willing to spend on wastewater treatment.

- how high the groundwater is to the surface and the type of soil on the site.

- what are the dimensions of the area.

- how many people will live in the house and how many plumbing fixtures form drains.

Features of the choice of septic tanks by materials and types

Manufacturers offer a large number of different models of septic tanks to their consumers. It is difficult to immediately make a choice, especially when the problem arose for the first time and there is no proper experience in installing such equipment. Septic tanks for home and summer cottages can be inexpensive and have a minimum of components and, on the contrary, differ in model complexity and high cost.

Types of treatment facilities

According to the principle of operation, it is customary to divide the equipment into two main types:

- cumulative.

- cleansing.

The simplest model is the usual storage capacity. In simple words, the storage tank is a cesspool (not a septic tank, since there is no wastewater treatment), which requires constant cleaning. It is extremely difficult to do such a procedure on your own, so you can’t do without the services of a sewage machine.

In the event that a small family intends to spend only the summer in the country, it is not advisable for it to install, for example, a biological treatment plant. The bacteria needed for recycling cannot survive the rest of the time without food, so a simple storage container may be the best solution for seasonal living.

Treatment facilities have a more complex design and corresponding price. They can be distinguished by the following parameters:

- principle of operation.

- final cleaning level.

- container volume.

- availability of additional functions.

If the family plans to live in a country house permanently, then the option of arranging a septic tank or a full-scale biological treatment plant will be a must. A cesspool (storage tank) will not work, as it will no longer be financially profitable.

For example, if 3 people live, the daily drain will be about 600 liters (200 liters per person), and 4200 liters (4 cubic meters) per week. With an average capacity of a sewage truck of 4 cubic meters, it turns out that you will have to order a car 4 times a month. Then you can calculate for yourself, based on the prices for these services in your region, how much you will spend per month and year. What will be more profitable for you?

According to the degree of cleaning, a septic tank for a private house can be very effective. To achieve 50-75% purification, it is enough to purchase (mount it yourself) 1-3 chamber sump (depending on the amount of wastewater). After that, the water is sent to the soil aftertreatment (filtration fields or drainage well).

A septic tank without pumping out will cost much more, but money can be saved on the constant call of a specialized machine. In fact, you will have to call a sewage truck in any case, the only question is how often. If you use a three-chamber septic tank, then about once a year you need to pump out the resulting sludge, and if you add special bacteria, then even less often once every 5 years.

Now let's talk a little about deep cleaning stations (not quite a septic tank and electricity is required for operation).

According to the manufacturers of such installations, the degree of wastewater purification reaches 98%, but there are points of view that this is just a marketing ploy and in fact the degree of purification is less. Water after such a station can be used to irrigate your site, but it is not recommended, since dangerous bacteria may still be present in it due to the disadvantages described below. To use the water after the station, additional filtration facilities are needed.

The main advantages of aeration plants:

- The biopurification station is small in size and does not take up much space (it is convenient to place it in a small area).

- Unlike the same cesspool (single-chamber storage tank), in the biological treatment plant, sewage does not accumulate, but biochemically decomposes into simple and practically safe compounds - technical water and stabilized activated sludge, even smells do not remain.

- Such an installation is convenient in that its installation is easiest to do, earthworks are small.

- Manufacturers, as a rule, have their own teams that can install equipment in a short time, and then provide service.

- All equipment is manufactured at the factory, so the reliability will be higher than that of a self-made design.

- Can be used at high groundwater levels.

Cons of deep cleaning stations:

- A more accurate performance calculation is required. There is a risk of an unstable degree of cleaning if there are more or less residents than the installation is designed for.

- Energy dependence. When the electricity is turned off, the degree of purification tends to zero.

- The complexity of the design. Periodic maintenance of the equipment and its repair is required.

- A long break in use is not allowed.

- Due to the small volume, it does not cope well with large household waste and with volley discharge (a large amount of wastewater in a short time, for example, draining a bath).

- Periodic maintenance by specialists is required (every 3-6 months).

Preferred material for a septic tank

When wondering what a septic tank should be, it is also necessary to decide on the material. Most often, containers are made of metal and plastic, as well as brick and concrete. It should be borne in mind that septic tanks made of brick or concrete rings must be waterproofed.

Brick and concrete rings

This type of treatment plant is most often built independently, since this is the most inexpensive type of septic tank, but it requires much more labor.

A number of features of this type of septic tank should be taken into account:

- Wastewater treatment in this type of septic tank occurs by overflowing wastewater from one chamber to another chamber. Therefore, 2-chamber septic tanks made of concrete rings are usually installed (a brick will require more effort and time). Both chambers are made with a sealed bottom (special bottom rings are sold), and after the septic tank, a drainage chamber is built without a solid bottom, instead of the bottom, an embankment of sand and gravel is made.

- It is necessary to pay attention to the diameter of the concrete rings. The volume of the final septic tank depends on them. By the way, rings are best taken with a lock so that they are not displaced by frosty heaving of the soil and the joints are more airtight. You should also take into account the number of people living, the larger the family, the more the volume of the septic tank is needed.

- If your site has a high groundwater level, then very good waterproofing is required to prevent contaminated sewer water from seeping into the soil and flooding the septic tank.

- For better wastewater treatment, special bacteria can be used, and for post-treatment of wastewater, it is recommended to arrange a filtration field, but you can also get by with a simple drainage well (chamber).

- If the soil at the installation site of the septic tank is clayey, then you should not make a drainage chamber, the water in it will still not go well. For the disposal of wastewater, it will be necessary to arrange filtration fields (soil post-treatment).

The disadvantages of this type of septic tank include:

- The complexity of self-assembly and a fairly large amount of earthwork;

- Unlike plastic or metal septic tanks, complete tightness of the joints of the rings is not ensured;

- Difficulty in ensuring proper operation at a high groundwater level (no point in a filter well and waterproofing is required).

If a brick or concrete septic tank is not waterproofed, then raw sewage from the receiving well will leave, contaminating your soil and groundwater, such as drinking water from a well or well. Do not forget that draining untreated water violates sanitary standards and threatens with a fine ( in the Criminal Code of the Russian Federation there is even Art. 250) . Among other things, in the spring, melt water can enter the septic tank and flood it, disrupting the operation of the entire sewage system.

Ready-made septic tanks made of metal and plastic

The main advantage of metal and plastic septic tanks over the same concrete ones is that you do not need to do expensive waterproofing and the groundwater level is not terrible.

Features of using septic tanks made of metal or plastic:

- The groundwater level is not critical, it can be used at high GWL, but it may be necessary to install filtration fields and a drainage pump (it turns out a volatile system)

- You need to choose septic tanks without seams. Almost all modern local treatment facilities are already made without seams, which provides protection against leaks.

- Plastic, being in the ground, is not subject to corrosion and delamination, therefore it can last more than 50 years.

Disadvantages of such systems:

- The metal has a short service life, as it is susceptible to corrosion (service life of 10-20 years), and if the septic tank has not yet been treated with an anti-corrosion coating, then even less.

- Metal and plastic wastewater treatment plants will cost more than installing a concrete septic tank.

- Septic tanks made of plastic or metal can be squeezed out of the ground at high groundwater levels when they are pumped out, so they are most often attached to a concrete slab.

- To protect plastic septic tanks from damage (squeezing with soil), especially if the soil in the area is heaving, an additional box (concrete) is made or sprinkled around the septic tank with a cement-sand mixture.

We make the necessary calculations before choosing a treatment plant.

- Calculation of the volume of a septic tank.

A simple but effective formula for determining the minimum volume (working or usable volume) in liters

Q(volume in liters) ≥ N*200*3

N- the number of people living (guests arriving for several days are not counted).

200 - the recommended daily water consumption per person.

3 - the number of days during which the drains are in the septic tank.

Important note: the volume of the septic tank is calculated for all chambers, so it is important to take this into account when building a treatment plant on your own. The volume of the chambers is calculated according to the scheme 2:1 for a two-chamber and 2:1:1 for a three-chamber.

- Ground water level- a very important requirement when choosing a septic tank. You can find out the GWL, for example, if you did a geological survey of the site, in the well passport or in the administration of your settlement. You can independently find out the GWL, for this a garden drill is suitable. Drill 2-3 wells with a drill at the proposed site for installing a septic tank and check how far the water will go from the surface. It is best to measure the GWL after the melt water has drained and been absorbed into the ground + 1-2 weeks. If the water is close to the surface from 1 meter or less, then it makes no sense to make a drainage well (without a bottom) and it will be expensive to make good waterproofing for a concrete or brick septic tank. The distance from the bottom of the drainage well to the groundwater table must be at least one meter.

At a very high GWL, for the post-treatment of wastewater after a sealed septic tank, an embankment (hill) is made in which infiltrators and filter cassettes are placed. Or use deep cleaning stations (aeration plants).

- Soil composition. You can find out in the same way as UGV. A system with wastewater discharge into the ground can only be used in sandy, sandy loamy and light loamy soils with a filtration coefficient of at least 0.1 m / day and a groundwater level of at least 1 m from the planned ground level. In simple words, if there is clay at the site of the soil treatment plant, then the discharged water will not leave. It is necessary to equip the filtering fields.

The most popular septic tanks

When choosing the best septic tank for a country house and a summer residence, it is necessary to decide whether volatile or non-volatile models should be considered. Large investments in the site are required if it is planned to use it often and in full. For seasonal cultivation of vegetables and a rare stay, a small septic tank is quite suitable, which does not require serious expenses. An excellent option for such cases would be a storage tank or sump. Their installation does not require special material costs and the capacity is enough for the needs of the inhabitants of the house. The non-volatile option is also suitable in case of constant power outages.

The second option of a septic tank will cost a little more, but will be durable. A volatile system does not take much electricity, but its supply must be continuous, otherwise the work, for example, of a deep cleaning station will be disrupted. The complete set of such models includes aerators and pumps involved in wastewater treatment.

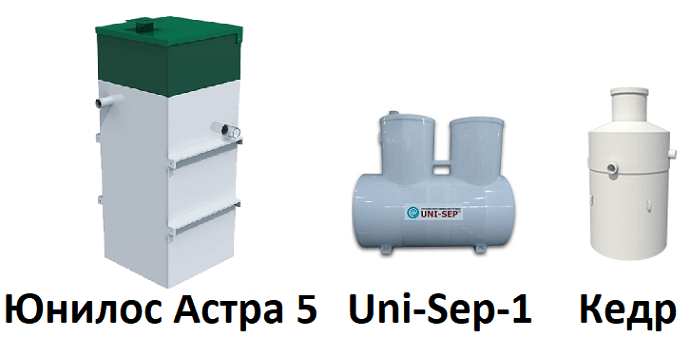

To choose the right septic tank, you need to navigate the most famous brands. All of them have positive feedback from users. The most commonly purchased septic tanks:

- Tank and Triton.

- Tver and Astra.

- Topas and Poplar.

- Leader and Eurobion.

Among these models, the Tank, which is non-volatile, is more popular. Also Astra and Topas have very good characteristics. All three models are different:

- ease of installation work.

- acceptable price.

- compactness and lightness of construction.

- high quality cleaning.

- the possibility of self-service.

Tank and Triton do not depend on the supply of electricity. Each modification has volume options and a different number of cleaning chambers. A septic tank from Unilos can be designed for a small village, and smaller sizes are also found.

- It is better to choose a system that does not require complex maintenance with the involvement of third-party companies.

- Water from a septic tank, as the most economical and environmentally friendly way, must be diverted into the ground.

- Choose a place for a septic tank so that a sewage truck can drive up to it.

- It is advisable to choose a non-volatile system.

- It is better to choose a system whose service life will be at least 50 years.

- When choosing a model, you need to get acquainted with user reviews.

All these simple rules will help you make a choice and install a septic tank for many years. Proper installation and calculations are the key to long-term use of cleaning systems.

rating of septic tanks for a country house 2018 (TOP -10)

And now the moment has come when the relief of the site is planned, the dream house is built of reliable material, it remains to complete only a couple of moments related to convenience and nature ... proper solution to this issue. Namely, the choice of an autonomous sewage system or a septic tank, which will allow you to purify wastewater and save the environment. Therefore, the only way out is to install a septic tank, which decomposes sewer and fecal matter into almost pure water and harmless sludge. Los or septic tank is better to choose for a country house? But what is the best septic tank or los? What suits me for temporary or (all-season) permanent residence? What does the rating of septic tanks look like volatile or non-volatile? This is probably one of the most difficult questions when building a house. We strive to always get the best in our lives, as this guarantees us peace of mind and reliability. Everyone asked this question when building their dream home, choosing a site or materials, which of the offered on the market is the most reliable and of high quality. I want to compare to understand the rating. Choose the best septic tank for you. Understand which quality septic tank has a great guarantee.

History of the septic tank

Long gone are the days when in a private house everyone was satisfied with a "birdhouse" on the street. The modern standard of comfortable life, even in the country, requires the presence of a normal toilet and, at least, a shower. And in the house there is often more than one bathroom, and in addition a lot of household appliances. To ensure the required level of comfort, sewerage for a private house must be done correctly and its basis is the choice of a method for processing wastewater. Since the correct selection and subsequent disposal of wastewater will ensure a comfortable stay on the site.

Article about the best /

What will we get from this article? - MAXIMUM in order to choose a septic tank / los. We will also pay attention to the definitions, principles of operation of various treatment plants, the most popular and efficient models. We will determine how to choose the best septic tank for your home or garden. And what characteristics should be considered when choosing the best septic tank or VOC for a country house. It is important not to make a mistake in choosing the best sewerage solution for yourself.

Variations of the best septic tank or in 2018

Today is already 2018 and in our modern world there is a lot of competition and it is very difficult for any consumer to make the right choice in favor of reliability, quality and peace of mind. Plunging completely into this very interesting topic, you understand how many of them, variations, materials, pros and cons. Septic tanks, VOCs and storage tanks - we will completely determine what is what? Since many people confuse the name of a septic tank with an autonomous sewer.

For temporary residence

For permanent residence

DESCRIPTION: Storage tank, or.

We suggest that you familiarize yourself with the general definition of what systems are and what they are intended for. Below is a block of information to understand the principle and operation of wastewater treatment and storage systems. Therefore, the best septic tank for home and garden will be your own. Let's start with the simplest - definitions and explanations of what is what.

A storage tank is a reservoir, from the word (fr. réserve from lat. reservare - save), designed to accumulate household wastewater from the sewer. The main purpose is the accumulation and storage of sewage, household waste, etc. The purpose of the storage tank, in the case of wastewater collection, is to exclude direct emissions into the environment (ditch, soil, water). This technological solution allows you to save the ecological environment on your and neighboring site. The storage tank does not process or treat wastewater from the sewer.

- Drains come to the storage tank, from where they are periodically pumped out by a sewage machine.

A septic tank is a complex structure consisting of a reservoir and a system of perforated drainage pipes, designed to treat household wastewater from the sewer. As mentioned earlier, this structure consists of two parts:

- The first part of the septic tank is a reservoir, or receiving chamber, where sewage from the house enters.

- The second part of the septic tank is a structure (filtration field or soil post-treatment) of perforated pipes laid on a layer of rubble.

The first part of the septic tank, or receiving chamber, can be made of many materials, but we would talk about this in the next article. He will also talk about all the pros and cons of these solutions with a septic tank.

VOC is a local treatment facility designed for mechanical and biological treatment of household wastewater from sewers. This facility is a multi-chamber closed system in which all steps and cycles of wastewater treatment take place. The whole complex of measures in VOC allows for complete and reliable treatment with a degree of 98%, which allows you to reuse treated wastewater from VOC. It can be used to water plants, wash a car, or simply dump it into a ditch, storage tank or absorption well. True, it meets these criteria only after the installation enters the operating mode (when the colony of bacteria multiplies in sufficient numbers). This may take up to 2-3 weeks.

Since everyone has different situations and conditions on the site, you first need to know the following:

- GWL - groundwater level. GWL is the first underground aquifer from the surface of the earth. It lies above the first water-resistant layer, which does not allow water to pass through and does not allow it to seep deeper). But it should also be taken into account that the GWL is a constant phenomenon. First of all, it depends on the time of year. For example, in spring, snow melts, at which GWL increases, while in winter it decreases.

- Availability of water protection facilities/zones — a limited regime for the implementation of any activity is established on them. Which are aimed at preventing pollution and clogging.

- The area under the septic tank / los - the size of the site that you are ready to give for the organization of wastewater treatment.

IMPORTANT: Bacteria for wastewater treatment in and

Why are they and why do we write about them? Bacteria - bacteria are everywhere and everywhere, but here you can’t do without them. Let's take a closer look at what and how bacteria form in a septic tank or VOC for (all-weather) permanent residence. It is important to understand not only the external structure, but also the internal processes. Proper operation and conditions for bacteria will ensure the reliable operation of the VOC and septic tank for permanent residence. They play the most important role in the purification stages. Let's get to know them better...

Anaerobic bacteria for and

Waste enters the septic tank, there is a reaction of their decomposition and the formation of bacteria. They form and need a minimum concentration of air or an oxygen-free environment. It is recommended to choose septic tanks that are airtight and durable. It is advisable to look at the warranty and production method. The cleaning process with these bacteria is quite slow. It is also called anaerobic treatment or simply clarification of wastewater.

As a result, after anaerobic treatment, wastewater is not allowed to be discharged into the ground or ditch, since it is not sufficiently cleaned and is not technical water. In order to dispose of it, a storage tank is used, and in the case of additional cleaning, aeration fields are used / equipped.

Aerobic bacteria for

In they are formed in the aerotank chamber. This is a special reservoir or structure located after the preliminary settling tank, in which anaerobic bacteria are formed. Pretreated wastewater with activated sludge flows or is pumped into the aeration tank chamber, where deep biological treatment takes place. This process occurs due to the forced saturation of wastewater with oxygen. For the vital activity and reproduction of aerobic bacteria, a favorable environment is needed - oxygen-enriched water. This process consists in the separation of natural waste into components. This type of bacteria is the most effective, because it quickly affects biological substances.

- Activated sludge organisms require small amounts of dissolved oxygen to function normally. The critical concentration is considered to be 0.2 mg / dm³, quite satisfactory - 0.5 mg / dm³ of dissolved oxygen.

- The maximum cleaning percentage for anaerobic bacteria is 60%.

- The maximum percentage of cleaning with aerobic bacteria is 98%.

PRINCIPLE OF WORK or how it works:, or.

Since the process and principle of operation of the storage tank is already clear, let's take a closer look at how the processes and work in the septic tank and /. Effluent through a pipeline or sewer enters the septic tank or. The principles of operation of all cleaning systems consists of several stages. The partial stage cannot provide the required quality of cleaning and is not recommended by law and regulations for discharge into the ground. First of all, let's analyze the information about the septic tank ...

The septic tank is a "beta" version of the on-site treatment plant. To begin with, how does the process of cleaning in a septic tank.

- After the effluent enters the septic tank (reservoir), primary settling occurs with a minimum amount of oxygen. This stage is necessary to carry out preliminary treatment of wastewater. First of all, sedimentation, fermentation and reproduction of anaerobic bacteria occur. As a result of the first stage, the heavy fractions settle to the bottom, the fat floats up and the effluents are clarified. After preliminary settling and all biological processes, the degree of purification is 60%.

- After the first stage, the degree of purification is not enough to be able to safely discharge effluents into the ground. It is not technical and does not meet standards and regulations. Water needs additional treatment, for this event it is necessary to make the outlet of settled effluents for soil post-treatment (field filtration). At this stage, wastewater gets the opportunity to form aerobic bacteria, passing through the soil and being cleaned of possible impurities. This event provides cleaning with a degree of - 90%.

These cycles are several stages of cleaning, which is why the container consists of several parts / compartments. Effluent from the sewer enters the VOC, which mainly consists of 3 parts.

- First compartment or pre-sump. It has a mechanical / anaerobic cleaning method. Bacteria arise as a result of sedimentation and fermentation of wastewater in a septic tank and an autonomous sewer. Similarly - like the first stage in the septic tank. Effluent flows into the second compartment through a system of airlifts or by gravity.

- The second compartment or aerotank. A biological / aerobic cleaning method takes place in it. Aerobic bacteria arise and continue their vital activity as a result of forced saturation of wastewater with oxygen, as a result, biological decomposition of organic matter occurs. For the formation of beneficial microorganisms, pumps or compressors are used. Effluent flows into the third compartment through a system of airlifts or by gravity.

- The third compartment or secondary sump. Here the last stage of cleaning takes place - the remains of organic matter turn into silt and settle to the bottom. Process water with a degree of 98% purification comes out of the secondary chamber. This water is suitable for watering the garden or discharge into the river. Some septic tanks consist of only two chambers, so the degree of wastewater treatment in them is lower.

- Septic tank - degree of purification 90%

- VOC - degree of purification 98%

WHO WHAT? how to choose OR OR

Let's take a closer look at the technical features and purposes for consumers. Most likely, after reading this block, you will understand exactly what you need for temporary residence, and what for (all-season) permanent residence. And the most important thing is that you choose the best septic tank for your dacha and home, and maybe VOCs.

A storage tank is an ideal option for a small country house in which 2-3 people live, and even then not in all cases, since they do not process wastewater. First of all, this option is suitable for those who plan to live in a house or summer cottage seasonally: 2-3 months a year (summer). This option is the simplest of all solutions for the removal of sewage. Given the direct purpose of the storage tank, you need to select the most optimal volume of the tank.

Service

There is only one storage tank service and it is quite simple. In order to implement it, it is necessary to call a sewage treatment machine for waste water, and pump out wastewater from the storage tank when it is full.

First of all, a septic tank for a house with a filtration field is used on well-permeable soil. It does not require electricity and is popular for temporary and seasonal living. If everything is properly organized and taken into account, it is an ideal option for country houses (all-weather) permanent residence. Of course, if it is possible to organize and install a septic tank with soil cleaning (filtration field), taking into account laws and regulations. As well as the low level of groundwater, is the main factor in the choice of existing options for the removal of treated wastewater. Minimum groundwater level (min. 1.5 m from drain pipes).

Filter field

The main visual differences between the storage tank and the septic tank are an additional construction of the second stage of cleaning.

The filtration field is an underground system of drainpipes located on a gravel layer on which wastewater is treated. The soil is the recipient of treated wastewater. In the case of a high groundwater level, a pumping station should be installed and the entire treatment plant should be placed higher and installed in an embankment.

At the moment, it is an ideal, practical and correct solution for a house, a summer residence or a cottage for permanent and temporary residence. First of all, to install a deep biological treatment station, a fairly small amount of space is required compared to a septic tank or storage tank. All biological treatment processes take place in one tank, there is no need to organize filtration fields and other technical solutions. It is only required to divert the treated effluents into the ground, ditch or water body.

Cleaning degree

VOC is a modern facility for wastewater treatment with a high degree of purification of 98%. Thanks to all the processes and new technologies, MBBR can be applied and will fit any area - size and conditions. It is clear that there are situations when it is impossible to organize the release of treated wastewater. Then the filtration fields in the embankment are applied. But these are unique cases that allow organizing the absorption of treated effluents into the soil.

Facilities

Manufacturers immediately indicate the number of users in order to perfectly match the los for your needs. But it is necessary to properly understand the processes inside the plant, since some deep biological treatment plants require a constant supply of effluent. Therefore, in LOS Delfin everything is implemented by gravity.

For permanent or temporary residence - DIFFERENCES:, or.

All systems are designed to treat wastewater after a house or a summer residence, but it is necessary to understand not only the positive side, but also the negative one in order to make the right decision. Below is a table that contains reviews, facts and technical features of the use of a particular cleaning system. A septic tank for permanent residence, according to its parameters, must fully cope with the expected volumes of flow, therefore, when buying, it is necessary to take into account how many people will live in the household. It is also worth noting that for temporary residence it is worth paying attention to inexpensive stations that require minimal financial costs. When it comes to a septic tank for a permanent stay, we recommend taking a deep cleaning station.

| Concrete septic tank / storage tank | Plastic | ||

|---|---|---|---|

| Frame | |||

| Possibility of self-production | Can be DIY | Factory version only | Factory version only. |

| Equipment tightness | When self-manufactured, it is difficult to seal, especially at high groundwater levels | The hull is sealed, requires anchoring or special devices. Simple structure, ensures stable operation of the pre-cleaning stage. Durable. Environmental Safety. | Sealed body, does not float (always full). All equipment is manufactured at the factory, so the reliability will be higher than that of a self-made design. Durable. Environmental Safety. |

| Cleaning of drains | |||

| Wastewater treatment options | Not | Filter well, sand and gravel filter, infiltrators. Limited service life of the filtration field. Fragility and high risk of contamination of soil and groundwater - especially true for cesspools and concrete wells | Autonomous sewerage is small. It is possible to place on absolutely any site and any conditions. Filter well, sand and gravel filter, infiltrators, drainage ditch. |

| Degree of sewage treatment | Degree of cleaning - 60%. | The degree of purification - 90%. An unpleasant odor coming from a storage septic tank, an overflow well or a filtration field. The penetration of sewage (faecal water) into groundwater, and then they often fall into water wells. The need to use special bacteria for maximum environmental friendliness. | High degree of purification - 98%. Thanks to all cleaning technologies, a high degree of cleaning is achieved, which makes it possible to discharge water into a ditch or drainage (technical water, reuse). |

| Dependence on electricity | No | Energy independence. There are no compressors or pumps in the design of the septic tank. An electrical connection is not required. But a permanent residence is required. Necessary for the flow of all cleaning processes. Without sewage, sewage rotting occurs, which entails unscheduled maintenance of the station. | Energy dependence. Not for all autonomous sewers, this factor is a disadvantage. Depending on the principle and modes of operation of the plant, energy dependence can play a key role in the operating cost of the entire plant. Since automation and compressors with pumps work constantly, the station quickly consumes motor resources, the reliability of the components of the station. |

| Demanding for the regularity of "replenishment" | Irrelevant | Irrelevant. Bacteria living in a septic tank do not need daily feeding. | It reacts badly to uneven flow of effluents, it is better to use it for permanent residence |

| Salvo drop | Works great with large volumes | Works great with large volumes. With the correct calculation of the volume, the septic tank is not afraid of the increased salvo discharge of wastewater. | Handles only a certain amount of stock |

| High groundwater level (GWL) | To ensure the pumping of settled wastewater, it is required to use a pumping station, which will affect the final cost of the entire station and become comparable to an autonomous sewage system. | Can be used at high groundwater levels. Organization of KNS or additional modifications. | |

| OPERATION and SERVICE | |||

| Service | Regular pumping with a sewage truck (1-3 times a year). Service as the tank fills up. Limited storage capacity. Constant control of the level of wastewater. | Regular pumping with a sewage truck (1-3 times a year). Convenient for houses with non-permanent residence. Minimum service and maintenance costs. Regular call of sewers (necessary even for septic tanks of the TANK type requiring constant backfilling of anaerobic bacteria) to pump out unprocessed effluents | Minimum service costs. Periodic maintenance by specialists. Many manufacturers seek to reduce the cost of their products, which requires the systematic intervention of the manufacturer's service department. Compressor maintenance. Convenient and easy operation, without constant attention. |

| Smell | Unpleasant odors during service. An excellent breeding ground for bacteria and viruses that are dangerous to health. | Silting field filtration. Depending on the use and correct design and installation of the entire system of the station, the need to relocate the filtration field occurs on average after 10-15 years, which entails additional costs. | Odorless. All gases exit through ventilation. |

| MOUNTING | |||

| Excavation. | Easy installation under the tank. | Area by field filtration. The complexity of installation and a fairly large amount of earthwork. Since soil post-treatment is required, it is necessary to have additional free area for field filtration. Cumbersome and not everywhere possible installation of primitive treatment septic tanks, the need to ensure the access of a sewage truck. | Easy installation. For autonomous sewerage, it is not required to organize field filtration (soil post-treatment), which entails an additional amount of excavation work (without restrictions on area and geological conditions). |

RATING: Description of the top IMPORT (Finnish, Polish) and domestic Russian / for permanent residence

This article will be a general comparison of existing autonomous sewers / VOCs on the territory of the Russian Federation. We will try to highlight the most popular autonomous sewers produced in Russia or in Europe. Despite the fact that there are many different septic tanks on the market today, not all of them are of high quality and reliable. When choosing, it is also necessary to build on not only the characteristics, but also the manufacturer. Comparing septic tanks for the home with each other, it is impossible to say definitely which one is the best, since each variety has its own advantages and disadvantages. But in general you can...

Since at present there are many varieties of septic tanks on the construction market, which differ not only in varieties, technical characteristics, but also in prices, it is quite difficult to choose them. Therefore, it is worthwhile to clearly analyze all the nuances and choose it according to the technical characteristics, the quality of the cleaning device and parameters, as well as depending on its manufacturer.

Delfin

Since 1993, one of the most popular European manufacturers of professional equipment for the treatment of any wastewater. Joint production with the largest company in Europe for the production of local treatment facilities - SEBICO.

TOPOL ECO

Topas is one of the most recognizable stations in Russia. Production with. It has been produced for a long time and has its own history. Topas is a hermetic system for the biological treatment of wastewater from the sewer system.

Alta Bio

The Russian manufacturer offers an integrated approach to water treatment. For more than 10 years, it has been a leader in the market.

Tver

Produce stations relatively recently compared to all. But they have good reviews and design features from analogues.

UPONOR

Finnish septic tanks and autonomous sewers. Known for their quality and competent design. Like all European septic tanks, they are made to minimally include their customers in the service.

UNILOS ASTRA

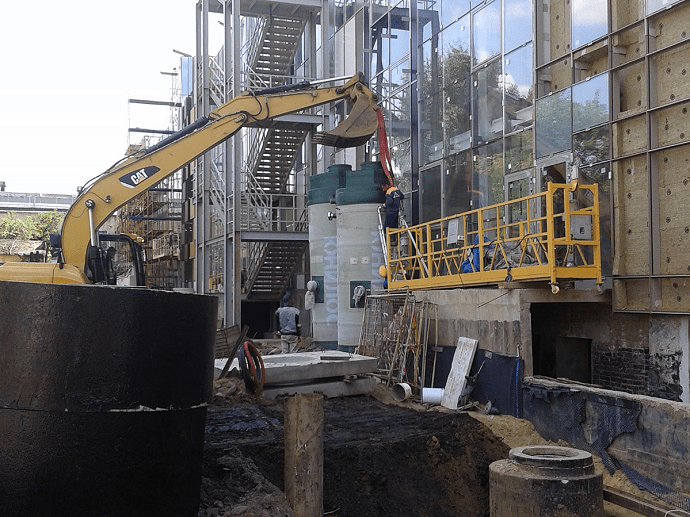

SBM-Group is the largest Russian manufacturer of UNILOS ® autonomous sewage systems for objects of various types.

EUROBION

In 2005, the group of companies "National Ecological Project" was established. Production in Russia of VOCs under the EUROBION and YUBAS trademarks.

TANK

External view of VOC and Septic tank

Appearance sometimes in this version can tell a lot. How the station will feel depending on the ground conditions.

VOC PRO from Delfin (Delfin)

LOS TOPAS from TOPOL ECO

VOC by Alta Bio

LOS Tver

UPONOR

LOS UNILOS ASTRA

LOS EUROBION

TANK

Principle of operation

PROCESS of reliable autonomous sewerage DELFIN PRO6

Premium class means no interruptions, no rotting drains and unscheduled maintenance

1st Camera

Pre-sump

Processes: Effluent accumulation, preliminary treatment and settling of effluents (heavy fraction sedimentation).

2nd Camera

Aerotank + MBBR technology

Processes: Active treatment of wastewater in the water column by aerobic bacteria through forced aeration.

3rd chamber

Secondary clarifier

Processes: Secondary settling of treated effluents before discharge from the station.

The process of deep biological treatment in autonomous sewage system DELFIN PRO /LOS occurs by gravity through all 3 chambers (preliminary settling tank, aerotank, secondary settling tank) without stopping the recirculation. This ensures reliable operation in the event of a power outage VOC. European Reliable Autonomous Sewerage PRO continues to work on the principle of a three-chamber septic tank.

- VOC No flooding

- Stable work of drains

- No unscheduled maintenance

Topas and Principle of operation

- This is a treatment plant built according to a four-chamber scheme. The transfer of purified water from one chamber to another does not occur by gravity, but with the help of an airlift, so the operation of the entire system depends on electricity. A power outage blocks the operation of the septic tank, which is a very significant drawback that outweighs the very deep sewage treatment (almost 98%). The compressor ensures the operation of the septic tank, so the installation requires a connection to the power supply. Therefore, it is worth planning the installation of such a septic tank only where the supply of electricity is stable. If the compressor stops, the station will not be able to function.

receiving chamber

Waste water enters the receiving chamber. In contrast to the "classical installations" in Topas, the receiving chamber is equipped with an aerator for mixing the drain and saturating it with air oxygen. Aeration in the receiving chamber is switched on when the level of flow in it drops to the operating minimum. Due to this, instead of settling and decaying the sediment, the effluent in the receiving chamber is averaged in composition, and purification processes begin - the molecules of organic compounds decompose under the action of enzymes secreted by bacteria. coarse filter Small particles of impurities mixed in the drain and passed through a filter with cells with a diameter of 10 mm enter the main pump. Large particles of dirt and debris remain in the receiving chamber. The main pump is an airlift, in which the air supplied by the compressor (9) lifts wastewater through the pipe and pumps it into the aerotank-reactor. Pumping occurs evenly with low productivity and, unlike other types of pumps, without high electricity costs and power surges caused by pump start-up. float switch To switch the Topas operating modes, a float switch is installed in the receiving chamber. In the first phase, when the receiving chamber is filled with sewage, the float rises and the first compressor is turned on. It supplies compressed air to:

When the flow level in the receiving chamber drops to the operating minimum, the float drops and the second compressor is turned on. The air supply switches to:

- aeration of the receiving chamber,

- airlift for pumping sludge from the aeration tank to the stabilizer sump,

- airlift removal of fatty film in the secondary clarifier,

- aeration in the secondary clarifier.

Aerotank-reactor

The chamber in which the main wastewater treatment by activated sludge microorganisms takes place. Due to aeration, the runoff is maintained in suspension and saturated with atmospheric oxygen. In the settling phase, the sludge begins to settle to the bottom and the sludge particles are combined into flakes. Due to a decrease in the amount of oxygen in the drain, bacteria begin to use dissolved nitrogen compounds, nitrates, for respiration, reducing them to nitrites and further to molecular nitrogen. Denitrification is the removal of nitrates and nitrites.

Secondary clarifier

A chamber shaped like a truncated inverted pyramid and located in the aerotank-reactor. In the sump, sludge is deposited, which returns to the aeration tank through the hole at the bottom. Additionally, a mixture of water and sludge is supplied from the aerotank-reactor to the secondary settling tank from above, using a recirculation airlift (6). This speeds up the process of sedimentation of sludge and clarification of water. A film of light fractions (fats, oils) is agitated by a bubbler in the upper layer of water and removed to the aerotank by an airlift built into the pyramid. The treated wastewater is discharged outside by gravity through the outlet in the unit housing or is collected in a forced ejection tank with a pump installed in it. Most quickly, dying sludge settles to the bottom of the aerotank-reactor, which, in the settling phase in the aerotank, is pumped with the help of an airlift (8) into the sludge stabilizing sump (G). This is the smallest chamber in which the accumulation and mineralization of sludge takes place. Through the existing hole in the upper part, the clarified sludge water enters the receiving chamber back, thus closing the process of internal circulation. A standard air-lift pump for pumping out sludge is installed in the stabilizer sump. This pump is muffled and the air supplied to it produces agitation of the sludge mass, preventing it from settling and compacting at the bottom. As part of self-service, a regular pump is used to pump out sludge; in order to avoid compaction of sludge in the stabilizer, pumping is required to be done once a quarter. It is possible to pump out sludge 1-2 times a year (as part of maintenance) with a drainage (fecal) pump for contaminated water.

The principle of operation of autonomous sewage Alta Bio

At the heart of each autonomous sewage system for a summer residence is a septic tank, which is designed to purify water from harmful impurities. It breaks down most organic waste. To date, there are a large number of various autonomous sewers. Alta Group offers a more advanced design, which is a complete water purification system from waste.

Two stages of water purification in Alta Bio autonomous sewerage:

The first stage of wastewater treatment is the sedimentation of suspended particles in a three-chamber sump. The sump (lower part of the Station) consists of 3 separate sections with overflows through which domestic sewage flows flow. The overflows are located in such a way that the wastewater flows at the lowest speed, due to which coarse suspended particles settle to the bottom in each chamber. The volume of the first section is 50%, and the second and third - 25% of the total volume of the sump. The total volume of the sump is designed for two days of waste processing.

The second stage of wastewater treatment

Post-treatment in a biofilter. From the third chamber of the sump, clarified wastewater is pumped to the upper part of the station with the help of a drainage pump controlled by an electronic unit and is evenly sprayed through a rotating sprayer over the entire area of the bioload (biofilter). The filter is a habitat for microorganisms. At the moment of spraying, wastewater is saturated with oxygen and filtered through the feed material.

Autonomous sewerage for a private house Alta Bio uses electricity in its work. However, even if it is turned off, the station will continue to operate normally, but as a normal septic tank. And when the power supply is restored, the station will go into operation.

Brief description and scope of the Alta Bio septic tank

The treatment plant in question is designed for use in private homes or public places with a small number of visitors. It can be used for arranging sewerage in summer cottages, cottages or other types of suburban structures. Often, septic tanks are installed in country cafes, restaurants or eateries.

The design and principle of operation of the septic tank Tver

The tank is delimited by internal partitions, which form the following chambers:

- septic. This is where the effluent enters in the first place, and it is here that the main processes of sedimentation of insoluble suspensions take place. Over time, some of them pass into the soluble phase and are sent to the next stage of purification;

- anaerobic bioreactor. The next chamber on the route of wastewater is the aerotank. An aerator is installed at the bottom of the aeration tank, through which air is supplied from a compressor installed in the house through a pipeline. Burnt expanded clay is poured onto the aerator, which does not float. A biofilm of microorganisms is formed on the claydite load, which, together with activated sludge, absorb and oxidize pollution. In this chamber, the components of the effluent are mechanically destroyed in the process of passing through the structural elements of the chamber (ruffs) and are partially hydrolyzed due to the vital activity of anaerobic microorganisms (yeast) - the process takes place here effluent fermentation;

- aeration tank. In this chamber there is an aerator, thanks to which the wastewater is saturated with oxygen. This, in turn, contributes to the intensification of the reproduction of aerobic microorganisms, which are always found in domestic wastewater as natural microflora. The oxygen-saturated liquid is sent for further processing;

- sump. Before entering the aerobic bioreactor, wastewater passes through a settling chamber, which retains heavy suspensions, which has a positive effect on subsequent processes of biological decomposition of organic matter;

- aerobic bioreactor. Two processes simultaneously take place in this chamber: aerobic microbes actively multiply and absorb organic inclusions that are part of the wastewater, and the limestone located at the bottom of the section gradually dissolves in water and binds with phosphorus and nitrogen compounds, which are characterized by high toxicity. In the aerobic bioreactor, as well as in the second chamber, there is a brush load. A layer of biofilm on the load collects and oxidizes organic contaminants remaining after deep cleaning. At the bottom of the bioreactor there is a layer of dolomite crushed stone, which gradually dissolves in wastewater, which helps to remove phosphates from it due to their binding with calcium and magnesium ions. The final chamber is a tertiary sedimentation tank, where the dead biofilm is retained, then the effluents are discharged by gravity to the discharge point.

- settler-calmifier. In this chamber, the liquid is additionally clarified by natural precipitation of heavier inclusions, and only after that the water purified by 95-98% leaves the Tver septic tank. Additionally, floats with chlorine-containing reagents are installed in this chamber, which are responsible for water disinfection.

The septic tank has a small weight and rather thin walls, this cannot be attributed to pluses or minuses. These factors make it easy to install, and the thin walls are made of high quality polypropylene. Under the influence of large loads, they can bend, but do not collapse.

FINNISH SEPTIC Uponor (Uponor)

The WehoPuts onsite treatment plant is a biochemical type treatment plant for use throughout the year as a wastewater treatment system.

Local treatment plant for a country house or cottage WehoPuts 5 and WehoPuts 10 are designed to treat wastewater from one household. The model number indicates the number of people living. The calculation uses a daily water consumption of at least 150 liters per person. Both systems are designed for year-round use.

The line of Finnish local treatment facilities (septic tanks) Uponor Bio is represented by products for the complete biochemical treatment of domestic wastewater. Those. after passing through such installations, the liquid can be drained without subsequent soil cleaning. The stations are volatile, moreover, their normal functioning requires the use of special floating (precipitating) additives. The principle of operation of such stations is as follows:

- effluents flow by gravity into the receiving chamber (sump), where the bulk of light and heavy inclusions are retained. There are several settling tanks, which allows you to get rid of obvious pollution as completely as possible;

- further, the effluents enter the process tank equipped with an aerator, in which the potential of activated sludge is activated (microbiological processes are actively taking place). Part of the sludge is periodically pumped into the receiving chamber;

- at the next stage, a special reagent is dosed into the drains in portions, which contributes to the precipitation of fine suspensions. He is also responsible for the binding of phosphorus compounds;

- after the entire cleaning cycle, the liquid can be discharged into the ground

Advantages of this system: wastewater is processed in portions, which allows achieving the same treatment quality indicators; containers are strong and durable; products are accompanied by all necessary documents, easy to operate. The disadvantages can be considered the overpriced cost of Uponor Bio septic tanks (compare, at least, with the cost of Tver or Topas septic tanks), the need to use additional reagents.

LOS Uponor BioClean is one of the innovative solutions from a Finnish manufacturer: compact, durable, easy to use, both in private homes and in summer cottages. Complies with all sanitary requirements. It consists of a single container in which the following processes take place:

- preliminary processes of rough wastewater treatment take place in the sump;

- in the next tank, the effluents are aerated, the inclusions are actively processed by aerobic microbes;

- then a floating reagent is added to the drains (the process is the same as in Uponor Bio);

- excess activated sludge is pumped into the receiving chamber;

- treated effluent is pumped to a sampling well

Astra Unilos. This is a well-known treatment plant for cleaning the sewerage of a cottage, a private house or a whole group of houses. Given the relatively high cost of this model, consumers often discount for the purchase of one powerful installation, which is mounted with the expectation of several families. Of the advantages: reliable operation, high cleaning efficiency. Among the disadvantages: relatively slow operation, high price. The body of the septic tank is divided into four sections: the receiving compartment, the aeration tank, the settling section and the system for discharging treated water into the external environment. The septic tank comes with pumps and ventilation systems that are required to move water from one section to another and to aerate wastewater.

Receiving chamber or surge tank

Untreated wastewater through the sewer line (1,2) enters the receiving chamber (A) of the installation, where they are prepared - crushed and partially oxidized due to aeration - forced saturation of wastewater with oxygen from the air that occurs during the operation of the air installed in a special compartment (I). compressor. Then, uniformly mixed effluents through a coarse filter, which prevents large mechanical and non-decomposable contaminants from passing further, are pumped by the main pump into the aerotank chamber (B).

Aerotank

It should be noted that all pumps that pump between chambers in Unilos are made according to the airlift (or mamut-pump) principle, where pumping is carried out by supplying air to a tube lowered into the pumped liquid. consisting of different types of microorganisms, which in the process of life decompose the substances that make up wastewater. The condition for the formation of activated sludge is the process of aeration in the aerotank chamber, which occurs in the direct (first) phase of operation.

Secondary clarifier

After the aeration tank, the mixture of treated effluents and activated sludge enters the next chamber - the secondary settling tank (C), where the sludge settles to the bottom under the action of gravity, and the clarified treated effluents, which are technically pure water, enter the outlet of the station (3). Between the chambers of the aerotank and the secondary clarifier, a greasy film trap (grease trap) is installed, which removes possible fat accumulations from the secondary sump back to the aerotank for further processing.

Sludge stabilizer

The sludge settled on the common bottom of the chambers of the aeration tank and the secondary settling tank is pumped out to the sludge stabilizer (D), where it also settles to the bottom, gradually accumulating until it is removed. To maintain a high degree of purification, a level sensor (float switch) is installed in the receiving chamber, which regulates the switching of aeration modes in the aeration tank and the receiving chamber, depending on the level of effluents in the latter.

Eurobion working principle

The operation of the Eurobion station is based on the biochemical method of wastewater treatment, which consists in the ability of microorganisms in the presence or temporary absence of dissolved oxygen to use wastewater pollutants as food. Below is the technological scheme of the Eurobion deep biological treatment plant.

Reception aerotank

Effluent flows through the inlet sewer pipe (1) to the receiving aerotank (2) in which, with the help of the aeration element "POLIATR" (3) and the operation of the compressor (19), the process of saturating the wastewater with atmospheric oxygen takes place - aeration. In the presence of dissolved oxygen, wastewater is mixed with activated sludge - the biomass of microorganisms that process pollution.

Primary aerobic clarifier

Partially treated effluents pass through two openings in the intermediate bottom (4) and enter the upper zone of the primary aerobic clarifier (5). This zone is characterized by an increased concentration of activated sludge and a minimum level of dissolved oxygen. Under these conditions, the denitrification process is intensively going on, which is the destruction of nitric acid salts (nitrates) to molecular nitrogen. Further, the effluents, as they move down, fall into the zone of aerobic sediment, where the processes of autoxidation and decomposition of hard-to-recycle pollutants take place. Part of the activated sludge flows through the overflow (6) into the lower part of the secondary sedimentation tank (10).

Secondary clarifier

The sludge settles to the bottom of the secondary clarifier and is returned to the aeration zone by the recirculation pump (9), i.e. to the beginning of the technological chain. The process is repeated until the effect of deep biological treatment is achieved. The biofilm that is formed during the purification process in the secondary clarifier enters the biofilm degasser (14) and is destroyed by bubbling in the vertical pipe of the degasser (11). The clarified effluent enters the tertiary clarifier, installed directly before the outlet dispenser AEROSPLAIN (12), the task of which is to regulate the flow rate of the treated effluents to the outlet of the installation. Purified wastewater up to the level of technically pure water is discharged by gravity through a pipe (13) outside the installation, or enters a storage tank and is pumped out from there by a drainage pump, in case of forced execution of the station.

AU BIOTANK

This series has proven to be absolutely unpretentious in operation and in practice maintenance free station for deep biological wastewater treatment. Does not require post-treatment in the ground. Advantages of this system: no post-treatment fields, no complex electronics, no problems in operation, quick access to the regime, not afraid of a temporary power outage, pure odorless water at the outlet.

The most modern station for deep biological treatment BIOTANK, developed by Triton Plastic, is available in four modifications.

Firstly, the separation of septic tanks follows the shape of the hull, vertical and horizontal. Vertical BIOTANK is designed for installation in small areas, because it requires a narrow but deep pit. Accordingly, a horizontal BIOTANK, consisting of universal buildings, which allows you to build a septic tank for any volume and productivity, is installed where there is no restriction on the area of the pit.

For each of the two cases, modifications are also provided. with gravity water ejection, as well as with forced reset on the relief with a pump. These series are marked as - MYSELF and ETC.

For the manufacture of the case, modern polymeric material is used. Inside, a polypropylene insert made by casting is used to divide the container into compartments. The tasks of each of the compartments: The first, as in other septic tanks, performs the function of a receiver and a sump to separate undissolved inclusions. The second compartment is equipped with an aerobic type nitrifier having a floating load covered with biofilm. In this compartment, the main purification process takes place, that is, the processes of oxidation of organic inclusions and ammonium nitrogen. To ensure the flow of chemical reactions, air is supplied to the chamber. The next chamber performs the functions of an additional sump, in which the medium is separated, the water is freed from residues that have formed during the purification process. The last compartment is a chamber with a biofilter, which functions on the principle of a separator. Pure water (purified by 98%) is fed to the outlet.

ATTENTION THERE ARE SUCH AUTONOMOUS SEWERS in 2018

- Requiring accurate calculation of station performance. There is a risk of a decrease in the degree of cleaning if there are more or less users, but not all autonomous sewers have an accurate calculation.

- During a power outage, most stations, due to their design features, lose the ability to continue cleaning and the degree of overall wastewater treatment tends to 0%.

- The design of many autonomous sewers requires frequent and periodic service, repair and replacement of station components.

- A long break in the use of the station is not allowed if it is not equipped with automatic circulation of sewage and activated sludge.

- The dimensions of the receiving chambers in some autonomous sewers are not designed for large household waste. Also, a volley discharge (draining the bath and simultaneous use of the entire sewage system) can disrupt the processes in the preliminary settling tank, which will lead to a decrease in the degree of wastewater treatment. volume poorly copes with large household waste and with volley discharge.

- Fully automatic station control with alarm system → very low power consumption

- Simple and fast installation

- Only high-quality raw materials and components from American, Japanese and European manufacturers are the key to high-quality, reliable and safe operation of autonomous sewage DELFIN for many years.

- Working mode

- Power of instruments and equipment

- breaking

- poor quality material

- defective parts, etc.

Basic parameters when choosing

Because all permanent residences are designed and built to treat wastewater, we need the hard facts to make the best possible comparison and provide you with a winner. It will not be so easy, because each station has its own zest. And how it has a positive effect, we will tell a little later. We compare the parameters and properties of deep biological treatment plants so that you get the result you expect. Facts and logic will be our guides in comparing all autonomous sewers. A high-quality septic tank or loss with a big guarantee is the key to quality and your peace of mind.

insensitivity to chemicals, hair and small debris

Oddly enough, there are also stations at which there is a direct restriction on discharge into an autonomous sewer. It is clear that the station is not a trash can, but we will still take into account how these problems are solved. In some, they are completely excluded in order to be as comparable as possible with the central sewer, but in others, unfortunately, having design limitations, this problem has not been solved. Below is a brief comparison and description of how the problem was solved.

location of the controller

The stable operation of electrical appliances depends on many environmental factors. Ambient temperature, its abrupt changes, humidity create a dew point, which can be critical. They affect the service life of electrical equipment, worsen their working conditions, cause accidents, damage and even destruction of the entire installation. The electrical properties of insulating materials are especially dependent on environmental conditions, without which no electrical device can do. Under the influence of climate and even weather changes, these materials can quickly and significantly change, and under critical circumstances, lose their electrical insulating properties. The influence of adverse environmental factors on electrical equipment must be taken into account when designing, installing and operating electrical installations.

The energy consumption of an autonomous sewer depends on

guarantee

When buying a product or receiving any service, we always want to be sure that we will not be left alone with the purchased product. You need to be careful not to make mistakes in marketing moves, such as a service life of more than 1000 years, when the official warranty is only 1 year. Therefore, in this rubric we would like to simply rank the companies in descending order according to the guarantee they can provide to their client. This is necessary: to repair and replace parts free of charge. This option guarantees you peace of mind and reliability for many years, during which you can contact the seller in case of malfunction or loss of product quality, such as:

Regarding autonomous sewage, some manufacturers offer pumps, 2 compressors, controllers, brushes, etc. Others use the laws of physics and gravity.