The closet plays an important role in any interior. It is not surprising that stringent requirements are imposed on it: not to take up too much space, to be roomy, to have a sufficient number of shelves and drawers. Models on the market do not always fully satisfy individual wishes.

It can be even more difficult for owners of non-standard layout apartments to choose an option that fits into the room. In this case, you can order a cabinet from specialists who will take into account all the wishes for the design and internal content.

Unfortunately, this option is not for everyone. Then the best solution to the problem will be to use your own hands and ingenuity, because it’s not difficult to assemble a cabinet on your own!

Preparatory stage

Each room has its own type of construction, so you should familiarize yourself with the main ones.

Cabinet with a closed facade - a direct model with hinged doors. To open them, you need to provide additional space, do not forget about this if you are making a closet for the hallway.

The cabinet with an open facade has no doors, and its contents are in plain sight. It imposes certain requirements on the order.

The wardrobe doors are mounted on a rail mechanism and open, moving apart. There are designs with an upper and lower rail, which one to choose is a matter of taste.

Ideal design for a built-in wardrobe

The corner cabinet fills the corner. Suitable for a room of any size, if it is square or close to it.

Having chosen a suitable design, you can begin to create a project for the future cabinet. Since this piece of furniture has been serving for more than one year, it is worth considering what functionality may be required of it. It is better to build a drawing on whatman paper, entering all measurements there.

Decide on the location and dimensions of the cabinet. If a niche is provided in the room, it is ideal, but if it is not possible to build it in, choose a place where neither he nor he will interfere with anything.

Think over the internal content: the location and number of shelves and drawers, their sizes, additional elements like mezzanines or interior lighting.

Do not forget about the choice of exterior finishes, decorations. The colors "oak", "alder", "beech" are the most popular today. And you can choose wood with an interesting pattern and leave your native pattern. Get creative, decorate the doors with a carved pattern.

materials

The material can be natural wood, plywood, MDF or chipboard - all of which are used by furniture manufacturers.

The tree is environmentally friendly, does not require additional decorations, it is convenient to use. A wooden cabinet will last more than one year and will look solid and impressive. The perfect choice for a classic style interior.

Plywood is glued sheets of veneer (birch or coniferous trees are used). This cheap, practical material is suitable for the manufacture of almost any furniture. It is best to choose laminated plywood (FOF brand).

Chipboard (chipboard) is the cheapest and most common option. When assembling your own closet, they usually use it. Short-lived.

A self-adhesive melamine film is also useful for processing the side faces.

The rod diameter must be at least 22 mm. The easiest way is to buy it in a specialized store. You can also buy pens there.

Tools

- Ruler, tape measure, pencil and others for taking measurements and building a drawing.

- Level.

- Electric jigsaw or hacksaw for cutting.

- Screwdriver or drill and screwdriver.

- Glue.

- Ratchet key.

- Iron for gluing edging film.

- Accessories. Each door opening mechanism has its own set.

- It is better to buy confirmations for a chipboard cabinet with a length of 7 cm and a diameter of 0.5 cm.

Progress

First of all, measurements are taken and a drawing of the future cabinet is built. The final result depends on a correctly drawn up drawing, so approach it with all seriousness.

Making cabinet doors with your own hands is not difficult, the main thing is to correctly calculate the dimensions. If its vertical height is less than the height of the opening, the door will not completely close it, and if more, it will not fit. Finding the horizontal dimension, we must not forget about the fastening elements: they will add a few millimeters to it. The width of the doors should be ~3 mm less than the opening.

Now you need to mark the placement of the mounting bolts on the sawn parts and drill all the holes.

The assembly begins with the installation of the bottom and attaching the walls to it. Make sure that the assembled cabinet fits into the allotted space and that other furniture will not interfere with the opening of the doors. If you are making a wardrobe, guides are installed at this stage.

The location of drawers and shelves is outlined, shelf holders and guides are installed. They must be strictly parallel so that they do not skew.

It is time to install the upper shelves and roof. A gap of ~ 7 cm is left between the ceiling and the roof for the installation of confirmations. Fasteners are made by hand, finally tightened with a ratchet.

The side shelves are attached to 4 confirmations (two on each side), in some cases dowels (small wooden cylinders) are used. One end of the dowel is inserted into the wall of the cabinet, a shelf is put on the other.

The last step is to install the doors. Before installation, attach the handles with an outward bend. For sliding doors, the correct installation of the mechanism is especially important. Don't rush, be careful.

It's time for the finishing touches. Treat the cuts with a decorative film, decorate the facade. Put mirrors, interior lighting and other elements.

Tricks and nuances

Build on existing cabinet layouts when designing your own.

A corner cabinet requires more care in design and assembly than a straight one, so it may be too complicated for an inexperienced person.

If you do not have enough experience, it is better to entrust the cutting of parts to the master. His hand will not tremble, and the cuts will be even and neat.

In order not to get a piece smaller than necessary, consider the thickness of the saw. The wall thickness must be at least 18 mm. Otherwise, the strength of the structure will be insufficient.

When working on the drawing, pay attention to the curvature of the floor. If the floor is not level, gaps may appear between the doors. To avoid this, adjust the mounting canopies for the swing mechanism, and change the height of the wheels for the sliding mechanism.

Guides for sliding doors should be parallel. Be very careful when marking and installing guides for drawers and shelves.

Drill holes for confirmations symmetrically. Use a drill of the correct size. The exact number of confirmations depends on the number of parts. Confirmates are covered with plugs to match the color of the structure.

Installation of the mirror begins with the installation of a seal around the perimeter. The film is glued to the slices of chipboard with an iron. Smooth it with a cloth, pressing it as tightly as possible. The edges can be trimmed with a regular knife.

Study photos of handmade cabinets: you will get a boost of inspiration and mark interesting ideas for yourself.

We hope our tips have helped answer the question of how to make a wardrobe with your own hands.

DIY cabinet photo

Housing furnishing is the final step that combines all the repair and design stages. In modern furniture, several important qualities should be combined: operational functionality, appearance as such, compliance with the general design idea.

Coupe systems or their elements are present in almost every home. The convenience and functionality of this furniture are indisputable, and for such design styles as minimalism, urban, hi-tech, they are completely irreplaceable. The article provides comprehensive recommendations for the independent manufacture of a sliding wardrobe.

Advantages

Having considered the pros and cons of this class of furniture, we will get a complete picture of the modern concept of a wardrobe with a sliding door opening system.

| Advantages | |

| Ergonomics | Standard designs require blind areas for opening. In coupe systems, doors move in the same plane along the guides when opening and closing. Significantly saves floor space. |

| capacity | The ability to arbitrarily configure the internal space (filling), which determines the spaciousness. The only requirement is ergonomic expediency. |

| Versatility | Fits into any interior. Various design and finishing methods allow you to install the wardrobe in the bedroom, kitchen, living room, etc. |

| Functionality | Inside, unlike conventional cabinets, you can store overall items, household appliances. Embed various devices - ironing board, workbench, countertop, etc. |

| Ideal solution for narrow spaces | For narrow aisles and corridors, a closet is often the only solution. Only it can be put in such places and comfortably operated. |

| Zoning | Dual functionality. Using such furniture, you can easily zone the room, that is, it can also perform the function of a partition. |

| Variety of designs | No restrictions for internal filling. A large number of materials for the manufacture of facades, which allows you to realize any design idea. |

| Using a mirror | A mirror can be installed on the facade. This will improve the functionality of the room and visually expand the space. |

| Operational reliability | Doors that move along rails will last much longer than those that open on hinges. |

The disadvantages are much less, but they are:

| Flaws | |

| Failure of the sliding system | Occurs only in the case of the acquisition of a low-quality sliding system. |

| The need for additional lighting | If the dimensions are large, additional light will be required, it significantly increases operational comfort. |

| The need to clean the guides | Over time, the lower guides become clogged, which can become an obstacle to the movement of the roller. Therefore, sometimes you have to clean the grooves of the guides. |

| Mirror gets dirty quickly | If a mirror is used in the decoration, then it will often have to be washed from stains and traces of hands. |

| No swap option | When designing, the dimensions are related to the specific location of the cabinet. Not suitable for fans of frequent permutations. |

Varieties in form

There are several varieties, they have structural and external differences:

- built-in;

- stand-alone;

- corner;

- diagonal corners.

Let's consider each of them separately.

built-in

When constructing such a cabinet, there is no top, back wall and base. Partitions are made only. The entire structure is screwed directly to the ceiling, walls and floor. Metal corners are used as fixation.

This is a stationary structure, and it is an invariable part of the created interior.

Standing separately

It has sidewalls, top, bottom, back and sliding doors. This is a complete piece of furniture. It can be moved, it is not attached to any design elements.

Angular

An excellent solution for small apartments, where every meter is expensive. Repeats the shape of the corner and allows you to rationally use the space of the room.

diagonal corner

This is a kind of corner, but the facade does not repeat the shape of the corner, but is made diagonal. The increased capacity of this design determines its frequent use as a dressing room.

Material used

Furniture with a sliding door system is made from a variety of materials. The table shows the main ones:

|

Material |

|

|

|

The most common and frequently used. Chipboard board, having a low price, is characterized by sufficient strength. A huge selection of textures, colors, patterns allows you to make a front part for any design solutions. There is one, but significant, drawback - it is difficult to fine-tune. For this reason, mostly simple structures are made from chipboard or chipboard. |

|

|

Eco-friendly material, easy to process. The variety of facade coatings is no less than that of chipboard. Practical and affordable material. |

|

|

An expensive option, but natural wood will last a long time. A great decoration for any interior. |

Types by design

Classification by design differences is as follows:

- embedded;

- case.

Embedded . There is no need for top, bottom and side parts. Their function is performed by the walls, floor and ceiling of the niche. Drywall can be used for manufacturing, which will reduce the overall cost of the product.

Cabinet . The main difference from a conventional cabinet is the method of opening the doors. If necessary, you can move. Transportation (moving) without disassembly is possible. Minus - increased consumption of materials, as side, lower and upper walls, the back are made.

Now let's take a closer look at the organization of the internal volume of the cabinet.

Design features

When designing, ergonomic and operational specifics should be taken into account.

Consider the main structural elements of the wardrobe.

Door width

The choice of door size depends on factors:

- manufacturers of sliding systems are limited to certain sizes. Some systems allow you to make a sash up to 120 cm wide;

- the width is affected by the number of internal sections. Each section must be freely accessible;

- choice is influenced by personal preference. There are no special rules, unless it goes beyond the restrictions listed above.

The optimal width, worked out in practice, is from 600 to 900 mm. This size provides the most comfortable conditions for use.

Sliding systems

Sliding systems are classified according to two main criteria:

- profile material;

- expansion principle.

For the manufacture of the profile of the movable system, aluminum or steel is used. The material of the sliding system is chosen, as a rule, the same as that used for the door frame. Steel structures are cheaper, but in most cases aluminum is preferred.

Structurally, two types of systems are produced - bottom-support and top-hung. In the lower support - the door with rollers moves along the rail. In top-hung - its rollers move along the upper guides.

Height

The height is chosen arbitrary. The only limitation may be the ceilings or the small stature of the owners of the apartment / house. Designs are made both from ceiling to floor, and smaller heights.

The standard length of the material used for the walls is 270 cm. A standard apartment has a ceiling height of 260–270 cm. Almost the same dimensions allow you not to saw or build up structural elements.

For ceilings above 270mm (if you want a floor-to-ceiling cabinet), there are two solutions. First, the sheets of material are joined to the required length. The second - the mezzanine is going. Sheets can be joined on high-precision equipment of companies specializing in such services.

Shelf depth

The depth of the shelves determines the daily usability of the cabinet. The optimal and recommended figure is 60–70 cm. Usually a hanger bar is placed in the closet, the width of which is about 48 cm. A depth of 60 cm will completely eliminate the contact of the inner surface of the door and the clothes hung on the hangers. Most furniture accessories (boxes, trays, etc.) are 50 cm wide. Shelves should not be made deeper, since it will be inconvenient to get "under the wall" when placing things.

Not always the dimensions of the premises allow you to install furniture with the maximum recommended depth of the shelves. But there are limitations on the minimum depth. The best option may be a depth of 40 cm. Considering that 10 cm goes under the sliding door mechanism, you can purchase small hangers 30 cm wide. Alternatively, install a hanging rod (rods) perpendicular to the doors and the back wall, in this case, the width not limited.

Such a solution is much better than completely abandoning the installation of a cabinet, especially since even such a "narrow" design for small apartments is an ideal solution.

Length

When designing, the length of the cabinet is selected in accordance with the place of its further installation.

Height of shelves and rods

The height between the shelves is 250–350 mm. The choice rule is simple: more depth of shelves - more distance between them, less depth - less distance. This dependence is associated with the convenience of access to the stacks of linen located in the depth of the shelf (near the back wall).

When designing a mezzanine, you should take into account the dimensions of things that are supposed to be stored on it. If these are suitcases, then the height of the mezzanine should be equal to the height of the suitcase, plus a small margin.

The mounting height of the hanger bar is determined by the length of the clothes placed on it. The maximum height will be equal to the longest thing. Average length of typical wardrobe items:

- shirts - up to 100 cm;

- jackets - up to 110 cm;

- long clothes - up to 130 cm;

- raincoats and fur coats - up to 150 cm.

These calculations are approximate, since the length of clothing depends on height, style and other parameters.

Video:

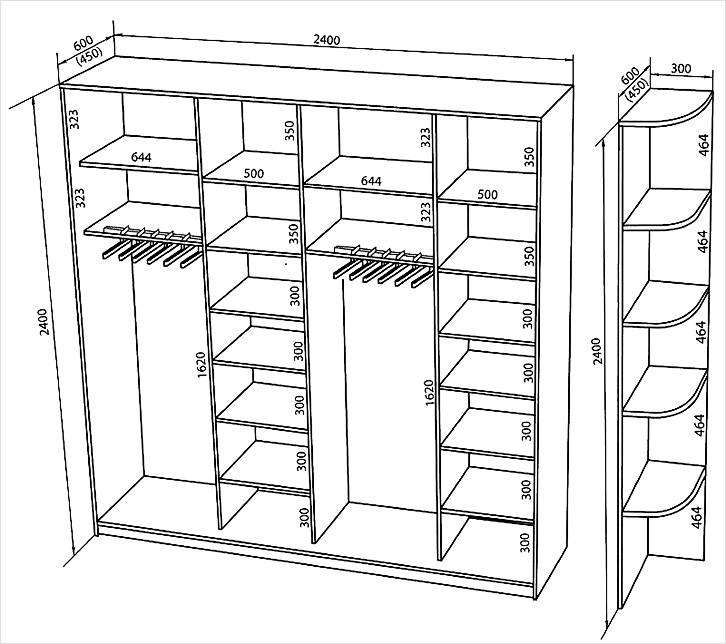

Schemes and drawings

The diagrams show various project options and furniture assembly technologies:

Device inside

When designing the filling of a sliding wardrobe, first of all, zoning of the internal space is done. The figure shows a universal scheme for dividing various things into storage zones:

When buying a finished product, you will have to agree with the filling configuration proposed by the manufacturer. Self-manufacturing will allow you to take into account the dimensions, functionality, location of various zones and much more, which, ultimately, will provide maximum operational comfort.

Below is a table with examples of frequently used elements of internal filling and zoning of a sliding wardrobe with their help.

| Zoning | |

|

|

Shelves are one of the main elements of filling. They can be fixed and retractable, solid and ventilated, half and full depth, etc. |

|

|

Drawers - the second most important element of the cabinet. |

|

|

Hanging bar - necessary for clothes on hangers. The material of manufacture is different, most often metal. |

|

|

Convenient storage baskets. All things are clearly visible in them, which creates a certain convenience. |

|

|

This device is called - bruchnik. Pants are always ironed and ready to wear. |

|

|

Rod (hanger) for storing ties - it is convenient to choose, do not wrinkle, the correct suspension prevents shape change. |

|

|

Convenient placement of belts, as an alternative - storage on a shelf in rolls. |

|

|

Compact and convenient storage of underwear. |

|

|

Placement of bed linen, towels, some clothes in piles on shelves. |

|

|

For storing blouses, light blazers, short sundresses, a significant part of the internal volume is allocated. A pipe with hangers is installed in the opening. You can make several of these departments - for short and long things. |

|

|

Section for accessories - bracelets, watches, glasses, etc. It is recommended to store these items in drawers. Inside the space can be divided into separate cells. |

|

|

Shelves for storing shoes. In the upper (mezzanine) part, you can place shoes in boxes. |

|

|

Hooks, hangers, carabiners, rings and other accessories for bags. |

| Hiking suitcases | Rarely used (once a year during the holidays) suitcases place on the far (upper) shelves or mezzanine. |

|

|

One of the options for bed linen. Shelf width up to 80 cm, height - up to 60 cm. |

Characteristics of the main filling elements:

- sliding and fixed shelves. For convenient use, the distance between them is from 350 to 450 mm;

- drawers. Two types - fully retractable (100%), partially retractable (80%). Can be equipped with closers that provide smooth semi-automatic closing of the drawer;

- mezzanines, known as hard-to-reach shelves. Located at the top. They store rarely used and overall things;

- bars are needed for hangers. Mounted across the width of the cabinet;

- pantographs or special "furniture lifts". Thanks to them, clothes are stored at the required level and can be easily pulled out with a special bar. They are electrical or mechanical;

- baskets are convenient for storing small items. Equipped with rollers and guides.

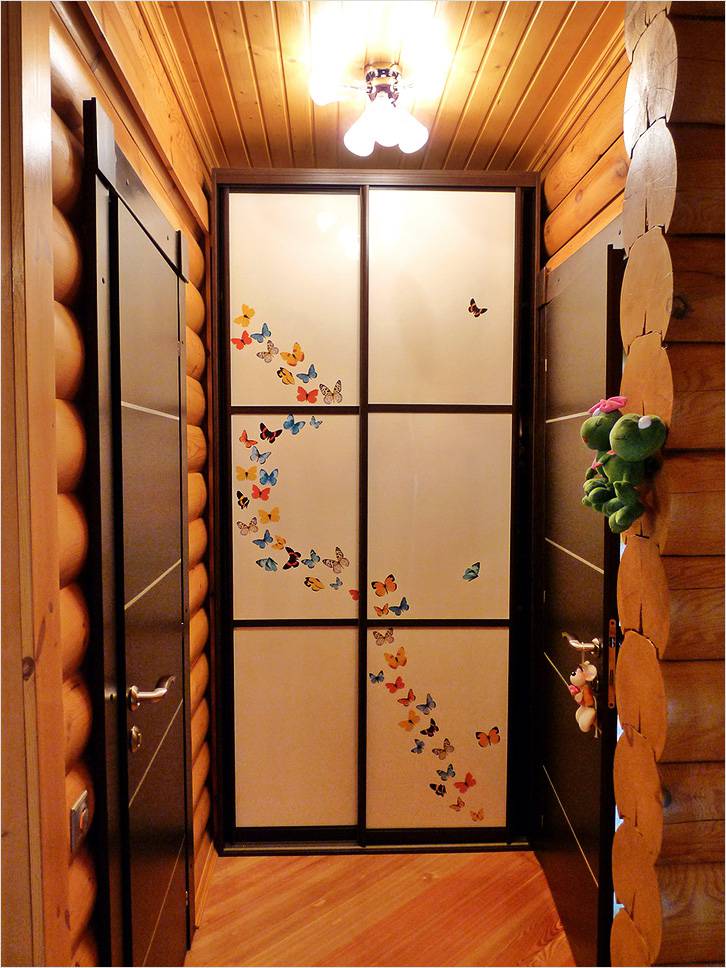

facades

Thought out to the smallest detail, the internal content will be sharply dissonant with unsuccessfully chosen facades. It is the facades that give the whole cabinet a special finished look. Consider several options for their implementation.

Mirrored

The mirror visually enlarges the space and makes the room brighter. It can be whole or divided into several parts. The large weight of the mirror determines the need to select high-quality and reliable rollers. Such a facade creates additional maintenance chores - the mirror quickly gets dirty. It will have to be wiped and washed regularly, especially if there are small children in the family.

A variety of finishes are used for facade mirrors - sandblasting patterns and drawings, spraying of various shades (silver, emerald, gold, etc.) for glass, printing color images and much more. For safety reasons, the mirror is covered with an anti-shock (armored) film from the inside. If the mirror breaks, the pieces will not scatter.

glass

Glass is no less popular than a mirror, facades are equipped with unbreakable. Mostly used frosted glass with a pattern. Vertical, horizontal stripes look original, dividing the canvas into separate squares.

MDF and chipboard

These materials are laminated with film. The facades look massive and heavy. To install them, you will need reliable roller systems. One of the advantages is a huge selection of colors, shades and patterns, in texture - from matte to bright glossy.

On MDF and chipboard facades, you can apply photo printing.

These are the main types of facades used in the manufacture of sliding wardrobes. You can combine them with each other. This article provides photographs with a considerable number of original ideas for the manufacture of facades.

Step by step instructions for making

Adhesive edge tape

After cutting all the elements, the edge tape is glued to the ends of the plate. The sequence of operations performed:

| Instructions for gluing the edge to the end of the blanks | |

|

|

If there is no assistant, you can use a simple trick. You will need a small box and a quick clamp. The clamp presses the board to the box, ensuring the stability of the workpiece and the convenience of gluing the edge tape. |

|

|

One side of the edge tape has an adhesive surface. Heating to a high temperature, it is easy to stick to the workpiece. |

|

|

Cut the edge to the desired length. Leave a margin of 1 cm around the edges. You can cut off after gluing with ordinary scissors. |

|

|

For gluing, set the position of the temperature sensor of the iron to "2". |

|

|

For safety reasons, wear two gloves on your left hand. There should be no pellets on the palm. |

|

|

Run the iron along the edge tape, and hold it with your left hand (leveling). |

|

|

We carry out the iron in the opposite direction, at the same time with a hand in a glove we firmly press (smooth out) the edge tape. |

|

|

Hand smooth the edge a few more times. |

|

|

The use of a special roller. Glue the edge tape with an iron and then roll it with a roller. Very comfortably. |

|

|

The cooled tape, with a sharp knife from the end, carefully cut off the remnants. |

|

|

We get such a cut. |

|

|

We repeat the procedure for all ends of the workpiece. We measure the tape with a margin of 1 centimeter, from each edge. |

|

|

Glue with an iron and smooth. |

|

|

We cut off the cooled edge. The edge has already been glued on the adjacent edge, we make the cut very carefully. |

|

|

From all sides we cut off the longitudinal remnants of the protruding edge. |

|

|

Result. We glue the ends of the remaining blanks with an edge tape. |

|

|

All cuts are ground with a special bar. The inner part of it is filled with foam rubber, the outside - fine-grained abrasive. |

|

|

Grinding of slices is done only with longitudinal movements. |

Processing of the main elements is carried out in a similar way.

Assembly

Details are cut according to the project. This operation is best done in the workshop on a special format machine. After cutting and gluing the edges, we assemble the cabinet:

| Frame Assembly Instructions | |

|

|

To work, you will need to assemble an additional device, consisting of a metal strip and two pieces of board connected at an angle. It turns out a corner with a metal guide. You will also need two quick clamps. With this device it is very convenient to connect workpieces at right angles. |

|

|

We make a check with a square - it should be 90˚. |

|

|

Set aside 70 mm from the top edge. |

|

|

In the example, a 16 mm plate is used, therefore, 9 mm must be retreated from the edge. Why not 8 mm? Because the plate protrudes 1 mm beyond the edge, forming a small ledge. The middle of the end of the adjoining plate is at a distance of 9 mm. |

|

|

Drill mark. |

|

|

A similar mark is placed below. |

|

|

Using a drill, we make holes for fasteners. |

|

|

A special drill replaces three at once. It allows you to make the main hole, corbel and chamfer in one operation. |

|

|

drilling. |

|

|

We twist the confirmation with a screwdriver. |

|

|

Having fixed the sidewall, according to the project, we mark the places for installing the shelves. |

|

|

Next, using a square, put marks on both sides under the holes for attaching the shelves. |

|

|

Marks on which holes for confirmations will be drilled. |

|

|

The device assembled at the beginning of work is convenient to use for attaching shelves. We measure with a tape measure 1/2 the thickness of the plate. The thickness of the plate is 16 mm, so we retreat 8 mm from the mark. |

|

|

At this level, we install the shelf using quick-clamp clamps. |

|

|

It is clearly seen here that the mark is in the middle of the end face of the workpiece. Everything is ready for drilling. |

|

|

Drilling. |

|

|

We twist the confirmations. |

|

|

Install the remaining shelves in the same way. |

|

|

Install the crossbar. And we fasten each shelf with confirmations. |

|

|

Having fixed the cross member with a quick-clamp clamp, we twist it with confirmations from above and below, then we fix each shelf. |

|

|

This is how the lower part of the closet is assembled. We clamp the strip from the plate with a clamp and fix it from the end with a confirmation. |

|

|

We drill shallow holes from below for installing furniture legs. |

|

|

We twist the metal sleeve with external and internal threads. |

|

|

Using a hexagon, tighten (retract) to the desired position. |

|

|

We twist the leg with a plastic support into the sleeve. Thanks to this, the furniture can be moved and leveled. |

|

|

Two parts of the support leg assembly. |

|

|

After assembling the cabinet, a fiberboard sheet is attached to its back side with ordinary carnations. |

|

|

Fastening fiberboard start from the top. By tilting the cabinet from side to side, we achieve a 90˚ angle between the sidewall and the top bar. We nail the side and bottom sides of the fiberboard sheet. |

|

|

When assembling, such plastic furniture corners were not used. Why? The use of confirmat is much more practical, since it is screwed into the slab by several centimeters and securely connects the structure, giving it additional rigidity. |

|

|

We close the hats of confirmations with a decorative cap. |

In the same operating sequence, you can assemble a sliding wardrobe of any configuration.

Video:

Door manufacturing

The door consists of a frame, metal guides and a system of rollers. It is worth ordering it from a company professionally dealing with such systems. Specialized software will calculate all the elements according to the given dimensions and issue a complete specification for assembly. Mirrors or slabs of other materials are cut to the size of the doors for mounting in frames.

| Elements for sliding system | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vertical bars/handles for the side parts of the door. |

|

|

Sealing rubber for a mirror. |

|

|

Self-adhesive brush to soften the impact of doors when they are opened / closed. |

|

|

|

|

|

|

|

|

Staples for fixing doors in extreme positions. |

The main parts for assembling the doors are made of aluminium. All metal components must be covered with a protective film that protects them from scratches during transportation.

Sliding system assembly

Consider the step-by-step assembly of the door leaf. In our example, there will be two mirror doors.

| Door Assembly Instructions | ||

|

|

The door is located in a horizontal position and provides free access from all sides. | |

|

|

In the upper part of the vertical rack, which also serves as a door handle, we drill two mounting holes. | |

|

|

The lower one is 6.5 mm in diameter. | |

|

|

Top hole - 10 mm. Through it, the upper profile of the doors and the roller will be attached. | |

|

|

The lower part of the same vertical profile. Top hole - 10 mm, bottom - 6.5 mm. Distance from the edge of the first hole - 7 mm, the second - 43 mm. Closer to the edge, the lower roller will be attached. The second hole is for the screw connecting to the profile. | |

| Profile mounting | From above we fix the rubber seal with a profile, gently inserting it. | |

|

|

The procedure is performed sequentially on all faces. We do not cut off the rubber seal at the corner, but continuously lay it around the entire perimeter. | |

|

|

This screw is not fully tightened. Later, the upper rollers will be installed in it. | |

|

|

Install the upper rollers and tighten the screw until it stops. | |

|

|

Rubber seal installed at the bottom of the door. | |

| The screw with the top roller is also twisted | In the upper part we fix the second pair of rollers. | |

|

|

Install the bottom roller. We press the spring on the roller and carefully insert it into the hole, fix it with a screw. | |

|

|

The screw is tightened with a hexagon. | Finished closetWardrobe with the first door installed. |

|

|

In the same sequence, we assemble and mount the second door. | |

Additionally, we install auxiliary elements - a pipe for hangers, etc.

Video:

At the end it should look like this

At the end it should look like this

We invite you to familiarize yourself with the diagrams and drawings. They will help you create your own project.

Video:

Video:

A photo

The built-in closet is not in vain very popular. A sliding wardrobe not only has a large capacity, taking away a minimum of usable living space. It is able to perform other useful functions in the interior, and making it with your own hands is not so difficult.

What does coupe mean?

In the common parts of ancient European cities, the streets were very cramped, and the sidewalks were so narrow that it was sometimes impossible to open the carriage door. Because of this, somewhere in the XVII century. carriages appeared with sliding doors. The legend ascribes the invention of the coupe to the court coachmaker of France Janto. But, most likely, this is only a legend - Janto is famous for inventing the steering linkage, which made it possible to make sharp turns without the risk of tipping over.

A carriage-coupe is a rather playful concept: parts of the city remote from comfortable quarters were visited mainly for secret dates. The very word "coupe" some linguists deduce from "couple" - a couple, an extramarital affair; marriage - "marriage", hence - known to gamblers mariage, a lady with a king of the same suit.

Then the sliding doors fit the railroad workers for 1st class and sleeping cars. And in the furniture business, any wardrobe with sliding doors is considered. So the wardrobe is not necessarily built-in. A built-in wardrobe may not be a compartment.

What is the use of a closet?

The main types of direct wardrobes are shown in the figure. It should be noted right away that radius wardrobes, in which the front surface is curved, require high furniture professionalism, and it’s better not to take it on your own. Therefore, we will leave the radius cabinets aside for now.

First of all, a wardrobe can be arranged in a niche, first pos. left. Making a cabinet of this type on your own is not much more difficult than a stool. Expenses are at a minimum; after all, there are already three walls, a bottom and a tire. An inconvenient place turns into a useful one.

Second from left- in fact, the same closet in a niche, but a niche in the entire width of a blank wall. Thus, it is possible in a small apartment, practically without reducing the living space. The visible volume of the room can even be expanded by trimming or decorating the doors accordingly.

next in order- in the opening of the interior partition. A common technique in the arrangement of open-plan apartments in modern monolithic houses. It gives convenience and allows you to save a lot on expensive construction and plastering and finishing works. By the way, the ones described above are also economical - the inside of the cabinet can be made of chipboard, and the doors too; After all, they most often go for decoration and decoration.

Cabinet on the far right- already hull, so the material for it is needed more expensive. These are mainly used for zoning budget odnushki or, conversely, expensive penthouses without interior doors.

And, finally, a closet, like a regular one, can be straight and angular, leaning against a wall or placed across it. The latter, as said, are used for zoning. They have two faces, but no rear at all. Often made double-sided, with doors back and forth, for easy access to content. The closet can also be turned into a closet by replacing the swing door with a sliding one.

We will take a closer look at the cabinet built into the niche; the rest will be touched upon in passing. It is easiest to make it yourself, and the money savings are the greatest. In addition, most likely you will not need a special tool and sawing work that requires a solid skill. Why? Let's get to that.

In general, the procedure for manufacturing a wardrobe is as follows:

- Choice of material;

- Determination of the degree, nature and method of placement of filling;

- Door design, with a choice of suspension method;

- The choice of the method of hanging the shelves;

- Niche preparation;

- Measurements and drawing;

- Purchase of accessories, materials and sawing of blanks;

- Assembly of the cabinet and installation of internal lighting;

- External finishing.

materials

Cabinet design must begin with the choice of material. The entire manufacturing process depends on it, and depending on the choice, it can fundamentally change.

Wood and lining

Wood is a traditional, and in our time, prestigious furniture material. But for a built-in wardrobe, wood is far from the most suitable. The humidity in the niche will certainly be higher than in the room, and the tree will warp; its decorative role in this case is minimal. If you still need a wooden cabinet, the wood for it should be straight-layered, without streaks, knots, cracks, seasoned and thoroughly impregnated with hot drying oil or a water-polymer emulsion.

Note: it is not at all necessary that the niche be damp. For warping of wood, the difference in humidity from a blank wall to the doors and its sharp jumps when opened are important. Because of this, it is not recommended to put cabinet wooden cabinets in niches.

Lining for a cabinet in a niche, plastic or MDF, can be used without its preliminary preparation, but another limitation appears - the frame of the door leaves. They have to be made of wood, with the same conditions and requirements as indicated above, plus - the care of manufacturing. You also need to glue the lining boards together, but this is not a problem: there is a tongue, there is a groove for it, and it holds perfectly on PVA. In general, a lining cabinet can be recommended only for those cases when a wardrobe in a niche should organically fit into the interior, as in fig.

Drywall

Drywall is an excellent, easy-to-work finishing material with ample opportunities. Designers and home-made amateurs create real masterpieces from it. But as a basis for a cabinet of any design, the GKL is completely unsuitable. You can make a drywall cabinet, see pic, but it's difficult. Let's see why.

Drywall is a rather heavy, fragile and at the same time not very durable material. It is intended exclusively for decoration and cannot be part of the supporting structure, even lightly loaded. Simply put, drywall cannot hold anything on itself; on the contrary, it must be attached to something and something must hold it. A piece of drywall 400x400 mm, laid flat on the frame, sags noticeably by itself within six months. GKL sheets according to TU are not allowed to be placed vertically or leaned against the wall during storage.

That is, it is impossible to simply cut the GKL and fasten it together, like, say, a laminate (see next). Each shelf must be a box-shaped space structure, which requires a complex frame (see the figure on the right). But the structure obtained as a result of assembly (see the next figure on the left), with the correct geometry and proper strength, will be far from aesthetic; need more putty and decorative trim.

Note: wood is doubly unsuitable for a cabinet frame made of plasterboard - the cavities of the finished structure will pull moisture into themselves. Only standard C- and U profiles with standard fasteners are suitable for the frame.

Then the doors. You can’t make them from GKL in any way - the fasteners will break off simply under the weight of the sash. And in the doors is just the essence of the closet. To make cabinet shelves with doors out of drywall is a monkey's work and a decrease in usable volume. There are no sliding wardrobes from GKL, and a wardrobe with shelves from GKL does not make sense.

In fact, a plasterboard cabinet is not furniture, but a building structure, and is carried out according to construction, not furniture technology. But at the same time, it can have outstanding aesthetic merits and be the most significant object of interior design.

Laminate, MDF, fiberboard

These are the best materials. Making a cabinet from them can be elementary simple at minimal cost, see sawing. These materials have all the useful properties of wood and at the same time are insensitive to moisture gradients and fluctuations. in the process of their manufacture, the microstructure of the tree is transformed into another. Just one note: fiberboard should be taken in medium or high density. The back wall of inexpensive cabinet cabinets is often made of low-density fiberboard, similar to thick cardboard corrugated on one side, but it will soon lead in a niche.

Filling

The internal filling of the cabinet determines its internal layout. There are four rules here:

- Raw - aside separately.

- Necessary and small - before your eyes.

- Dry - higher.

- Valuable - in boxes.

For example, it is wrong to place a section for outerwear in the middle - dampness will go to the sides from it. If you place it on the side, the moisture from the clothes will go where it is easier - out. In the bedroom, drawers or shelves for bed linen do not need to be arranged immediately above the floor - dust and moisture are concentrated about 40 cm above its flooring. Well, and that a wallet or a smartphone in plain sight near the entrance should not be lying around, and so it is clear.

The ultimate goal of content layout is to get a minimum shelf width; this will be needed to calculate the doors. The placement procedure is quite responsible, the convenience and durability of the cabinet largely depends on the successful layout.

Video: wardrobe interior layout

doors

Doors are the salt of the closet, its most complex and critical element. Three significant points:

- Number and width of doors.

- Suspension structure.

- Sash stoppers.

sashes

At this stage, the task is to find the number of doors for a given width of the opening under the cabinet. The smaller the doors, the more convenient the cabinet, but the likelihood of skew and jamming is higher. The maximum allowable width is 600-700 mm; with a larger sash, they can walk tight simply because they turn out to be very heavy.

The overlap of wardrobe doors should be within 50-70 mm. If the overlap is too small, you will either have to open and close the doors carefully, or put up with gaps. If the overlap is too large, the internal layout of the cabinet is difficult, especially if it is intended for a hallway or other cramped room.

At the same time, the width of the door should not exceed the width of the narrowest of the shelves, otherwise it may not be accessible. We also take into account the allowable overlap and subtract 40-50 mm to the side profiles; without them, the doors will beat the wall. In general, the procedure is as follows: based on the maximum for the width of the door, we first determine the number of overlaps (one less than the doors) and check the resulting door width. It does not fit into the maximum - you need to make one more door, and so on, until everything converges.

Calculation example:

Opening width - 1.75 m; the narrowest shelf is 0.45 m. A double-leaf cabinet will no longer work, it does not come out both in terms of convenience and the maximum allowable width of the door. Then we put two overlaps, this will give 100-140 mm minus to the opening, and put another 50 mm on the sidewalls. Total - 150-190 mm, 0.15-0.19 m. 1.75 remains on the doors - (0.15-0.19) \u003d 1.6-1.56 m. Divide by 3, the door width comes out 0 ,53-0.52 m. A lot, what to do? Let's figure it out with 3 overlaps (4 doors). It comes out 37-39 cm per door. But making 4 doors is more difficult and expensive (an extra set of fittings), so it makes sense to go back to the placement sketch and re-arrange the inside so that the narrowest shelf comes out at 55 cm.

suspension

There are three well-known door suspension systems for wardrobes: two-rail with a lower support, two-rail with an upper support and a monorail. Each of them has its own advantages and disadvantages. The choice is ultimately determined by the size, purpose of the cabinet and the financial capabilities of the customer/master.

bottom rail

The most common system; schematically its device is shown in fig. on the right, and the design of the upper and lower rails is shown in Fig. left. Support - lower rollers, upper - prevent the sash from falling out. This system is also the most reliable: the doors almost never jam or touch each other.

The lower rollers are heavily loaded, therefore, when self-assembling, certain rules must be observed, which is illustrated in Fig. below. The rollers are made of plastic, and when buying, you need to look to take polypropylene ones; there are a lot of cheap plastic ones on sale in a low-quality metal carriage. If the rollers are propylene, then you don’t have to look too closely at the metal; both steel and aluminum are equally reliable.

The installation of the sashes is simple: insert the top into the groove of the rail, lift it up to the stop, insert the bottom into the groove - you're done. However, the bottom support system has disadvantages:

- Sensitivity to subsidence of the floor, and the weight of the cabinet itself enhances it. On an old wooden floor, after a while, the doors can start to ride on their own, or even fall out.

- Sensitivity to dust and dirt. The loaded surface of the rail is in the most dusty layer of air, the rollers roll and compact the dust, tubercles form in the groove of the lower rail, after a while the doors begin to rumble unpleasantly, and the rail with the rollers needs to be cleaned.

top rail

Here the support has been moved to the upper rail, see fig. on right. The concrete ceiling does not sag, and properly finished and does not generate dust, so the doors move quietly and smoothly. Fittings of this type are not complicated and not expensive, and the installation differs from the previous one only in that the sash must be tilted during installation. There are three disadvantages, but two of them are significant, so the suspension with the top rail is not widely used:

- You definitely need a lower guide, without it the sashes will inevitably beat and rub each other.

- With an accidental push or pressure on the sash, its rollers come out of the groove and the sash falls into the cabinet.

- The top rail is not very rigid, so in some cases it is necessary to level the ceiling at the place where the suspension is installed.

Monorail

The peculiarity of the system is that in each carriage there are 2 pairs of rollers (see the following figure), and the suspension of each sash runs in a separate guide. Paired rollers, together with the profile of the guide, to some extent fend off the reeling of the doors. Thanks to this, with careful handling, you can do without the bottom rail and not touch the floor. But it is still impossible to push the sashes inward, while they will touch each other. Therefore, lower guide rollers with a rail under them are also sold for the monorail.

A wardrobe with such a suspension is suitable, first of all, in the bedroom, where adults use it, and neatly. A strong and precisely adjustable suspension allows you to make wide doors, and this, in turn, can be placed against a blank wall and a closet and dressing room. Rigid box rails allow in most cases to do without leveling the ceiling. There are four main disadvantages of a monorail:

- Complicated and expensive hardware.

- The need for a decorative overlay at the top, because. a wide gap remains between the sash and the rail.

- Difficult installation: you must first insert carriages with rollers into the rail, then attach the rail to the ceiling, and only then hang the door. An assistant is needed to hang the sashes into the monorail.

- After hanging the sashes, adjustment is required.

Stoppers

It is desirable that the cabinet doors do not roll back and forth on their own, and that they do not need to be carefully pushed into place. In a double-wing cabinet, the problem is solved by magnetic latches on the sides. But there is nowhere to put the latches on the middle doors: the magnet does not hold casually. Therefore, the main type of sliding wardrobe latches is mechanical.

Two varieties are mainly used: a recess in the support rail and a flat curly spring. If you make a cabinet yourself, then the recess is not suitable: such rails are factory-made in a standard size for standard cabinets.

The spring retainer shown in the figure is easy to make yourself and install in place in the cut-to-size guide. The principle of its operation is simple: the antennae protrude slightly and the roller sinks between them. And when the roller rolls on the edge of the spring, the edges of the antenna rest against the sides of the groove, which prevents the latch from moving. To push the latch into place, you need to press both antennae at once.

But all latches for wardrobes have a common drawback. When opening / closing the door, the force already acts skewed, and the resistance of the latch further strengthens it. Most of the breakdowns of wardrobes occur just because of the latches.

Therefore, the best stopper for sliding wardrobe doors is a carefully aligned support rail, high-quality fittings and careful use.

Shelf fixing

For a cabinet built into a niche, the methods of hanging shelves in cabinet furniture are poorly suited or not suitable at all - you can’t get to the sidewalls from the outside. In a niche, either a rigid frame is built, which is difficult and expensive, or special adjustable suspension systems are used, like the one shown in the figure. It's easier, but also expensive.

Meanwhile, the simplest and cheapest way to mount the shelves is on segments of an ordinary plinth, floor or ceiling, see fig. on right. MDF skirting, as you know, comes in a huge range of sizes, textures and profiles. So that the fasteners of the shelf are not conspicuous, a segment of the plinth can be taken shorter than the depth of the shelf by a third, and its end can also be cut obliquely. In this case, the self-tapping screw farthest from the edge of the shelf must be screwed in from above through the shelf board.

Note: the upper and lower partitions in the closet can be fixed to the floor and ceiling in the same way, without shortening the plinth pieces for reliability. Their ends, if you take a small ceiling plinth, completely cover the upper and lower rails, and together with the shelves fixed in a similar way, a very strong and rigid structure is formed. Which, in addition, will support the plank floor from sagging under the weight of the doors.

Niche

Professional furniture makers rarely and reluctantly undertake to make built-in furniture on site - the work is tedious, unprofitable. Custom-made built-in furniture is most often the same cabinet furniture that is brought and assembled in a niche. And here the do-it-yourselfer has a great opportunity to simplify and reduce the cost of his closet, making it stronger and more spacious at the same time.

Diagonals

A necessary condition for the success of such an undertaking is that the niche opening must be rectangular, and the floor and ceiling at the place where the doors are installed must be horizontal. Here, you may have to devote a little time to construction work, but their volume is small, and the complexity is low.

Note: under a monorail suspension, the usual building horizontality of the ceiling is sufficient. The rail is aligned with gaskets. But not by adjusting the sashes after! In an inclined guide and vertically hanging sashes will move out to the side.

The floor and ceiling are checked by level, but what about squareness? The usual method in construction - diagonal cord - does not fit well. The fact is that furniture accuracy is higher than construction accuracy. In finishing work, 3 mm / 1 m is permissible. In furniture, if a seam 2 m long diverges in length from a millimeter to two, this is already noticeable to the eye. And any cord is stretchable, and it is inconvenient to use it in a vertical opening; here without a lot of experience and construction accuracy will not work.

There is a way to measure the diagonals of the opening, not only with furniture - with machine-building accuracy, see fig. Everything is very simple: two slats with pointed ends. The angle at the top is less than 45 degrees, and preferably 20-30, if only the material of the rails is strong enough. The slats are fastened with rings of "money" rubber bands, which are sold in any stationery store.

The measurement procedure is elementary simple:

- We insert the device into the diagonal until the ends of the rails stop at the corners.

- We make a risk with a pencil or a nail, as in pos. one.

- We insert it into another diagonal, push it apart / move it all the way.

By the divergence of the halves of the risk, the magnitude of the inequality of the diagonals is immediately visible. Limiting accuracy - half the thickness of the risks, i.e. 0.15-0.2 mm can be achieved. And in order to assemble the cabinet without problems, you need up to 3 mm in an opening of 2x2.5 m.

Note: if a place is being prepared for a closet - a zoning partition, standing perpendicular to the wall, you will have to measure and fit 8 diagonals - under a pair in on the face and rear, and two pairs inside between the upper and lower opposite corners. Two perpendiculars are beaten off the wall along the width of the cabinet, and instead of the missing sidewall, two slats or a piece of plywood are placed.

And now, what prevents you from using the walls of a niche, its floor and ceiling as the same for a closet? It just needs to be dust free. And to achieve this is not at all difficult and not expensive:

- We remove old wallpaper or paint with a gel surface-active (surfactant) remover. It is non-toxic, odorless, and the old coating can be removed with a spatula after 10-40 minutes.

- We impregnate the walls 2-3 times, with an interval of a day, using a foam roller with a PVA water-polymer emulsion.

- We paint with acrylic enamel.

A niche prepared in this way does not dust for 10 years for sure, and there is no need to remove the old plinth from the floor. Damage to durable acrylic enamel is not easy. And the costs are less than for a sheet of simple, non-laminated fiberboard for the back wall.

Note: small irregularities of the walls visible to the eye can be removed with an abrasive mesh on a wooden block. It is better to do this after the first impregnation of PVA - there will be less dust.

Dimensions and drawing

Shelves and partitions with this method of manufacture, of course, will have to be cut in place. To do this, you will have to draw a view of the cabinet from the facade, approximately as shown in the figure. Then on the ceiling, for any method of suspension, beat off the line at the installation site of the guide. Then, from its ends along the plumb lines, beat off the verticals on the walls, and from this imaginary plane, measure out the configuration of each shelf and partition in place. From the resulting depth of the shelves / partitions, you need to subtract the width of the support profile + 20 mm FROM THE FRONT.

What's the point? The peculiarity of the finishing work is that the layer of plaster / primer to the inner corners is thicker. This happens because in the middle of the wall or at the outer corner there is more freedom of movement with the tool. The difference in the width of the room in the middle and between the corners rarely exceeds 10 mm and is not noticeable to the eye, but even 2 mm is too much for furniture.

The niche configuration is, in general, a low truncated rectangular pyramid, overturned on its side. Accordingly, the shape of the shelves with partitions in the plan will be close to a trapezoid. But is it possible to cut them with the required precision? In our time, it is quite possible, and you don’t have to arrange carpentry at home. And a jigsaw with a circular saw is not needed. Templates and patterns - too.

Sawing and fittings

The fact is that now sawing blanks is easier and cheaper just to order. In almost every town there is a furniture workshop with a computer and an ACAD specialist, if the drawings were accurate. Many furniture makers also acquire computer-controlled sawing robots - the cost of sawing by such a hard worker almost does not depend on the size and complexity of the part, and it pays off well on non-standard small things that are always in demand.

Furniture makers buy material at wholesale prices, therefore, considering the total area, the cost of blanks is 20% or more less than when purchasing material independently at retail. Many also give a discount on scraps (almost all robotic ones); after all, they will not wallow in the trash, but will go to work.

Note: the thickness of the laminate or MDF for the cabinet is at least 16 mm. For doors on a monorail - at least 25 mm.

Also, a standard sawing service is edging, i.e. sealing the ends of PVC boards to match. For a built-in cabinet, edging, of course, you only need the front ends - it will come out cheaper. The thickness of the PVC edge can be from 0.2 to 2 mm. If you want a thick edge, in the drawing, its thickness must be subtracted from the width of the board.

Assembly, lighting, finishing

Techniques for assembling the cabinet, in fact, have already been described. It is necessary to add only about the suspension of the doors. The suspension systems described are not the only ones on the market. Technique is developing, existing ones are being improved, new ones are appearing. But for each more or less decent quality, a specification is necessarily given indicating installation dimensions and tolerances, technical specifications for rails, etc.

Therefore, before ordering sawing doors, take a closer look - what is sold around, what suits you best. The final size of the sashes depends on the suspension method, and the necessary clearances are specified in the specification for the suspension.

About interior lighting. Cabinets are made of combustible materials, so indoor lighting is best done on low-power 12V halogens. The cabinet lights are powered by a plug-in AC/DC adapter with double-insulated wires. Running 220 V wiring into the cabinet, and even permanent wiring, is completely unacceptable!

As for the decoration - mirrors, decorations, paintings and drawings - this is a matter of taste. One remark: it is undesirable to hang glass mirrors on doors made of wood materials, they are painfully fragile and heavy. Acrylic mirror is better. Or one-piece mirrored doors, but this is a separate conversation, and very expensive.

How much can you win?

And now let's figure out whether a home-made closet in a niche is really inexpensive. Will the savings be worth the time and effort?

If you make a closet in the niche of the hallway as described above, the materials will cost 5-8 thousand rubles, including the payment for sawing. Well, 10,000, if, as they say, from the belly. Time - 2-3 pairs of weekends for a medium-sized home master. And ordering a wardrobe in the same niche - less than 12,000 is hardly possible. Most likely, from 20,000. Deadline - 2 weeks.

Savings on a wardrobe-wardrobe in the entire bedroom wall is even more. Here, the ratio of home-made / custom-made value, typical for the regions, is 13,000/32,000. But for the manufacture of this, more serious skills are required.

But making a partition wall yourself is no longer so profitable: the advantages of well-established technology also affect the pros. And the work is difficult - a skilled craftsman will have to tinker with it for a month, if he doesn’t have to redo it. It will turn out to win no more than 2000 on a closet in a medium-sized odnushka.

(1

ratings, average: 5,00

out of 5)

The market of furniture products simply surprises with its diversity. But, despite this, it is very difficult to find something truly unique and inimitable even in such a huge commodity flow. This statement is also true for cabinets. Designer models cost a lot of money, and in the workshop they will ask for a considerable amount for personal production.

But making a cabinet with your own hands from chipboard will remain the most profitable way to acquire something truly unique. To do this, you will need: a drill, a set of drills, screwdrivers, a clerical knife and an iron. If you prefer to cut chipboard yourself, then you need to have an electric jigsaw, as well as special skins for grinding and leveling surfaces.

How to make a wardrobe with your own hands from chipboard?

Before proceeding with the construction of the structure, it is necessary to carry out some preparatory work:

- Site selection and sizing. Before making a cabinet, you need to choose a place for it in the room. After all, the dimensions of the assembly elements and the final design will depend on this. Then you need to make all the necessary measurements (width, height, depth).

- Drafting. In order to choose the right assembly, fastening, connecting and decorative elements, you need to draw up a layout of the desired design. It must take into account all dimensions, the number of shelves, hooks, their placement in the internal volume, etc. To do this, it is enough to have a measuring tape, a pencil and a piece of paper.

- Preparing chipboard boards. In accordance with the layout drawn up, it is necessary to cut the plates. You can use your own tool (for example, a jigsaw), but this requires some skill. The easiest option is to contact professional carpenters. They will do it quickly and efficiently.

- Selection of accessories. One of the important stages is the choice of fittings. You should take into account all the features of a particular design, as well as your own style preferences.

type of cabinet made of chipboard - hinged doors

type of cabinet made of chipboard - hinged doors  cabinet drawings

cabinet drawings

Before proceeding with the assembly, it is necessary to prepare the swing doors for the cabinet. First you need to choose the size of the door. Vertically, they must fit into the opening exactly to the millimeter. Otherwise, the doors may not fit or completely cover the internal cavity of the structure.

The width of each door should be selected with the expectation that they will be mounted on special elements that also have their own width. Therefore, it is necessary to take the horizontal dimension 2-3 mm less than the entire opening.

To give the hinged doors for the cabinet a more aesthetic appearance, you can use special furniture tapes. They are glued to the side faces of chipboard boards, hiding their internal structure.

Also read our article dedicated to the bathroom.

hinged wardrobe doors

hinged wardrobe doors  hinged wardrobe doors

hinged wardrobe doors

Assembly - the main stage in the manufacture of a cabinet with your own hands from chipboard

After all the necessary elements and accessories are ready, you can proceed to assembly of the structure. It is carried out in the following order:

- Using a drill and special drills for confirmation, we prepare holes for docking joints. All openings must be taken into account: for shelves, hangers, partitions, etc.

- We connect together the bottom, sides and top of the cabinet. To do this, it is enough to arm yourself with a screwdriver and screws. First of all, we lay the lower part, then alternately attach the side walls to it and lay the upper partition on the U-shaped structure.

- At the base of the cabinet, we install fixtures for shelves, hooks and other elements. The correctness of their installation can be checked with a level. Opposite fasteners must be placed strictly horizontally.

- At the very end, hinged doors for the cabinet are fastened. Before installation, it is better to mount the handles, because in the future it will be more difficult to do.

The last step is to polish the appearance of the cabinet. A decorative edge is glued along all cut edges of chipboard plates. All confirmations are hidden under special plugs, the color of which matches the design of the entire structure. Also, if desired, you can install mirrors, lighting and other functional or decorative elements.

Do not miss our article: Assembling with a lifting mechanism. It will be useful if you like to create furniture at home with your own hands.

The resulting cabinet, with a responsible approach to its manufacture, will have a sufficiently high strength and stability. But most importantly, it will be a unique element of your interior, which fits perfectly into the dimensions of the room. At the same time, the price of such furniture is much lower than the cost of similar models in the store.

The built-in wardrobe can be installed in the bedroom or in the hallway, in a one-room apartment or a chic country house with a large area. These interior items are both maximally functional and stylish in a modern way, they fit into any interior. You can point out their main advantages:

- such furniture with excellent capacity occupies a minimum of free space in the house;

- you can put all the family wardrobe items in one place and get rid of unnecessary furniture for clothes;

- thanks to sliding doors, they do not require free space to open them;

- doors on rails are safe, especially if there are children in the house, they will not pinch their fingers, like swing systems;

- from the outside you can hang a large mirror;

- sliding wardrobes have modern fashionable design.

You can order a ready-made model of built-in wardrobes with installation services, assemble the structure yourself from factory parts, or completely make the entire wardrobe yourself.

How to make a built-in corner cabinet with your own hands: step by step instructions

In order to properly do all the work yourself, you must first determine the location of the future wardrobe, taking into account the space for it, draw up drawings and diagrams detailing the outer walls, ceilings, shelves, drawers and hanging rods with their dimensions. Then choose the materials and type of doors with a sliding mechanism and guides. When all the tools and materials are available, it is useful to create a description of the work, which indicates step by step all the stages of manufacturing built-in furniture.

The necessary materials and tools for building a wardrobe are as follows:

- raw materials for the body, walls, shelves and doors (wood, lining, drywall, laminate, MDF, fiberboard);

- metal guides;

- rollers for doors;

- fasteners: bolts, screws, self-tapping screws, corners, brackets, profiles;

- magnetic latches and stoppers for fixing;

- soft dust collector;

- building level;

- roulette;

- drill, screwdriver, Phillips screwdriver;

- a hacksaw for sawing wood materials or a knife for cutting drywall parts;

- hexagon;

- scissors for metal or an angle grinder (grinder) with discs for metal.

Natural wood is a traditional material for making furniture, which is now also prestigious. For wardrobes, you should select straight-layer sheets without knots, cracks and chips, seasoned and treated with drying oil or emulsion. Wood is the purest natural material, which is durable and looks great. But among the shortcomings for the closet, one can note its heavy weight, high cost and exposure to moisture, which is important for the room where outerwear is stored.

Lining made of wood is a less durable material and requires fastening its individual boards. This can be done with PVA glue, joining the tongues with grooves. This material is rarely used to create wardrobes, mainly for models built into a niche.

Drywall is easy to process, easy to attach and has protection from moisture. But in itself, it is very fragile, and under heavy weight it sags over time. But if you make a rigid frame of metal ribs and drywall sheets, you can get a reliable and durable design. It is used to create internal shelves, niches and partitions in wardrobes because of the ease of installation and low cost compared to wood and laminated boards. But sliding doors are not made of drywall, because with regular slamming of the doors, it will crack.

Laminate, MDF and fiberboard are considered by many to be the most successful materials for the production of wardrobes. They are durable, easy to process, protected from moisture due to the special microstructure of wood and moisture-resistant components added to the fibers. The laminated surface has a smooth, shiny look with any color and can be cleaned with a damp cloth. For the production of such furniture, medium and high density fiberboards are used, which are less susceptible to mechanical damage and deformation.

The location should be chosen based on the area of \u200b\u200bthe apartment and the number of things stored. The easiest way is to build a wardrobe in the niche of the hallway, which are available in most standard-plan apartments. Usually, from the moment of housewarming, they are equipped with hinged doors that can be easily dismantled. Three walls are ready and it remains only to equip the place with a system of guide rails and sliding doors.

A similar option can be used with a full-wall niche, using existing ceilings in any room. They will serve as three walls of the cabinet, the fourth with moving doors will have to be mounted independently. Such models can be installed in the bedroom, in the nursery, in the hall. The advantage is that all items of clothing are at hand in the living room, and the disadvantage is that such a design takes up the usable area of the room.

In small apartments, to save room space, you can mount a corner wardrobe yourself. In profile, it will have a triangular shape, two existing walls of the room and a third being erected - with a sliding door. Due to the small dimensions, only one sash can be used. If the space of the living room allows, then many build a corner version of a rectangular shape. It already has 2 own walls, more internal space where you can put the bars with hangers, drawers and shelving.

The finished model is a cabinet wardrobe with 4 walls. It can be placed across the room, then it will divide the room, performing the function of zoning. And if you put it close to the wall, then the clothes will have additional protection from cold and dampness.

In a country house, it is possible to equip a closet in the attic, if the attic is insulated, protected from moisture, and has a fine finish. There are two options for the location of the outer wall with sliding doors: along sloping ceilings or across them. In any case, you can not do without non-standard parts with beveled corners. This will complicate the assembly work, but will allow you to create an original interior and give more free space on the 1st floor.

The assembly of the structure begins with the installation of the base. If it has adjustable legs, then you need to use them to create a horizontal level of the lower floor. The disadvantage of this design is that the lower part of the cabinet rises several centimeters above the floor, dust penetrates into the voids. Next, you need to assemble the vertical stiffeners of the structure, attaching them to the base, their correct position determines the entire stability of the cabinet. After that, transverse ceilings, shelves and rods are installed. The rear thin wall is screwed or nailed to the finished rigid frame.

Then we assemble the sliding sash system. The bottom rail is installed first. It is not fixed to the end, first you need to insert it into it and try on the roller wheels from the door. Then the position of the upper rail is marked along them. Both rails are attached to the body, the roller door slides in and is adjusted with a hex head screw at the bottom of the end face. It is necessary that it move freely along the guides without much effort. Then a duster brush is attached to the bottom of the sash, and fixing stoppers on the side.

Lighting for the closet is best selected from LED spotlights. They create an even and flicker-free light, are trouble-free in operation and last much longer than conventional incandescent lamps. They consume low power, which saves energy, do not emit much heat, so the surrounding surface does not deteriorate under their influence.

If all the details of the cabinet body are made independently, then a special protrusion can be provided for the upper part that extends beyond the plane of the folding doors. Round holes are cut out in it and lamps are mounted there in a row, 3-4 lamps are enough for 1 meter of length. This creates a modern and stylish design, and inside the cabinet will be effectively lit. This method requires additional wiring from the household mains, but you can simplify the task by using battery-powered pendant lights. Lighting can also be mounted in a cabinet niche, so it will be more convenient to navigate inside, to save electricity or battery power, you can build in touch sensors.

The design of the facade is most often arranged with the help of a mirror. This is the most practical option for furniture that performs the function of a wardrobe. Since large full-length mirrors are heavy, the design of sliding doors must be as strong as possible. It is worth choosing MDF and high-density chipboard or dense types of wood as materials, lining will not work. The facade of sliding wardrobes can be made of various decorative materials: colored plastic, transparent or translucent PVC, laminated plywood or lightweight organic glass. The strength of facade materials is not important, since the internal stiffeners take on the entire load.

The filling of the closet should be carried out in accordance with your needs and the wealth of your personal wardrobe. But regardless of the amount of clothing, the standard model of such furniture should contain the following elements:

- horizontal bars for hanging suits, coats, jackets, raincoats, jackets, shirts;

- retractable trousers;

- closed and open shelves for small accessories;

- drawers for underwear, T-shirts, knitwear, bedding;

- lower shelves for shoes.

If the closet has small dimensions, for example, 3 wings in length, then you can install one longitudinal bar on 2/3, where to hang all the outerwear on the hangers. Use the rest for drawers, and leave some space on top for open shelving. From the bottom, in full length, you can organize a compartment for shoes, which is separated from the main space by a horizontal shelf.

In more spacious wardrobe models - the entire wall of the bedroom or large corner ones, you can make several rows of shelving, separate horizontal bars for summer and winter clothes, a trouser compartment and full-height open shelves. You can even find a place for an interior mirror and try on outfits in front of it. Then the built-in wardrobe can turn into a full-fledged isolated dressing room.

Cost of work

Material prices vary by region and supplier. The most expensive raw material for the manufacture of wardrobes is natural wood, especially elite varieties aged for several years and treated with strengthening compounds. Lower in cost are laminated MDF and chipboard, then high-quality polished lining. Moisture-resistant drywall is considered the cheapest, but it must be borne in mind that it needs metal profiles in sufficient quantities, and the door will have to be made from other materials. In addition, you must consider the cost of fasteners, aluminum guides, rollers and stoppers.