Due to the simplicity of design, ease of assembly and excellent performance, log cabins have earned the trust of residents of various climatic zones since ancient times.

It is worth noting that the quality and warmth of a wooden structure primarily depends on the master involved in its construction.

Material properties

Another important indicator is the wood used for construction. At the same time, different types of wood are preferred in different regions. It all depends on the climatic conditions in which the building will stand. For a humid climate, one type is better, and for a cold one, a completely different one. It is also worth considering the location of the building, as well as the technology for the production of materials.

All this at all times was done by specialists who were valued "worth their weight in gold." Nowadays, this is done by construction companies specializing in the construction of various buildings from wood, whether it is a year-round residential building, a summer country cottage, or simply an ordinary bathhouse. But with the desire and due attitude to the matter, everything can be done with your own hands.

Advantages of wooden buildings:

- The most important and main advantage can be called the microclimate created in such a room. It favorably affects the condition of people with various diseases. People have long noticed that buildings made of coniferous trees benefit human health.

- The second important factor is the high rate of heat retention. But this advantage is true only if the thickness of the walls is more than a quarter of a meter.

- The third and, as a rule, the most striking plus of such a structure is, of course, the appearance. Buildings made of wood look very beautiful and solid. Log cabins from afar draw attention to themselves and attract admiring glances.

- It is also worth noting the absolute ecological cleanliness of such a building.

- Another advantage of this type of buildings is the durability of the building. This advantage will be relevant only with the right choice of all parameters for construction, including wood species, wood preservative and season for construction.

Disadvantages of buildings made of wood:

- The most significant and frightening parameter is the price. The prices for wooden fellings "bite" for the majority of inhabitants. Although this is fully offset by all the advantages, the price often stops the buyer from choosing a wooden building.

- Also, one of the disadvantages of wood is vulnerability to insects and mold, but this flaw is eliminated by treatment with special preparations.

- Increased fire hazard of buildings. They fight this problem with the help of special impregnation.

Advantages and disadvantages of round log cabins

You can find log cabins built both from logs and using timber. The main and indisputable advantage of a building using rounded logs is, of course, the price, which, in comparison with buildings made of profiled or glued material, is much lower. This is due to the simple production technology. It is also worth noting the aesthetics of the construction of logs. The disadvantage is the high fire hazard, which is due to the high combustibility of the building material.

The advantage of buildings made of this material is easier installation. Laying timber crowns takes much less time than when building a house from logs.

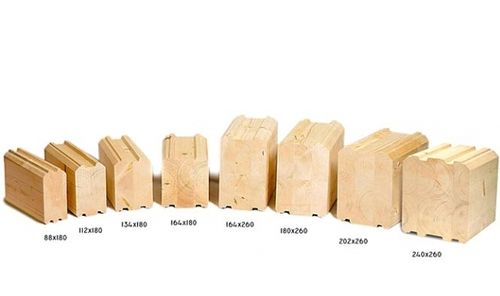

According to the shape, the product can be divided into 2 types: regular and profiled. The usual one is a simple rectangular beam, while the profiled beam has special cutouts and grooves that provide ease of assembly of structures and additional thermal insulation of the room. According to the structure, the products are divided into solid and glued. A solid beam consists of a solid mass of wood, and a glued beam consists of several elements glued together.

In the manufacture of a glued product, pre-selected lamellas of certain parameters are used. The slats are made using a special technology from wood, with the exception of all flaws. After carrying out certain manipulations, the lamellas are glued together with two-part wood glue under certain conditions. All these manipulations make it possible to obtain products of the most accurate dimensions and with certain characteristics.

As a rule, laying crowns from a bar is not an easy task. But if you wish, with the necessary knowledge and sufficient resources, you can do everything with your own hands. First you need to decide on the size of the house and the placement of rooms, draw a plan and calculate all costs. During the construction of a log house, options are possible: “with a remainder” and “without a remainder”. You must immediately decide on the appropriate option and select the type of material: profiled or ordinary.

First of all, you need to build the foundation of the house according to the preliminary plan. Laying timber for the house begins with the first crown. Laying the timber on the foundation begins with covering the place of contact with a material that will provide proper waterproofing. The first crown is most strongly affected by destructive factors, so experts advise choosing a product for it from the hardest material (preferably oak or larch). For reliability and additional stability, it is necessary to fix the first crown on the foundation.

Ways of fastening the crown on the foundation:

- Pre-insert reinforcement into the foundation and put a beam on it, as shown in the photo;

- After installation, drill holes and fix the crown with an anchor;

- After installation, hammer the dowel into the drilled holes.

Another thorny issue is the choice of the option for laying the timber in the corners. We will not go into refined and complex methods. Consider the most common and trustworthy.

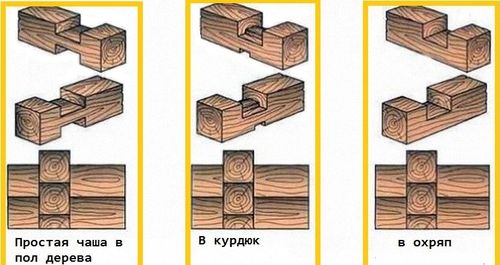

Methods for laying timber in corners with a residue:

- "in half a tree";

- "in a fat tail";

- "in ohryap".

Stacking without residue:

- on the root spike;

- on the plug-in spike;

- "in the paw".

All installation methods have their advantages and disadvantages. Some do not always give the expected result, but are easy to assemble, others give excellent performance, but confuses the complexity of execution. You can see all the methods in more detail in the video.

All elements are fastened together with wooden dowels, which are inserted into the drilled holes. Laying a profiled beam will make it possible to achieve the most accurate and quick assembly of the structure.