Before you start building your house, you should decide on the technology of its construction. Its choice depends primarily on the cost of money and time for a future new building. A frame house is a low-rise prefabricated housing built on the basis of a wooden or metal structure.

Mounted wooden frame cottage

Every year it is gaining popularity due to the fact that it is less susceptible to external influences, warm, light, has a modern attractive look.

In terms of quality characteristics, wooden frame housing is not inferior to concrete houses, and surpasses them in some parameters:

The disadvantage of frame housing, like all wooden buildings, is a fire hazard. And if you use cheap materials containing phenol-formaldehyde resins for decoration, then you can’t talk about environmental safety either. Therefore, when building a house, you should select building materials very carefully.

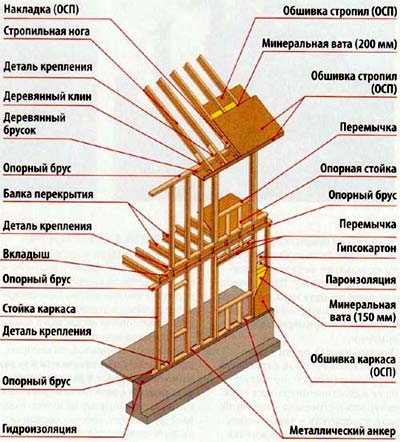

Main components

The frame of a low-rise wooden structure consists of:

Vertical racks are angular and intermediate. The purpose of both is to connect the upper and lower straps. It is usually carried out in ways: using metal corners or using a full cut and dowels. The slopes are used so that the frame does not warp, does not change its position when exposed to strong winds.

materials

If, then the following main elements should be made of wood:

- timber for the embedded crown, upper strapping and side racks of the structure;

- boards for cross members and rough sheathing of the frame;

- bars for supporting slopes.

In addition to wood, the installation of the house is carried out using materials for roofing, vapor barrier, and insulation.

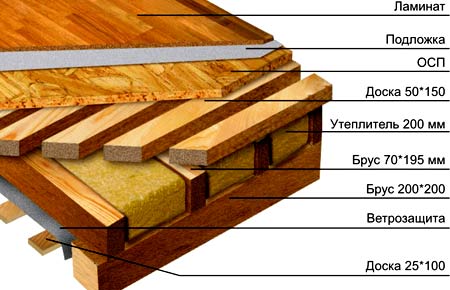

Scheme of flooring in a frame house

We should not forget about antiseptics, as well as flame retardants for wood processing. The roof is usually made of flexible Finnish tiles. The decoration of the frame dwelling, imitating a wooden beam, looks very attractive. For thermal insulation, foam or mineral wool is used. The insulation from the outside of the walls is protected by moisture-resistant plywood, cement-bonded particle boards.

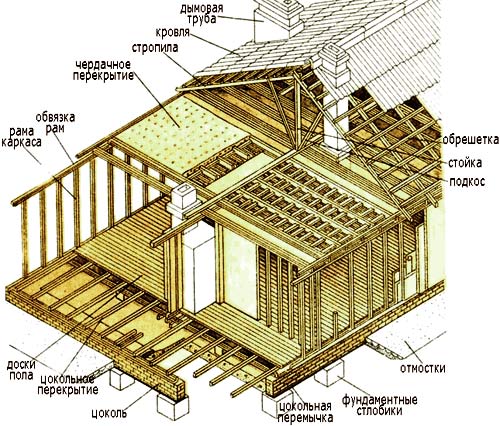

Construction of a frame wooden house

To become the owner of frame housing, you can buy ready-made elements made at the factory, transport them home and assemble them. This is called shield technology, the dignity of which is determined by the speed of construction of a new building. It requires the use of a crane to install the finished panels and, as a rule, pour the strip foundation.

You can build your own hands from scratch, which will cost much less, and the homeowner will receive great satisfaction from implementing his ideas during the construction process.

Drawing for the construction of a frame cottage

The frame of the dwelling can be made of metal beams. But they are not used very often. This is due to the fact that metal is much more expensive than wood, and lifting equipment is needed to mount the structure.

The use of wooden beams allows you to build a house on your own, without the involvement of qualified builders and special equipment. As in the construction of any building, the frame of the future building is worked out on paper or in a special computer program. It can be developed by the home master himself, special skills are optional. On, their dimensions, fit, connection methods, fastening of the main parts.

When performing construction work, you can not do without the following tools and materials:

Foundation

Construction begins with laying the foundation. Due to the low weight of a wooden building, it can be light tape or columnar. Having chosen one or another option, they mark the territory.

The foundation pit for the foundation tape should be of such size that it itself is 5–7 centimeters wider than the wall and goes into the ground by about 30 cm.

At the bottom of the excavated trench, a sand cushion of 5 cm is poured and rammed. It is necessary in order to reduce the influence of shifting soil layers. Then the pit is reinforced with formwork made of boards or other sheet material. After that, the reinforcement is mounted on the rods. They are hammered into the ground in order to hold a reinforcing mesh on them, for the installation of which you can use the longitudinal metal parts of unsuitable bicycles or baby carriages.

Ready-made tape-column foundation for a frame house

They are connected using a metal wire. The home master can prepare and pour the cement mortar himself, using high-grade cement, water, sand, plasticizer, crushed stone or gravel in certain proportions. Before installing the frame, the finished foundation must be covered with a waterproofing material.

If or basement, then a columnar foundation is used. Concrete, brick or metal poles are installed at the corners of the future building, as well as at the intersection of internal and external walls. From above, these elements are combined with a thick strapping beam, on which the structure will stand. The strapping is isolated from the foundation supports with two layers of roofing material.

Otherwise, condensation may appear at the points of contact between wood and concrete, brick or metal, and the wood will begin to rot.

strapping

For the installation of the lower and upper strapping, a bar with dimensions of 150x150 mm is required. It can be oak, larch or pine. It is pre-treated with a flame retardant and an antiseptic solution. The corners are reduced according to the tenon-groove principle with a tight fit, without gaps.

It can be connected using metal fasteners, but in contact with wood, they oxidize, causing wood to rot over time.

As a result, the entire structure loses its original strength. The frame is mounted on the bottom trim. It should occupy the entire perimeter of the strip or column foundation, to which it is attached with anchor bolts. For greater strength during pouring of concrete or installation of piles at the corners of the foundation, metal pins can be concreted to fasten the strapping frame to the foundation.  When the strengthening of the lower trim is completed, you need to make sure that it is laid strictly horizontally. Later, distortions of the structure are very difficult to correct. Now you can lay the logs for the floor.

When the strengthening of the lower trim is completed, you need to make sure that it is laid strictly horizontally. Later, distortions of the structure are very difficult to correct. Now you can lay the logs for the floor.

Vertical support bars along the length should provide a ceiling at a height of about 2.7 m. Above - there may be problems with heating, below - it will be stuffy in summer.

They are placed in the corners, and intermediate between them.

Initially, the vertical posts are strengthened with temporary cuts, two for each support, but after installing the upper trim, they are replaced with permanent ones. For mounting the ceiling strapping frame, bars with grooves are used. When it is ready, it is placed on vertical racks and nailed. Ceiling beams are laid in grooves and fastened with steel brackets or corners.

Walls

It is preferable that the board for warm walls be at least 10 cm thick.

Drawing of the construction of the walls of the frame cottage

And the choice of material for warming the house is determined by the preferences of the owner. Today, polystyrene foam is recognized as the most high-quality insulation. It is inexpensive, breathable, is a good heat insulator.

It does not stray in the insulating niche, does not slide down, as it happens with mineral wool. After that, the walls are finished from the inside, often with clapboard. Installed double-glazed windows with double or triple glazing also help keep the heat in.

Roof

Initially, a strong beam is laid, on which all other elements will rest. The rafters are connected with nails and at an angle in the shape of the letter "A".

An example of fastening the roof rafters of the frame roof

Then a crate is made, knocked together from boards one from the other at a distance of 10 cm. Its upper part, using a construction stapler, is covered with roofing material. On top of it, starting from the bottom, a profiled sheet, slate or tile is overlapped.

The ridge strip after the completion of the flooring should be strengthened with self-tapping screws. Along the edges of the roof, catchment areas with a drain are made. After this procedure, doors, windows are installed, a porch is built, and, if desired, an attic.