Unfortunately, it is impossible to lay out a fully working fireplace in the apartment. In this aspect, the owners of private houses were more fortunate. It is quite realistic to build a fireplace there, especially if you provide for it at the design stage of the structure itself. But the inhabitants of apartments in modern high-rise buildings have a worthy alternative: they can make a decorative fireplace with their own hands. This will create a relaxing and cozy atmosphere in the interior of the room.

Decorative fireplaces are divided into the following groups:

- symbolic. Any material can be used to create them. A feature of such a decorative fireplace in the apartment is its dissimilarity with the usual fireplace. An example is his image on the wall, decorated with decorative paraphernalia;

- conditional. Thanks to a self-made portal protruding from the wall, this type of fireplace is very reminiscent of a real one. At the same time, you can decorate it as you wish, for example, by placing firewood or candles in the firebox;

- reliable. This is an option for the most complete imitation of a fireplace in an apartment, in compliance with the principles of design and the corresponding dimensions of the structure. To create the effect of a real flame, the inside of the pseudo-furnace is equipped with a bio-burner. The impressive price of this option is offset by its extreme realism.

You can make a decorative fireplace with your own hands from a variety of materials. Moreover, any such design is easy to implement. The materials you need can be purchased at any hardware or hardware store, and a number of them can even be found at home.

Making a fireplace with your own hands from boxes

It is noteworthy that from this material it is possible to create a portal for an electric fireplace with your own hands, and not just a purely decorative design. Of course, this option excludes the installation of a gas burner due to the presence of an open flame, which can cause a fire. It is impossible to place a heat-exchange fireplace with a casing and a water boiler in it due to the fact that cardboard can catch fire from overheating, and because of the bulkiness of the final design. For the same reasons, do-it-yourself installation of an electric fireplace with a built-in heating function and with an open firebox is unacceptable.

From the foregoing, we can draw the following conclusion: in a structure created from boxes, it is allowed to install only an electric fireplace with imitation of a flame using a backlight or on an LCD screen.

Useful advice! To make it look more like a real fireplace, finish the product from the boxes with decorative plaster or paint with acrylic paint.

The only drawback of such structures is their lightness. Therefore, fastening a homemade fireplace from boxes must be carried out to the floor or wall.

This material allows you to implement a wide variety of design ideas. There are several style directions of a fireplace from boxes created by one's own hands in an apartment today.

Modern. The design of the fireplace portal in this style involves a variety of colors and textures, a combination of antique decorative elements (sockets, stucco moldings, etc.) and modern forms. Such a fireplace will be in perfect harmony with almost any interior.

High tech. This style suggests a certain futurism. Therefore, in this case, to create a fireplace in the apartment with your own hands, such ultra-modern materials as plexiglass, steel are used. It would seem, what does cardboard boxes have to do with it? However, even from them you can make a fireplace in a modern style. It is enough to give it an interesting geometric shape and paint it steel or black, and simply insert a mirror into the firebox. It is also allowed to lay glass on the mantelpiece.

Classic. This style is always in fashion. A minimum of additional decorations, strict lines - you can put such a fireplace in absolutely any apartment.

Country. Rustic style is preferred by many of our contemporaries. Such fireplaces differ in that they are made of natural stone. To give the product from the boxes such a look, it is enough to paste over it with self-adhesive wallpaper or film with a stone print, and firewood must be placed in the firebox.

What materials and tools will be needed to make a cardboard fireplace with your own hands

It is clear that in the first place it is necessary to have several large cardboard boxes. In addition, in this case, you will need to buy to create an imitation of a fireplace:

- glue for connecting boxes together;

- polymer-based adhesive;

- paint suitable for working with cardboard "building materials" (usually water-based);

- paint "gold" in a can;

- colorless varnish;

- ceiling molding;

- brushes and sponges;

- masking tape and adhesive tape;

- ruler, level, measuring instruments.

Let's briefly consider the question of how to make a decorative fireplace with your own hands. The length of the base is about 120, and the height is 50 mm. The main part is constructed from a cardboard box and pasted over with adhesive tape. As a result, you need to get a blank that looks like a dollhouse. The portal is also created from cardboard. To simplify the work, opt for the option with a solid back wall.

On a note! When drawing lines for cutting a cardboard box, do not use felt-tip pens and markers. They will show through the paint and ruin the whole look.

The front part of the portal is made from a piece of cardboard in the form of a strip. Then the furnace part is cut out. To connect all the parts together, adhesive tape is used.

Next up is the top shelf. It must be understood that the strength of an artificial fireplace created by one's own hands is determined by the quality of this particular element. To ensure that the installation of heavy objects on the top shelf does not lead to its deformation, it is necessary to glue several layers of cardboard together. And to give this part rigidity, press it until it dries completely. Fixation of the upper shelf on the portal is carried out using polymer-based adhesive. Then the joints between all the details of the fireplace are sealed using masking tape.

The process of decorating a do-it-yourself decorative cardboard fireplace is the most pleasant and easy of all the works on its manufacture. One of the most attractive options is the use of stucco. But most often moldings or baguettes made of foam are used to frame the fireplace.

Making your own brick fireplace

This material is used to ensure that the appearance of the structure is similar to that of a traditional fireplace. Usually used decorative or facing bricks. Laying must be carried out according to a previously drawn up drawing or sketched order. Only a master with experience in masonry work can perform this type of construction.

Decorative brick fireplace does not need additional finishing. This material itself looks very original. Wooden shelves and real logs are suitable for decorating this type of structure. A special romantic atmosphere will reign in the apartment during the construction of a false brick fireplace with candles in it.

What is live fire? Types of fireplaces with 3D fire effect. Features of the choice of electric fireplaces. Rules for the installation of an electric fireplace.

Brick laying for a fireplace is in order. Before moving on to the next row, it is advisable to give the previous one time to dry. Be sure to wipe the front side of the brick.

A gap of 5 millimeters must be left between all metal components and the brick. Lay an asbestos cord of the same width in it. The gap is left in order to prevent damage to the structure of the fake fireplace caused by different coefficients of linear expansion of metal and brick.

Note! Jointing of masonry joints should be done immediately. Then there will be no need for additional finishing.

To decorate the structure, it will be enough to install a hardwood mantel on it. As a budget option - a foam concrete shelf. Inside the furnace hole, you can install an electronic portal with the functions of simulating live fire and sound. Of course, using such a self-made brick fireplace for heating is impossible, but the visual perception of “dancing” flames will bring notes of real warmth to the room.

Creation of decorative fireplaces from plaster

Gypsum is included in the group of the most practical and at the same time cheap materials for the construction and decoration of false fireplaces. It is safe for health because it is environmentally friendly. Gypsum is able to absorb excess moisture in the room and, conversely, give it away if the air there is very dry. The plasticity of this material ensures the ease of decorating the surface of the product.

A gypsum fireplace portal can be decorated with elements that match the style of the interior of a particular room. A wide range of options available for artistic processing of such a design is the main advantage of this material in terms of the implementation of design ideas. For example, its surface can be decorated with alfreine painting or covered with gilding, made to look like marble or wood, tinted with acrylic or water-based paint in any color.

The answer to the question of how to make a decorative gypsum fireplace portal depends on what kind of homeowner prefers it. According to the criterion "manufacturing method", experts distinguish two main types of such structures:

- profiled. Individual elements of the decorative frame are attached to the profile: cuts, pilasters, moldings, friezes, rods;

- sculptural. Here it is supposed to use such sculptural elements as atlases, bas-reliefs and caryatids.

A good help when choosing will be the study of a photo of imitation fireplaces with a plaster portal.

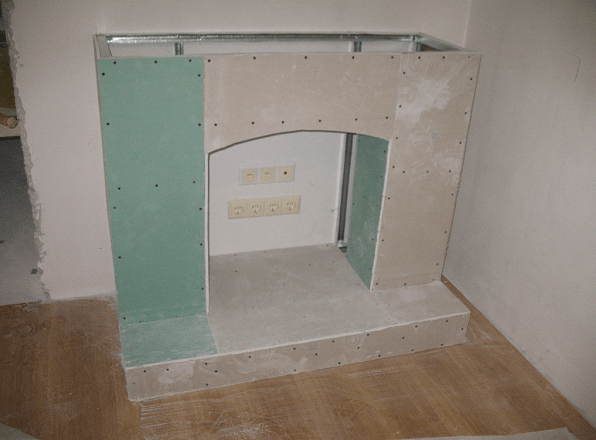

Features of manufacturing a corner raised fireplace from drywall

In accordance with the name, such a decorative fireplace is placed in the corner of the room. Thus, the floor and two interlocking walls serve as the supports of the structure. The use of drywall sheets allows you to give the fireplace smooth and curved shapes and perfectly fit it into the interior of your apartment.

And in this embodiment, the final product is often equipped with a top shelf. By placing decorative items on it, the owner will bring a touch of sophistication and originality to the home.

The following advantages of such a design solution can be distinguished:

- saving indoor space;

- in almost any room you can find a free corner and place a false fireplace in it;

- this placement allows you to increase the size of the corner fireplace. Due to this, the decorative component of the interior of the housing will increase;

- installing a false fireplace in the corner does not create obstacles to moving around the room;

- any home master will be able to mount the design of a corner decorative fireplace with his own hands. Photos of this product will be the best assistant in carrying out such work. To increase the level of visual appeal, decorate the corner false oven with natural or ceramic tiles, etc. In addition, elements made of polyurethane and gypsum can be used for decoration, for example, in the form of columns.

Note! One of the most common design decisions is to install a false stove in the corner opposite the front door. Then the decorative fireplace will become the central accent of the interior.

What tools and materials will be needed to make a false plasterboard fireplace

Beginners who do not know how to make an artificial plasterboard fireplace portal should heed the recommendations of professionals. The main advice is formulated as follows: before starting work, you need to decide on the design of the product and create a drawing. It is this scheme that will allow you to calculate the approximate amount of materials.

Typically, the case will require:

- drywall. It is sold in sheets with different sizes;

- metallic profile. A frame is created from it;

- self-tapping screws;

- putty and primer;

- lining material.

A metal profile made of galvanized sheet acts as the basis for fastening the elements of the fireplace portal. During installation, several types of such products are used: arched, guide, rack, corner profiles.

To build a frame, the following tools should be at hand:

- grinder - angle grinder;

- level, better laser;

- drill;

- jigsaw;

- long ruler and tape measure;

- square.

The beginning of work on the installation of a raised plasterboard corner fireplace

The choice of installation site is made taking into account the following factors:

- distance from other objects. Placing the structure close to cabinets and other furniture is not the best solution. The fireplace will not look here;

- the presence of free space - in it the fireplace attracts the attention of others more;

- away from windows. Even a decorative fireplace is always associated with warmth. And near the window opening, such an association can be broken.

Having chosen a place, we draw a drawing. It should display the parameters of each element of the false furnace. There are two options here: choose a ready-made plan from the Web or create a drawing yourself. In favor of the first, he says that you will definitely be sure of the correctness of the indicated figures characterizing the dimensions of all structural details.

Having made a drawing, we apply markings on the floor and walls. Having done this, check all the lines for level. Even the slightest irregularities must be excluded.

On a note! Before you go to the building materials store to buy elements of the future frame, you should calculate the optimal thickness of the metal profile, taking into account the magnitude of the load. Evaluation "by eye" is unacceptable.

How to install a corner decorative fireplace made of drywall

The appearance of certain nuances is due to the angular arrangement of the false furnace. To assemble a frame from metal profiles, the following sequence of actions is performed:

- we install the starting profile along the walls on the floor. It must converge in the corner;

- then we build the base of the fireplace on the floor. We assemble it according to the standard scheme using guide profiles;

- along the lines in the corner and along the walls we fasten the guide profile, which is included in the starting one fixed on the floor;

- all fastenings between profiles and walls, as well as the floor, are carried out using dowels.

The basis is metal profiles of different types

Remember that the key to the strength of the entire structure is a stable and powerful foundation. After its installation, we proceed to the assembly of the frame and the niche of the fireplace portal. First, we insert the guide profiles into the base and remove the box. After that, we fix the jumpers between the guide profiles. We connect the profiles to each other using screws for metal. The final stage of the installation of the frame is the laying of wires through which power will be supplied to devices that simulate a real flame.

Sheathing the frame and decorating a false fireplace

Plasterboard sheets are used for sheathing. Meanwhile, in the context of the question of how to make a fireplace from this material in an apartment, this procedure has the following features:

- to sheathe the inside of the portal and the base, you will have to cut drywall sheets into small pieces;

- at this stage, you will need a much larger number of perforated corners than in the previous ones. Only with them the created structure will have ideal right angles.

In all other respects, the sheathing of the frame with plasterboard sheets is carried out according to the standard scheme. Upon completion, proceed to decorate the fireplace with your own hands. When choosing a finishing option, it is necessary to focus, first of all, on the design features of the living space.

Most often, ceramic tiles, decorative bricks and artificial stone are used for external coating. To fasten the finishing components, liquid nails or tile adhesive are used. If the cladding is done with tiles of the correct shape, it is necessary to lay them so that the gaps are the same. To achieve this result will allow the use of special plastic crosses.

However, for the finishing of a decorative fireplace in an apartment in a multi-storey building, a less expensive option is allowed. For example, the use of paint or decorative plaster. In this case, the surface should be carefully processed with putty, all irregularities should be eliminated and the joints between the skin components should be repaired.

Important! Even a neatly cut drywall sheet will have notches on the edges. Before puttying, they must be removed with sandpaper.

In conclusion, it remains to place an electric fireplace in the opening of the "firebox". However, you can decorate the free space in accordance with your taste preferences. So, one of the great options for a classic interior is the arrangement of warm and soft lighting in the “firebox”.

In general, today there are many ideas for decorating a decorative fireplace. You can implement the proposed solutions, or come up with your own, unique.

Many people dream of having a real fireplace with live fire in their home. But, unfortunately, not everyone can afford it due to various reasons. A decorative plasterboard fireplace is an alternative to a stone structure. You can do it yourself, without resorting to the help of specialists.

Benefits of drywall fireplaces

- It does not require permission from the fire inspectorate to install it.

- A decorative fireplace will cost much less than a real one - it can be built from the remnants of building materials after repair. In addition, it does not need to be constantly heated and spent on firewood.

- It does not require a chimney device.

- A fake fireplace is safe to use.

- It can be placed in any convenient place.

- When arranging such a fireplace, you can turn your fantasies into reality, make a “hearth” according to your own project.

- During its construction there are no "dirty" works. You can make a plasterboard fireplace and install it even after repairs in the room, etc.

A paper fireplace, a master class for the manufacture of which is presented, can be made independently from improvised materials. The question arises, how? Let's figure it out.

What is needed for the construction of a plasterboard false fireplace?

To install a decorative plasterboard fireplace with your own hands, you need to prepare the following tools and materials:

- drywall sheet;

- rails / fence / metal profile;

- screwdriver and self-tapping screws for plasterboard and metal;

- putty;

- Bulgarian;

- roulette;

- screwdriver;

- building level;

- pencil/marker/pen;

- whatman paper / sheet of paper;

- jigsaw / circular saw;

- abrasive mesh / sandpaper;

- bar;

- metal scissors.

Read also information about in addition to this article.

Video: making a drywall fireplace with your own hands

Advice! It is not necessary to buy a drywall sheet and a metal profile. For the device of a false fireplace, there will be enough scraps of materials left after the repair work.

A plasterboard fireplace can be equipped with an electronic portal with an imitation of live fire. Some people prefer to leave the firebox empty by placing candles, garlands or lanterns there.

Stages of creation

Making a decorative fireplace with your own hands - a list of successive events. By correctly performing the algorithm of actions described below, you can make an excellent drywall hearth without any extra cost and effort. Main stages of work:

- Choice of installation location.

- Create a sketch.

- Mounting.

- Facing.

- Finishing work.

- Decoration.

Earlier we already wrote about and advised to bookmark the article.

Place for a fireplace

Traditionally, a fireplace is placed in the middle of the wall in the living room. However, in modern city apartments there is not much free space and you have to improvise. A false fireplace can be installed in a corner, hiding an unsightly space from the eyes. An equally popular option is to build a “hearth” under the TV if it hangs on the wall. For spacious rooms, it is recommended to install a fireplace as a separate structure in the middle of the main wall opposite the entrance.

Advice! The fireplace can be installed in any room. It will look great in the hall, office, bedroom or nursery.

Sketch

A decorative fireplace always attracts the eyes of others, so it must fully match the interior of the room. It is recommended to pay great attention to its design. To do this, several sketches of the future structure are created and the best option is selected. Masters advise to draw a fireplace on a piece of drawing paper in the full size of the structure. The sketch is made in accordance with the dimensions of the selected place. Next, start creating the layout. It will help to calculate the required amount of building material and see the design errors. Some make it out of cardboard or paper.

Important! It is not necessary to develop a drawing on your own; you can take ready-made projects on the Internet as a basis.

Mounting

- The construction of a fireplace begins with the creation of a frame from a metal U-shaped profile. If one was not at hand, you can use a CD or UD profile.

Important! The frame structure does not carry a serious load, therefore, to create it, you can use trimmings of a metal profile, a picket fence or unnecessary rails.

The first step in creating a frame is cutting a metal profile and screwing a support (rear wall).

- The metal profile is cut according to the dimensions of the sketch. First, the support frame is assembled (the back wall of the frame) and screwed to the wall with dowel-nails or self-tapping screws.

Advice! You can assemble the design of the fireplace, and only then screw it to the wall. This is done after facing the side walls of the "hearth".

- Next, assemble the rest of the frame. Every 30 cm, jumpers are inserted between the horizontal and vertical guides for structural strength.

Advice! The most important thing when creating a frame is to make a geometrically correct design. All corners must be checked with a building level. With the curvature of the "body" of the fireplace at this stage, everything can be corrected.

Facing

The finished frame is sheathed with drywall. The sheets are pre-cut into several parts according to the sketch and screwed with self-tapping screws every 10 cm. If you plan to use heaters or candles inside the furnace hole, then the frame is sheathed with heat-resistant material. Most often magnesite, asbestos or sheet metal is used.

Details are cut out separately from drywall under the foot of the fireplace and under the mantelpiece. The corners of the structure are rounded off with an abrasive mesh and a bar. Sliding movements of the surface give smoothness and remove roughness. The shelf and foot are fixed with self-tapping screws and silicone glue.

Read also the article about in addition to this material.

Advice! If decorative finishing materials are applied to drywall, then the frame is sheathed with plasterboard in two layers.

Finishing

Do-it-yourself decorative plasterboard fireplace is “trimmed” to your taste. You can paste over the finished structure with a film or wallpaper, putty and paint, overlay with stone or tile.

If the plasterboard fireplace will be puttied and painted, then a primer layer is first applied to the surface of the structure, then all joints and seams are sealed. Putty is applied in several layers, first - starting, followed by rubbing with sandpaper, then - finishing. Dust is removed with a damp sponge or washcloth.

Advice! To make the corners of the fireplace even, a perforated corner is attached to them.

If you plan to make the fireplace as similar as possible to a traditional one, then it is recommended to decorate the installation with an artificial stone. To do this, the surface of the "hearth" is primed and the finishing material is glued to a special glue. After the glue has dried, the gaps between the stone / tile are sealed with a fugue.

You can cover the false fireplace with decorative plaster. After applying the first layer on the surface with a spatula, you can “draw” bricks or any other pattern. After drying, the edges of the ornament are passed with a brush, then a layer of acrylic paint is applied.

Decoration

The resulting decorative plasterboard fireplace can be decorated with plaster columns, forged products, stucco moldings, moldings, borders or baseboards. Some paste over the installation with a decorative film with stone imitation. The tabletop is also decorated to your taste. Decorating a fireplace is a creative process, and homemade logs, real logs, lantern candles, candlesticks, and other attributes can be used to create the atmosphere of a real hearth. Read the article about it on our website.

It is not difficult to make a decorative drywall fireplace with your own hands. It is not necessary to have building skills to make such a structure. All that is required from the master is attentiveness, ingenuity and imagination.

For a long time, fireplaces have ceased to be bulky brick structures that are used to heat homes. Now they are increasingly used for decorative purposes, and heating occurs due to electricity. More and more people live in city apartments, where it is impossible to install a real fireplace, and it is not necessary. Therefore, electrical analogues are installed or imitations are created from various materials. In the latter case, the most popular material for creating such a decorative element is drywall.

They make a decorative fireplace with their own hands from drywall for two reasons:

- Protect the room from heat sources and increase their efficiency. In this case, a special device is bought that is powered by the mains and simulates a flame, but gives off heat. In this case, refractory drywall for the fireplace is used.

- For decorating the interior with a fake fireplace without a heat source. For plating, any GKL is suitable.

Regardless of the reason, you can create a fireplace from hl with your own hands, because the order of work will be the same. This design has a number of advantages:

- safety. The absence of open fire and the use of GKLO reduce the risk of fire to a minimum;

- homemade plasterboard fireplace has a simple design. Although it is possible to create such complex projects that they can occupy huge areas;

- the use of GKL allows you to create any shape of the fireplace, even the most bizarre. You can even create a design with a chimney;

- the size of the room does not play a big role, because the installation of the structure can be carried out anywhere, even in the corner;

- lining can be carried out using any materials.

Varieties of false fireplaces

All false fireplaces can be divided into three categories: authentic, conditional and symbolic. Having understood which of the options you are interested in, you can begin to implement it.

Decorative chimney gives more authenticity to the whole structure

Decorative chimney gives more authenticity to the whole structure Authentic fireplaces are made to be exact replicas of the original designs.. If this option is used outside the apartment, then you will never think that this is an imitation. A characteristic feature of such structures is the use of furnaces, where various types of fuel are burned. The imitation comes out so good that it has the appropriate dimensions and design principles. Such a plasterboard fireplace in the interior can look very massive, and it is rational to install it in a cottage where there are large rooms.

Having the dimensions of the future design, you can calculate how much profile, fasteners and GKL will be required. Let us remind you once again that you need heat-resistant drywall for a fireplace only if there is a heating element inside the structure being created. Otherwise, the material for finishing the metal frame is suitable.

To make it easier to work, you need to make a drawing of a plasterboard fireplace with dimensions. After that, the dimensions can be transferred to the wall so that you can see exactly where to mount the frame. At this stage, you will need a level (ideally a laser one) so that the finished structure is not skewed. By the way, for work you will need the following tools and fasteners:

- level to create a smooth structure;

- metal guide profile to create a frame;

- metal scissors for cutting profiles;

- tape measure for performing various measurements;

- electric drill and dowels for attaching the frame to the wall;

- drywall for sheathing the frame;

- knife for cutting GKL according to the given dimensions;

- a screwdriver and self-tapping screws for attaching the frame elements to each other and drywall to the profile.

Additionally, materials for finishing will be required (trowel, putty, tape for seams and facing material). At the very end, we will consider the question of how to finish a plasterboard fireplace.

Assembly and fastening of the frame

There should be markings on the wall and on the floor so that it is clear where the do-it-yourself plasterboard fireplace frame will be installed. For its assembly, rack or guide profiles can be used. You can assemble the frame separately, and then attach it to the wall, but it is better not to resort to this method. You can miss with a hit in the markup, and it is inconvenient to mount the entire bulky structure. It's better to do everything in sequence. You need to make do-it-yourself fireplaces from drywall step by step, and not try to combine several stages into one or skip them.

It is advisable to provide a stand in the frame

It is advisable to provide a stand in the frame First of all, the guides are attached to the wall and to the floor. To do this, you need to outline the places of their fixation, after which holes are drilled with a drill, and the profiles are attached to the wall and to the floor with dowels. It is not necessary to cut the profile into many pieces, because it can be cut with scissors, and then simply bent at a right angle. In this case, the guide on the floor and the wall will be the same, and there will be no need to worry about everything being installed on the same line.

Vertical guides are checked with a plumb line to ensure they are fixed evenly. Ideally, use a laser level.

Racks are inserted into the guide profiles on the floor, which are fastened with metal screws. These posts run from the bottom profiles to the top, where they will be fixed into rails that are mounted parallel to the profile on the floor. You should get some kind of parallelepiped if you assemble the simplest design. This will be the main frame, in which you will still need to make a place to insert a heater. A drawing of a false plasterboard fireplace will help with this.

Frame option without anchoring to the floor

Frame option without anchoring to the floor Jumpers between the racks are installed at the height at which the electric fireplace will be installed. One of the guide profiles at this height is attached to the wall. It turns out a quadrangle, which will be the bottom of the niche. For greater reliability, you can add a few more jumpers inside this rectangle (relevant for heavy heaters). All other elements of the frame are assembled in a similar way. For example, you can create a drywall fireplace box that will mimic a chimney.

Plasterboard sheathing

On top of the fireplace, you can install a wooden tabletop for decor

On top of the fireplace, you can install a wooden tabletop for decor GKL must be cut so that it can be used for sheathing the assembled frame. It is not difficult to guess how to sheathe the structure with drywall. Just take drywall sheets and fasten them with self-tapping screws. Facing the fireplace with drywall with your own hands begins with a niche for an electric fireplace, into which it is then inserted. If mistakes were made, then part of the structure may have to be reassembled again. If the fireplace went perfectly, then we take it out and continue to work.

| The main characteristics of wall (GKL) and refractory (GKLO) drywall | ||||

| Name | Size in mm. | Leaf area in sq.m. | Sheet weight in kg. | Color |

| GKL | 1200x2000x12.5 | 2,4 | 23 | Grey |

| 1200x2500x12.5 | 3 | 29 | ||

| 1200x3000x12.5 | 3,6 | 35 | ||

| GKL | 1200x2000x12.5 | 2,4 | 26 | Pink |

| 1200x2500x12.5 | 3 | 31 | ||

| 1200x3000x12.5 | 3,6 | 37 | ||

After sheathing the internal space of the structure, you need to move on to the outside. We fasten everything with small self-tapping screws in increments of 15 cm. The procedure is quite standard and ordinary. Do not forget that the caps of the self-tapping screws should be flush (do not protrude and not be pressed in too much). Now you know how to make a fake drywall fireplace, but that's not all.

It is possible to provide specially double walls for the furnace hole (if it is used for its intended purpose). A non-combustible insulation is laid between these walls, for more efficient heating of the room.

Features of corner fireplaces

I would like to dwell on the option of installing a fireplace in a corner. This method has both advantages and disadvantages. Let's talk about the benefits:

- You can save space, since the occupied area is smaller in the corner.

- The space of the corner of the room is used, and usually the corners are empty.

- Less consumption of materials and lower cost of the entire structure.

- Looks original and stylish.

Unfortunately, a do-it-yourself corner false fireplace made of drywall will also have disadvantages. There is not always a free corner of sufficient size so that there is no window with a radiator. Even if the window is far away, then there are curtains that will interfere. Therefore, always two corners in the room cannot be used.

Imitation of a chimney will not steal space and will look stylish

Imitation of a chimney will not steal space and will look stylish The remaining two corners are usually formed by the part of the wall where the doors are located. For some people, if a do-it-yourself corner decorative fireplace made of plasterboard is located in such a place, then this is unacceptable from the point of view of room design.

Step-by-step instruction

For the most part, the creation of corner false fireplaces from plasterboard is not much different from the procedure described above for frontal structures. The main difference is in the shape of the frame.

Do-it-yourself drywall corner fireplace - step by step instructions:

- Size calculation. Everything needs to be accounted for. For example, a heating pipe running along the corner of the wall that needs to be hidden. It can interfere with assembling a solid frame. If the battery is hidden, then you should definitely provide for a design feature that will make it easy to get to it if necessary. When a drywall corner fireplace is assembled, the dimensions of all elements must be carefully considered.

- We mount the frame. For this, the cheapest profile or the one with which it is most convenient to work will fit. There are no special requirements for guides.

- We provide electrical wiring. These can be sockets or wiring to illuminate the finished structure. Especially additional lighting is relevant if the work is carried out with a large frame.

- The frame is sheathed with sheets of drywall.

- Finishing coating is being carried out.

Here's how to make a drywall fireplace yourself. You just need to follow the sequence of work in the instructions.

Finishing - the last step

The fireplace must harmoniously fit into the interior of the room where it is installed. That is why it is so important to choose the right finish. The most popular materials for such work are decorative bricks, ceramic tiles and artificial stone. However, for these purposes, ordinary paint is often used.

With the right finish, no one will guess the use of drywall

With the right finish, no one will guess the use of drywall Before painting a drywall fireplace, it is puttied, making all surfaces smooth. Then everything is painted twice with water-based paint using a brush. For other types of finishes, you will have to use plaster compositions so that nothing falls off. All this significantly increases the weight of the structure. So you need to know in advance whether the drywall will be faced with ceramic tiles (stone) or not.

It is not so difficult to make a fireplace in an apartment with your own hands from drywall, as it may seem. The main thing is to correctly carry out calculations and use the level, do not forget about jumpers and finishing.

The presence of a fireplace in the interior of the apartment gives the atmosphere weight and a certain style. And many of us would agree to be able to sit at home by the fireplace. But modern living conditions are such that one can only dream of a fireplace, especially in multi-storey buildings. You can replace the living warmth of a real fire with a decorative fireplace, moreover, made by yourself.

The first step is the idea of how to make a decorative fireplace

Before you rush headlong into the implementation of the idea, look at the photos of the best options for decorative fireplaces built by yourself. They are available in a wide variety of materials and styles. This will help you competently approach the problem, how to make a decorative one, evaluate your capabilities.

Among the variety of products, decorative fireplaces can be made:

- In the style of exaggerated imitation and stylization, emphasize only the decorative properties of the product;

- To give a decorative fireplace a maximum of useful properties: from a heater to a book shelf;

- Try to give the decorative fireplace the most authentic appearance with your own hands due to the excellent imitation of the attributes of the heater and finish.

In any case, it is worthwhile to first analyze the location of the building, the most acceptable dimensions and, of course, the style of execution. With the choice of a place, the hardest thing is, rather, a relaxation area with armchairs or a sofa, so you have to do a little rearrangement in the room with your own hands.

Decorative fireplace in artwork style

The first version of a decorative fireplace will require maximum design abilities and the ability to make an expressive object with your own hands from materials that imitate natural stone, ceramic brick or wood. More than half of the designs of such a decorative fireplace can be made from cardboard with your own hands.

Part of the decor for the portal and countertops will have to be made from ceiling bovelacci, friezes and skirting boards. A mandatory attribute of such a decorative fireplace will be the presence in the furnace niche of a lamp or flickering lighting that complements the overall impression. Most of these decors, in terms of depth of study and design, are more like an author's sculpture or an installation element.

The advantages of this approach are an amazing opportunity to make a real object of art with your own hands, visualization of fiction and the grotesque.

Decorative fireplace as a bar, furniture shelf or heating appliance

The desire to have a decorative fireplace in the interior of the room, which can give more than an object to relax the eyes, requires a thorough study of the design with your own hands and head, an assessment of your capabilities. Modern building materials will allow, if financial resources are available, to make the exact embodiment of the plan.

Important ! When designing a decorative fireplace, make two or three times the safety margin in its design in advance. Practice shows that most of the subsequent problems arise precisely because of subsidence or destruction of the supporting frame of the fireplace.

Among the popular materials for building decorative fireplaces with your own hands, shown in the photo, it is worth focusing on the most suitable ones:

- Oriented strand board OSB, often used as a base for laminate or parquet, has excellent frame strength. Requires additional exterior finishing. Working with OSB-plate allows you to make a furniture structure with full strength and capabilities with your own hands. In some cases, a frame made of such material can withstand paneling under natural rubble stone or brick, bringing the appearance of the decorative fireplace as close as possible to the appearance of the original product. But the cost and weight of such a product will be at least twice as high as other options.

- Gypsum plasterboards can be used both simple and water and heat resistant, of various thicknesses, from 8 to 15mm. Do-it-yourself decorative fireplaces made of drywall, like a photo, allow you to achieve the highest degree of similarity with a real brick version. It can be completely made with your own hands from drywall, even if, in addition to "furniture" duties, he still has to perform the functions of a heater or heater.

- Wooden slats up to 60-70mm wide, pre-sorted and calibrated for thickness and curvature of the surface. The most environmentally friendly and labor-intensive option, implies the presence of carpentry skills. As a rule, in expensive versions, the surface of the rack shield is ground, polished and often glued with furniture veneer.

Step-by-step instructions for making a decorative fireplace with your own hands

Gypsum plasterboards allow you to create light and durable, the most intricate designs in shape, but with one condition - the presence of a strong frame of the product and properly fastened and sealed seams. Currently, this is the most affordable and cheapest option for any frame products.

Step one - choose the basis of the design

For a plasterboard version of a decorative fireplace, you will need to make a capital frame and a supporting base. According to the chosen location in the room of the decorative fireplace or according to our own plans, we will make a sketch of the “face” of the decorative fireplace with our own hands, it is better to do this from a photo of one of the options for a decorative fireplace, folded with our own hands from drywall. According to the sketch, we will make a drawing with reference to the terrain according to the estimated dimensions of the decorative fireplace. The next step is the calculation of the required amount of drywall and frame profile. For financial calculations of the estimate, we multiply the obtained values by 20%.

In most cases, a special perforated metal profile is used to fasten and connect sheets. To build a frame, you can use a polished wooden beam or a frame metal mesh, but in most cases, the choice is given to a flexible and durable profile.

Step two - assemble the frame of a decorative fireplace

The frame of the fireplace must be fixed along the contour with plugs and screws on the wall on which the structure will rest with the back wall. In a secluded place on the wall, it is necessary to make electrical wiring connectors or sockets for further connection to the fan heater or lamp network.

According to the scheme, a preliminary or rough fixing of the back wall of the fireplace is carried out on the frame, then side walls and bearing elements of the combustion chamber are made from a metal corner. The connection of metal pieces of the corner must be done using screw fasteners and self-tapping screws.

Important ! If it is planned to install or use a heating device in a decorative fireplace - a heater or a fan heater, the heater and the cold air intake window should be “sewn” into the frame structure even before the frame is completed.

This will avoid mistakes in the most critical part - the organization of the correct supply and removal of cold and hot air, respectively. To remove hot air, it is better to use GPLO brand drywall.

The lower part or supports of the vertical racks of the frame must not be fixed to the floor! As the load on the frame increases, the position of the support points of the structure will change; if they are fixed, deformation and distortion of the frame will occur.

Important ! If, according to the project, the front part and the portal are to be faced with decorative artificial stone or imitation of red brick, the vertical racks of the frame should be reinforced by installing a paired double corner of the metal profile.

Step three - fixing the drywall panels

Panels should be cut from drywall sheets only on the basis of measurements of the actual dimensions of the assembled fireplace frame. This is clear. In the process of assembling the frame, errors or miscalculations in dimensional chains could accumulate in the structure, and blind copying of the dimensions and shape of the panels from the drawing will lead to the appearance of gaps. As a rule, there are no big problems in fixing finished panels. To mask the heads of the self-tapping screws in the drilled hole, it is necessary to make an additional reaming with a 10mm drill to a depth of 3mm. Due to this, the head is wrapped flush with the surface.

For the top shelf of a decorative fireplace - countertops, a double sheet of drywall is used, fixed along the perimeter with additional self-tapping screws or with PVA glue.

After hanging and fixing all drywall panels, we will check the strength of the structure, if necessary, add attachment points with additional self-tapping screws. We carefully cover the joints, cracks and heads of self-tapping screws with putty, if necessary, a plaster mesh can be glued on the inside of the crack, which increases the strength of the layer of the applied material. After 10-12 hours, the places of putty are rubbed and sanded with fine emery.

Step four - decorating

The most realistic and natural finish will look like ceramic bricks or decorative tiles. It is possible to perform the sticker of brick-like panels on a flat and primed surface, even without experience in such work.

The simplest and most affordable option is to paint the water-based composition in a color that is most suitable for the interior of the room. If the top shelf of the fireplace is intended for permanent use as a work surface, then it is better to make it from a laminated or varnished furniture board-panel.

Often, electronic photo frames with images of fire, flames or hot coals are mounted in the combustion chamber of a decorative fireplace. For fans of a complete reconstruction, you can make a decorative fence for the firebox, supplement it with a restrictive grid and candlesticks.

A fireplace can make even the dullest interior of a room much cozier and more comfortable. But such a pleasure is quite expensive, and it is not always possible to install something similar in an apartment. But there is a way out. You can make a fake fireplace with your own hands of absolutely any shape and size, and it is so simple that the process itself does not take much time and does not require special skills.

Can a fireplace be artificial

A false fireplace is a structure that looks like a real fireplace, but without a chimney. In some cases, this is just an element of the decor of the room, in other cases there is still an element of imitation of a living flame, for example, as in electrical installations.

A false fireplace can be a great decor in a room of any size.

The main advantages of this design can be considered absolute safety (unless, of course, you decide to install a lot of candles in the portal) and low cost compared to a real fireplace. In addition, there are other advantages of false fireplaces:

- allowed for installation even in an apartment, while it is forbidden to mount a real fireplace in an apartment building;

- with it, you can mask the defects and shortcomings of the room, for example, hide a battery or a pipe, and it is also advantageous to use the so-called dead zones, for example, a corner;

- top and side you can equip shelves for decor and storage of various small things;

- emphasize the stylistic direction of the room design, for example, when choosing a baroque or other classical style.

A false fireplace will be appropriate even in a children's room

Types of structures

There are several types of false fireplaces that you can install in your own apartment:

There is another classification, which is based on the installation site of such a design:

- suspension;

- wall-mounted;

- angular;

- built-in;

- island.

What can be made

If you are a fan of making crafts, then you can use absolutely any building material to make a decorative fireplace, including:

- Brick. It allows you to create an artificial hearth as close as possible to the present. For installation, you can choose a decorative or facing brick. The disadvantages of this design are a significant mass, which means that it can be mounted only after checking the overlap for the ability to withstand such a weight. However, there are also advantages, in addition to naturalness. Such a false fireplace can not be faced with anything.

Brick false fireplace is as similar as possible to the real one

- Plates with laminated coating. Before using this material, it is imperative to draw up a drawing, on which it is necessary to indicate all the dimensions of the future structure. The drawing is needed in order to cut the material. Chipboard sheets have similar properties, however, such a design requires further finishing, for example, with foam plastic "bricks".

A fireplace made of laminated sheets looks very concise

- Polyurethane. As a rule, this material is used to finish an already finished structure. However, special pieces such as mouldings, architraves and half-columns can be glued directly to the wall and decorated accordingly. Using decor and trying various techniques with highlighting, it can be turned into an unusual piece of furniture. There is one more advantage - if desired, such a fireplace can be repainted in any color. This allows you to update the interior with minimal investment in a short time.

Polyurethane fireplace can be simply glued to the wall

- Drywall. This material is most popular for the manufacture of false fireplaces. It has undoubted advantages - ease of assembly and combination with other finishing materials. If desired, the plasterboard construction can be decorated in any style, which means it is suitable for any interior. In addition, you can build a structure of any complexity. An artificial hearth can be deep, with a square or round portal, with columns or minimalistic. You can change the lining without disassembling the entire structure, which is very convenient.

Most often, a false fireplace is made of drywall.

- Wood. Using this material, you can make a false fireplace, which will be part of the furniture set, which means it will be made in the same style as the entire design of the room.

Wooden false fireplace can be artificially aged

In addition to those listed, for the manufacture of a false fireplace, you can also use improvised materials, for example, cardboard boxes or old furniture.

Dimensional drawings

The dimensions of the structure largely depend directly on the area of \u200b\u200bthe room where it will be installed. For example, a corner unit for a small room might be 330 mm deep and 1,300 mm long.

A small room can also be decorated with a wall-mounted false fireplace. At the same time, the dimensions of the structure are recommended to be slightly reduced, for example, to make a portal with parameters of 1,360 * 500 * 1,050 mm.

In a small room, you can install a wall or hanging fireplace

When installing a false fireplace in a medium-sized room, more opportunities appear:

- you can make a more massive structure by decorating it with additional decorative elements, for example, columns and stucco;

- it is allowed to use not only shelves, but also countertops, but only if the partition is able to withstand such a design;

- you can place an artificial fireplace in the center of the room, and not just near the wall.

The drawing should indicate the dimensions of each part.

When decorating a room in a classic style, a false fireplace can be massive with appropriate decorations. For example, the dimensions of the bottom can be 1500mm, the top 1490mm and the depth 345mm.

If you want an artificial fireplace to look attractive, expensive, and high-status, then it is recommended to use artificial and natural stone, forged elements, valuable wood for decoration.

In a large room, a false fireplace can be installed in the center of the room

When making a copy of the fireplace for a large living room, you can follow the following rules:

- island location, thanks to which you can create a very massive and unusual design that will perform several functions at once;

- you can not use a hinged structure;

- the partition wall for a false fireplace must be such that it does not deform under the influence of a large weight of the structure.

A false fireplace can also look like a home oven

How to make a fake fireplace with your own hands - step by step instructions

You can make a fake fireplace with your own hands from any building material. It all depends on your imagination and financial capabilities.

From drywall

The corner construction of drywall looks very original. Such a fake fireplace can be installed even if the room is too small for any such devices, because it can also be used as a storage space. To make it, you need to prepare:

- metal profile - 13 pcs.;

- drywall 9.5 mm thick, better moisture resistant - 3 sheets;

- tiles - 5 m;

- self-tapping screws - 200 pcs.;

- grout for ceramic tiles of the corresponding color;

- LED strip imitating fire;

- decorative grille.

It is necessary to make a corner decorative fireplace from drywall in accordance with the following instructions:

- Correctly calculate the dimensions. In the event that you close the battery with the design, this must be done in such a way that it has free access.

From drywall you can build any complexity

- Install the frame. To do this, you can use a ceiling metal profile.

Ceiling profile suitable for the frame

- Lay electrical wiring if an electric fireplace is installed in the portal. Such a fireplace should have at least three exits: two on the facade and one above the shelf. For additional illumination, an LED strip is suitable.

- Finish the fire hole. Here you need to make two walls, between which you need to lay any non-combustible material.

The fireplace insert must have two walls, between which non-combustible material must be laid.

- Now the frame can be sheathed with drywall. Details must be pre-cut from the sheets according to the drawn up drawing.

You need to cut out the parts from drywall in advance

- Make a few holes in the casing. They are needed so that warm air can circulate freely.

Holes are needed for air circulation

- Revet with ceramic tiles or any other material. It is better to give preference to facade tiles, as they are resistant to temperature changes and negative external influences. You can also use gypsum tiles imitating stone. In this case, it is recommended to use a heat-resistant adhesive.

When using facing bricks, you can make a fireplace very similar to a real one.

Such a fireplace will occupy an area of only 1.5 m 2.

Video: plasterboard false fireplace

Reuse of cardboard boxes

You can also make a decoration in the form of a fireplace from large cardboard boxes. They should be as dense as possible, should keep their shape well. For this you need to prepare:

- cardboard boxes of different sizes (4 pcs. large and 5-6 pcs. small);

- white paper that can be replaced with wallpaper;

- glue;

- scotch;

- colored cardboard, paints or wallpaper with a pattern of bricks.

It is necessary to make a false fireplace from cardboard boxes in the following sequence:

- Place the boxes in the order in which they should be in the finished version.

For the fireplace, you can use boxes of different sizes.

- Now you can connect these boxes to each other. It is very convenient to use tape for this.

- After the frame is made, it must be pasted over with white paper or wallpaper. For this purpose, you can use either adhesive tape or PVA glue. All edges should be even, for which you need to cut the paper in the corners.

You can use tape or glue to attach.

- Separately, make the top shelf, which is also pasted over with white paper, and then fixed on the prepared frame.

The shelf at the cardboard fireplace should also be

- Cut out bricks from red cardboard, which are then glued to the frame using clerical glue. Instead of colored cardboard bricks, you can use decorated wallpaper. Also, bricks can simply be drawn.

Bricks can be made from cardboard

- The top surface can be left undecorated or covered with paint.

Cardboard fireplace is very light and mobile

Video: do-it-yourself fireplace from boxes

from wood

Using a similar technology, you can make a structure or chipboard or plywood:

- According to the drawing, cut out all the necessary parts.

- Assemble the frame from the timber. All other wooden parts will need to be attached to it. In this case, you can use several methods of fixation at once: tongue and groove, gluing, connecting with hardware. The choice of method of fastening depends on the exclusivity of the required reliability of fixation.

- Fix on the assembled frame decorative elements from bars of different sizes, moldings.

- External finishing. There are several options for exterior finishes. Such a false fireplace can simply be covered with white paint, tiled or decorative bricks.

- The decor of the firebox, which will give maximum credibility to the fireplace. For a wooden structure, it is recommended to use natural and decorative accessories, such as fir branches, cones, dry firewood.

In order to make the structure less massive, some wooden parts can be replaced with plywood elements.

Video: do-it-yourself decorative fireplace

Polyurethane

To make a false fireplace from this material, you must first choose the style of the product, and also, in the case of using an electric fireplace for the portal, take into account the dimensions of this device, the way it is connected, and the need for ventilation. Additionally, you need to prepare:

- polyurethane portal;

- miter box;

- hacksaw for metal;

- roulette;

- drill;

- glue;

- putty;

- sandpaper;

- facing material.

The installation process itself takes place in the following sequence:

- Decide on the installation location. It is best to do this on the side wall of the room. Moreover, it is necessary to place a false fireplace made of polyurethane so that it does not interfere with free movement.

A polyurethane fake fireplace is very easy to do yourself

- Socket installation. This stage is necessary if an electric fireplace will be located inside the portal. The wiring must match the voltage used, while the outlet itself must be placed as close as possible to the false fireplace.

- Wall surface preparation. It needs to be leveled and cleaned.

- Application of markings on polyurethane. This information can be taken from a drawing prepared in advance.

- Fixation of polyurethane parts. To fasten parts, you need to use special contact glue and self-tapping screws. This will increase the reliability of the structure and extend its service life. During this process, care must be taken to ensure that the corners of the parts correlate with each other. In advance, for self-tapping screws, you need to make holes with a drill.

For ease of manufacture, the entire structure can first be laid out on the floor

- External finishing. There are several options for a raised polyurethane fireplace. Stucco molding can either be attached to a special glue, or with self-tapping screws. The second option is more reliable, but there is a risk that the caps of the screws will be visible to the naked eye. Therefore, when using a mechanical method of fastening, additional decoration of the joints is recommended.

You can cut polyurethane with a hacksaw

It is possible to give aesthetics to the structure if it is puttied, primed and painted after manufacturing.

Video: installation of polyurethane false fireplace moldings

From old furniture

Turning an old wardrobe or chest of drawers is the most budgetary option for making a false fireplace. To convert you will need:

- plywood;

- grinder with a nozzle for wood;

- jigsaw;

- screwdriver;

- paint, best acrylic;

- putty;

- LED Strip Light;

- plaster molding.

After preparing all the necessary tools and material, you must follow the following instructions:

- Remove the doors from the sideboard, remove extra drawers and cabinets.

All doors and drawers must be removed from the sideboard

- Install two beams in front.

In addition to the frame, you will also need bars and plywood sheets.

- Attach plywood sheets with which to form a portal hole.

You can set the dimensions of the furnace yourself

- Make a hole for the blower. It can have any shape, the most ergonomic will be a semicircle. Also, the space can serve to wound firewood.

The blower can be used to store firewood

- Make a pedestal and a decorative shelf. For this purpose, you can take the backs of an old bed, first you need to unscrew the legs of these parts.

The fireplace needs a pedestal and a shelf

- Proceed to the external decoration of the false fireplace. All polished surfaces of the cabinet must be processed with a grinding machine, then primed, puttied and carefully leveled. After the putty has dried, sand the surface with sandpaper. Now the false fireplace can be painted, and then finished with a facing material, for example, facing bricks. You need to finish the work by gluing all the decorative elements and installing the shelf.

For finishing, you can use any facing material

- Arrange the space of the firebox. Why lay an orange or yellow LED strip around the perimeter. At the bottom you can lay stones or shells.

To simulate fire, you can use an LED strip

By following these instructions, you can create a raised fireplace in any style.

No one will guess that a sideboard was turned into a fireplaceFalse fireplace made of decorative bricksFor a false fireplace made of large bricks, a foundation may be required

from brick

A false brick fireplace looks the most natural. In its manufacture, it is necessary to strictly follow the masonry technology, otherwise the structure will be unreliable and quickly collapse. You need to prepare in advance:

- brick - 25 pcs.;

- steel strip for overlapping;

- solid board with a thickness of 4 cm or more for a mantelpiece;

- cement mortar.

For a fireplace, you can set the standard dimensions of the base 900 * 250 mm and the firebox 500 * 380 mm. The mass of such a design will not exceed 100 kg, which means that an additional foundation will not be needed.

A large brick false fireplace may require a foundation.

The technique for making a false brick fireplace is as follows:

- First you need to prepare a solution. It is better to purchase a special powder designed for such work. It is enough to dilute it with water in the proportions indicated on the package.

- Lay out the brick base in half a brick, after which you can go to the walls and the firebox. Lay the walls brick-thick with overlapping seams.

- Lay a shelf on top of the frame or attach a countertop.

- Decorate the firebox. To do this, you can stick a film with the image of a brick on the back wall, put candles or brushwood in the firebox itself. Instead of a film, you can use a mirror, so that the depth of the firebox will appear larger.

What to make fire

In no case should a real fire be kindled in a false fireplace, even if the structure was made of brick. Can be used to simulate a flame.