We will send the material to you by e-mail

The age of electronics is inexorably pushing books out of our lives. Indeed, an electronic gadget can hold a whole collection of popular reading material in a small tablet. But you must admit, how pleasant it is to leaf through a real tome, admire the embossed cover, enjoy the comfort of a home library. The editors of the site have prepared tips for you on how to choose the right shelves for books. We will talk about how to fix the rack on the wall, and consider original design ideas.

Books in the house are a sign of the education of its owners

Not everyone can afford to allocate a separate room for the home library. Most often, favorite books are placed in or in the bedroom, children's literature - in the child's room.

Modern designers offer many original and practical ideas. Recently, it has been especially popular, including modular shelving. They can change their appearance and design, move around, gather in or podiums. Such models will appeal to lovers of rearrangements.

Classic wall shelves never go out of style. They are reliable, static and can be decorated in the style of your interior. And here there are many interesting ideas for implementation. Consider several options that can be used in a house or apartment.

Classics of the genre: wall-mounted bookshelves

Hanging shelves for books can be bought at any furniture store. Their range is quite wide, and you can easily pick up models that fit the main headset.

Conventionally, wall shelves can be divided into several types:

| View | Description |

|---|---|

| Classic | Simple and light shelves of various shapes are attached to load-bearing walls and can be assembled in rows or complex compositions. They can be in the form of a simple board, located flat or at an angle. |

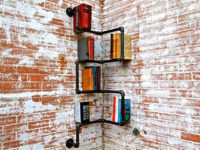

| corner | To make the most of a room's space, corner bookshelves are a great option. They fill the usually empty corner, and are attached to both adjoining walls. Shelves can be mounted on internal and external corners. |

| Suspended | If you want something unusual - hang the shelf on a beam or from the ceiling against the wall. The hinged structure must be reliable and firmly fixed, because books weigh a lot. |

Wall shelves for books are good because they save space.

Built-in drywall book shelves

If your walls have suitable niches, drywall shelves can be installed in them. With the help of drywall, unusual shelves for books are obtained on the walls near windows and doors. It is easy to integrate lighting into such racks.

The only disadvantage of this solution is the fragility of the material. Such structures need additional frame reinforcement; heavy tomes should not be installed on them.

Related article:

Methods for attaching shelves to the wall

Accurate and strong fastening is an important point in the installation of shelves. There are several types of fasteners:

- Hidden- bolts or nails are invisible on such fasteners. The shelf seems to be hanging in the air, and the main load is distributed to the metal console, hidden behind the back wall.

- bracket- the metal holder is attached to the wall separately, and then the shelf is put on it and fixed in special grooves.

- Corner or loop- this type of fastener does not look as neat as others, but it is distinguished by increased strength. Corners increase the strength of the structure, and built-in hinges allow you to raise or lower the shelf as needed.

- Glass fasteners- this is a special type of canopies, which allows you to accurately and firmly fix the glass panel on the wall.

Important! When choosing a mount for a shelf, pay attention to the indicator of the permissible load.

If you are going to use an original idea, first evaluate it according to several parameters:

Shelves made of wood or plywood are easy to cut yourself with a saw or saw, but it is better to order glass surfaces in the workshop. At home, it is difficult to qualitatively process the edge or perform curly cutting. You might like the ideas of using scrap materials in the manufacture of bookcases.

Master class: a small do-it-yourself wooden bookshelf

A small shelf is suitable for you, which can be installed on a windowsill, table or even on the floor. To make it, you will need a sheet of plywood, a jigsaw, a ruler, sandpaper and wood glue. Step by step description of the process:

| Photo | Description |

|---|---|

| On a sheet of plywood, you need to draw the outline of a sheep, horse, dog or any other animal if this is a shelf for a child. For an adult's room, you can limit yourself to abstract contours. |

| Using a jigsaw, cut out the main part along the drawn outline. |

| On the workpiece, you need to draw three grooves: two - from below and one - from above. |

| The thickness of the groove should be equal to the thickness of the material from which you are making the shelf. |

| This is how the workpiece looks with finished lower grooves. |

| The legs of the shelf are two semicircular parts with grooves cut out from above. |

| The third vertical part is made with a groove from below. When assembled, it looks like this. |

| For the surface on which the books will stand, you need to mark a perpendicular line on all inserts. Use the building level for this purpose. |

| On vertical inserts, cut out the guides for the shelf with a jigsaw. |

| The shelf itself is a long piece with three slots. |

| During final assembly, all grooves must be treated with wood glue. |

| Shelf for children's books is ready. It can be painted, decoupaged or left as is. |

Master class: do-it-yourself bookcase

The simplest rack can be made from ordinary planed and sanded boards.

The main difficulty of this task is to understand how much glass you need to buy to make bookshelves.

Task B4. For the manufacture of bookshelves, it is required to order 44 identical glasses from one of the three companies. The area of each glass is 0.25 m2. The table shows prices for glass, as well as glass cutting and edge grinding. How much will the cheapest order cost?

Typical mistakes in solving such problems:

- Students completely forget that we are buying not one large glass with an area of 44 0.25 = 11 m ^ 2, but 44 small glasses. As a result, the third column remains unaccounted for;

- For some reason, some people believe that glass is sold in pieces of 1 m^(1), since the price in the table is given exactly for 1 meter. In this case, the answer may also turn out to be wrong.

The second point I would like to discuss in more detail. Of course, in today's problem, the area of each small glass is 0.25 m 2, i.e. glass with an area of 1 m 2 is cut into a whole number of pieces. But sometimes the numbers are chosen so that this number turns out to be non-integer. And then what to do with the "stubs"? Throw them out? Then the answer will be wrong.

Therefore, the most correct approach would be to consider that in the task we are given one huge glass, from which we cut off as many pieces of 0.25 m 2 as we need. In this case, no extra cores will appear, and the answer will always be correct.

Almost everyone can make bookshelves with their own hands, since this is the simplest type of furniture. Their manufacture requires minimal skills, a small amount of material and fasteners. In this article you will find the answer to the question of how to make bookshelves with your own hands.

A simple bookshelf is a box assembled from four plates - two vertical elements (racks) and two horizontal elements (shelves). Do-it-yourself bookshelves are easy!

Manufacturing steps

Sizing

Making a bookshelf should begin with determining the overall dimensions. The length of the horizontal members from upright to upright should not exceed 80 cm to avoid deflection of the shelves under load. Therefore, if the total length of the shelf exceeds the specified size, it is necessary to increase the number of vertical elements in the shelf or increase the number of shelves.

It is possible to make a bookshelf with your own hands from wood. If books are planned to be installed in one row, then the optimal depth of the shelf is 23 cm, with a two-row installation of books - 40 cm.

The height of the racks is determined by the distance between the horizontal elements, at least 33 cm, if you plan to put books in a non-standard format or folders for files). It is desirable that the height of the racks exceed the distance between the shelves by 10 - 12 cm. This will allow you to use the top shelf for installing books or decorative interior elements.

Make yourself a drawing, it's more convenient to make bookshelves. In order to fix the shelf to the wall with dowel-nails without the use of metal canopies that violate the appearance, one more detail is added - the tsarga.

Its length is equal to the length of the shelf, since it is located under the top shelf or above it, depending on the overall design of the product, the width is not more than 10 cm. It is connected with one long end to the top shelf and two short ends with racks behind the shelf flat to the wall. A couple of holes are drilled in it for dowel nails.

The dimensions of the parts are defined:

- 80 x 23 cm - 2 pieces (shelves), hem on one long side;

- 45 x 23 cm - 2 pieces (racks), edge from one long and two short sides;

- 80 x 10 cm - 1 piece (tsarga), hem on one long side.

It is customary to edge only prominent ends, but if you make a bookshelf with your own hands, you can close all ends with an edge, as they are one of the sources of environmental disturbance in the room.

Cutting details

To make a hanging bookshelf with your own hands carefully, you need to order the cutting of parts of the required color from laminated chipboard and edging at the company providing these services. If you have problems finding a company (usually there are several of them in each city, but also in a village), contact a furniture store, but you will overpay for mediation.

Laminate board in various sizes can be found in the building materials markets, as well as in large stores specializing in the sale of goods for repairs.

You will have to purchase an edge. The edge should be melamine with adhesive applied to it. On a straight end, it is simply glued with an iron at home and processed with a sharp knife (for cutting wallpaper) and a small file (a bar with fine sandpaper). We will talk about this in more detail in another article.

Assembling a bookshelf

As it is more convenient to make bookshelves, we fasten all five parts together at a right angle using euro screws (large self-tapping screws with a diameter of 6 mm and a length of 50 mm).  It is necessary to prepare the parts for assembly:

It is necessary to prepare the parts for assembly:

- mark and drill in the planes of the racks (the ends of the shelves are adjacent to the planes of the racks) holes with a diameter of 7-7.5 mm (the holes are larger than the diameter of the Euro screw, so that when tightening it is possible to slightly shift the parts to be fastened relative to each other to compensate for inaccurate marking and withdrawal of the drill when drilling);

- mark and drill holes with a diameter of 5 - 5.2 mm at the ends of the shelves and drawers, into which the Euroscrew will be screwed.

Make the bookshelf yourself - we make the markup using a tape measure, a pencil and a core (awl). The coordinates of the holes on the uprights, shelf and drawer side are shown in the figures below. Inaccuracies in marking and drilling of 1 - 2 mm are quite acceptable.

Calculate the coordinates of holes on planes with a diameter of 7-7.5 mm slowly and carefully. An erroneously drilled hole as a result of an incorrect calculation spoils the appearance of the product, since it cannot be hidden or repaired (only stick a plug for a euro screw).

All calculations are simple and based on the fact that the euroscrew is twisted into the middle of the end of a chipboard 16 mm thick. Therefore, 8 mm is added to all distances between parts when marking for a euro screw on a plane.

If the end is adjacent to the edge of the plane (the connection of the lower shelf with the rack), set aside not 8 mm, but 9 mm from the edge of the rack to compensate for marking and drilling errors (it is better to drown the end relative to the plane than it protrudes).

In the figure we see the estimated size of 342 mm. The distance from the top end of the rack to the shelf is determined by the width of the drawer side 100 mm. Therefore, the middle of the upper shelf relative to the bottom of the rack is calculated as follows: 450 - 100 - 8 = 342 mm

What's the best way to make bookshelves? At this distance from the bottom of the rack, draw a line with a pencil and mark on it 60 mm from each edge (60 mm is the most optimal size in terms of the possibility of chipboard delamination when screwing a Euro screw into it).

Holes for fastening the drawer on the top shelf are drilled along the long end adjacent to the wall. At a distance of 800 mm, three holes are enough: one in the center and two at the edges. Holes for connecting the shelf with the uprights are drilled in the middle of the chipboard thickness in two opposite short ends at a distance of 60 mm (coinciding with the distance on the uprights). There are no holes for the drawstring on the bottom shelf.

In the drawer side, we drill holes only at the ends at the distances previously set on the top shelf and on the stand.

We twist the prepared parts together with euro screws using a 4mm hexagon. The rigidity of the shelf is provided by the drawer side, so you can do without the back wall of fiberboard or plywood. We close the heads of the euro screws with special plugs to match the color of the material, drill two holes in the drawer for the dowel-nails and fix the shelf on the wall.

The process of making a bookshelf with your own hands is completed. I hope you got the answer to the question of how to make bookshelves with your own hands, see the photo of the bookshelf design:

There is nothing better than shelves for organizing space in rooms, as well as for decorating the interior. Comfortable, functional, original form, they help to conveniently arrange a lot of things and give the rooms a more comfortable look. Making shelves on the wall with your own hands is not at all difficult, and you can use a wide variety of materials - wood, fiberboard, glass, pieces of tin, plywood.

| Types of wall shelves | Description |

|---|---|

| Classic | This type of shelves is the most common because of its simplicity, aesthetic appearance and ease of installation. They are a huge flight of fancy: from simple squares to creative asymmetric shapes. |

| corner | This type of wall shelves differs in the method of fastening - it is carried out on adjacent adjacent walls. Most often they are mounted in utility rooms and bathrooms. |

| Suspended | This original way of creating a shelf involves attaching a simple structure to the ceiling using cables or vertical racks. |

| floor standing | This wall shelf is a floor support structure. This type of product is especially relevant in hallways, as well as large rooms where you don’t have to think about wasting space. |

| Open and closed shelves on the wall | Wall shelves can be designed, for example, with or without glass |

Making a simple wooden shelf

Wood is the most convenient material for work. Wooden shelves are simple, complex, open and closed, vertical, horizontal and angular. Taking the basic version as a basis, you can assemble a shelf from several modules and give it the most incredible look. In order for the product to serve for a long time, you should choose the right wood: the boards must be perfectly even, completely dry, without cracks, voids and mold.

During the assembly process you will need:

- hacksaw;

- drill;

- building level;

- pencil and ruler;

- boards 16 mm thick;

- stain;

- varnish for wood;

- grinder;

- screws, brackets, dowels.

As an example, a simple rectangular shelf 250 mm wide, 300 mm high and 1100 mm long is used.

Step 1. Markup

The boards are laid flat on the table and measurements are transferred from the drawing. The height of the side walls should be 268 mm, since they will be located between the top and bottom: wall height + board thickness x 2 = 300 mm.

Step 2. Cutting the boards

If the markup exactly matches the pattern, you can start cutting. It is best to use a jigsaw for this, then the cuts are perfectly even and neat. You should get 2 long blanks and 2 short ones.

Step 3. Processing blanks

Before proceeding with the assembly, each workpiece must be sanded, stained and varnished. If you plan to simply paint the shelf, the blanks are processed - this way the service life increases, and the paint lays down more evenly.

Step 4. Assembly of the product

The bottom board is laid flat on a flat surface. 8 mm retreat from the ends of the workpiece and draw 2 straight lines parallel to the cuts. Now on these lines you need to mark two points at a distance of 5 cm from the edge, and drill holes for the screws there. Do the same with the top piece. When all the holes are ready, side blanks are installed on the bottom board and screws are screwed in. A second board is applied on top and the side walls are also fixed with self-tapping screws.

Brackets are fixed at the ends of the side walls, holes for dowels are drilled in the wall, self-tapping screws are inserted and twisted so that they protrude by about 5 mm. The dowels must be located strictly horizontally, therefore, before drilling, a line is drawn using a level. Now it remains only to attach the brackets to the fasteners and hang the shelf. If desired, the back wall of the product can be hammered with a piece of plywood, and glass can be inserted in front.

To make such a simple shelf more original, you can replace one side wall with a stump of a thick branch. To do this, choose an even branch with a diameter of about 7-8 cm with a smooth clean bark, saw off a piece 28 cm long, cut off all the lateral processes. Chock is treated with a primer, dried and varnished. The bark does not need to be removed. After the varnish has dried, the workpiece is inserted between the upper and lower boards and screwed tightly with self-tapping screws.

Based on this drawing, you can make various variations of wall shelves. For example, reduce the length to 400 mm and make 3-4 blocks at once. Then install them on top of each other in a checkerboard pattern and secure them together with metal plates. Or simply fix them on the wall separately, placing them at a short distance from each other.

Often, to save space, shelves are made angular, and they can be mounted both in the inner and outer corners.

The blanks are made according to the scheme described above, only the upper and lower boards consist of two elements, with ends sawn at an angle. The process of making such a shelf is quite simple:

- the halves of the top board are smeared at the ends with glue and clamped with clamps;

- repeat the same steps with the bottom board;

- when the glue dries, all the workpieces are stained or primed;

- fastening lines are marked on the upper and lower blanks and holes are drilled;

- insert the side walls and fix them with self-tapping screws.

| Wall shelf materials | Advantages and disadvantages |

|---|---|

| Wood: plywood, chipboard, MDF and others | This material is relatively easy to work with, it looks beautiful, natural and spectacular, its service life is quite long, especially if pre-treatment is carried out. |

| Plastic | This material is the most versatile, it can imitate both wood and stone, while removing their imperfections. |

| Metal | Such wall shelves will be very strong, reliable and durable, but they will hardly fit into a classic interior. In addition, corrosion can also become a problem, so special processing and conditions will be required for metal products. |

| Glass | Transparent wall shelves will create an atmosphere of lightness and comfort in the house. Of course, it will be difficult to make a glass structure with your own hands, but if you nevertheless decide to do all the work yourself, then you will have to work with glass for quite a long time and very carefully, especially if various cutouts are planned in the design of the shelf. |

Original book shelves

Shelves of non-standard shape are in increasing demand, so if you wish, you can try to assemble something original. For example, a bookshelf in the form of a simplified labyrinth is used.

For manufacturing you will need:

- edged board 20 mm thick;

- wood glue;

- clamps;

- roulette;

- hacksaw;

- miter box;

- Sander;

- stain;

- furniture screws, self-tapping screws;

- decorative shelf holders.

If you have everything you need, you can start making the shelf.

Step 1. Markup

On the prepared boards, cut lines are marked with a pencil under the ruler. Measurements should be transferred very carefully, since all horizontal parts have different lengths.

Step 2. Trimming blanks

The ends of each workpiece are cut at an angle of 45 or 90 degrees. The diagram shows the first option, so you need a miter box for sawing. It is very important to correctly install the miter box on the board so that the cuts are symmetrical. If the ends are cut off incorrectly, it will not work to fold the shelf.

Step 3. Assembly of the structure

The ends of the parts are smeared with glue, tightly compressed and additionally fixed with slotted furniture screws. Ordinary self-tapping screws do not fit here. At least 2 screws are required for each joint. Both parts of the shelf are applied to the wall, leveled and the attachment points are marked with a pencil. After that, holes for dowels are drilled, brackets are screwed to the shelf with self-tapping screws and the structure is hung on the wall. Instead of brackets, decorative pelican shelf holders are often used.

Hanging shelf with straps

If you need a decorative shelf for small items, the next option is perfect - a board suspended on belts.

To make a shelf you will need:

- 2 edged boards 300x750 mm, 30 mm thick;

- 4 leather belts 75 cm long;

- 4 long screws with plastic dowels;

- 4 short screws;

- building level;

- ruler;

- sharp knife;

- drill.

Step 1. Preparing the straps

The cuts of the belts must be perfectly even, therefore, if necessary, they are cut with a knife. Fold each belt in half, press the ends against the table, retreat from the edge 2 cm and drill a neat through hole with a drill. Do the same with the remaining three.

Step 2 Attach the straps to the wall

On the wall, using a level, two points are determined at a distance of 60 cm. Holes are drilled and plastic dowels are inserted. A belt folded in half is applied to one of the holes and fixed with a long screw - a large loop is obtained on the wall. Another such loop is attached nearby.

Step 3. Installing the shelf

A polished board is inserted into the loops and aligned horizontally. To prevent the shelf from moving, the parts of the belts adjacent to the wall near the board itself are screwed with short self-tapping screws. Now another one is hung under this shelf, exactly repeating the steps described above. The result is a light and neat bunk shelf. If desired, you can add 1-2 more tiers.

For the manufacture of the shelves described above, you can use not only wood, but also plywood, as well as chipboard sheets. The latter option is used most often, since chipboard is light in weight, high strength, practicality and durability. When assembling shelves from this material, all sections must be pasted over with a melamine edge to match the color of the sheet.

Making a glass shelf

Glass shelves harmoniously fit into any interior, and the installation process does not take much time. For work you will need:

- strained glass;

- hammer;

- electric drill;

- building level;

- aluminum profile;

- dowels;

- adhesive tape;

- ruler;

- pencil.

Not everyone knows how to cut glass correctly, and therefore it is better to order cutting blanks in the workshop. They will also perform grinding and polishing of the edges, so that when installing the shelf, you will not be cut on sharp edges. Everything else can be done on your own.

Step 1. Marking for fasteners

The section of the wall where the shelf will hang should be as large as possible. Using a building level, draw a horizontal line on the wall with a pencil. On the line mark the location of the fasteners, drill holes.

Step 2: Install profiles

An aluminum profile is applied to the wall surface and the conformity of the mounting marks is checked. Then dowels are inserted into the holes, the profile is baited with one screw and leveled horizontally. After that, tighten the rest of the screws.

Instead of a drill, insert the bracket screw

Instead of a drill, insert the bracket screw  Screw in the bracket screw

Screw in the bracket screw  Leave the bracket screw protruding from the wall

Leave the bracket screw protruding from the wall

Checking the position

Checking the position  We have shelves

We have shelves Step 3 Attaching the Shelf

The rear edge of the glass shelf is closed with adhesive tape. You can use separate spacers from the tape, placing them where the glass will touch the heads of the screws. The shelf is inserted into the profile, the edges of the profile are closed with protective caps. If two shelves touch on the sides, their edges are fastened with metal fittings.

If you have free time and a desire to experiment, you can create very unusual wall shelves from improvised materials. For example, the corner shelf made of plastic pipes looks original. For its manufacture, you will need sections of sewer pipes and corner cuts. The shelf is attached to the wall with screws and dowels.

Old suitcases and diplomats also make great wall shelves. To do this, they are cut in height to half, cover the back with plywood and fix on the wall with screws or on brackets.

Drawers from unnecessary bedside tables are quite suitable for making shelves. To give them an elegant look, the boxes should be carefully sanded, primed and painted in bright colors. Then they are leaned with the back wall against the surface, the attachment points are marked and holes are drilled for them. Even one such shelf looks very original, and a composition of 2-3 drawers will become a real decoration.

Video - Shelves on the wall with your own hands

Interesting wooden shelf. Master Class

You will need:

- Rope;

- Board at least 2 cm thick;

- 2 corners (mounts) for shelves;

- Steel washers;

- Lighter;

- Drill;

- Saw.

The fashion for a minimalist interior forces designers to look for non-standard solutions for familiar things. The arrangement of bulky bookcases in the interior has long sunk into oblivion. Instead of massive furniture attributes, original wall-mounted bookshelves have become popular. One of the advantages of this trend is that you can make your own shelving for your favorite works. This is all the more true when you want to fit the shelf into the overall decor. In this case, it is not at all necessary to purchase exclusive material. Consider further what is needed to arrange stylish book shelves in your own home.

- What is the purpose of the shelf? Exclusively for books? Or just decoration?

- What are the dimensions of the future product? How many tiers do you need to satisfy?

- What material is needed to support the weight of all items?

- What method of fastening the structure: wall or on?

These are the most obvious questions that need to be answered. By understanding your own needs, it will be easier for a person to decide on. The choice of materials will also put the craftsman in front of the need to search for a particular tool. For example, wood products will require saws, sandpaper, screwdrivers and varnish.

These are the most obvious questions that need to be answered. By understanding your own needs, it will be easier for a person to decide on. The choice of materials will also put the craftsman in front of the need to search for a particular tool. For example, wood products will require saws, sandpaper, screwdrivers and varnish.

Wooden bookshelves

The classic version is in constant demand. Wood material is easy to get, and its processing with a grinder works wonders for design. In this case, it is not necessary to paint the finished product. You can get away with just a means to protect the surface. It is also not always necessary to go to the hardware store for wooden boards. For a bookshelf, it is quite possible to use handy materials. Old crates, a guitar or in a pantry - all this can be sawn up and reused.

Attention! For example, a shelf-boat will wonderfully fit into the marine theme of the interior. And if a rare TV is freed from the screen, and the inside is covered with wallpaper, then you get the perfect repository for women's novels.

The algorithm of actions in this case is quite simple. It is necessary to make or order long wooden corners (about 25 cm) for attaching the shelves. At the same time, the latter should not exceed 1 m, so as not to break under the weight of thick novels.

Children's shelves

An interesting option for kids can be a bookshelf - a showcase. To build a fabulous locker, you will need several planks up to 10 cm wide. Fixing them on the wall in an unusual way will forever be remembered by a little person. There is also a fabric option. For this:

- It is necessary to find a dense fabric and some pipes or sticks.

- The simplicity of the design lies in attaching it to the wall with conventional brackets. The latter are installed with screws.

- It is recommended to hem the fabric on a sewing machine to make neat cuts for pipes.

Rope shelves

To follow the popular ship theme, you will need to stock up on bars, suitable rope and planed boards. Of the tools you need only an electric drill. Even nails are not needed. You will also need a tool for processing wood material. The algorithm of work is as follows: using a drill, suitable holes are drilled in the boards. A rope is then threaded through these holes.

The originality of this solution lies in the fact that this thick rope itself serves as a fastener - it is enough to tie it with a sea knot.

A multi-tiered option will require the use of bars additionally. They should be located between the shelves like a rope ladder. Therefore, the parts must be the same length. The uppermost knots of the rope are hung on proud hooks in the wall.

Such a hinged structure is quite versatile: it is easy to imagine it both in a children's room and in the office of an adult owner of the house.

invisible shelves

Instead of ordinary shelves, you can make inconspicuous products with your own hands. They compare favorably with boring cabinets in that the books seem to stick to the wall. This miracle is quite simple to carry out: you need to stock up on L-shaped brackets for each book. You will also need screws and double-sided tape.

Advice. To prevent the book from falling off such a shelf, the staples must be fastened according to the level. On the horizontal part, your favorite books will then be located.

Cable reel

You can even use this to arrange a bookshelf. A traditional wooden spool with a black cable is connected to furniture wheels. To do this, it is necessary to cut round bars of sufficient width. They will subsequently be inserted into the holes made in the middle of the above-mentioned wheels.

Attention! Wheels should not be drilled through - the holes should not exceed half the depth.

An adhesive binder is then used in the drilled holes to secure the bars. To solidify the structure, it is recommended to press down with something heavy. Painting is allowed only after the glue has completely dried. The bookshelf can easily become mobile if it has wheels.

old stairs

Another option for using stairs is unusual hanging. Unlike the marine version with ropes, it is better to turn the old ladder horizontally and put it on the same brackets. In this case, the option with a half of the stairs will look good. Or even two copies.

Another feature of this type of fastening is the priority of painting the stairs before its installation. It is also recommended to slightly move the newly appeared bookshelf away from the wall: either completely, or only the lower part.

Arranging a cool bookshelf is easy to do with your own hands. This will require a little imagination and a minimum of handy materials. You don't even have to go to the market. But the interior design will be updated beyond recognition, which friends and acquaintances will be able to appreciate both in the photo and live.

Bookshelf Ideas: Video