We all know what cast-iron heating radiators are, but not everyone knows their history of occurrence, technical characteristics, and how modern specimens differ from their predecessors. All this and much more will be discussed in the material below.

So, the first heavy radiator was introduced to the world back in 1857, but its creator was the famous Russian engineer and businessman of German origin, Franz San Galli. Of course, the batteries of that time were significantly different in appearance from those that we are used to seeing in our apartment. They were a tube of rather large diameter, with protruding disk elements. This design was empty and filled, however, like modern specimens, with hot water. So despite the slightly different appearance, the essence still remains the same.

As you can see, such batteries have been popular for over a century, and not every invention manages to stay afloat for such a long period. And all due to the fact that cast-iron heating radiators have characteristics that are very necessary for a person. One of the main advantages of this material is corrosion resistance, due to which the inner surface of the heater remains in excellent condition for many years.

In addition, it should be noted that the water entering the heating system of your home goes a long way and turns into a chemically aggressive environment. It is also possible that various abrasive particles, such as pebbles, etc., get into the system. However, even this is not scary for cast-iron batteries, so they are better suited both for installation in private buildings and in apartments of multi-storey buildings.

The next advantage, which should not be ignored, is a long operational period. You are more likely to want to make a major overhaul and replace old cast-iron radiators with new heating elements that are more modern and suitable in design than you have to update them due to failure. Indeed, with proper care, the service life can reach half a century, but under ideal conditions, such batteries will generally be able to celebrate a century in working order. True, manufacturers usually indicate in the characteristics a service life of no more than 30 years, but these data are underestimated.

It is also necessary to mention the inertia of cast iron. Such units heat up somewhat longer than their counterparts, while retaining heat for a long period, unlike the same aluminum batteries, which cool down in just a matter of minutes, and the technical characteristics of steel are in many ways incomparable with cast iron. And thick walls and a fairly large internal section not only affect their thermal qualities in the most favorable way, but are also the key to long work. And the cost that cast-iron radiators have is affordable for all segments of the population.

Everything is clear with the advantages, there are really a lot of them, but we should also mention the disadvantages inherent in such elements of the heating system. Let's start with elementary things, one section has a mass of about 6 kg, so, resorting to the simplest mathematics, we get the weight of a six-section cast-iron radiator equal to 36 kg. But it is far from always possible to limit ourselves to just such a number of segments. Such an indicator of weight will not only complicate the transportation, but also the installation process. Firstly, it is really harder to work with him in the literal sense. Secondly, due to such weight, not every wall can support the battery. For example, if we are talking about, then it is better to play it safe and install radiators on special legs.

The next minus after the weight is the dimensions. Basically, these heating devices are rather bulky, which again complicates the installation process, steals the area of already small rooms and does not always fit organically into the design. In addition, to fill them, you need a large volume of liquid. Not the best characteristic is also the heat transfer of all cast-iron radiators. And all because it is only 20% dependent on the convention, and the remaining 80% is due to thermal radiation. Therefore, if we compare them with analogues made from other materials, then the designs of cast-iron batteries should consist of a larger number of sections. And also because of the long cooling of the alloy, their joint work with temperature controllers is impossible.

Having discussed all the pros and cons, we can move on to another important issue, namely, what technical characteristics are inherent in such heating elements. Someone may think that it is important to know only the power, but much more will be interesting. Basically, they all have a sectional design, and the number of segments can be adjusted depending on the area of \u200b\u200bthe room and the desired results. However, one-piece cast specimens are also found. Inside, as mentioned above, the batteries are hollow, and a coolant flows through them, the maximum temperature of which can reach as much as 130 ° C, although in practice this is not always the case, sometimes 90 ° C.

When calculations are carried out, parameters such as heat transfer and the power of cast-iron radiators are always taken into account. Moreover, the last characteristic is mainly indicated for one section and is about 160 watts. Already from this value, their optimal number is determined if you know the desired power of the future battery. You should also say a few words about the width of one section, it is almost 10 cm, but the weight has already been mentioned, this parameter ranges from 5 to 6 kg. Another important characteristic that plays a decisive role is the crimping pressure, it reaches 15 atm. The working one ranges from 6 to 9 atmospheres.

The website site masters have prepared a special calculator for you. You can easily calculate the required number of sections.

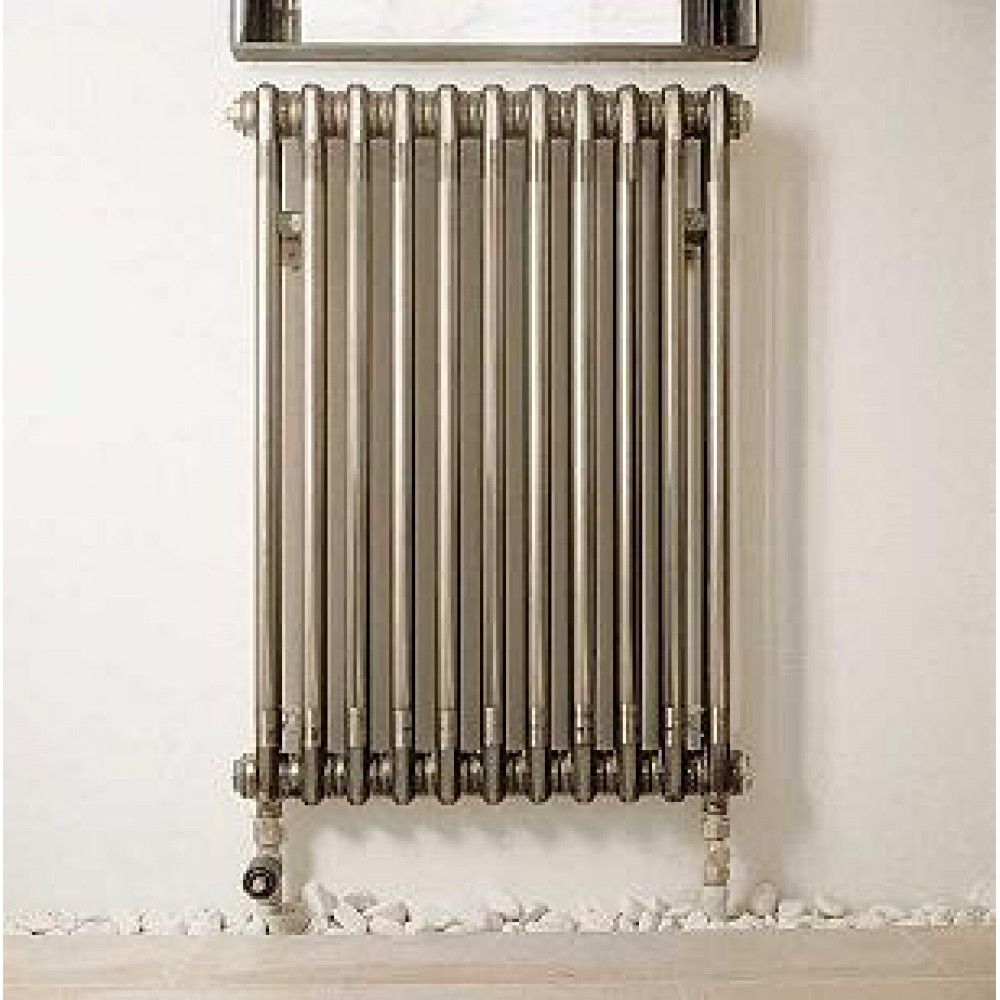

One of the drawbacks that heating radiators of this type have was their bulkiness and, as a result, the inability to fit into a modern interior. However, this is not quite true. If we talk about standard inexpensive models, then you will surely encounter the above difficulties. Modern products harmonize much better with the ideas of designers and can not only cheer you up with their original and colorful appearance, but also easily add zest to the interior.

Batteries come in various shapes, have original castings of various patterns and ornaments. Incredibly interesting options are antique products that will fit perfectly into almost any interior, but best of all they will decorate a room that has a design in a classic style. As for ordinary models, they can always be painted, while the variety of colors makes it easy to find the perfect shade. And bold experiments will make it possible to decorate the room in an original way. Therefore, it is up to you to decide which batteries will decorate your walls.

Radiators can be solid and sectional.

Let's take a closer look at the designs of cast iron and which ones are better. The most common models are sectional, which are prefabricated devices. Their main advantage is the ability to adjust the dimensions and power by selecting the number of fragments. The next type is solid cast iron radiators. The advantages of this type include the absence of joints, which in the most favorable way affects the strength and tightness of the structure. But it will not work to adjust the power and dimensions, these parameters will be clearly set. But this is not a big problem, the main thing is to make preliminary calculations correctly and buy a battery with a power that will immediately meet your needs.

So, cast-iron radiators, the design and technical characteristics of which were discussed above, have been very popular for many decades, and today, despite the variety of thermal elements, their contribution to apartment heating is significant. And which of them are best suited for your purposes, you can already determine without difficulty.

The heating system is a large, warm "heart" of the house and a complex engineering structure that does not tolerate approximation and requires competent engineering miscalculation. After all, all this is not just radiators and pipes, but a serious issue of the microclimate in the house, aesthetics and energy saving.

Not all radiators on the market today are suitable for installation in an apartment with a central heating system, so the choice should be approached with all responsibility. To understand how to choose the right heating radiators, let's look at their main types.

Most often, heating radiators made of the following materials are presented in stores and markets:

- Cast iron.

- Steel (tubular and panel).

- Aluminum.

- Anodized.

- Bimetallic.

- Copper.

- Plastic.

So, which one to choose for an apartment, let's try to figure this issue out together!

Cast iron radiators

They can be called one of the most "ancient" heating devices, which have not lost their relevance even now.

Due to the peculiarities of cast iron, today these batteries are very popular in our country. Due to the thick walls, they are not afraid of water hammer and are able to withstand a pressure of 25-30 atmospheres. Cast iron radiators are able to function not only in an autonomous heating system, but also in central communication. This material is not subject to corrosion, which makes batteries popular in our country, because, as you know, the heat carrier is often not clean in our country. Another advantage of cast iron batteries is their ability to retain heat for a long time, even after turning off the heating system.

The disadvantages of cast iron batteries include heavy weight, which greatly complicates the installation process. It is impossible to install these radiators alone.

In addition, cast iron has low thermal conductivity, which is why efficiency is achieved only at a stable temperature of 70 0 C. For a private house or autonomous heating, this can become overhead, but for an apartment solution with the normal functioning of the central heating system, this is a good option.

In Soviet times, cast-iron sizes were produced in standard sizes. To increase the heating of the apartment, it was necessary to build up the system, which did not always have a positive effect on the aesthetic appearance. Today, on the modern market, there are many options for cast-iron radiators from domestic and foreign manufacturers of different capacities. Therefore, you can pick up small batteries that fit perfectly into the overall concept of the interior. Previously, cast-iron batteries were attached to the wall with brackets. Today, you can choose beautiful floor-mounted radiators that have an elegant look.

Modern cast iron batteries do not need additional processing and painting. They are already sold ready for installation, and there is no need to paint them every year. Care for them is minimal: due to the smooth surface, dust practically does not settle on them.

The variety of colors and styles of cast iron batteries today helps not only to harmoniously fit them into a classic or retro style, but also to make radiators a separate decorative element.

Advantages of cast iron radiators:

- Corrosion resistance.

- Stylish appearance.

- Unpretentiousness to the purity of the carrier.

- Affordable price.

- Keep warm for a long time.

- Can function in the central and autonomous heating system.

Disadvantages:

- Heavy weight.

- Difficulty of installation.

- Takes a long time to reach the desired temperature.

We conclude: for apartments with central heating, the choice of cast-iron radiators is optimal. They will last at least 15-20 years and will effectively give off heat.

Features of mounting cast iron batteries

Given the large weight of cast iron batteries, installation is a rather laborious and difficult process. If you decide to independently install cast-iron radiators, then the following factors must be considered:

| Installation is best done in the summer, when the central heating system is turned off. Determine a place to install the future battery. The best place would be the area under the window. This will ensure the normal circulation of cold and hot air throughout the room. |

| Mark the fastenings and the location of the structure on the wall. Use a spirit level to check if the line is level. If the battery is tilted unevenly, air pockets may form during operation. |

| Before the installation process, adjust the nipples. This is especially true for devices of domestic manufacturers. To do this, you need to unwind the battery, adjust the nipples and assemble everything back. In order to avoid distortion of the nipples, the battery must be disassembled on a radiator workbench using special keys. At the same time, we make one turn on each side to avoid skew. Having unscrewed the nipples, remove the sections. After adjusting the nipples, we assemble back strictly in the reverse order. It is necessary to test whether the battery will leak. We make a "pressure". Only now you can start installation. |

| In concrete and brick walls, cast-iron batteries are attached to the wall using special brackets. This will be enough to keep the battery from tilting under the pressure of the water. A standard size radiator must be secured to the wall with at least four posts. When attaching cast iron batteries to a wooden wall, you need to play it safe and create an additional floor support. The distance from the wall should be - 5 cm, from the floor - 10 cm. Having driven the supports into the wall, install the battery on them immediately on all the brackets. |

| The installation process depends on the type of fasteners. Typically, batteries are supplied with four holes located at the corners of the structure. Two openings are used to connect the direct and return lines, the rest are closed with air vent valves and plugs. Connect the battery to the water supply only after checking the level of the horizontal position of the structure. Connect the open ends of the pipes by gas welding to ensure a reliable, tight and durable connection. At the end of all work, check the tightness of the entire structure by turning on the water. |

Steel radiators

Steel batteries represent the best value for money. They are able to withstand a sufficiently large load and water hammer of the heating system. And due to the high level of thermal conductivity, steel batteries heat up quickly. For autonomous heating or heating a private house, this option is quite practical.

Speaking of steel radiators, it should be mentioned that they are of two types: panel and tubular.

Panel steel batteries

Panel radiators are a structure of two steel sheets connected by welding. Some models are equipped with convection elements to create a vertical direction of heated air. This allows you to create a kind of thermal barrier for the cold stream coming from the window.

To ensure strength and durability, the structure is painted only after complete assembly. When buying, be sure to carefully study the coating, as this affects further operation. Corrosion may occur in poorly painted areas. Panel radiators are designed for the normal pressure generated in the central heating system. The length can vary from 40 cm to 3 meters, and the height - from 20 to 90 cm. The size must be calculated based on the total area of \u200b\u200bthe room.

The connection to the coolant can be from below or from the side, so when choosing, you need to take into account the location of the heating circuit piping.

Pros:

- a light weight;

- ease of installation;

- fast heating, which saves on utilities;

- attractive appearance;

- compact size.

Minuses:

- vulnerability to powerful water hammers of the central heating system. If the choice when arranging the heating system at home still falls on panel steel batteries, it is necessary to protect the structure and install a gearbox that will smooth out pressure drops in the network.

- Susceptibility to corrosion.

- Short service life. As a rule, the inner surface of steel panels does not have an anti-corrosion coating, and the coolant is not always clean. As a result, already after 7-10 years, the inner layer of the battery can be destroyed.

Tubular steel batteries

Unlike panel batteries, tubular radiators are a structure consisting of several sections, fastened together by welding. Depending on the area of the room and the heating effect, it is necessary to calculate the power of the finished module and choose the optimal size. The small thickness of the pipes from 1.5 to 2 mm warns to be careful and try to use such structures only for low-rise buildings with closed systems.

Normal operation of tubular steel batteries is possible at a pressure of 8-10 atmospheres. If the central heating system “sins” with pressure jumps, then it would be advisable to install a reducer to smooth out the voltage.

Due to the small thickness of the walls, the coolant quickly heats up the steel structure. Today, the market offers a huge selection of tubular steel batteries in a variety of design solutions. They are installed not only traditionally at the window or wall, but even in the center of the room. Some designs are made in the form of a bench, the footboard of which is a heating device. It is advisable to install such a battery in the corridor. During the day, it will be comfortable to wear shoes on it, and at night it will be possible to place shoes on a chair to dry.

Pros:

- Rapid heating. Due to the thin walls (1.5 mm), the heating of the batteries occurs in a matter of minutes, which allows you to save on utilities (in the event that a meter is installed in the apartment). However, this plus can also turn into a minus. Thin walls are subject to mechanical destruction of the "dirty" water supplied by the central heating system.

- Higher resistance to mechanical damage compared to panel batteries.

- Large selection of styles. Given the rich selection of colors, such radiators are easy to choose for almost any interior of the apartment. There will be no need to spend effort and money on additional decoration in the form of screens.

Minuses:

- Vulnerability to powerful water hammer of the central heating system. However, almost all devices connected by welding are guilty of this drawback. During a powerful pressure drop, the structure may begin to collapse at the junctions.

Summing up, it should be said that tubular steel batteries are far from the best option for an apartment. Installation in a house with independent heating will lead to unnecessary costs due to rapid cooling. And installation in an apartment with central heating can cause emergency situations.

Features of mounting steel radiators

Steel batteries are quite easy to install, but it is better not to remove the packaging film until the end of the installation work. This will keep a clean look and not disturb the outer coating of the panel. The distance to the floor and wall is different for each model, so carefully study the installation diagram in the instructions.

Depending on the type of construction, we select the mount. We will attach the hinged radiator to the wall using brackets and dowels. The floor structure is installed on the floor on conventional racks and traditionally connected to the heating pipe.

Steel radiators are easily integrated into the heating system and, depending on the model, have a different type of connection: side, bottom, top. The distance between the wall and the rear panel of the steel radiator must be at least 25 mm, otherwise, the heat transfer of the device will be significantly reduced.

Modern models have a locking system against accidental “dismantling”, therefore, before installing the device, it is necessary to pull up the mounting grip and fix it in this position. We begin the installation with the lower fasteners, and after that we put on the upper ones. If you have done everything correctly, the top fastener will automatically snap into place, securely fixing the radiator to the wall.

aluminum batteries

Despite their beautiful appearance, aluminum radiators are not the best choice for heating an apartment with a central system. In apartments with an autonomous heating system, this choice of batteries is very popular. Along with a stylish appearance, they are distinguished by reliability and a fairly long service life - 20-25 years.

The material for creation is aluminum with the addition of silicon alloys, which gives the batteries a special strength. In industry, as a rule, silumin and duralumin are used to improve technical properties. In addition, the addition of silicon alloys can reduce the cost of the original product.

The design of aluminum batteries is quite simple: each section consists of two horizontal channels of large diameter and one vertical one with a smaller diameter. Several ribs depart from the vertical channel, which "take" thermal energy from hot water and "give" it to the air.

Designed for a pressure of 15 atmospheres, they are very vulnerable to air locks and water hammer. The connection of individual sections is carried out using the coupling threaded method, which allows you to quickly install the battery.

The tightness of aluminum radiators is achieved through the casting method. Each section is cast in a separate mold, after which it is combined into one common structure.

Aluminum radiators of various shapes and sizes are presented on the market, which allows you to choose the best option for the finished design of the apartment. Depending on the area of the room and the heating effect, the size of the aluminum battery is also selected.

Batteries produced using injection molding technology have a higher margin of safety against pressure drops. The working pressure in them reaches 16 atmospheres, but during testing, the manufacturer tests radiators with a pressure of 25 atmospheres, which sometimes allows the batteries to withstand sudden surges. The smooth surface of cast panels provides higher heat dissipation.

Another method of manufacturing aluminum batteries is extrusion. This significantly reduces the cost of the product, but in terms of technical characteristics it is inferior to cast batteries. Recycled aluminum is used as the main raw material here, which over time leads to brittleness and corrosion. Therefore, when choosing radiators, it is necessary to focus not only on the material, but also to clarify the production method. Batteries produced using extrusion technology cannot be extended. They go on sale already in a standard size.

Aluminum radiators have a fairly low weight, which greatly simplifies their installation, which can be done independently. Due to the high heat dissipation of aluminum, the batteries heat up very quickly. This allows you to control the flow rate and manually control the system, creating a comfortable room temperature.

Pros:

- Corrosion resistance.

- Stylish appearance.

- Light weight (3-4 times lighter than cast iron).

- Variety of colors.

- High heat dissipation.

- Variety of sizes.

- Possibility to add sections during operation (only applicable for the casting method).

Minuses:

- Sensitivity to pressure drops.

- Dependence on water quality. With contaminated water with a high pH, the structure can quickly fail.

Features of mounting aluminum batteries

When installing aluminum batteries, one should, first of all, focus on the technical properties of the material. If during the installation of cast-iron batteries the main feature was a lot of weight, then the opposite is true here. Aluminum batteries are light and fragile, so installation should be carried out very carefully without removing the packaging.

The surface of an aluminum radiator can be damaged during installation even from a slight blow with a tool. Aluminum batteries are already on sale complete with brackets, which can be easily attached to the wall with dowels.

To create the most efficient heat transfer, you should be guided by the following parameters during installation:

- The distance between the window and the heating panel should not exceed 10 cm.

- The distance to the wall is 3-6 cm.

- The distance from the panel to the floor should be within 5-6 cm.

A shut-off valve is installed on both sides of the radiator for temperature control and for emergencies.

After completing the installation and before connecting to the heating system, it is necessary to “pressurize” the device. To do this, call a representative of the relevant service or buy a crimping machine.

Anode radiators

In fact, these are also aluminum batteries. Only the raw material (aluminum) undergoes more severe cleaning with anodic oxidation of the surface. This improves resistance to corrosion and the chemical attack of dirty water.

Anode batteries are produced using casting technology, which provides them with tightness and resistance to water hammer. They are able to withstand pressure of 20-25 atmospheres. Due to the fact that the individual sections are assembled using threaded couplings and hermetic seals, the battery can be disassembled and supplemented.

Due to the perfectly smooth surface of the inside of the radiators, maximum heat transfer and more efficient circulation of hot water inside the structure is achieved. Externally, anode radiators are also pleasing to the eye. Their smooth shape and smooth surface are safer than the angular design of cast iron batteries.

The only drawback of anode structures, perhaps, is their high cost compared to aluminum radiators.

Pros:

- High heat dissipation.

- A variety of sizes and the possibility of adding sections during operation.

- Withstand high pressure (20-25 atmospheres).

- Corrosion resistance.

- Stylish appearance.

Minuses:

- High price.

Anode aluminum batteries are great for apartments with both central and autonomous heating systems. If financial possibilities allow, then such radiators will last a very long time, delighting with their practicality, functionality and excellent appearance.

Installation of anode batteries is carried out in the same way as the installation of aluminum radiators (see above).

Bimetal radiators

These batteries demonstrate the best value for money. They are able to withstand sufficiently excessive pressure, and are not too demanding on the coolant. This is what determines their current popularity in the construction market, which is second only to cast iron batteries.

The name of the radiators already indicates that they are assembled from two materials. The outer part is made of aluminum, and the inner layer is made of high quality copper alloy or steel. This combination of materials allows us to solve two problems at once: to improve heat transfer and increase corrosion resistance. The enamel coating in any color scheme gives the batteries a beautiful appearance.

The bimetallic radiator is available in two versions:

- Absolutely bimetallic apparatus, which is characterized by increased strength and resistance to pressure drops in the network. Their service life is at least 25 years, which fully justifies the high price. In such a device, the core is made in the form of pipes through which water flows without contact with the body itself.

- Semi-bimetallic is a design, the internal channels of which are simply reinforced with plates of another metal.

The design of bimetallic radiators consists of several sections, which are interconnected using a threaded coupling. If desired, you can always buy more sections and build up.

Bimetal radiators will be the best choice for apartments with a central heating system due to their high resistance to high pressure of 35-40 atmospheres. They are not afraid of sudden changes in operating conditions.

Pros:

- They heat up quickly and give off heat easily.

- Corrosion resistance.

- Stylish appearance.

- Large selection of sizes.

- Possibility to deliver sections during operation.

- Withstand strong water hammer.

- Light weight and easy installation.

Minuses:

- High price.

Such radiators should be purchased only in specialized stores, subject to familiarization with the documentation. Outwardly, they cannot be distinguished from aluminum batteries, but the difference in price will be very noticeable.

Bimetal radiators are a great option for apartments with any type of heating. The high price is offset by a long service life.

Features of mounting bimetallic radiators

The basic rule for the installation of bimetallic radiators is that the installation is carried out in a package. Do not remove the film until all work is completed. The fact is that the outer surface of the radiators is quite fragile and can be damaged by the impact of a tool.

Do not clean the parts to be joined with a file or emery, in order to avoid water leakage in the future.

In order for the bimetallic radiator to work properly and efficiently, the following distance requirements must be followed during installation:

- The distance from the wall to the device is 3-5 cm. If you install it closer to the wall, the natural air circulation will be disturbed, which will significantly reduce the efficiency of the device.

- The distance from the floor is no more than 10 cm. If you install it lower, this will not only reduce the efficiency of heat transfer, but also make it difficult to maintain the radiator in the future.

Start the installation by attaching the brackets to the wall, having previously marked out. Each radiator must be equipped with an air release valve. This will help prevent air pockets in the future. Use a torque wrench to securely tighten the valve.

Video. Do-it-yourself installation of bimetallic radiators

Copper radiators

Perhaps the only significant drawback of this type of radiators is their high price. Otherwise, they are distinguished by high technical properties, have a magnificent appearance and will last at least 25-30 years with proper care.

Copper batteries level the resistance of the coolant, increasing its efficiency. High efficiency is due to high thermal conductivity. Compared to the popular cast iron - 4 times more.

Pros:

- Corrosion resistance.

- Withstand high pressure in pipes (30-36 atmospheres).

- High heat dissipation.

Minuses:

- High price.

Features of mounting copper radiators

- The ideal material for pipes to which the radiator is soldered is copper. This will provide a seal and prolong battery life. When combined with other types of metal, corrosion can form over time. This also applies to the choice of fittings.

- Before installing a copper battery, it is necessary to install a filter designed to purify water. Otherwise, during operation, the inside of the device may become rough, which will provoke the deposition of salts.

- All structural elements are connected by soldering.

- On the brackets with which copper pipes are attached to the wall, it is necessary to install rubber pads, which will help protect the surface of the pipes from deformation and corrosion.

Video. How to install heating radiators

How do the features and nuances of the central heating system affect the service life of radiators?

Before you start choosing a radiator for your apartment, you should take into account some of the nuances of the central heating system. Of course, central heating has more advantages than disadvantages. No need to bother with the selection and installation of boilers, installation of a chimney. The cost of utilities is easily controlled by installing a meter. But there are also disadvantages that affect the choice of batteries.

- The composition of the carrier always contains aggressive substances that adversely affect the material of pipes and batteries. Most often, it is corrosion that causes a destructive effect on the inner layer of radiators, reducing the service life. As a preventive measure, some utilities add lignosulfonate powder to water tanks, which does not have the best effect on the service life of radiators.

- In the water that goes through the pipes for heating, fine sand, clay, and lime are often present. Gradually, this small debris wipes the metal from the inside. If the inner layer is rough, it will shorten the service life much faster.

- One of the enemies of heating radiators in apartments is pressure drops, the so-called water hammer. This, of course, negatively affects the condition of the batteries. Air locks created by the unstable operation of the central line gradually lead to cracking and rupture of the metal. But many modern radiators are equipped with protective valves that allow you to regulate the pressure in the pipes and thus deal with pressure instability.

- The instability of the temperature of the heating system has the greatest effect on the internal part of the battery. Cast iron tends to expand when heated and shrink when the temperature drops, which leads to cracking of the inner layer. Therefore, it is these batteries that are most vulnerable to temperature changes.

Therefore, when choosing a radiator for heating an apartment, be guided by these points and take into account the operation of the highway and local housing and communal services.

Calculator for calculating the number of sections of heating radiators

How to choose the right radiators for an apartment?

Choosing a radiator for an apartment is a crucial step. Not all types of heating systems on the market today are suitable. Some appliances are not capable of withstanding the stress and water hammer that is common in our utilities. Here it is important to consider not only the material, but also the maximum load of the radiator.

In addition, for the efficient operation of the heater and its maximum heat transfer, it is necessary to correctly calculate the number of sections.

When choosing a radiator for an apartment, the following factors must be considered:

- The total area of the apartment. Based on this parameter, it is necessary to select the power of the radiator.

- Maximum pressure in the heating system. Each device has its own load limit.

- The material and the maximum temperature that the radiator can withstand. Radiator power. This will be a fundamental factor, based on which it is necessary to calculate the number of sections and the total length of the device.

- General design and style of batteries.

When choosing batteries for your apartment, you do not need to be overly prudent. A low price can cause cold in the room, and the service life of inexpensive radiators does not exceed 5-6 years.

In the event of an accident in the central heating system, cheap batteries can quickly fail due to water hammer.

At the end of the article, we offer you a very detailed lecture on choosing radiators for an apartment.

Video: How to choose heating radiators

High-quality and efficient operation of the heating system is a guarantee of comfort and coziness in any room. This means that the choice of all elements of the heating system must be approached with the utmost care, giving preference only to the best offers on the market.

One of the main components of any heating system is radiator - a specialized device that transfers heat from the coolant to the air in the room. Currently, the choice of heating batteries is simply huge and often property owners are lost if they have to choose a particular option.

In order to eliminate such troubles, it is necessary to understand the main characteristics of the equipment, consider the advantages and disadvantages of each radiator.

Heating radiators: functions and features

Modern heating batteries are devices that, in addition to solving the main task (heat transfer), also have a number of additional advantages:

- Stable heat dissipation with high energy output;

- Stylish appearance, the ability to fit into any interior;

- Small thermal inertia;

- A variety of design options, ranging from standard to designer models.

Design solutions for heating radiators: a variety of types

In the domestic market, types of heating radiators are extremely widely represented. Differentiation of all such equipment can be carried out according to several basic parameters, including the material of manufacture and design features. It is the last parameter that means a lot for the efficiency of the heating system, it also affects the cost:

- Sectional heating batteries. Such types of heating radiators differ in that they consist of a certain number of sections. Can be made from steel or aluminium. Dimensions, as well as width, depth and weight may vary depending on the model range;

- tubular radiators. The main component of such elements of heating technology are special curved tubes, through which the coolant circulates. Materials for such devices can be very diverse, ranging from steel to copper;

- Panel radiators. Tanks, where the coolant circulates from the system, are made in the form of rectangular panels. The dimensions of such products can be very diverse.

The most popular panel radiators are all kinds of wall and ceiling panels. As a rule, a feature of such devices can be called a low-temperature heating surface, the radiation component of the heat flow and the ability to install it yourself;

- Plate batteries. In fact, these are plates of steel or copper, on which additional heating elements are baited. The design can be either closed by a casing or equipped with a decorative grille, or even simply open.

Tip: The choice of the design of one or another heating radiator should be made based not only on personal preferences, but also on the basis of the design of the heating system, the area of \u200b\u200bthe room.

Materials for the manufacture of heating radiators: a large selection and unique qualities

To date, types of radiators for heating are presented simply in the widest range.

One of the factors that you should pay attention to when choosing one or another type is the materials of manufacture.

- Steel radiators. Such batteries can be seen in the photo and video designs of many modern houses. Radiators appeared relatively recently on the domestic market (only 20-30 years ago), but gained immense popularity among consumers.

Heating devices of this group transfer heat from the coolant in a convection way. At the same time, the distinctive features of this type of heating radiators are an increased level of heat transfer, ease of installation and versatility. In addition, the price of steel batteries is available to everyone.

Sections of steel radiators are connected by spot welding, which increases strength and extends the period of trouble-free operation of the equipment. The main coating for batteries is high-quality and environmentally friendly varnish, resistant to many aggressive factors and mechanical damage.

It should be noted that in addition to the advantages, steel radiators also have some disadvantages. For example, steel batteries are afraid of water hammer and are sensitive to the quality of the coolant;

- Cast iron radiators. The most traditional and practical heating batteries. They have excellent thermal conductivity, are able to withstand the effects of low-quality coolant.

Radiators made of cast iron can be effectively used in any heating systems, from centralized to autonomous. In the domestic market, these are the most popular radiators, due to their low cost.

Despite all the advantages, cast-iron batteries also have disadvantages. For example, with an increase in pressure in the system of more than 6 atm, gusts may occur. Yes, and such designs look bulky and not very attractive, and therefore their use in newfangled interiors is unacceptable;

- Aluminum heating radiators. Beautiful appearance, sectionality, low weight and an increased level of heat transfer - all this today attracts consumers in batteries made of aluminum. They work efficiently and without problems for about 5-7 years, do not require repair or replacement.

The main problem that may arise during the operation of these batteries is the need to maintain a certain pH value of the coolant in the system (the optimal value is 7-8). Another problem that haunts owners is the regular airing of the system.

In various specialized stores in our country, you can find three main types of aluminum radiators - solid (profiles connected by welding), sectional and combined. The cost of radiators of this group depends, as a rule, on the number of sections;

Tip: If you plan to install aluminum radiators in the heating system of a house, apartment or office, it is important to follow some installation requirements. So, for example, there should be no antagonist metals in the system, otherwise there will be a conflict of materials, which will lead to accelerated corrosion.

- Bimetal radiators. A modern and original choice for any type of heating system. A feature of such heaters is the ability to withstand high pressure in the system, resistance to hydraulic shocks, as well as the use of any coolant.

These types of heating radiators have an original design - they combine two types of materials at once (usually copper and aluminum or steel and aluminum), which allows to achieve increased efficiency and heat transfer, and significantly extend the period of trouble-free operation. At the same time, bimetallic batteries are resistant to high pressure, and therefore they can be chosen for both autonomous and centralized heating systems.

The long service life of bimetallic heating radiators (about 20 years), the ability to work at high pressure (up to 20 atm), as well as the possibility of individual selection of the number of sections, make such batteries the best choice for many real estate objects.

Another advantage of bimetallic radiators is the reduced volume of coolant circulation, which allows you to save on coolant. Disadvantages - a small cross-section of pipes (12-15 mm) and increased pressure in the system, which affects the life of the boiler and threaded fittings.

The duration of the heating season in our latitudes is close to 2/3 of the year. The indicator depends on the region, but on average it is about 250 days. For us, all issues related to the efficiency of the heating system are extremely important, which largely depends on the correct choice of its devices.

Let's analyze which heating radiators are better, how the varieties differ. The article submitted for consideration describes in detail the criteria for choosing heating devices. For independent home craftsmen, we have provided advice from experienced plumbers.

Regardless of the complexity of the heating system, the main task is to maintain the desired temperature in the house or apartment. The heating radiator plays a key role in this, exchanging heat between the air in the room and the coolant.

Uniform heating, efficient heat transfer, maintaining a microclimate, stable operation are the main requirements for a heating battery.

In residential premises, single, panel or sectional paired radiators are installed that do not emit toxins when heated

The main parameters influencing the choice of a particular model:

- Working pressure of the system. Depends on whether the device is included in an autonomous or centralized network. It is arranged by gravity or forced principle. On average, it varies from 3 to 10 bar or in a similar range of atmospheres.

- Thermal power. The characteristic required to calculate the thermal power required to heat the room. It is also needed for the selection of individual components of sectional batteries. For processing 10 m², 1 kW is rounded.

- Modularity. The quality inherent in prefabricated radiators, which makes it possible to assemble and disassemble the device according to individual requirements.

- Speed of reaction to tº. More precisely, the ability to respond to changes in the temperature of the coolant. period of time for cooling and warming up.

- The possibility of equipping with automation. Devices that monitor weather conditions and independently eliminate air congestion.

The devices presented now for sale provide free circulation through the system. Differ in corrosion resistance and attractive appearance.

Sectional radiators differ in the shape and size of the sections, which ensure the supply of the required amount of thermal energy

The thermal efficiency of a heatsink depends on the surface area of the energy dissipation. A flat metal convector has a much smaller area compared to a sectional aluminum convector of the same geometric size. Because the latter radiates heat over the entire area of the fins.

Types of modern heating radiators

In the days of the USSR, the question of which heating battery is better to choose was never asked for a simple reason. The industry produced only two types of them - steel and cast iron. We live in a happy time of diversity, technological and environmental excellence.

The world and domestic industry offer a wide range of products to choose from. There are several signs by which it is advisable to separate the heating batteries.

Radiators can be divided according to the materials of manufacture:

- steel panel convectors;

- cast iron batteries;

- aluminum radiators;

- bimetallic radiators.

By design features:

- sectional;

- panel.

Each of these types is best suited for its operating conditions, and therefore has its own nuances. A separate type of heating radiators is highly specialized. These are devices designed to solve one problem, often to the detriment of overall functionality.

Image Gallery

Conclusions and useful video on the topic

Useful tips from experts will help you figure out the choice of heating device:

The best choice of a heating radiator can be considered the one in which the greatest comfort and coziness is achieved. The radiator can be invisible or vice versa - be part of the overall design. But the most important thing is reliability and no hassle.

You can tell about how you chose a radiator to replace old batteries in an apartment or to equip a new house in the block below. Please write comments, ask questions, share useful tips and photos on the topic of the article. We are interested in your opinion.

Not every battery is suitable for installation in apartment buildings, because frequent pressure surges in the system and the use of water as a coolant affect the performance of radiators. Some metals, when exposed to water and air, corrode and oxidize. The cast-iron radiator remains tested.

Characteristics of cast iron radiators

- The material used is corrosion resistant.

- Due to the resistance of cast iron to physical influences, batteries are used with any type of coolant. Its maximum temperature can be 150 degrees. A distinctive feature is oxidation resistance, because cast iron does not react when in contact with water, even if the acid-base balance reaches 9-10 Ph.

- It perfectly accumulates heat, which increases its heat transfer when compared with other materials. Cast iron batteries retain heat for a long time after the coolant supply is turned off.

- Durability of heating devices up to 30 years. With proper installation and care, air conditioning equipment lives longer than the allotted time.

- Thick walls are the reason why cast iron radiators live a long life.

- The number of sections can be varied to achieve the desired level of heating.

- If one section is damaged, replace only it, and not the entire battery.

The design of modern heating appliances is different from the usual old "accordions" that are in some apartments. Popular devices created using artistic casting, made in retro style.

Suitable for three types of connection.

- Lower. With this connection, the pipes are connected to the lower outlets on both sides. The downside of the bottom connection is low circulation.

- Side. This connection method provides for maximum circulation of the coolant, since the pipes are connected to the extreme section in the lower and upper outlets of one side.

- Upper. The pipes are connected to the top outlets of the end sections. The circulation with this connection is much higher than with the lower one.

Cast iron radiators are cast from an alloy of homogeneous mass, intended for use in heating systems of apartment buildings. Sections are made separately and connected using engineered gaskets and nipples for tightness.

The power of the heater declared in the technical specifications almost always differs from the actual one. This is due to the testing of the radiator in laboratory conditions that differ from real ones.

The heated coolant enters the radiator compartments through the pipes of the heating system and heats the air in the room, giving off heat.

Types of cast iron radiators

- Single-channel. In the design of radiators of this type, each section has a channel through which the liquid coolant circulates. Climatic devices of this type are easy to clean, so they are installed in medical institutions.

- Dual channel. In one section of heating devices of this type there are 2 channels, which increases heat transfer.

- Three-channel. The heat transfer indicators are higher compared to other types, while their weight and depth are much greater than those of their counterparts.

In two- and three-channel heating radiators, fins are used, which increase heat transfer. Sections are stylized in different styles, from retro to futuristic. Sometimes a metal casing is used to hide the battery.

Two-channel heating radiators are popular, as they are compact and have good heat dissipation.

Cast iron heating radiators are divided according to the installation method:

- Wall. Mounted on the walls with reinforced brackets, this type of mounting is a classic.

- Floor.Batteries are supplied with four legs. They are part of the end sections, so they are difficult to break off. These do not need additional fasteners, which will save the wall. In addition, not all walls can withstand cast iron. It is more convenient to clean up behind them, since the distance from the wall can be much greater than that of the classic types of fasteners.

In height, on average, the dimensions range from 35 to 150 cm. The length depends only on your preferences, because the number of sections can be different, and the width directly depends on the number of channels.

Disadvantages of cast iron radiators

- The weight. This is the main disadvantage for a cast iron product, and radiators are no exception. Because of the weight, and not because of aesthetics, the production of batteries on "legs" began, because not every wall is able to withstand the considerable weight of cast iron.

- Thermos effect. Listed as pluses and minuses. Cold radiators take a long time to warm up. When the heating is turned off, cast iron, due to the same property, remains warm for a long period of time and continues to give off heat.

- Water hammer. Some models of cast iron heaters do not withstand hydraulic shocks. The strikes occur in apartment buildings connected to a centralized heating system. This is solved by installing a pressure regulator.

- Pollution. Cast iron batteries are very dusty, and the design does not always allow for a complete and high-quality cleaning.

- Appearance. Externally, cast-iron devices are attractive, however, it is worth paying extra for beauty. Products made of this metal are sold unpainted, so the appearance does not cause sympathy.

Ways out of this situation:

Paint the battery yourself. A painted battery can look unaesthetic if layers of paint are applied unevenly.

Install a grate above the air conditioner. With the help of metal covers, you can “hide” the battery from prying eyes, however, such linings reduce the quality of heat transfer, and the room becomes cooler.

Order a cast-iron radiator made in the style of an artistic ebb. Batteries molded in various styles do not need to be painted. Such a radiator is not suitable for all interiors.

Calculation of sections of cast iron radiators

Before purchasing a cast-iron unit, calculations will be required that will more accurately determine the required number of sections. The example uses the following data:

1. The amount of heat generated by one section is 145 watts (the average figure is taken, the exact data is in the product data sheet).

2. The calculation is made for a room with normal insulation, one street wall and one window. According to SNiP, the amount of heat required to heat it is 100 watts.

3. Room dimensions - 4 x 3 meters.

Payment

1. The area of the room is determined. It is equal to 12 m2.

2. The area and the amount of heat that is needed to heat one square meter of the room are multiplied. According to SNiP, the room from the example requires 100 watts / m2. After performing this action, 1200 watts are obtained.

3. The amount of heat required for the room must be divided by the heat output of one part of the battery. Then, round the result up.

4. It turns out the number of sections required for installation. For the room indicated in the example, a radiator is installed, consisting of 9 sections.

The calculation is focused on rooms whose height does not exceed 3 meters.

Since each room is unique, there are coefficients that allow you to more accurately calculate:

To accurately measure the amount of heat per square meter, you need to divide the height of the ceilings by a factor equal to 3. For a room with a ceiling of 2.5 m, it will be 0.83.

For calculations, the average temperature of the heat carriers, which is 70 degrees, is used. With an increase in this indicator, 15% must be subtracted from the final number every 10 degrees, with a decrease in temperature, the opposite action must be performed.

If the room has not one, but 2 or 3 street walls, then it is worth multiplying the amount of heat for 1 m2 by a factor of 1.75. After that, the number of sections must be divided by the number of windows and radiators should be installed under each of them. This will ensure uniform heating of the entire room.

If the room has additional heat-insulating layers, as well as if double-glazed windows are installed, the amount of heat for 1 m2 is allowed to be divided by 0.8.

For houses located in regions with extremely low temperatures, the amount of heat for 1 m2 is doubled.

Before installing a cast-iron radiator, you need to disassemble it into sections, check the fastening of the nipples, then assemble it. You need to mount, taking into account the weight of the battery and the material of the wall in the room. The minimum set of tools is a grinder, a puncher, an adjustable wrench, a building level and a die.

1. If the wall is brick or concrete, fasteners are selected that are designed for the weight of the radiator with coolant. According to SNiP, it is recommended to use 3 or more brackets.

2. Do not hang cast iron radiators on walls made of wood or drywall as they may not be able to withstand the load. In this case, you can install the radiator on a floor stand or legs. It is attached to the wall only to maintain it in an upright position.

After installing the radiator, it is connected to the central heating using connecting bushings and a drive. Threaded connections are recommended to be sealed.

Cast iron radiators need to be periodically tinted with paint that can withstand the heating temperature without changing color.

Connection to the heating system:

1. Diagonal. Used when connecting multi-section units. The supply pipe is connected at the top on one side, and the return pipe is connected at the bottom on the other.

2. Lower. Used when pipes are hidden in the floor of a room or behind skirting boards. This is an aesthetic way to connect. The supply and return pipes are located at the bottom.

3. Lateral. The supply pipe is connected to the top futorka, the return pipe - to the bottom. Lateral connection is characterized by the highest heat transfer. In case of poor heating in multi-section heaters, it is recommended to install an extension of the coolant flow.

4. Consistent. The coolant moves under the pressure of the heating structure. Mayevsky taps are used to remove air. The disadvantage is the need to remove the batteries and turn off the heaters during repairs.

5. Parallel. The connection is created through a pipeline connected to the supply riser. The coolant leaves through a pipe connected to the return.